文章编号:1004-0609(2015)-03-0733-07

Ag-IPMC的制备及形貌表征

徐 岩1, 2,赵 刚1,朱玉敏1,孙壮志1

(1. 哈尔滨工程大学 机电工程学院,哈尔滨 150001;

2. 哈尔滨工程大学 工程训练中心,哈尔滨 150001)

摘 要:为了提高Ag-IPMC的性能,采用两种不同的粗化方法对基膜进行粗化处理,同时对Ag-IPMC制备过程中的离子交换银氨溶液浓度及化学还原反应温度进行分析,并采用扫描电镜对3种影响因素下制备的Ag-IPMC样件表面形貌进行表征,分析其表面显微结构特性,最后对制备改善前后的Ag-IPMC样件进行致动性能对比分析。结果表明:采用自制的电动装置对基膜粗化处理效果较好,基膜表面凹坑均匀,且保证了其不被损伤;在Ag-IPMC制备过程中离子交换银氨溶液浓度为0.030 mol/L时最佳,这为后续还原反应中Ag单质沉积到基膜内一定深度提供良好的保障条件;化学还原反应温度为20℃时最佳,制备改善后得到的Ag-IPMC样件运动寿命比改善前的提高超过1倍,运动位移更加稳定。

关键词:IPMC;粗化处理;溶液浓度;反应温度

中图分类号:TB381 文献标志码:A

Preparation and morphology characterization of Ag-IPMC

XU Yan1, 2, ZHAO Gang1, ZHU Yu-min1, SUN Zhuang-zhi1

(1. College of Mechanical and Electrical Engineering, Harbin Engineering University, Harbin 150001, China;

2. Engineering Training Center, Harbin Engineering University, Harbin 150001, China)

Abstract: In order to improve the performance of the Ag-IPMC, two different coarsening methods were used to conduct coarsening processing for basement membrane. And the concentration of silver ion exchange ammonia solution and chemical reduction reaction temperature were studied during preparation process of Ag-IPMC. The surface morphology and microstructure of Ag-IPMC sample with three influence factors were analyzed using scanning electron microscopy. Drive performances of Ag-IPMC sample before and after preparation were compared and analyzed. The results show that the coarsening processing effect of basement membrane using self-made electric device is relatively excellent. Basement membrane surface has a even pit, and this also ensures its surface not to be damaged. Concentration of 0.03 mol/L of silver ion exchange ammonia solution is better in the preparation of Ag-IPMC, which provides a good condition for Ag substance deposition into basement membrane in subsequent reduction reaction. Additionally, it is most appropriate when chemical reduction reaction temperature keeps at 20 ℃. The motional lifetime of sample after preparation is increased by more than 100% and motional displacement is more stable.

Key words: IPMC; coarsening treatment; solution concentration; reaction temperature

电活性聚合物具有特殊的机电耦合特性,在电激励下产生一定的形变,IPMC就是一种新型的离子型电活性聚合物,由离子交换膜和两侧金属电极构成,具有柔性好、质量轻、驱动电压低以及生物兼容性好等特点。在正负交替电压下,IPMC能产生超过90°的反复挠曲,其变形机理源于薄膜内部水合阳离子迁移现象,即在外加电压作用下,薄膜内部的水合阳离子向阴极方向迁移,致使IPMC变形,且变形无需任何机械传动系统便可将电能转化为机械能[1-4]。IPMC在微型仿生机器人,特别是水下智能低噪推进系统中,有着广阔的应用前景[5-6]。SHAHINPOOR等[7]利用IPMC制作抓取器,能在5V电压下提起约为自身质量26倍的小石子。MCDAID等[8]采用IPMC制作了一种两自由度控制器;FU等[9]设计了一种力耦合的外科手术机器人,采用IPMC作为驱动器间接驱动执行机构;CHANG等[10]研究了一种多自由度的水上行走机器人,在IPMC驱动下其行走速度可达到2 mm/s;SHI等[11]研制了一种多功能水下机器人,应用IPMC实现水下行走、旋转和漂浮等运动。

