Performance of engineered cementitious composite containing stone slurry powder waste

来源期刊:中南大学学报(英文版)2021年第7期

论文作者:Maninder SINGH Babita SAINI H.D. CHALAK

文章页码:1990 - 2002

Key words:stone slurry powder; fine sand; scanning electron microscopy; energy dispersive X-ray spectroscopy; ultrasonic pulse velocity

Abstract: Most of the materials used in engineered cementitious composite are fine in size to achieve ductile nature. Stone slurry powder (SSP) is an inert material obtained from stone industries as by-product which may cause hazardous impact on environment. In this research work, partial replacement of silica sand (SS) and fine sand (FS) by SSP with different contents (25% and 50% each) for making engineered cementitious composite has been explored. The performance was evaluated on the basis of strength, tensile strain, mid span deflection capacity, ultra-sonic pulse velocity and microstructure. Mechanical strength was found to be increased at 25% SSP in both replacements; whereas, strength decreased slightly at 50% replacement. Tensile strain, mid span deflection and quality of concrete were enhanced with increase in SSP content. Using SSP formed denser cementitious composite can help to save the natural resources and contribute in making green cementitious composite.

Cite this article as: Maninder SINGH, Babita SAINI, H.D. CHALAK. Performance of engineered cementitious composite containing stone slurry powder waste [J]. Journal of Central South University, 2021, 28(7): 1990-2002. DOI: https://doi.org/10.1007/s11771-021-4747-1.

J. Cent. South Univ. (2021) 28: 1990-2002

DOI: https://doi.org/10.1007/s11771-021-4747-1

Maninder SINGH, Babita SAINI, H.D. CHALAK

Department of Civil Engineering, National Institute of Technology Kurukshetra, Haryana 136119, India

Central South University Press and Springer-Verlag GmbH Germany, part of Springer Nature 2021

Central South University Press and Springer-Verlag GmbH Germany, part of Springer Nature 2021

Abstract: Most of the materials used in engineered cementitious composite are fine in size to achieve ductile nature. Stone slurry powder (SSP) is an inert material obtained from stone industries as by-product which may cause hazardous impact on environment. In this research work, partial replacement of silica sand (SS) and fine sand (FS) by SSP with different contents (25% and 50% each) for making engineered cementitious composite has been explored. The performance was evaluated on the basis of strength, tensile strain, mid span deflection capacity, ultra-sonic pulse velocity and microstructure. Mechanical strength was found to be increased at 25% SSP in both replacements; whereas, strength decreased slightly at 50% replacement. Tensile strain, mid span deflection and quality of concrete were enhanced with increase in SSP content. Using SSP formed denser cementitious composite can help to save the natural resources and contribute in making green cementitious composite.

Key words: stone slurry powder; fine sand; scanning electron microscopy; energy dispersive X-ray spectroscopy; ultrasonic pulse velocity

Cite this article as: Maninder SINGH, Babita SAINI, H.D. CHALAK. Performance of engineered cementitious composite containing stone slurry powder waste [J]. Journal of Central South University, 2021, 28(7): 1990-2002. DOI: https://doi.org/10.1007/s11771-021-4747-1.

1 Introduction

Concrete is the major product worldwide, used in the construction industry to complete the need of shelter on earth [1]. In India, the construction industry is growing faster which consumes 400 Mt concrete every year and is expected to approximately reach 1000 Mt in a decade [2]. Cement is used as a major part in the construction which needs lime stone in large amount for production. 1.5 t limestone is required for production of 1 t cement, which emits estimated 1 t CO2 [3, 4]. The cement demand will escalate with construction growth. Presently environmental protection and sustainability are becoming the major challenge worldwide. The major cause of natural resources depletion is the construction industry globally, which approximately consumes 50% of the natural resources and the waste products from it is also 50% [5]. In this work, main focus is to decrease the natural depletion of resources and escalate the utilization of wastes.

Recycling of waste materials helps in making environment eco-friendly and development of green cementitious concrete. Due to large consumption capacity of materials in construction industry, the reutilization of waste in it is the best solution [6]. Various types of solid waste materials such as glass waste, slag, silica fume (SF), recycled aggregates (RA), palm oil fuel ash (POFA), tire rubber (TR), pond ash (PA), stone waste (SW), crushed waste CW), and fly ash (FA) have been used in the concrete and found to have beneficial effects on fresh, mechanical and durability performance of concrete [7-16].

Italy, China, Brazil, U.S.A, France, Turkey and India are the leading producers of marble in the world. In India, only in single state Rajasthan, more than 1100 marble stone processing plants, generate approximately 5-6 Mt stone slurry during excavation and cutting process [17]. During the dimensioning process of stone, different types of wastes are generated: solid waste and semi-solid waste. Solid waste is generated at the mine site during cutting process and semi solid waste is generated from the sawing and cutting process, where the water is used as a lubricant to cool down the blades or machine [18]. Cutting and sawing process of 1t stone produces approximately 1t stone slurry with 35%- 45% water content [19]. The very fine particulate of stone slurry waste clogs the pores of agricultural land and escalates the alkalinity of soil, which reduces the fertile capacity of the soil. Hence, to minimize the harmful impacts of stone slurry on environment, the utilization of this waste is necessary in construction industry.

