Influence of Sc on high temperature strengthening behavior of

Ti-6Al-4V alloy

LIU Hui-qun(刘会群)1, YI Dan-qing(易丹青)1, WANG Wei-qi(王韦琪)2,

WANG Li-ping(王立平)2, LIAN Cai-hao(廉才浩)1

1. School of Materials Science and Engineering, Central South University, Changsha 410083, China;

2. Baoji Titanium Industry Co. Ltd., Baoji 721014, China

Received 15 July 2007; accepted 10 September 2007

Abstract: Vacuum arc melting technique was used to prepare Ti-6Al-4V alloy containing Sc (0.3% and 0.5%, mass fraction). The ingots were melted twice by vacuum self-consumable electrode arc furnace. Forging of ingots was started in β-phase region and finished in high (α+β)-phase region. Annealing after forging was performed in low (α+β)-phase region for 30 min. Isothermal high temperature compression tests were conducted using thermal simulation machine under Ar atmosphere at 850 ℃ and 1 000 ℃, and the strain rate were 0.001, 0.01, 0.1 and 1.0 s-1. Optical microscope(OM), scanning electron microscopy(SEM), energy dispersive spectrum(EDS) and transmission electron microscope(TEM) were used to study the microstructure evolution during high temperature deformation. The results show that, the peak stress value of alloys increases with increasing Sc content after deformation at 850 ℃, however, there is no obvious strengthening of Sc when the alloys are deformed at 1 000 ℃. Sc exists as Sc2O3 forms by internal oxidation during forging procedure, only minor Sc solutes in matrix. At 850 ℃, the interaction between dislocation and participated particles and twinning mechanism controls the deformation procedure accompanied recrystallization. At 1 000 ℃, the deformation of alloys containing Sc is mainly controlled by twinning, while the deformation of alloy without Sc is not only controlled by twinning, but also the interaction between dislocation and precipitated particles inside the twinning lamellar.

Key words: Ti-6Al-4V alloy; scandium; high temperature deformation; strengthening

1 Introduction

Due to excellent comprehensive properties, Ti-6Al-4V alloy was widely used in biomedical applications, automotive applications, sports related applications, energy industry, blades and discs for aircraft turbines, marine components, chemical components, and structural forgings[1-3].

Mechanical properties of alloys, such as strength, ductility, creep resistance, fracture toughness and crack propagation resistance, depend mainly on microstructure, processing history and heat treatment procedures. Over last decade some work was conducted to the microstructure evolution and deformation mechanism of Ti-6Al-4V alloy during hot deformation under different processing and heat treatment procedures[4-10]. SHEPPARD and NORLEY[4] have considered that the deformation modes of Ti-6Al-4V alloy are dynamic recovery in the β-phase region and dynamic recrystallization in the (α+β)-phase region during torsion testing at 800-1 150 ℃. While DING et al[9] and SESHACHARYULU et al[10] have obtained the results that dynamic or metadynamic recrystallization can occur for Ti-6Al-4V alloy in the β-phase region but almost does not occur in (α+β) phase region during isothermal forging and hot compression. The addition of Sc has prompted high temperature strength by 110 MPa for Ti-48Al alloy at 900 ℃ where the reinforcement compound formed is (Sc, Ti)3Al of cubic structure with point group Ia3d and lattice constant a=0.984 nm[11-13]. Introduction of Sc helps to decrease the transformation temperature of α→α2+γ and β→α+β in Ti-40Al-16Nb alloy[14]. In aluminum alloys, Sc helps to refine microstructure leading to increase in strength and recrystallization temperature by forming intermetallic phase of composition Al3Sc[15-18]. Al3Sc is coherent with matrix, resulting in significant strength increase.

However, no work has been done about the influence of Sc on microstructure, deformation behavior and properties of Ti-6Al-4V alloy.