目前制备IPMC主要是通过化学镀方法在基膜表面沉积铂得到,由于研究成本过高,因此,研究制备低成本电极材料,成为IPMC领域的一个重要研究方向。LIAN等[12]采用浸渍提拉法制备出新型的IPMC碳纳米管电极。陈骐等[13]为降低成本,采用银替代铂制备电极,银的室温电阻率低,具有良好的导电性及延展性,因此更适合制备IPMC的电极[14-15]。但化学沉积法制备银型IPMC过程中,银沉积不易控制,且银与基膜的结合能力不佳导致镀层电极易受损或剥落,因此,优化Ag-IPMC的制备,提升其性能是当前研究重点之一[16-17]。

实验以Nafion-117膜为基膜,通过化学还原方法制备得到表面为Ag镀层电极的Ag-IPMC,其制备主要包括基膜预处理、离子交换以及化学还原反应等过程,具体制备工艺流程详见文献[18]。通过对IPMC制备的研究[19-20],分析制备过程中影响Ag-IPMC的3种关键因素,分别为粗化处理、离子交换银氨溶液浓度及化学还原反应温度,对每个关键因素进行实验分析,并采用扫描电镜对样件的表面形貌进行了表征[21-23],分析3种因素影响下得到样件的表面显微结构,揭示其最佳制备方法,对制备改善前后样件进行致动性能对比分析,为提高Ag-IPMC的性能提供可靠的依据。

1 粗化处理分析

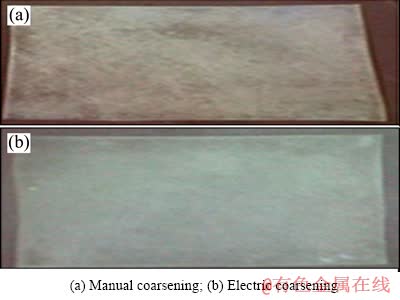

Ag-IPMC制备首先是基膜的粗化处理,目的是去除基膜表面杂质以提高氧化还原时Ag对基膜表面的附着力,并且基膜粗化处理的好坏直接关系到Ag-IPMC的表面电极质量,影响IPMC的运动性能。由于基膜很薄,为了保证其不被损伤以及制备Ag-IPMC样件质量的一致性,需要对基膜表面进行高质量的粗化,实验采用自制的电动装置对基膜进行粗化处理,装置如图1所示。使用电动装置粗化的基膜与手工打磨粗化的基膜如图2所示。

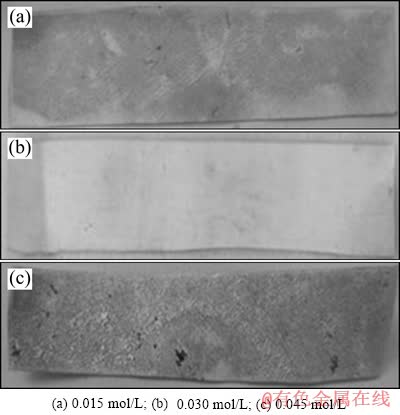

图2(a)所示为手工打磨粗化的基膜,由于打磨中基膜表面受力不均匀、不稳定,基膜上部分表面容易疏漏,致使其表面粗化程度不够,粗化后的基膜很难到达理想的使用要求。图2(b)所示为采用电动装置粗化的基膜,表面粗糙度更均匀,达到了基膜粗化处理要求,并且采用电动装置进行粗化的基膜时间短、效率高,基膜质量良好,为后续基膜表面镀Ag提供良好的保障条件。