Concrete can be divided into number of branches such as normal concrete, high strength concrete (HSC), fiber reinforced concrete (FRC), high performance fiber reinforced concrete (HPFRC), reactive powder concrete (RPC) and engineered cementitious composite (ECC) as per performance. ECC is the distinctive branch of high performance fiber reinforced cementitious composite (HPFRCC). The ductile nature of ECC makes it different from other types of concrete. To design ECC mix most of the finer size particles are used. The design theory of ECC relys on micromechanics of fiber bridging and crack extension [20, 21]. To achieve the ductile nature in ECC coarser size materials or particles are eliminated, because they affect the unique ductile behaviour of cementitious composite [22]. Polymeric nature fibers such as polyethylene, polyvinyl alcohol, and polypropylene have been used to reinforce the ECC to achieve extensive strain hardening behaviour with multiple micro cracking under tensile loading [23-26]. A number of experimental works have been conducted on ECC and it has been reported that most of the fine size particles were used for the design of ECC mix. Various types of industrial by products, such as (FA, TR, POFA, recycled concrete fines (RCF) and slag), are used in ECC as a partial substitution of cementitious material and sand. From reported studies it was observed that stone slurry has not been used in ECC as subrogation of silica sand and fine sand. Stone slurry is the by-product of marble, produced during sawing and polishing process. The high fineness of stone slurry is very effective in concrete and mortar, because it acts as a filler material [18]. The intention of this investigation is to explore utilization of stone slurry powder in ECC and try to make environment and eco-friendly material. This present research focuses on the utilization of stone slurry powder (SSP) as partial subrogation of silica sand (SS) and fine sand (FS) in ECC.

2 Experimental

2.1 Materials selection

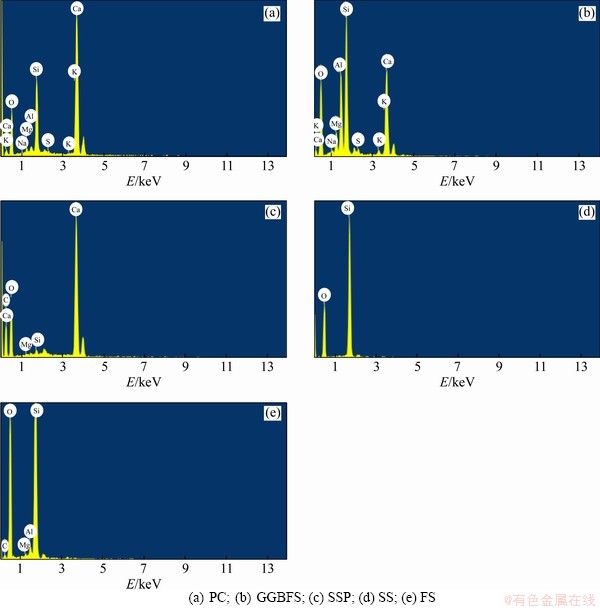

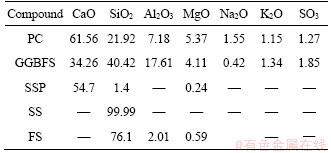

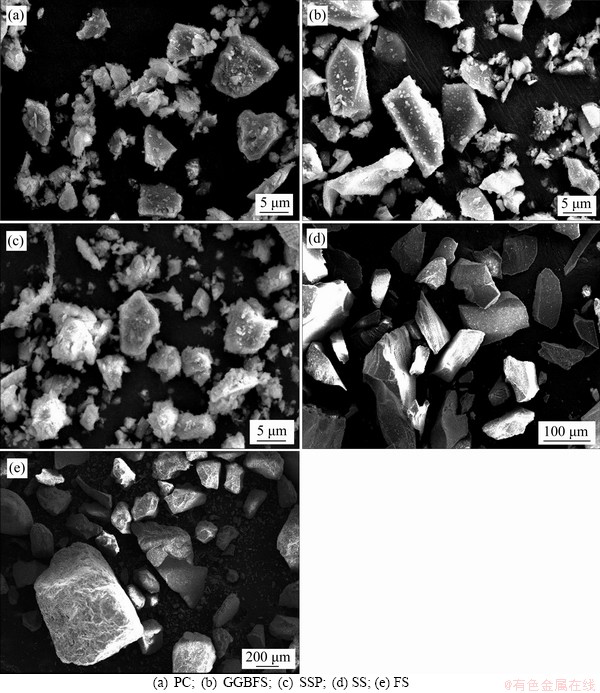

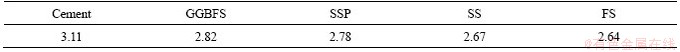

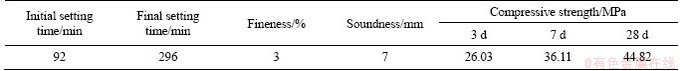

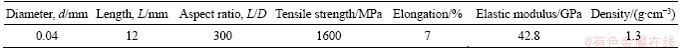

To achieve the unique characteristics of mortar mixture, the selection of materials is primary important step in design of ECC. Solid powdered materials selected for this research work i.e. Portland cement (PC) of 43 grade, were confirming to IS 8112 (2013) [27] and ASTM C150 [28], GGBFS (Ground granulated blast furnace slag) as a supplementary cementitious material, silica sand (SS) and fine sand (FS) with the maximum size of 175 and 600 mm as fine aggregate, polyvinyl alcohol (PVA) fiber REC15 (d39 mm×12 mm) oiled by 1.2% coating as a reinforcing material were used for control mixes. The stone slurry powder (SSP) as a subrogation of fine aggregates (SS & FS) at different ratios was also used in this research work. To achieve proper workability polycarboxylic ether type, master glenium SKY 8233 high performance superplasticizer provided by BASF India was used. The chemical composition of solid ingredients analyzed by energy dispersive X-ray spectroscopy analysis is shown in Figure 1 and presented in Table 1. The images by scanning electron microscopy of all used powdered materials are presented in Figure 2. It is confirmed that the particles of SSP were very fine as compared to SS and FS. Density of all powdered materials, physical characteristics of PC and PVA fibers are presented in Tables 2-4, respectively.