2 Experimental

Materials preparation was conducted in Baoji Titanium Industry Co. Ltd.. Raw materials in this study were titanium sponge, Al-55%V intermediate alloy, pure Al, pure Sc. The ingots of Ti-6Al-4V (TC4), Ti-6Al-4V-0.3Sc (TS3) and Ti-6Al-4V-0.5Sc (TS5) were melted twice by vacuum self-consumable electrode arc furnace. The composition (mass fraction, %) of materials was as follows: 6.4Al, 4.15V, 0.15O, 0.25Fe, 0.05N, 0.10C, 0.015H. Forging of ingots started in β-phase region and finished in high (α+β)-phase region. Annealing after forging was performed in low (α+β)-phase region for 30 min.

Specimens of 12 mm in height and 8 mm in diameter were machined for high temperature compression test. Concentric grooves of 0.2 mm in depth were made on the top and bottom faces of the specimens to put lubricant and reduce friction. Isothermal hot compression tests were conducted using thermal simulation machine in Ar atmosphere. The hot compression test was performed at 850, 900, 950, 1 000 and 1 050 ℃ (TD), and constant true strain rate was 0.001, 0.01, 0.1 and 1 s-1. The temperature of the specimen was monitored using a chromel-alumel thermocouple welded on the specimen and temperature was maintained within ±(2-4) ℃ fluctuation. The specimens were deformed to 60% height and quenched in water. Deformed specimens were sectioned parallel to the compression axis for microstructure examination.

The microstructure and phase compositions of high temperature deformed samples were studied by OM, SEM and EDS. Ion beam thinning technique was used to prepare TEM samples in order to know the deformation behavior of samples at high temperature.

3 Results and discussion

3.1 Stress-strain behavior of high temperature deformed samples

Fig.1 shows the stress—strain curves of Ti-6Al-4V- 0.5Sc alloy. The shape of stress—strain curves indicates the different hot deformation mechanisms at 850 ℃ and 1 000 ℃. From Fig.1(a) it can be seen the typical dynamic recrystallization curve at low temperature and high strain rate. The true stress decreases with the decreasing strain rate indicating the working hardening

Fig.1 Stress—strain curves of Ti-6Al-4V-0.5Sc alloy at 850 ℃ (a) and 1 000 ℃ (b)

during the hot deformation. The magnitude of the drop in stress after peak increases with increasing strain rate, at strain rates of 0.01 and 0.001 s-1, the shape of curve could be explained by a dynamic recovery deformation process with an associated large temperature inverse. When deformed at β phase region temperature 1 000 ℃ (see Fig.1(b)), the curve is typical of a high temperature with low strain rate test in which a rapid rise to peak can be observed followed by a steady state regime, in which the stress is almost independent of the strain rate. The subsequent decreases of curve indicate that dislocation annihilation occurs far more rapidly than generation, which probably indicates an increase in temperature during working. It is also an indication that dynamic recovery processes occur very rapidly.

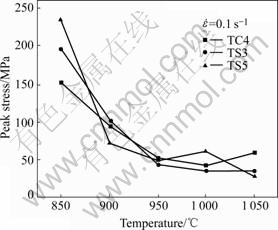

Fig.2 shows the relationship between peak stress and temperature of the alloys TC4, TS3 and TS5. The peak stress decreases with the increase of deformation temperature and strain rate. From Fig.2 it can be seen that Sc strengthens the alloy only under the deformation conditions of low temperature and high strain rates.

Fig.2 Relationship between deformation temperature and peak stress of TC4, TS3 and TS5 alloys under 0.1 s-1 of strain rate

3.2 Microstructure of as-forged alloys

The electron back scattering microstructures and EDS result of as-forged TC4, TS3 and TS5 alloys shown in Fig.3 indicate that Sc exists as Sc2O3 particle in the alloys due to the internal oxidation[14] during forging process. With the addition of Sc, the volume fraction of equiaxial α phase decreases, the microstructure changes from bi-modal (TC4) to lamellar (TS5).