图1 电动装置照片

Fig. 1 Photo of electric device

图2 两种粗化方法制备的基膜

Fig. 2 Basement membrane prepared by two coarsening methods

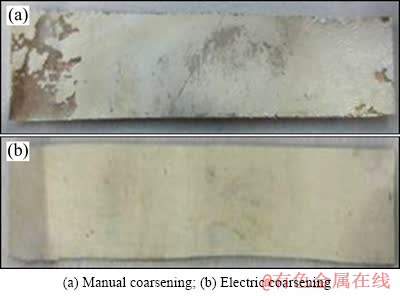

对手工打磨与电动装置两种粗化方法得到的基膜分别进行镀Ag处理,得到的Ag-IPMC样件如图3所示。由图3可以看出,在相同制备环境下,不同基膜粗化方法对IPMC质量产生明显的影响,在图3(a)中经手工打磨粗化后的Ag-IPMC样件整体表现出凸凹不平、干硬发白的特点,有明显Ag镀层脱落,表明Ag镀层不能很好地与基膜结合,只是简单地沉积于基膜表面,因此,Ag镀层不能起到良好的电极作用。在图3(b)中经电动装置粗化后的Ag-IPMC样件表面光滑平整、均匀柔软,Ag镀层附着力强,不易脱落,因此,Ag镀层能够起到很好的电极作用。通过对比分析可知,基膜粗化对IPMC样件质量影响很大,是制备过程的一个重要环节,因此需要不断优化粗化装置来更好地完成基膜的粗化处理。

图3 两种粗化方法制备的Ag-IPMC样件

Fig. 3 Ag-IPMC sample prepared by two coarsening methods

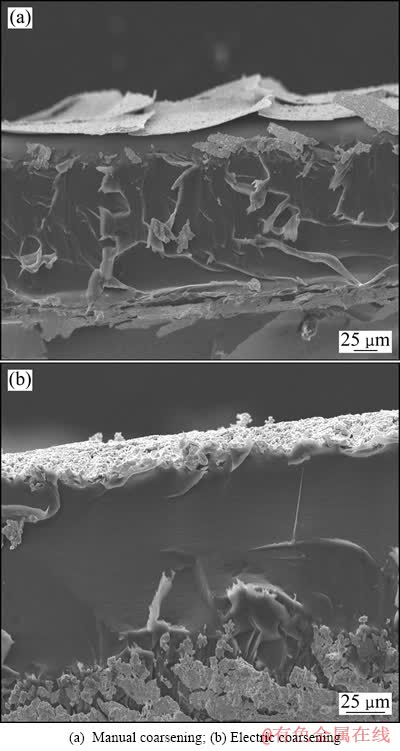

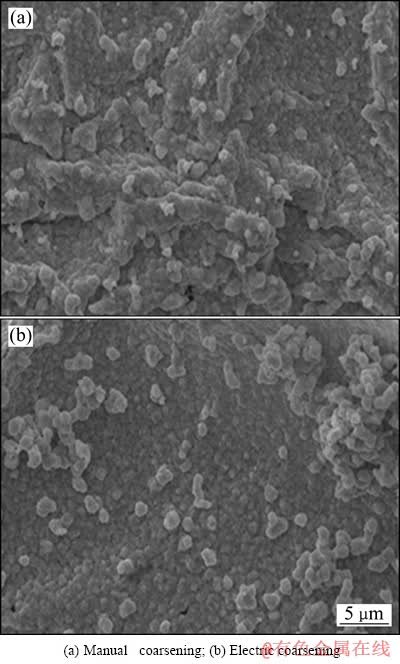

为了进一步明确粗化处理对Ag-IPMC的影响,分别对两种粗化方法得到的Ag-IPMC样件进行截面显微结构和表面显微结构扫描电镜分析,SEM像如图4和5所示。

在图4中,经手工打磨粗化后的Ag-IPMC样件表面Ag镀层严重破碎,镀层很薄,镀层与基膜之间存在大量裂缝甚至脱落(见图4(a))。经电动装置粗化后的Ag-IPMC样件表面的Ag镀层整体结构完整、致密均匀,镀层有一定的厚度,且与基膜附着牢固,基膜粗化留下的凹坑被镀层填满(见图4(b))。