Figure 1 Energy dispersive X-ray spectroscopy analysis:

Table 1 Chemical compositions of PC, GGBFS, SSP, SS and FS (wt%)

2.2 Mix proportion

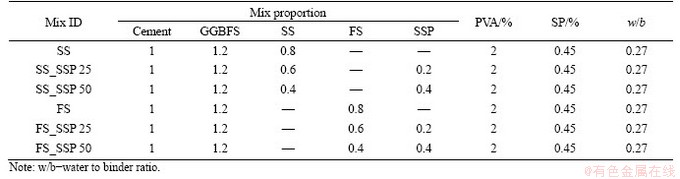

In the present paper, the effect of replacement of silica sand and fine sand by SSP was studied experimentally. Various mix proportions prepared by varying quantity of SSP are shown in Table 5. SSP was used to replace SS and FS by 25 wt% and 50 wt% each in various mixtures.

Numerous research investigations revealed that the incorporation of stone waste in cementitious products reduced the flowability of the matrix [17, 18]. Therefore, in present investigation the percentage of SP was adjusted in such a way i.e. 0.45%×(Total quantity of cement+GGBFS+SSP) to achieve the desired workability.

2.3 Mixing procedure

Mixer type, speed, temperature and mixing procedure are very important factors in the fresh cement matrix for achieving desired properties [29, 30]. Cement matrix was mixed through a power-driven mortar mixer. As per mix proportions all solid ingredients like OPC, GGBFS, FS, SS, and SSP mixed first in mixer at low speed for approximately 2-3 min. Then water and high range water reducer admixture (HRWRA) were added in the mixed solid constituents and mixed for another 3-4 min to achieve uniform mix. After that, fibers were added slowly in the rotating mixer manually until all the fibers distributed uniformly in mix.

Figure 2 Micrographs of scanning electron microscopy:

Table 2 Density (g·cm-3) of all powdered materials

Table 3 Physical characteristics of PC

Table 4 Physical characteristics of PVA fibers

2.4 Specimen casting

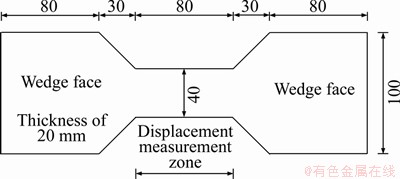

Mortar cubes and prisms with dimensions of 70.6 mm×70.6 mm×70.6 mm and 500 mm×100 mm×100 mm respectively were cast for testing compressive strength (CS) and flexural strength as per IS 516:1959 [31] recommendations. The prism specimens shown in Figure 3 were also used for non-destructive testing. Dumbbell shaped specimens of 310 mm×100 mm×20 mm with 80 mm gauge length as described in Figure 4 were employed for direct tensile testing. Fresh homogenous cement matrix after complete mixing process was poured into the moulds for each shaped specimen as per testing requirement. After casting, the specimens were immersed into the water curing tank at controlled temperature after 24 h. The schedule of tests performed at required ages is described in Table 6.

Table 5 Mix proportions (volume ratio) of SSP containing ECC mixture

Figure 3 Schematic view of rectangular prism specimen (Unit: mm)

Figure 4 Schematic view of dumbbell specimen (Unit: mm)

Table 6 Schedule of tests performed

3 Test methodologies

3.1 Fresh state properties

To get the idea about workability, consistency and horizontal flow of fresh, the unhardened self-consolidating cementitious (SCC) matrix slump flow test was performed. The two parameters horizontal slump flow range and time to spread for 500 mm i.e. T50 were recorded as per ASTM C1611 [32] to confirm the self-consolidated specifications. This test indicated the deformability without any obstruction and latter measured variables describing the viscosity of SCC matrix.

3.2 Compressive strength

To study the effect of SSP on CS, mortar cubes were tested in the compression testing machine at loading rate of 3 kN/s after required age as per IS 516:1959 [31] and BS-EN-12390 part 3 [33] specifications.

3.3 Direct tensile test

Dumbbell shaped specimens were tested in the universal testing machine (UTM) at loading rate of 0.2 mm/min to analyze the role of SSP on tensile properties. The tensile behaviour was measured on a maintained 80 mm gauge length.

3.4 Four-point bending test

Prism specimens were tested for flexural strength as per IS 516:1959 [31] and BS-EN-12390 part 5 [34] specifications. The load-defection behaviour of different mixes was analysed under this testing.

3.5 Ultrasonic pulse velocity

The quality of concrete was examined by using non-destructive ultrasonic pulse velocity test using Pundit’s apparatus as per IS 13311 (Part 1):1992 [35] and ASTM C597 [36] specifications.