3.3 Microstructure of high temperature deformed samples

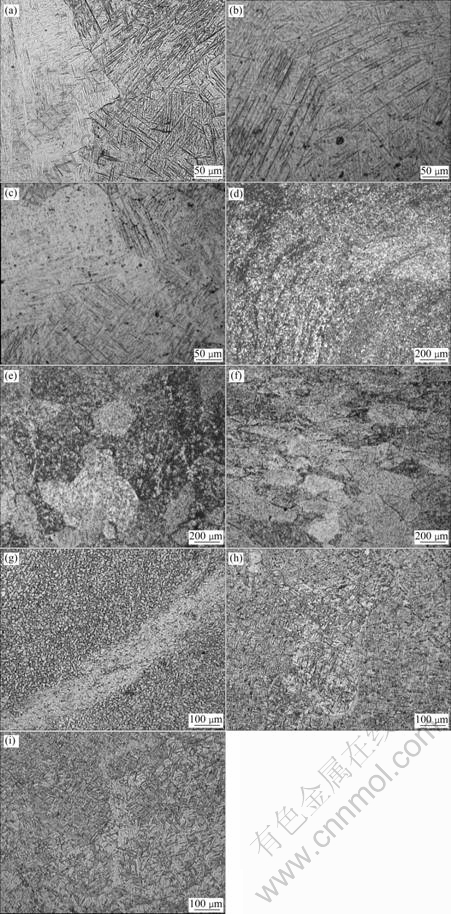

Both optical and electron microscope studies were performed on the compressed deformation microstructures of the alloys in order to identify the mechanism operative during deformation. The microstructure of specimens deformed in the β-region consists of coarse β grains. The optical micrographs of the alloys deformed in β-region are shown in Fig.4. The specimens were quenched in water immediately, the β grains transformed martensitically into the form of acicular plates. This martensitic transformation destroys any deformation substructure, but the boundaries of the deformed β grains are retained[4] (see Figs.4(a)-(c)). From the deformed microstructures of TS3 and TS5 alloys shown in Figs.4(b) and (c), it can be seen Sc2O3 particles distribute homogeneously in the matrix, but it seems finer in TS5 alloy. Figs.4(d)-(f) show the obvious recrystallization happens in TS3 and TS5 alloys, while without the addition of Sc in TC4 alloy we did not found recrystallization, the microstructure of TC4 alloy consists of equiaxed α phase, which exhibits the feature of compressed deformation flow line. With the deformation temperature decreasing, we found no recrystallization at 850 ℃ for TC4, TS3 and TS5 alloys.

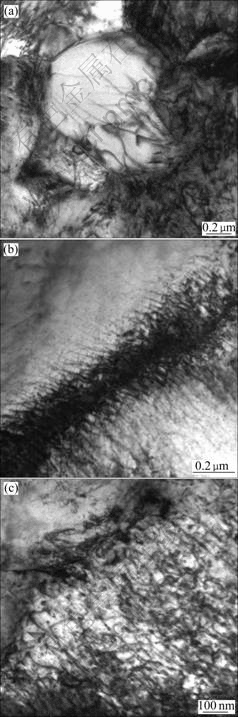

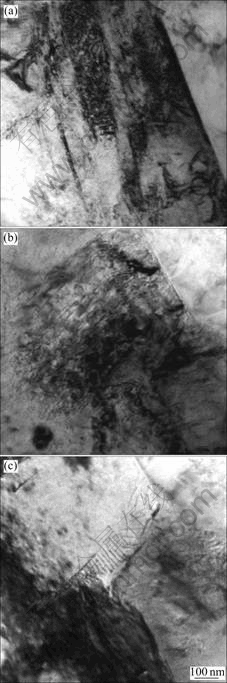

TEM bright field images of TC4 alloy deformed at 850 ℃ and strain rate 0.1 s-1 show an area of very small equiaxed α-grains having a low internal dislocation density (Fig.5(a)), some areas form sub-boundary induced by dislocation distortion (Fig.5(b)), dislocation tangled around grain boundary (Fig.5(c)). This evidence suggests that dynamic recrystallization is the deformation mode in the (α+β)-region.