由图5可知,经电动装置粗化后的Ag-IPMC样件表面Ag镀层均匀致密,而经手工打磨粗化后的Ag-IPMC样件表面Ag镀层凹凸感明显,结晶体间有错位和断裂痕迹。

通过以上分析可知,Ag-IPMC样件的截面显微结构和表面显微结构的扫描电镜形貌表征能够更直观地看到基膜粗化处理对Ag-IPMC的影响,表明粗化处理的重要性以及粗化对制备样件实际作用及意义,为更好地完成基膜前处理过程提供了更加有力的依据。

图4 Ag-IPMC样件的截面SEM像

Fig. 4 Sectional SEM images of Ag-IPMC sample

图5 Ag-IPMC样件的表面SEM像

Fig. 5 Surface SEM images of Ag-IPMC sample

2 制备分析

2.1 离子交换银氨溶液浓度对Ag-IPMC的影响

采用自制的电动装置对基膜进行粗化处理及其他预处理,然后进行离子交换,为了对比分析离子交换银氨溶液浓度对制备IPMC的影响,在银氨溶液浓度为0.015、0.030、0.045 mol/L 3种情况下分别进行实验,最后通过化学还原反应等过程得到Ag-IPMC样件,其表面照片如图6所示。

图6 采用不同浓度银氨溶液制备得到的Ag-IPMC样件表面照片

Fig. 6 Ag-IPMC samples prepared with different concentrations of sliver ammonia solution

由图6可知,当离子交换银氨溶液浓度过低时,还原反应时反应速度降低,反应时间增加,使得制备的样件表面Ag镀层稀薄、不均匀,如图6(a)所示,因此,Ag起不到良好的电极作用。当银氨溶液浓度过高时,还原反应时反应快速,大量Ag过于集中沉积于基膜表面,附着性不牢,出现脱落现象,如图6(c)所。经多次大量实验得出,离子交换银氨溶液浓度为0.03 mol/L时得到的Ag-IPMC样件质量最好,如图6(b)所示。

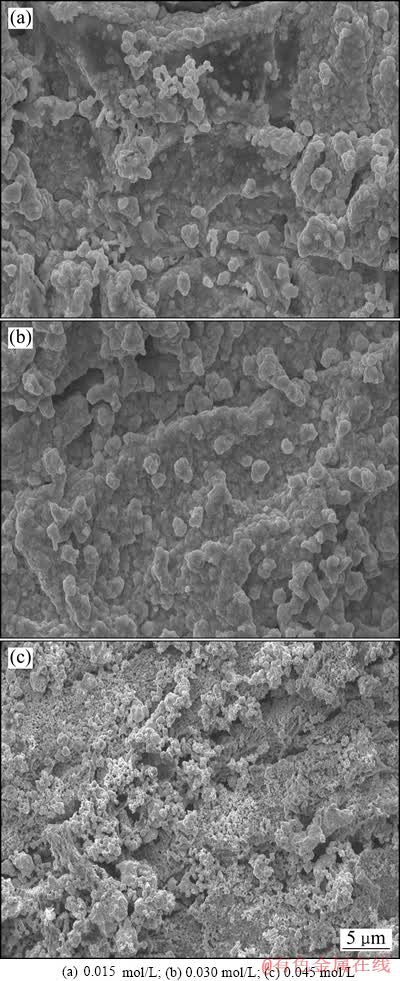

为进一步明确银氨溶液浓度对Ag-IPMC的影响,对3种浓度银氨溶液制备得到的Ag-IPMC样件进行表面扫描电镜分析,结果如图7所示。

从图7(a)与(c)中可以发现,采用0.015和0.045 mol/L的银氨溶液制备得到样件表面的Ag镀层颗粒间的排列间距不均匀、杂乱、疏松,且形成间隙、裂纹的空间立体结构,因此不能采用这两种浓度的银氨溶液进行制备Ag-IPMC。图7(b)所示的0.03 mol/L的银氨溶液制备得到样件表面的Ag镀层没有异物及空腔结构,镀层均匀致密,整体结构完好,能够很好地起到电极的作用,为基膜内离子的交换提供稳定的电场环境。