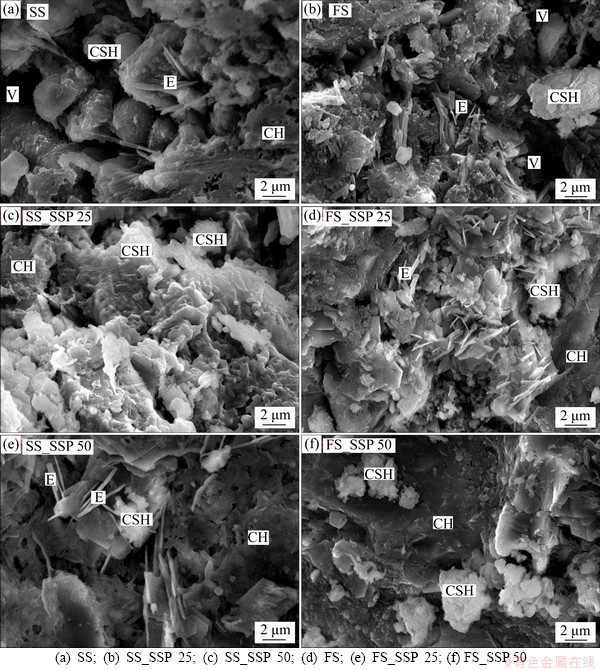

3.6 Micro-structural analysis

Scanning electron microscopy (SEM) technique was used to analyze the micro-structural analysis of different mix proportions. The samples for SEM testing were collected from tested cubes. A focused beam of electron on specimens surface generates a variety of signal and through reflection of electron, beams develop topographical images of specimens that reveal information about the microstructure and external morphology of the cementitious composite.

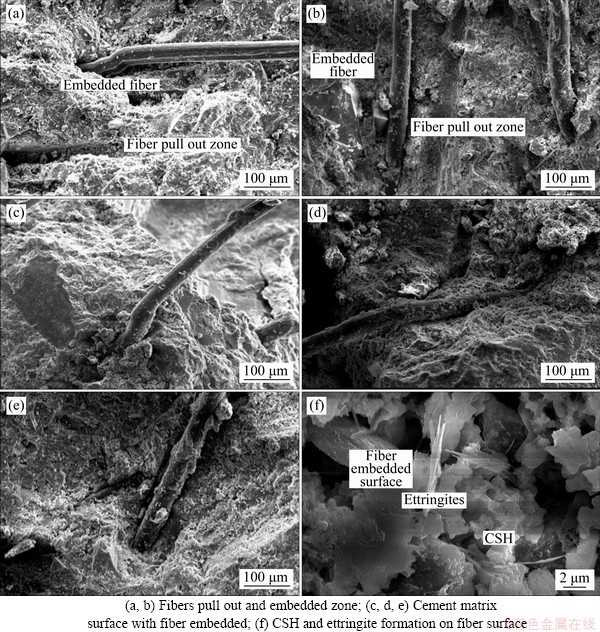

The SEM photographs of different mixes shown in Figures 5(a)-(f) reveal the information about fiber embedded, pull out zone of fibers in cement matrix and CSH formation on fiber surface with cement matrix.

4 Results and discussion

4.1 Visual inspection

The surface of the hardened cementitious composite specimen with fully SS and FS blended mix was less smooth than SSP blended mixes. The substitution of SSP in ECC mixtures gave better finishing and well sound surface than fully SS and FS mixes.

4.2 Self consolidated fresh properties of ECC

The self-consolidated fresh properties of all ECC mixes were evaluated based on slump flow (mm) and time (T50, s) to first reach the outer edge of 500 mm diameter circle. The values of slump flow, T50 and relationship between both are illustrated in Figure 6.

From Figure 6 it is seen that the slump flow of fully SS mix was higher than fully FS mix. The maximum value (752 mm) of slump flow was found for SS_SSP 50 mix proportion and minimum (638 mm) for FS mix proportion. The slump flow of SS mix proportion was 11.63% higher compared to FS mix proportion. The values of slump flow increased with the addition of SSP, which might be attributed to increase in the quantity of SP. The slump flow of silica sand containing mixes increased by 2.63% and 4.15% at 25% and 50% replacement, respectively. Moreover, the slump flow of fine sand containing mixes increased by 3.60% and 7.36% at 25% and 50% replacement, respectively. The relationship between slump flow and T50 revealed that the time to flow reduced with increasing slump flow values. The T50 of silica sand containing mixes reduced by 14.18% and 24% at 25% and 50% replacement, respectively. Moreover, the T50 of fine sand containing mixes reduced by 17.86% and 28.52% at 25% and 50% replacement, respectively. However, the T50 of FS mix proportion increased by 16% as compared to SS mix proportion, which was due to lower flowability of FS mix proportion. Finally, based on the slump flow and T50 values, it is concluded that all the fresh ECC mixes possessed the self-consolidated properties.

Figure 5 SEM photographs of fiber reinforced ECC:

