文章编号:1004-0609(2009)02-0378-05

20CaO?13Al2O3?3MgO?3SiO2的合成与氧化铝的浸出性能

王 波,于海燕,孙会兰,毕诗文,涂赣峰

(东北大学 材料与冶金学院,沈阳 110004)

摘 要:使用分析纯试剂配料,在1 500 ℃、保温1 h的条件下得到了四元化合物20CaO?13Al2O3?3MgO?3SiO2 (C20A13M3S3),研究了其氧化铝浸出性能,并通过XRD和SEM等分析了其在碳酸钠溶液中的作用机理。结果表明:C20A13M3S3具有一定的氧化铝浸出能力,其浸出率随着浸出时间的延长而提高,并在浸出2 h后达到最大值68.87%,低于同条件下12CaO?7Al2O3的氧化铝浸出率(92.78%);C20A13M3S3和Na2CO3反应的主要产物为NaAl(OH)4和CaCO3,并含有少量的Ca2SiO4和Mg(OH)2;生成的Ca2SiO4具有较高的活性,浸出2 h后,其分解率可达到19.35%。

关键词:铝酸钙炉渣;MgO;C20A13M3S3;氧化铝;浸出

中图分类号:TF 803.21 文献标识码: A

Synthesis and Al2O3 leaching property of 20CaO?13Al2O3?3MgO?3SiO2

WANG Bo, YU Hai-yan, SUN Hui-lan, BI Shi-wen, TU Gan-feng

(School of Materials and Metallurgy, Northeastern University, Shenyang 110004, China)

Abstract: 20CaO?13Al2O3?3MgO?3SiO2 (C20A13M3S3) was obtained at 1 500 ℃ for 1h with analysis pure reagents proportioning. Alumina leaching property of C20A13M3S3 was studied. And the mechanism of the reaction between C20A13M3S3 and Na2CO3 solution was discussed by XRD and SEM method. The results indicate that alumina can be leached from C20A13M3S3. The leaching rate rises gradually with the prolongation of leaching time and reaches its maximum 68.87% after leaching for 2 h. The maximum leaching rate of C20A13M3S3 is lower than that of C12A7, which is 92.78% under the same condition. The main products of C20A13M3S3 reaction with Na2CO3 are NaAl(OH)4 and CaCO3, and a few amount of Ca2SiO4 and Mg(OH)2 are also generated. Ca2SiO4 generated from the reaction has high activity, and the decomposition rate can achieve 19.35% after leaching for 2 h.

Key words: calcium aluminate slag; MgO; C20A13M3S3; alumina; leaching

铝酸钙炉渣是利用烧结—高炉冶炼—氧化铝提取工艺处理高铁铝土矿过程中非常重要的中间物料。铝酸钙炉渣的物相组成和质量不仅关系到高炉冶炼的正常运行,而且直接影响到后面的氧化铝浸出工艺[1?3]。

MgO是铝酸钙炉渣中含量相对较多的杂质之一,它主要来源于高铁铝土矿和烧结过程中添加的石灰和焦粉,另外,在高炉冶炼过程中,炉衬中的MgO也会部分进入炉渣导致其MgO含量提高。当体系中含有一定量的MgO时,它会和体系中的CaO、Al2O3和SiO2形成四元系化合物20CaO·13Al2O3·3MgO·3SiO2 (C20A13M3S3),该化合物在CaO-Al2O3-SiO2-MgO体系中是一个热力学稳定的化合物[4],它的存在会降低铝酸钙炉渣中Al2O3的浸出率。

C20A13M3S3是高铝水泥中Q相的组成成分[5?7],这是由于它具有良好的水化性能,早期强度高,中后期强度不退缩。最初,人们认为Q相的组成为6CaO·4Al2O3·MgO·SiO2(C6A4MS)。而后,KAPRALIK等[8]的研究结果表明:化学式20CaO·13Al2O3·3MgO·- 3SiO2是该物相的稳定组成,且化学式随着晶体中固溶量的变化而有微小变化,并给出了其通式:20CaO·(16?x)Al2O3·xMgO·xSiO2(x=2.5~3.5)。孟涛等[9]的研究表明,C6A4MS的形成反应方程式为C2AS+ CA(C12A7)+f-MgO→C6A4MS。