图7 采用不同浓度的银氨溶液制备得到的Ag-IPMC样件SEM像

Fig. 7 SEM images of Ag-IPMC sample prepared with different concentrations of sliver ammonia solution

离子交换的目的是在还原反应前使Ag+聚集在基膜两侧,在后续的还原反应中基膜表层在一定深度会产生Ag,为Ag单质良好附着在基膜两侧提供保障。通过以上分析可知,3种浓度银氨溶液制备得到的Ag-IPMC样件SEM像更明确的表明了银氨溶液对制备Ag-IPMC样件的影响,并且银氨溶液的浓度为0.030 mol/L时最合适。

2.2 化学还原反应温度对Ag-IPMC的影响

为了分析化学还原反应温度对Ag-IPMC的影响,首先采用自制的电动装置对基膜进行粗化处理及其它预处理,然后采用0.030 mol/L的银氨溶液进行离子交换,最后进行化学还原反应制备得到Ag-IPMC样件。选取3种还原反应温度进行实验,得到的Ag-IPMC样件表面照片如图8所示。

图8 在不同温度下制备得到的Ag-IPMC样件表面照片

Fig. 8 Ag-IPMC samples prepared at different temperatures

当化学还原反应温度为20 ℃时,沉积速度稳定,基膜表面形成的Ag颗粒细小致密、平整光滑且均匀一致,如图8(b)所示;当化学还原反应温度过低时,析出Ag的速度过慢,样件表面局部有银脱落,间隙部分有基膜露出,表明反应不完全,如图8(a)所示;当化学还原反应温度过高时,析出Ag的速度过快,导致Ag颗粒直径变大,层与层之间连接不紧密,致密性较差,出现分层现象,如图8(c)所示。

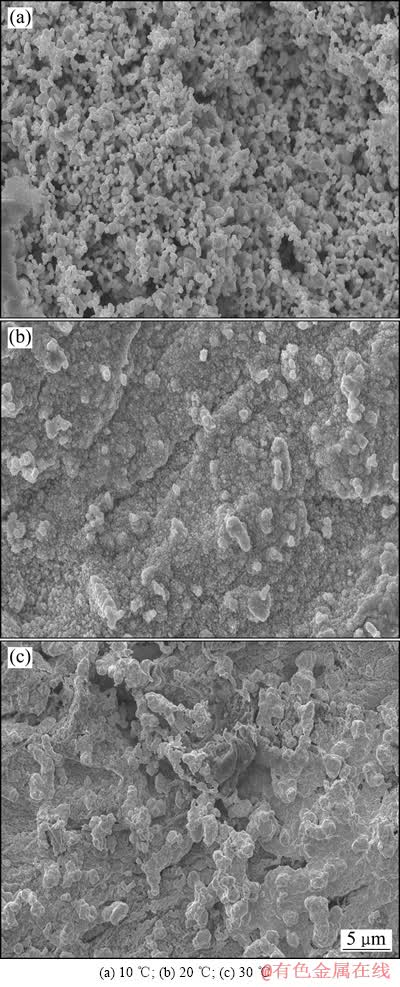

为了进一步明确温度对Ag-IPMC的影响,分别对在不同化学还原反应温度制备得到的Ag-IPMC样件进行其表面SEM分析,结果如图9所示。

分析图9可知,在不同温度下进行氧化还原反应镀Ag得到的IPMC样件表面显微结构区别明显,图9(b)中Ag镀层与基膜之间未出现龟裂、剥落、裂纹等现象,Ag镀层以层状结构存在,且镀层均匀致密,结构较为完整;由图9(a)与(c)可知,得到的样件Ag镀层严重破碎,Ag镀层有蜂窝状结构,且有疏松凹凸不平的空间立体结构,甚至出现了断裂、脱落、团聚等现象。因此,化学还原反应温度保证在20 ℃最为合适。