Fig.3 Back scattering images of as-forged TC4 (a), TS3 (b) and TS5 (c) alloys and EDS result of TS3 alloy (d)

Fig.4 Optical micrographs of TC4, TS3 and TS5 alloys deformed at β-region and (α+β)-region: (a) TC4, 1 050 ℃, 0.1 s-1; (b) TS3, 1 050 ℃, 0.01 s-1; (c) TS5, 1 050 ℃, 0.01 s-1; (d) TC4, 900 ℃, 0.1 s-1; (e) TS3, 900 ℃, 0.1 s-1; (f) TS5, 900 ℃, 0.1 s-1; (g) TC4, 850 ℃, 0.1 s-1; (h) TS3, 850 ℃, 0.01 s-1; (i) TS5, 850 ℃, 0.01 s-1

Fig.5 TEM bright field images of TC4 alloy at 850 ℃ and 0.1 s-1: (a) Area of small equiaxed α-grains having low internal dislocation density; (b) Dislocation distortion region induced sub-boundary; (c) Tangled dislocation around grain boundary

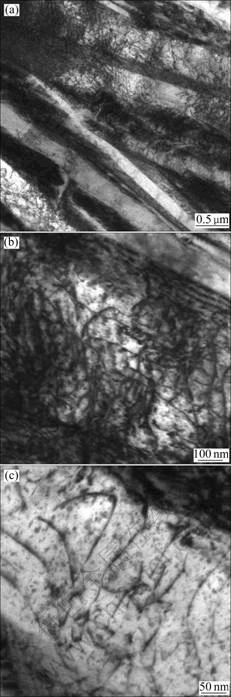

The addition of Sc changes the microstructure a lot in TC4 alloy, the microstructures of TS3 alloy show a small area of very fine equiaxed α-grains, there exist lots of martensite α plates showing twinning feature in TEM micrographs of TS3 alloy (Fig.6(b)), only a few of low density dislocations and precipitates appear around the grain boundaries (Fig.6(c)).

TEM images (Fig.7) of TS5 alloy deformed at 850℃ and 0.1 s-1 strain rate also exhibit an area of very fine

Fig.6 TEM bright field images of TS3 alloy at 850 ℃ and 0.1 s-1: (a) Equiaxed α-grains having low internal dislocation density; (b) α plates indicating twinning deformation mode; (c) Precipitation and low density dislocation around grain boundary

Fig.7 TEM bright field images of TS5 alloy at 850 ℃ with 0.1 s-1: (a) α plates indicating twinning deformation mode; (b) High density dislocation near grain boundary; (c) Dis- location blocking near triple grain boundary

equiaxed α-grains that are not given here. Besides lots of parallel α plates showing twinning feature in microstructure of TS5 alloy, high density dislocations near grain boundary and dislocation blockings near triple grain boundaries can also be found. These are the strengthening reasons that will be summarized in next part.

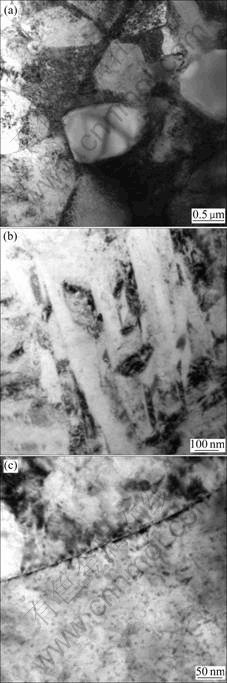

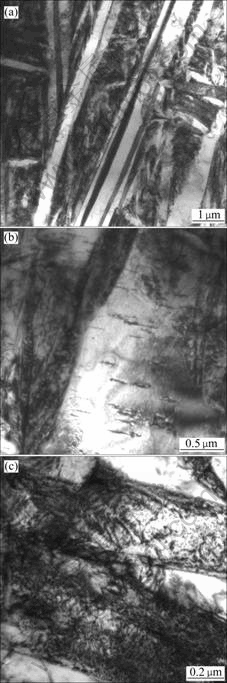

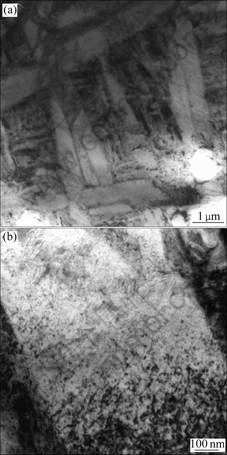

When the alloys of TC4, TS3 and TS5 are deformed at β-region, equiaxed α-grains cannot be found, because the samples are water quenched after test, most of β phase transforms martensitically into the form of acicular plates. Figs.8-10 show the microstructures of three alloys deformed at 1 000 ℃ and strain rate of 0.1 s-1, it is found near all α plates in microstructure, which indicates the features of twinning deformation mode, inside the lamellar high density dislocation (TC4 alloy), low density dislocation (TS5), interaction between particles and dislocation appears in microstructure.