Figure 6 Relationship between slump flow and T50

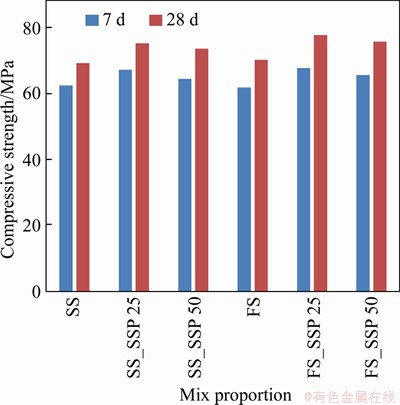

4.3 Compressive strength

The CS of SS blended mix was observed slightly lower than FS blended mix. The strength behaviour of different mix proportions under compression shows that the subrogation of silica sand and fine sand with stone slurry powder increased compressive strength up to 25% replacement and afterwards it decreased. The optimum enhancement in CS was found for substitution of fine sand with stone slurry powder. The same trend was observed at 7 and 28 d water curing for all the mix proportions. The maximum CS was found in mix FS_SSP 25 as compared to other mixes. The CS increased by 7.66%, 3.21% and 8.77%, 6.34% after 7 and 28 d, respectively with the subrogation of silica sand by SSP at 25% and 50%, respectively. Replacement of FS increased the CS by 9.54%, 6.04% and 10.68%, 7.74% at 7 and 28 d respectively with substitution level of 25% and 50%. The CS of different mixes at 7 and 28 d is shown in Figure 7. The results of CS show that SSP is more effective in FS replacement as compared to SS replacement. Micro filler effect of SSP was responsible for the increase of CS up to 25% replacement. Further increase in substitution of FS with SSP resulted in the decrease in CS, which may be due to the lack of binding ability of SSP and inappropriate grading [17, 18].

Figure 7 Graphical view of compressive strength of various mix proportions

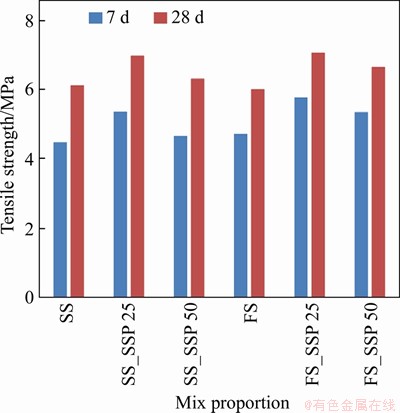

4.4 Tensile strength

The tensile strength (TS) of ECC mixture with SS was found slightly higher than FS blended mix. Substitution of silica sand and fine sand with SSP up to 25 % increased the TS and afterwards it decreased; whereas, the tensile strain capacity was found to increase up to 50% replacement of both sand with SSP. The tensile strength increased by 19.73%, 4.21% and 13.96%, 3.08% after 7 and 28 d respectively with the subrogation of silica sand by SSP at 25% and 50%. The maximum enhancement in tensile strength was found in 25% substitution of fine sand with SSP compared to other 50% replacement and other mixes. Replacement of FS at 25% and 50% increased the tensile strength by 22.31%, 13.26% at 7 d and 17.52%, 10.74% after 28 d water curing respectively. The enhancement in TS was due to the filling effect of SSP in cement matrix [18, 37].

The behaviour of cementitious composite with the use of SSP at different levels is shown in Figure 8.

Figure 8 Graphical view of maximum tensile strength of various mix proportions

4.5 Tensile strain

The tensile strain of fully SS blended ECC mixture was observed higher than fully FS blended mix. Subrogation of silica sand and fine sand with stone slurry powder up to 50% replacement increased the tensile strain capacity. The tensile strain increased by 6.54%, 9.07% and 9.39%, 15.51% after 7 and 28 d respectively with the subrogation of silica sand with SSP at replacement level of 25% and 50%. The subrogation of fine sand with SSP also increased the tensile strain, the enhancement in tensile strain was found 9.6%, 16.2% and 10.97%, 18.28% after 7 and 28 d respectively at replacement levels of 25% and 50%. The maximum enhancement (18.28%) was observed in FS_SSP 50 mix as compared to other mixes. The tensile strain behaviour of different mix proportions is shown in Figure 9. The enhancement in strain observed might be due to finer size of SSP, as the use of fine size particles in ECC improved the ductile nature [22]. The decrease in strong chemical bonding between PVA fiber and matrix may be due to the use of SSP in cementitious composite. The strong chemical bonding between fiber and matrix observed was due to hydrophilic nature of PVA fiber.

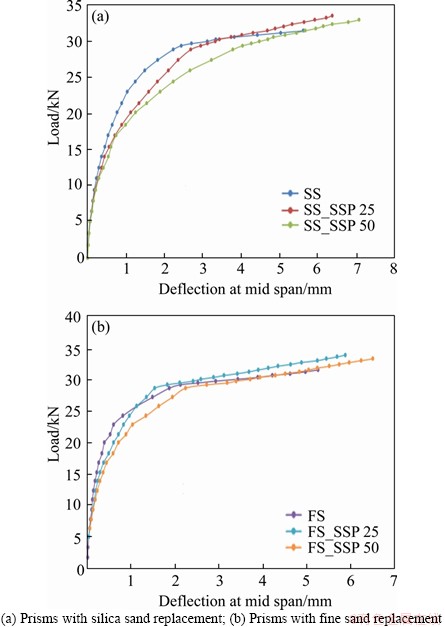

4.6 Flexural strength

The flexural strength of fully SS blended mix was found lower than FS mix; whereas, the deflection capacity was observed higher. The use of SSP in cementitious composite increased the flexural strength up to 25% replacement; whereas, the deflection capacity increased up to 50% replacement in both silica sand and fine sand. Silica sand at 25% and 50% replacement by SSP increased the flexural strength by 6.56% and 4.63% respectively; and fine sand at both replacement increased flexural strength by 7.47% and 5.56% respectively after 28 d water curing. The deflection capacity also increased with the substitution of silica sand and fine sand i.e. 13.32%, 16% and 26%, 29% at 25% and 50% replacement level after required curing age. The maximum enhancement of 7.47% in flexural strength was observed in FS_SSP 25 mix; whereas, 29% enhancement in deflection capacity was observed in FS_SSP 50 mix as compared to other mixes. The increment in substitution percentages of SSP in both sand increased the number of multiple micro cracks on prisms specimens under flexural loading. The flexural cracks were first generated in the tension zone and propagated towards the top surface (compression zone). The use of finer size particles promotes the ductile nature of ECC, so the enhancement in deflection capacity is observed due to finer size particles of SSP.