图9 在不同温度制备得到的Ag-IPMC样件SEM像

Fig. 9 SEM images of Ag-IPMC sample prepared at different temperatures

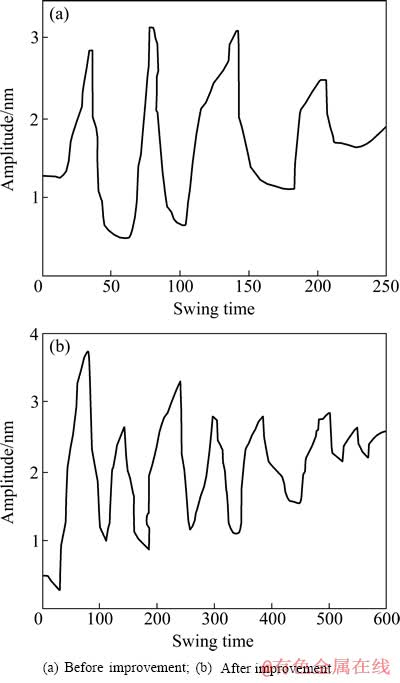

2.3 致动性能分析

为了研究上述3种因素对Ag-IPMC样件致动性能的影响,采用自制的电动装置对基膜进行粗化处理及其他预处理,然后采用0.030 mol/L的银氨溶液进行离子交换,最后在20 ℃时进行化学还原反应制备得到Ag-IPMC样件。对改善前后Ag-IPMC样件进行电致动实验对比,如图10所示。

图10所示为通过激光位移传感器获得的数据,可以看出改善后的样件尖端位移在同一时刻要明显大于改善前的样件尖端位移,同时随着运动时间推移,改善前样件的尖端位移衰减很严重,在较短的时间内就失去了运动活性,而改善后样件的尖端位移在运动初始阶段随时间增加缓慢变化,在运动一段时间后才出现明显的衰减,直至失去运动活性,到最终停止运动的摆动次数为600,运动寿命提高超过1倍,运动位移更加稳定。

图10 Ag-IPMC样件电致动实验对比图

Fig. 10 Comparison diagrams of Ag-IPMC samples measured with electrical drive experiment

3 结论

1) Ag-IPMC的制备是通过化学还原反应在非金属基膜表面上镀Ag来实现的,Ag镀层在IPMC运动性能中充当重要的电极作用。

2) 对Ag-IPMC制备过程中银氨溶液浓度、化学还原反应温度和基膜粗化处理3种关键影响因素实验分析可知:两种粗化方法制备的样件存在着较大的差异,采用自制的电动装置粗化的基膜,为后续的制备提供很好的保障条件。在制备时,Ag能够均匀、牢固附着在基膜上且不易脱落,起到良好的电极作用;离子交换的目的是使Ag+渗透到基膜表面,为化学还原反应时Ag的析出提供条件,实验确定离子交换银氨溶液浓度为0.030 mol/L时最合适;化学还原反应即Ag析出过程是IPMC制备最重要的过程之一,为了保证IPMC的质量,化学还原反应温度保证在20 ℃为宜,改善后得到的Ag-IPMC样件运动寿命提高超过1倍,运动位移更加稳定。

REFERENCES

[1] BANDOPADHYA D, NJUGUNA J. Modelling and analysis of an ionic polymer-metal composite (IPMC)-rocker-based four-bar for variable path generation using the Euler-Bernoulli approach[J]. Proceedings of the Institution of Mechanical Engineers, Part C: Journal of Mechanical Engineering Science, 2009, 223(10): 2045-2411.

[2] SHAHINPOOR M, KIM K J. Novel ionic polymer-metal composites equipped with physically loaded particulate electrodes as biomimetic sensors, actuators and artificial muscles[J]. Sensor and Actuators, A: Physical, 2002, 96(2/3): 125-132.

[3] 安 逸, 熊 克, 顾 娜. 采用梯度功能方法的IPMC弹性模量改进模型[J]. 复合材料学报, 2009, 26(6): 189-193.