Fig.8 TEM bright field images of TC4 alloy at 1 000 ℃ and 0.1 s-1: (a) α plates indicating twinning deformation mode; (b) High density dislocation inside lamellar; (c) Interaction between particle and dislocation inside lamellar

Fig.9 TEM bright field images of TS3 alloy at 1 000 ℃ and 0.1 s-1: (a) α plates indicating twinning deformation mode; (b) Parallel dislocation with low density inside lamellar; (c) Interaction between particle and dislocation inside lamellar

3.4 Deformation and strengthening mechanism

The addition of Sc changes the as-forged microstructure of TC4 alloy significantly (Fig.3), so, it is sure that the deformation mode is different at high temperatures. Table 1 summarizes the deformation mechanisms of TC4, TS3 and TS5 alloys. The peak stress value increases with the increasing addition of Sc at 850 ℃ deformation temperature, dislocation controlled the deformation process of TC4 alloy, while in

Fig.10 TEM bright field images of TS5 alloy at 1 000 ℃ and 0.1 s-1: (a) α plates indicating twinning deformation mode; (b) Interaction between particles and dislocation

Table 1 Deformation mechanism of alloys

1 High density dislocation; 2 Low density dislocation; 3 Martensitically transformed α plates showing twinning deformation feature; 4 Dislocation blocking; 5 Interaction between particles and dislocation

TS3 and TS5 alloys, martensitically transformed α plates strengthen the alloy, as well as dislocation blocking appears in TS5 alloy. Multifactor controls the deformation process indicating that the alloys have higher stress value. However, when the alloys are deformed at 1 000 ℃, the addition of Sc has no obvious strengthening effect, the deformation mechanisms of TC4, TS3 and TS5 alloys are almost the same, that is, martensitically transformed α plates and the interaction between particles and dislocation inside the lamellar appear in the deformed microstructure of three alloys. So, when the alloy is deformed in (α+β)-region, Sc plays a role of strengthening.

4 Conclusions

1) Sc which exists as Sc2O3 is formed by internal oxidation during forging procedure, only minor Sc solves in the matrix.

2) The peak stress decreases with the increase of deformation temperature and strain rate. The addition of Sc strengthens the alloy only under the deformation conditions of low temperature and high strain rates.

3) Optical microstructure reveals that obvious recrystallization happens in the alloys containing Sc (TS3 and TS5) which are deformed in (α+β)-region at 900 ℃, while without the addition of Sc in TC4 alloy it is not found recrystallization at this temperature, the microstructure of TC4 alloy consists of equiaxed α phase, which exhibits the feature of compressed deformation flow line. With the deformation temperature decreasing, there is no recrystallization at 850 ℃ for TC4, TS3 and TS5 alloys.

4) At 850 ℃, dislocation controls the deformation of TC4 alloy, the interaction between dislocation and participated particles and martensitically transformed α plates controls the deformation procedure of TS3 and TS5 alloys. The deformation mechanism at 850 ℃ indicates that the peak stress value increases with the increasing addition of Sc. At 1 000 ℃, the deformation of alloys containing Sc is controlled by martensitically transformed α plates and low density dislocation inside the lamellar. The deformation mechanisms of three alloys at 1 000 ℃ are almost same, although the dislocation density is not the same, but the strengthening induced by the addition of Sc is not obvious.

Acknowledgement

The authors wish to express their gratitude to Baoji Titanium Industry Co. Ltd., for their raw materials, vacuum arc melting and kind help.