Figure 9 Graphical view of maximum tensile strain of various mix proportions

The load-deflection curves of different mix proportions with silica sand and fine sand replacement are shown in Figures 10(a) and (b) respectively.

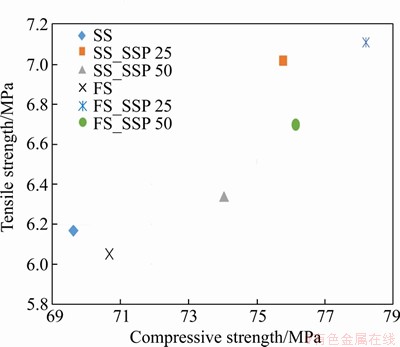

4.7 Relationships between strength parameters

Figure 11 illustrates the relationship between compressive strength and tensile strength at 28 d. Figure 12 illustrates the relationship between compressive strength and flexural strength at 28 d. It is revealed that the addition of SSP positively affects the strength parameters. Almost similar findings are observed for CS, TS and flexural strength. The maximum CS, TS and flexural strength were recorded in FS_SSP 25 mix proportion, while the minimum was in SS mix proportion. The relationship between strength parameters revealed that the inclusions of SSP not only enhance the strength parameters, but also improve the fiber bridging and fiber-matrix interfacial properties.

Figure 10 Load-deflection curves:

Figure 11 Relationship between compressive strength and tensile strength at 28 d

Figure 12 Relationship between compressive strength and flexural strength at 28 d

4.8 Ultrasonic pulse velocity test

The ultrasonic pulse velocity (UPV) values of all mix proportions observed were in ‘excellent’ category range as per IS 13311 (Part 1):1992 specifications [35]. The UPV values show that the quality of fully SS blended mix was 3.40 % higher than fully FS blended mix. The pulse velocity values showed that the use of stone slurry powder as subrogation of silica sand and fine sand has no effect on the quality of the cementitious composites. The values of pulse velocities with subrogation of SS and FS by SSP marginally increased. The maximum enhancement in pulse velocity was found in partial replacement of FS, which may be due to micro filling effect of SSP, i.e., improved compactness of mixes [35]. Figure 13 depicts the ultrasonic pulse velocity of different mix proportions.

4.9 Scanning electron microscopy

The SEM micrographs of grounded cementitious composite samples show the SSP blended cement matrix is much denser as compared to fully SS and FS blended specimens. The observation from SEM images of SS and FS replacement shows that CSH formation at 25% replacement was the maximum, more than 50% subrogation and fully SS and FS bended mix. The SEM images reveal that the use of SSP makes the cement matrix denser than SS and FS mixes. The dense microstructure of cement matrix containing SSP would help to improve the durability of cementitious composite. The scanning electron microscope photographs are shown in Figure 14.

Figure 13 Ultrasonic pulse velocity of various mix proportions

4.10 Cost effectiveness and greenness impact

In this work, with the use of GGBFS as cementitious material, 50% substitution of SSP as a sand, and a total of 64 wt% powdered ingredients, the waste utilization has been explored. The waste utilization on this scale in cement matrix contributes in decreasing the total cost of the cementitious composite and reducing the effect of waste materials on environment in different ways. The cost of different ECC mixes was computed by summation of product of weight of the ingredients used with respective market price. The cost (in Indian rupees, INR) analysis of various ECC cement matrix (without fibers) is illustrated in Figure 15. It was observed that the cost of FS_SSP 50 mix decreased by 17.27% as compared to SS mix proportion. The reutilization of waste helps in conserving the natural resources and contribute in development of eco-friendly cement matrix composite and greenness impact on environment. The reutilization of waste in this higher percentage produced a promising impact on eco-friendly nature of mix.

Figure 14 SEM photographs of various mixes:(CSH-Calcium silicate hydrate, E-Ettringite, CH-Calcium hydroxide, V-Voids)

Figure 15 Cost analysis of various ECC mixes (without fibers)

5 Conclusions

Gainful utilization of waste stone slurry powder in making engineered cementitious composite was explored. The appraisal on partial substitution of silica sand and fine sand by stone slurry powder with different ratios in ECC was analyzed. The key findings of this comprehensive appraisal are summarized below.

1) The CS and flexural strength of fully FS blended mix are higher than those of fully SS blended mix; whereas the higher tensile parameters and deflection capacity are found in fully SS blended mix.

2) The microstructure of materials shows that SSP contains high contents of fines as compared to sand particles, which develops a denser microstructure in cement matrix due to filling effect.

3) Substitution of SS and FS with SSP up to 25% replacement enhances the compressive, direct tensile and flexural strength. The maximum percentage of enhancement is found in FS_SSP 25 mix.

4) Increment in compressive strength is observed 8.77% and 10.68% by substitution of SS and FS with SSP up to 25% after 28 d water curing. At 50% replacement the value of compressive strength is 6.34% and 7.74% more than fully SS and FS blended mixes, but less than the 25% replacement.