EREMIN[10]对含MgO的铝酸钙炉渣进行了研究,指出MgO在炉渣中生成一种C6A4MS的化合物,该化合物不溶于碳酸钠溶液中。王波等[11]对含MgO的铝酸钙炉渣研究结果表明,铝酸钙炉渣中含有少量MgO时,会生成C20A13M3S3;当MgO含量大于2%后,Al2O3在A/S=1.3(Al2O3和SiO2质量比),C/A=1.7 (CaO和Al2O3的质量比)的炉渣中的赋存状态主要为C20A13M3S3,并明显降低了铝酸钙炉渣的氧化铝浸出率。研究结果表明:该化合物可以与碳酸钠溶液反应,具有一定的氧化铝浸出性能。

因此,为排除其他因素和杂质的影响,本文作者以分析纯化学试剂为配料,按照化合物中C20A13M3S3各氧化物的配比,合成纯C20A13M3S3,研究该化合物的氧化铝浸出性能,并探讨其在碳酸钠溶液中反应 机理。

1 实验

1.1 实验仪器和设备

SX2?38?16型气体保护MoSi2箱式高温炉;磁力搅拌恒温水浴箱;722S型可见光分光光度计;荷兰PANalytical PW3040/60型X射线衍射分析仪;日本岛津SSX?550型扫描电镜;SDT.Q600型综合热分析仪。

1.2 原料

实验过程中使用的CaCO3、Na2CO3、NaOH、SiO2和MgO均为分析纯化学试剂,Al(OH)3为工业纯。

1.3 C20A13M3S3的合成

合成实验用氧化铝由工业氢氧化铝在1 100 ℃煅烧200 min制得。将实验原料按照化学式配比称量混匀,在二硅化钼高温电阻炉中进行熔炼,容器为石墨坩埚,熔炼温度为1 500 ℃,保温时间为1 h。然后,将熔体在炉中以5 ℃/min速度冷却至400 ℃时取出。将 得到的产物破碎,粒度棒磨至小于74 μm,在120 ℃干燥4 h,待用。

1.4 C20A13M3S3的浸出

由于高炉渣浸出后得到的铝酸钠溶液采用碳酸化分解工艺,碳分后的循环母液再返回去浸出新的高炉铝酸钙渣,因此,本研究模拟铝酸钙炉渣浸出用调整液的成分为:苛性碱7 g/L,摩尔比r=1.6,碳酸钠120 g/L,液固比10,浸出温度75 ℃,浸出时间15~150 min。浸出实验在多孔磁力搅拌恒温水浴箱中进行。先将准确量取的50 mL调整液预热至75 ℃,然后,倒入装有5 g自粉炉渣的磨口锥形瓶中。搅拌并计时浸出。浸出结束后,干过滤,滤渣用温水洗涤并干燥保存,待分析检测。溶液中Al2O3浓度分析采用EDTA容量法;SiO2浓度分析采用硅钼兰比色法。

2 结果与分析

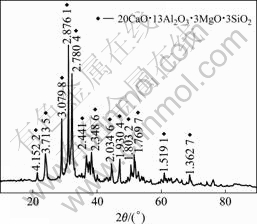

2.1 合成产物物相分析

对合成的物质进行XRD分析,结果如图1所示。由图1可知,在1 500 ℃,保温1 h的条件下合成的产物中仅有1个物相C20A13M3S3(d为0.308,0.288,0.278 nm),合成产物的物相组成比较单一。这是由于在1 500 ℃时,12CaO·7Al2O3(熔点1 455 ℃)已经进入液相,液相的出现使得离子的扩散加速,从而使得化合物C20A13M3S3的形成反应C2AS+CA(C12A7)+f-MgO→C20A13M3S3进行得比较彻底,因此,没有检正到其他物相的特征峰。

图1 合成产物20CaO?13Al2O3?3MgO?3SiO2的XRD谱

Fig.1 XRD pattern of synthesized product 20CaO?13Al2O3?- 3MgO?3SiO2

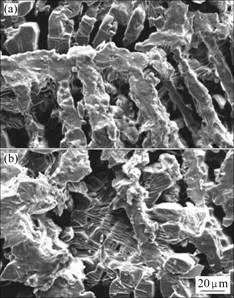

2.2 C20A13M3S3的形貌特征

通过扫描电镜对合成产物得到表观形貌进行分析。图2所示为在放大500倍时C20A13M3S3的SEM像。由图2可看出,晶体多以条状搭接在一起,并有较多的沟壑和孔洞(见图2(a));少量晶体以层状堆积在一起,仍有明显的条状结构出现(见图2(b))。总的来说,C20A13M3S3晶体主要以板条状形式立体堆积。