References

[1] L?TJERING G, WILLIAMS J C. Titanium [M]. Heidelberg, Berlin: Springer-Verlag, 2003.

[2] SCHUTZ R W, WATKINS H B. Recent developments in titanium alloy application in the energy industry [J]. Materials Science and Engineering, 1998, A243: 305-315.

[3] LEYENS C, PETERS M. Titanium and titanium alloys [M]. Weinheim: WILEY-VCH Verlag GmbH & Co. KGaA, 2003.

[4] SHEPPARD T, NORLEY J. Deformation characteristics of Ti-6Al-4V [J]. Materials Science and Technology, 1998, 4: 903-908.

[5] SAUER C, L?TJERING G. Influence of α layers at β grain boundaries on mechanical properties of Ti-alloys [J]. Materials Science and Engineering, 2001, A319/321: 393-397.

[6] L?TJERING G. Influence of processing on microstructure and mechanical properties of (α+β) titanium alloys [J]. Materials and Engineering, 1998, A243: 32-45.

[7] MAJORELL A, SRIVATSA S, PICU R C. Mechanical behavior of Ti-6Al-4V at high and moderate temperatures (Part Ⅰ): Experimental results [J]. Materials Science and Engineering, 2002, A326: 297-305.

[8] PICU R C, MAJORELL A. Mechanical behavior of Ti-6Al-4V at high and moderate temperatures (Part Ⅱ): Constitutive modeling [J]. Materials Science and Engineering, 2002, A326: 306-316.

[9] DING R, GUO Z X, WILSON A. Microstructural evolution of a Ti-6Al-4V alloy during thermomechanical processing [J]. Materials Science and Engineering, 2002, A327: 233-245.

[10] SESHACHARYULU T, MEDEIROS S C, FRAZIER W G, PRASAD Y V R K. Hot working of commercial Ti-6Al-4V with an equiaxed α-β microstructure: materials modeling considerations [J]. Materials Science and Engineering, 2000, A284: 184-194.

[11] YIN S B, HUANG B Y, YIN Z M. Effect of Sc on high temperature mechanical properties of Ti-Al based alloys [J]. Materials Science and Engineering, 2000, A280: 204-207.

[12] JIN Tou-nan, YIN Zhi-min, LI Dou-xing. Influence of trace Sc addition on mechanical properties and microstructure of TiAl base alloy [J]. Journal of Aeronautical Materials, 2000, 20(4): 8-13. (in Chinese)

[13] JIN Tou-nan, YIN Zhi-min, LI Dou-xing. Crystal structure determination of a novel Ti-Al-Sc phase in Sc-doped TiAl alloy [J]. Acta Metallurgica Sinica, 2001, 37(4): 225-229. (in Chinese)

[14] YANG C T, KOO C H. Improving the microstructure and high temperature properties of the Ti-40Al-16Nb alloy by the addition of a minor Sc or La-rich Misch metal [J]. Intermetallics, 2004, 12: 235-251.

[15] DAVYDOV V G, ROSTOVA T G, ZAKHAROV V V, FILATOV Y A, YELAGIN V I. Scientific principles of making an alloying addition of scandium to aluminium alloys [J]. Materials Science and Engineering, 2000, A280: 30-36.

[16] FULLER C B, KRAUSE A R, DUNAND D C, SEIDMAN D N. Microstructure and mechanical properties of a 5754 aluminum alloy modified by Sc and Zr additions [J]. Materials and Engineering, 2002, A338: 8-16.

[17] KENDIG K L, MIRACLE D B. Strengthening mechanisms of an Al-Mg-Sc-Zr alloy [J]. Acta Materialia, 2002, 50: 4165-4175.

[18] SUH D W, LEE S Y, LEE K H, LIM S K, OH K H. Microstructural evolution of Al-Zn-Mg-Cu-(Sc) alloy during hot extrusion and heat treatments [J]. Journal of Materials Processing Technology, 2004, 155/156: 1330-1336.

(Edited by LI Xiang-qun)

Corresponding author: LIU Hui-qun; Tel: +86-731-8830263; Fax: +86-731-8836320; E-mail: lhq234@gmail.com