5) Substitution of SS with SSP increases the tensile strength by 13.96% and 3.08% at 25% and 50% replacement level after 28 d. The subrogation of FS with SSP increases the tensile strength by 17.52% and 10.74% respectively at 25% and 50% replacement after 28 d curing.

6) Increase in flexural strength enhancement is observed by 6.56% and 4.63% respectively at 25% and 50% substitution of SS. The substitution of FS at both replacement (25% and 50%) level increases the flexural strength by 7.47% and 5.56% after 28 d. The strength properties of cement matrix are enhanced due to micro filling effect of SSP.

7) The use of SSP as subrogation of SS and FS enhanced the tensile strain and mid span deflection up to 50% replacement. Tensile strain capacity is increased by 9.39%, 10.97% and 15.51%, 18.28% respectively at 25% and 50% substitution level of SS and FS.

8) The mid span deflection capacity increases by 13.32%, 16% and 26%, 29% respectively at 25% and 50% substitution level of SS and FS. And the number of cracks increases with the increase in replacement from 25% to 50%.

9) Non-destructive testing of different mixes reveals that the use of SSP slightly improves the quality of cementitious composite; denser microstructure of cement matrix increases the compactness of the cement matrix. On the basis of different parameters studied, the use of SSP as FS substitution is found more effective than SS substitution.

10) The use of SSP waste saves the total cost of cement matrix per cubic meter by 9.62%, reduces the use of agricultural land and natural aggregates and contributes in making eco-friendly environment.

On the basis of the results above, it is found that fully SS blended mix pronounces more promising results in terms of ductile nature of ECC than fully FS blended mix. The maximum mechanical strength is observed in mix FS_SSP 25; optimum tensile strain and mid span deflection capacity are obtained with mix SS_SSP 50. The increment in tensile strain and deflection capacity of ECC is higher for FS substitution than SS. The substitution of FS with SSP gives better performance in all aspects than that of SS with SSP.

Finally, this research demonstrates that the utilization of waste in cementitious composite contributes to making green eco-friendly ECC, saving cost and natural resources. It will also help in reducing the impact of waste on environment with large saving of agricultural land and sand extraction.

Acknowledgements

The authors would like to thank Kuraray India Limited for providing fibers.

Contributors

Maninder SINGH provided the concept and performed the experimental work, data analysis and wrote the original draft of the manuscript. Babita SAINI decided the methodology and helped in data analysis and contributed in writing, reviewed and edited the draft of the manuscript. H.D. CHALAK edited the draft of the manuscript.

Conflict of interest

The authors declare that there is no known competing financial interest or personal relationship that could have appeared to influence the work reported in this paper. Maninder SINGH, Babita SAINI, and H.D. CHALAK declare that they have no conflict of interest.

References

[1] GAUTAM N, KRISHNA V, SRIVASTAVA A. Sustainability in the concrete construction [J]. Int J of Environ Res Dev, 2014, 4: 81-90.

[2] PATHAK P P. Inclusion of Portland and pozzolona (fly ash waste) cement in specifications [J]. Ind Highw, 2009, 37: 23-29.

[3] WOODSON R D. Concrete materials [M]// Concrete Portable Handbook. Oxford: Elsevier Inc, 2012.

[4] RANA A, KALLA P, CSETENYI L J. Sustainable use of marble slurry in concrete [J]. Journal of Cleaner Production, 2015, 94: 304-311.

[5] SCHEPPER M D, HEEDE P V D, DRIESSCHE I V, BELIE N D. Life cycle assessment of completely recyclable concrete [J]. Materials, 2014, 7: 6010-6027.

[6] LI L G, HUANG Z H, TAN Y P, KWAN A K H, LIU F. Use of marble dust as paste replacement for recycling waste and improving durability and dimensional stability of mortar [J]. Constr Build Mater, 2018, 166: 423-432.

[7] LING T C, POON C S. Feasible use of large volumes of GGBS in 100% recycled glass architectural mortar [J]. Cem Concr Compos, 2014, 53: 350-356.

[8] HU C, LI Z. Property investigation of individual phases in cementitious composites containing silica fume and fly ash [J]. Cem Concr Compos, 2015, 57: 17-26.

[9] Dos ANJOS M A G, SALES A T C, ANDRADE N. Blasted copper slag as fine aggregate in Portland cement concrete [J]. J Environ Manage, 2017, 196: 607-613.

[10] AMARIO M, RANGEL C S, PEPE M, FILHO R D T. Optimization of normal and high strength recycled aggregate concrete mixtures by using packing model [J]. Cem Concr Compos, 2017, 84: 83-92.

[11] UYSAL M, YILMAZ K. Effect of mineral admixtures on properties of self-compacting concrete [J]. Cem Concr Compos, 2011, 33(7): 771-776.

[12] LIU F, ZHENG W, LI L, FENG W, NING G. Mechanical and fatigue performance of rubber concrete [J]. Constr Build Mater, 2013, 47: 711-719.

[13] LI Jun-xia, YANG En-hua. Macroscopic and micro structural properties of engineered cementitious composites incorporating recycled concrete fines [J]. Cem Concr Compos, 2017, 78: 33-42.

[14] ALTWAIR N M, JOHARI M A M, HASHIM S F S. Flexural performance of green engineered cementitious composites containing high volume of palm oil fuel ash [J]. Constr Build Mater, 2012, 37: 518-525.

[15] HUANG X, RANADE R, NI W, LI V C. On the use of recycled tire rubber to develop low E-modulus ECC for durable concrete repairs [J]. Constr Build Mater, 2013, 46: 134-141.