AN Yi, XIONG Ke, GU Na. Improved model of IPMC’s elastic modulus using functionally gradient method[J]. Acta Materiae Compositae Sinica, 2009, 26(6): 189-193.

[4] NEMAT-NASSER S, LI J Y. Electromechanical response of ionic polymer-metal composites[J]. Journal of Applied Physics, 2000, 87(7): 3321-3331.

[5] CHEN Zheng, UM T I, BART-SMITH H. A novel fabricated of ionic polymer-metal composite membrane actuator capable of 3-dimensional kinematic motions[J]. Sensors and Actuators, A: Physical, 2011, 168(1): 131-139.

[6] SHAHINPOOR M. Biomimetic robotic venus flytrap (dionaea muscipula ellis) made with ionic polymer metal composites[J]. Bioinspiration and Biomimetics, 2011, 6(4): 1-11.

[7] SHAHINPOOR M, KIM K J. Ionic polymer-metal composites: IV. Industrial and medical application[J]. Smart Materials and Structures, 2005, 14(1): 197-214.

[8] MCDAID A J, AW K C, HAEMMERLE E, SHAHINPOOR M, XIE S Q. Adaptive tuning of a 2dof controller for robust cell manipulation using IPMC Actuators[J]. Journal of Micromechanics and Microengineering, 2011, 21(12): 1-11.

[9] FU Li-xue, ANDREW J M, KEAN C A. A force compliant surgical robotic tool with IPMC actuator and integrated sensing[C]. Fourth International Conference on Smart Materials and Nanotechnology in Engineering//Gold Coast, QLD. Australia, 2013, 8793: 1-11.

[10] CHANG Yi-chu, Kim W J. Aquatic ionic-polymer- metal-composite insectile robot with multi-DOF legs[J]. ASME Transactions on Mechatronics, 2013, 18(2): 547-555.

[11] SHI Li-wei, GUO Shu-xiang, ASAKA K. A novel multifunctional underwater microrobot[C]//2010 IEEE International Conference on Robotics and Biomimetics. Tianjin, 2010: 873-878.

[12] LIAN Yuan-feng, LIU Yue-xian, JIANG tao, SHU Jing, LIAN Hui-qin, CAO Min-hua. Enhanced electromechanical performance of graphite oxide-Nafion nanocomposite actuator[J]. The Journal of Physical Chemistry C, 2010, 114(21): 9659-9663.

[13] 陈 骐, 熊 克, 卞 侃, 金 宁, 王帮峰. Ag型IPMC柔性驱动器的制备及性能[J]. 材料科学与工程学报, 2009, 27(3): 426-429.

CHEN Qi, XIONG Ke, BIAN Kan, JIN Ning, WANG Bang-feng. Fabrication and properties of Ag based IPMC flexible actuator[J]. Journal of Materials & Engineering, 2009, 27(3): 426-429.

[14] TAMAGAWA H, NOGATA F, WATANABE T, ABE A, YAGASAKI K, JIN J Y. Influence of metal plating treatment on the electric response of Nafion[J]. Journal of Materials Science, 2003, 38(5): 1039-1044.

[15] TAMAGAWA H, GOTO S, T SUGIYAMA. Bending influence of metal plating treatment on the electric response of Nafion direction of Ag-plated IPMC containing immobile anions and/or cations[J]. Composites Science and Technology, 2008, 68(15/16): 3412-3417.

[16] 卞 侃, 熊 克, 陈 琪, 刘 刚, 王帮峰. 银基离子聚合物金属复合材料的制备和驱动特性[J]. 材料研究学报, 2010, 24(5): 520-524.

BIAN Kan, XIONG Ke, CHEN Qi, LIU Gang, WANG Bang-feng. Manufacture and actuating characteristic of ionic polymer metal composites with silver electrodes[J]. Journal of Materials Research, 2010, 24(5): 520-524.

