铝合金半固态加工技术应用

来源期刊:中国有色金属学报2000年第z1期

论文作者:张奎 刘国钧 张景新 徐庭 石力开 崔代金 吴绪平 郑宇新 袁序弟

文章页码:135 - 140

关键词:铝硅合金; 半固态金属; 电磁搅拌; 半固态压铸

Key words:Al-Si alloy; semi solid metal; electromagnetic stirring; thixocasting

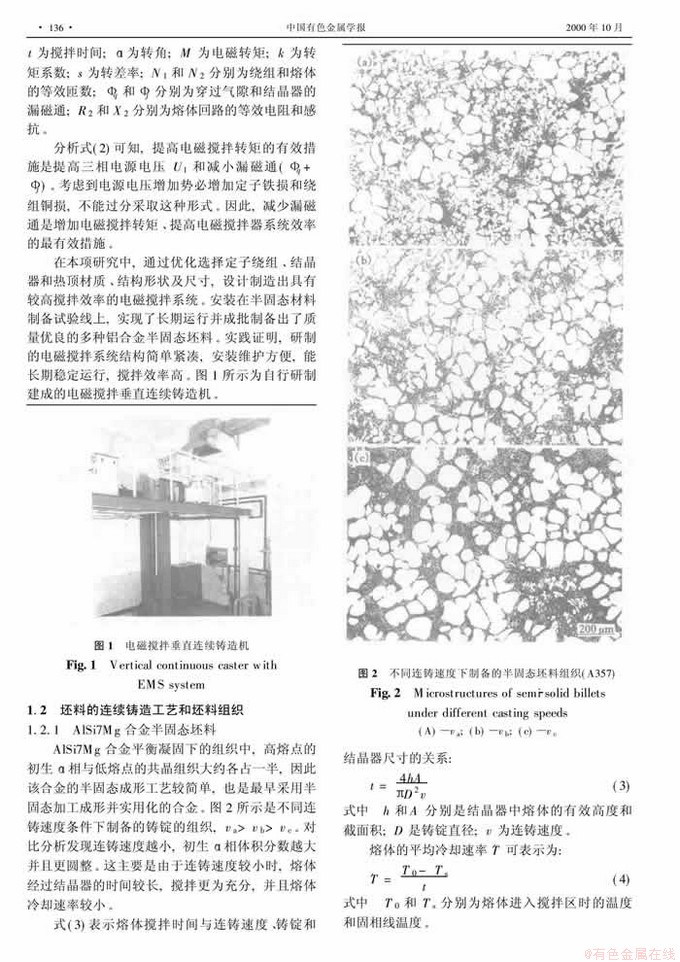

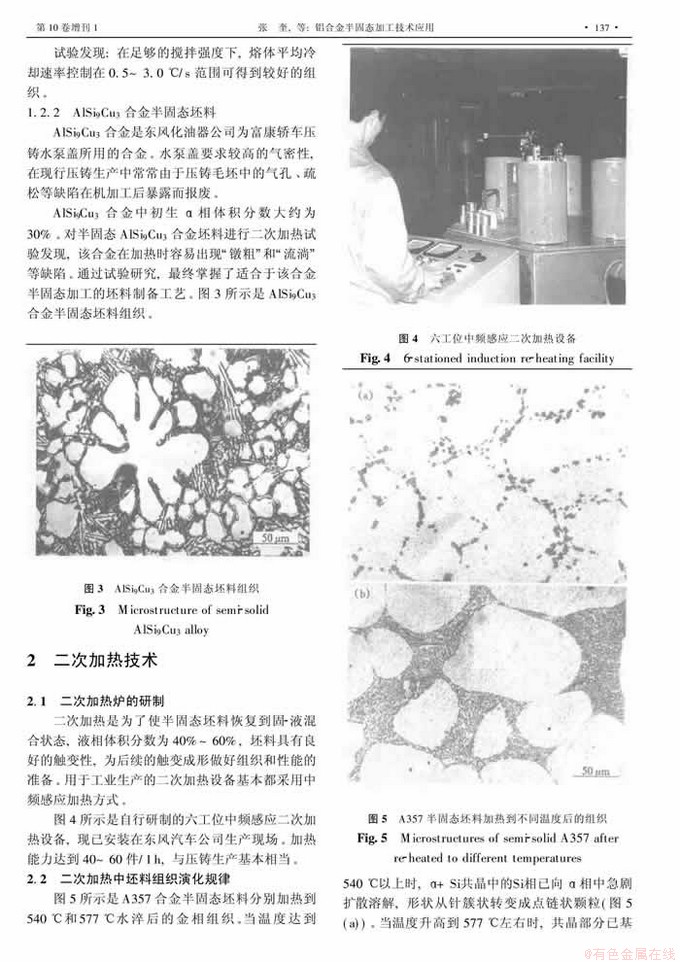

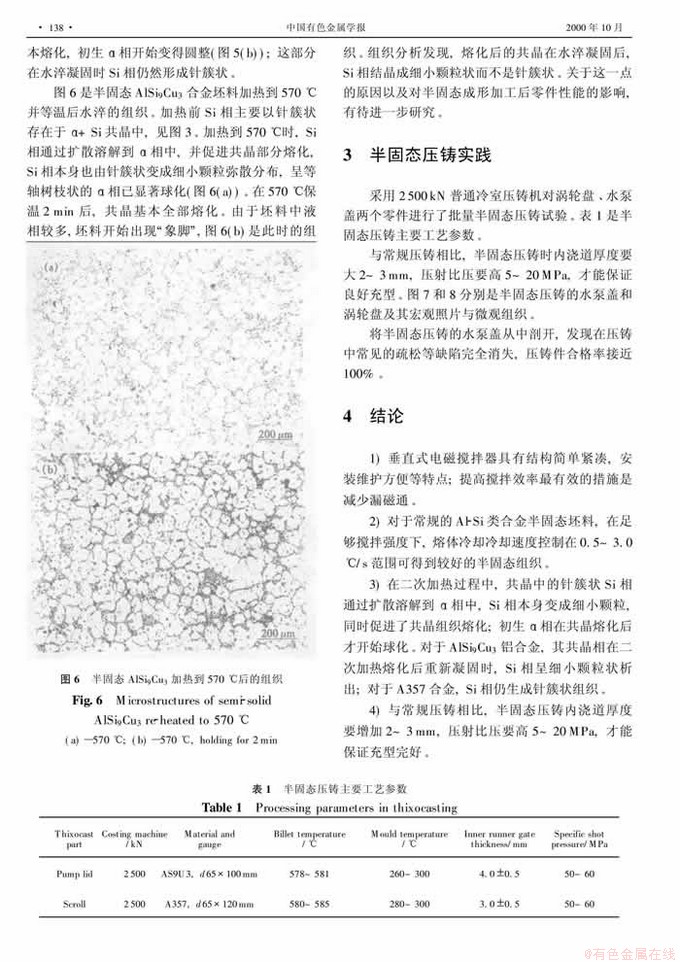

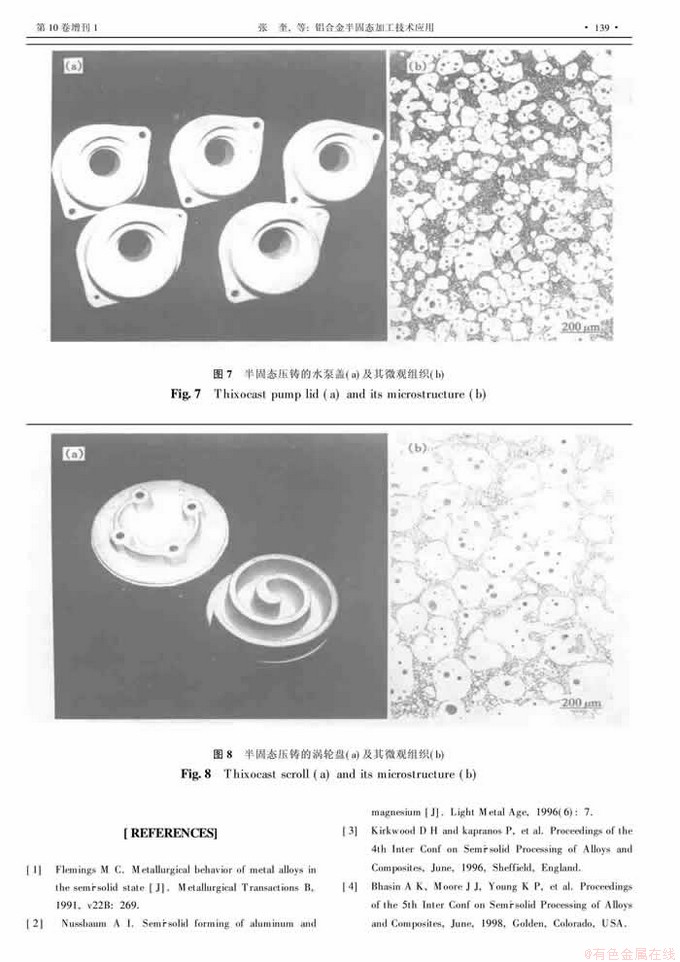

摘 要:对于垂直式电磁搅拌器 ,提高搅拌效率的最有效措施是减少漏磁通。对于通常的Al-Si类合金的半固态加工坯料 ,在足够的搅拌强度下 ,熔体冷却速度控制在 0.5~3.0℃/s可得到较好的组织。在二次加热时共晶体中的针簇状Si相通过扩散溶解到α相中 ,Si相本身变成细小颗粒 ,初生α相在共晶熔化后才开始球化。对于AlSi9Cu3合金 ,其共晶相在二次加热熔化后重新凝固时 ,Si相呈细小颗粒析出 ;对于A357合金 ,仍然生成针簇状组织。与常规压铸相比 ,半固态压铸内浇道厚度要增加 2~ 3mm ,压射比压要高 5~20MPa,才能保证充型完好。

Abstract: For vertical continuous casting with electromagnetic stirring, the most effective way to improve the stirring efficiency is to reduce leak magnetic flux. In the production of semi solid billets of conventional Al Si alloys, suitable microstructure can be obtained under enough stirring intensity when the cooling rate is controlled within 0.5~3.0 ℃/s. During re heating process, the needle like Si phase in the eutectic is transformed into fine particle through its diffusion toward α phase. The primary α phase begins to spheroidize only after the eutectic melts. For AlSi9Cu3 alloy, the Si phase precipitates in a form of fine particle when the eutectic solidifies after re heating and melting. But for AlSi7Mg alloy, the Si phase still displays neddle like structure. Compared with common high pressure die casting, the inner cast gate should be set 2~3 mm thicker and the injection pressure should be set 5~20 MPa higher to ensure complete die filling.