[16] KHODABAKHSHIAN A, BRITO J D, GHALEHNOVI M, SHAMSABADI E A. Mechanical, environmental and economic performance of structural concrete containing silica fume and marble industry waste powder [J]. Constr Build Mater, 2018, 169: 237-251.

[17] SINGH M, SRIVASTAVA A, BHUNIA D. An investigation on effect of partial replacement of cement by waste marble slurry [J]. Constr Build Mater, 2017, 134: 471-488.

[18] ALMEIDA N, BRANCO F, BRITO J D, SANTOS J R. High-performance concrete with recycled stone slurry [J]. Cem Concr Res, 2007, 37(2): 210-220.

[19] AUKOUR F J. Incorporation of marble sludge in industrial building eco-blocks or cement bricks formulation [J]. Jordan J Civ Eng, 2009, 3: 58-65.

[20] SINGH M, SAINI B, CHALAK H D. Performance and composition analysis of engineered cementitious composite (ECC) – A review [J]. Journal of Building Engineering, 2019, 26: 100851.

[21] LI V C. Engineered cementitious composites-tailored composites through micromechanical modelling [M]// Fiber Reinforced Concrete. Montreal: Canadian Society for Civil Engineering, 1998: 64-97.

[22] LI V C, KANDA T. Engineered cementitious composites for structural applications [J]. J. Materials in Civil Engineering, 1998, 10: 66-69.

[23] LI V C. Engineered cementitious composites (ECC)– Material, structural, and durability performance [M]// Concrete Construction Engineering Handbook. CRC Press, 2007.

[24] ALTWAIR N M, JOHARI M A M, HASHIM S F S. Influence of treated palm oil fuel ash on compressive properties and chloride resistance of engineered cementitious composites [J]. Materials and Structures, 2014, 47: 667-662.

[25] LI M, LI V C. Rheology, fiber dispersion, and robust properties of engineered cementitious composites [J]. Materials and Structures, 2013, 46: 405-420.

[26] SINGH M, SAINI B, CHALAK H D. Properties of engineered cementitious composites: A review [C]//Proceedings of the 1st International Conference on Sustainable Waste Management through Design. 2018: 473-483.

[27] IS-8112. Specification for 43 grade ordinary Portland cement [S]. New Delhi: Bureau of Indian Standards, 2013.

[28] ASTM-C150/C150M-16e1. Standard specification for Portland cement [S]. West Conshohocken, PA: ASTM International, 2016.

[29] YANG E H, SAHMARAN M, YANG Y, LI V C. Rheological control in production of engineered cementitious composites [J]. ACI Mater J, 2009, 106: 357-366.

[30] FERRARIS C F, OBLA K, HILL R. The influence of mineral admixtures on the rheology of cement paste and concrete [J]. Cem Concr Com, 2001, 31: 245-255.

[31] IS 516-1959. Methods of tests for strength of concrete [S]. 18th ed. New Delhi: Bureau of Indian Standards, 2006.

[32] ASTM C1611. Standard test method for slump flow of self-consolidating concrete [S]. West Conshohocken, PA, USA: American Society for Testing and Materials, 2014.

[33] BS-EN-12390-3. Testing hardened concrete-Compressive strength of test specimens [S]. British Standard Institution, 2009.

[34] BS-EN-12390-5. Testing hardened concrete-Flexural strength of test specimens [S]. British Standard Institution, 2009.

[35] IS 13311 (Part 1). Code of practice for non-destructive testing of concrete-Methods of test. Part: 1 Ultrasonic pulse test [S]. New Delhi: Bureau of Indian Standards (BIS), 1992, reaffirmed 2004.

[36] ASTM C597-16. Standard Test method for pulse velocity through concrete [S]. West Conshohocken, PA: ASTM International, 2016.

[37] ALIABDO A A, ABD ELMOATY A E M, AUDA E M. Re-use of waste marble dust in the production of cement and concrete [J]. Constr Build Mater, 2014, 50: 28-41.

(Edited by FANG Jing-hua)

中文导读

含石浆粉废弃物工程胶结复合材料的性能

摘要:工程胶结复合材料中使用的大多数材料的晶粒尺寸细小,有较好的韧性。石浆粉(SSP)是石工业中的一种惰性材料副产品,对环境产生有害影响。本文研究了用不同含量(25%和50%)SSP部分替代硅砂(SS)和细砂(FS)来制备工程胶结复合材料。根据强度、拉伸应变、中跨度偏转能力、超声波脉冲速度和微观结构对其性能进行了评价。在两种替换含量下,替换含量为25%时材料强度增加,而替换含量为50%时材料强度略有下降。拉伸应变、中跨度挠度和混凝土质量随着SSP含量的增加而提高。使用SSP形成的冷凝胶复合材料,可以节省自然资源,也促进了绿色胶凝复合材料的制备。

关键词:石浆粉;细砂;扫描电子显微镜;能散X射线光谱;超声波脉冲速度

Foundation item: Project(F1-17.1/2017-18/MANF-2017-18-HAR-78129) supported by the University Grants Commission New Delhi, India

Received date: 2020-05-24; Accepted date: 2020-10-30

Corresponding author: Babita SAINI, PhD, Associate Professor; Tel: +91-9416781980; E-mail: bsaini@nitkkr.ac.in; ORCID: https://orcid.org/ 0000-0002-3418-3082