[17] 卞 侃, 熊 克, 刘 刚, 陈 骐, 王帮峰. 铂型离子聚合物金属复合材料的制备及驱动位移测试[J]. 复合材料学报, 2011, 28(3): 115-120.

BIAN Kan, XIONG Ke, LIU Gang, CHEN Qi, WANG Bang-feng. Preparation and dynamic displacement testing of ionic polymer metal composites with platinum as electrodes[J]. Acta Materiae Compositae Sinica, 2011, 28(3): 115-120.

[18] 徐 岩, 赵 刚, 杨立明, 郑金兴, 马长顺, 朱玉敏. IPMC人工肌肉的制备工艺研究[J]. 功能材料, 2013, 44(11): 1646-1650.

XU Yan, ZHAO Gang, YANG Li-ming, ZHENG Jin-xing, MA Chang-shun, ZHU Yu-min. Research on preparation technique of IPMC artificial muscle[J]. Journal of Functional Materials, 2013, 44(11): 1646-1650.

[19] 徐 兵, 赵 扬, 郑高峰, 庄明凤, 黄伟伟, 王 伟. 基于PXI虚拟仪器的IPMC输出力测试[J]. 厦门大学学报: 自然科学版, 2014, 53(1): 52-55.

XU Bing, ZHAO Yang, ZHENG Gao-feng, ZHUANG Ming-feng, HUANG Wei-wei, WANG Wei. The blocking force test of IPMC based on PXI platform[J]. Journal of Xiamen University: Natural Science, 2014, 53(1): 52-55.

[20] 鞠博伟, 王先友, 魏启亮, 吴 春, 杨秀康, 舒洪波, 宋云峰, 温伟成. 球形高电压LiNi0.5Mn1.5O4的制备及其电化学性能[J]. 中国有色金属学报, 2013, 23(6): 1633-1639.

JU Bo-wei, WANG Xian-you, WEI Qi-liang, WU Chun, YANG Xiu-chun, SHU Hong-bo, SONG Yun-feng, WEN Wei-cheng. Synthesis and electrochemical performance of spherical high-voltage LiNi0.5Mn1.5O4[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(6): 1633-1639.

[21] 辛世刚, 赵荣根, 都 徽, 宋力昕. 铝合金表面氧化锆等离子体电解氧化涂层的制备及形成机理研究[J]. 无机材料学报, 2009, 24(1): 107-110.

XIN Shi-gang, ZHAO Rong-gen, DU Hui, SONG Li-xin.. Prepare and formation mechanism of the zirconia coating on aluminium alloy by plasma electrolytic oxidation[J]. Journal of Inorganic Materials, 2009, 24(1): 107-110.

[22] 徐云霞, 丁 燕, 邓 凯, 何青松, 于 敏, 郭东杰, 戴振东. 碳纳米管、石墨烯电极修饰的IPMC致动器的制备及性能[J]. 材料科学与工程学报, 2013, 31(3): 331-335.

XU Yun-xia, DING Yan, DENG Kai, HE Qing-song, YU Min, GUO Dong-jie, DAI Zhen-dong. Fabrication and properties of carbon nanotube and graphene for ionic polymer actuators[J]. Journal of Materials Science & Engineering, 2013, 31(3): 331-335.

[23] 汪创伟, 尹建成, 周静波, 刘英莉, 高 鹏, 李明翰, 钟 毅. 喷射沉积连续挤压制备2A12铝合金[J]. 中国有色金属学报, 2013, 23(4): 957-963.

WANG Chuang-wei, YIN Jian-cheng, ZHOU Jing-bo, LIU Ying-li, GAO Peng, LI Ming-han, ZHONG Yi. 2A12 aluminum alloy produced by spray forming conform[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(4): 957-963.

(编辑 王 超)

基金项目:国家自然科学基金资助项目(51275102,21203040)

收稿日期:2014-07-13;修订日期:2014-12-11

通信作者:赵 刚,教授,博士;电话:0451-82589096;E-mail: xychangke@163.com