图2 C20A13M3S3的SEM像

Fig.2 SEM images of C20A13M3S3: (a) Region of gully and hole; (b) Region of layer stacking

2.3 浸出实验

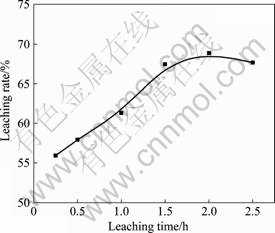

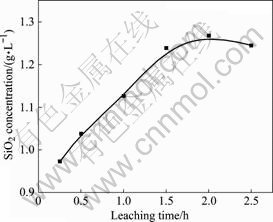

在75 ℃时,在Na2CO3溶液中对C20A13M3S3进行氧化铝浸出实验,考察不同浸出时间下C20A13M3S3的氧化铝浸出率,并分析溶液中SiO2的浓度,结果如图3和4所示。

图3 浸出时间不同时C20A13M3S3的氧化铝浸出率

Fig.3 Alumina leaching rate of C20A13M3S3 under different leaching times

图4 浸出时间不同时浸出液中SiO2浓度

Fig.4 SiO2 concentration of leaching solution under different leaching times

由图3可知,C20A13M3S3可溶于碳酸钠溶液,具有一定的氧化铝浸出性能,且其氧化铝浸出率在2 h内随着浸出时间的增大而逐渐变大。继续提高浸出时间,氧化铝浸出率不再提高,而是趋于平缓,这说明在该体系中,C20A13M3S3、Al(OH)4?和CO32?已经基本达到平衡状态,各相的量不再发生变化。但总体来看,其氧化铝浸出性能相对12CaO·7Al2O3较差,即使反应了2 h,浸出率也只有68.87%,远低于同条件下纯12CaO·7Al2O3的氧化铝浸出率(92.78%)[12]。图4所示为不同反应时间下溶液中SiO2含量的变化。由图4可看出,溶液中SiO2的含量随着氧化铝浸出率的提高而提高,而溶液中除C20A13M3S3外没有其他SiO2来源,故SiO2全部来源于C20A13M3S3的分解。

2.4 浸出机理

由前面的实验结果可知,C20A13M3S3与溶液中的Na2CO3发生了反应,并使得一定量的Al2O3和SiO2进入了溶液。为了探讨C20A13M3S3与Na2CO3反应的机理,对浸出时间为2 h的浸出渣进行XRD分析,结果如图5所示。

由图5可知,赤泥中的主要物相为2种晶型的CaCO3,并含有少量的2CaO·SiO2和未反应完全的C20A13M3S3。渣中的CaCO3并不完全以三方方解石型CaCO3存在,仅有一少部分以六方球方解石(球文石)CaCO3存在,它是CaCO3很不稳定的同质多相变体[13?14]。由于其在常温常压下很不稳定,因此,其在自然界中非常少见,通常在实验室合成获得,其形成机理还待进一步研究。浸出完成后,溶液中苛碱质量浓度为40~50 g/L,碳碱质量浓度为70~80 g/L。根据Mg(OH)2和MgCO3的溶度积进行计算,可以判断Mg2+处于Mg(OH)2的稳定区域,在检索过程中没有发现Mg(OH)2,可能是由于其相对含量比较少(低于4%),低于XRD所能检测出的最低含量。

图5 浸出2 h渣的XRD谱

Fig.5 XRD pattern of residue after leaching for 2 h

由前面的分析可知,浸出过程中发生的主要反应为:

另外,溶液中进入了一定量的SiO2,这是由于物料C20A13M3S3和碳酸钠溶液反应后生成了Ca2SiO4,Ca2SiO4在碳酸钠和氢氧化钠的作用下,发生了分解,分解反应如下[15]:

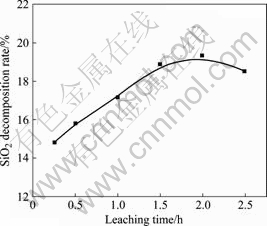

经计算,溶液中SiO2的总量占体系中SiO2总量的15%~20%,结果如图6所示。由图6可看出,C20A13M3S3分解出的2CaO·SiO2具有较强的活性,在该溶液体系中比较容易发生分解,浸出2 h后,其分解率可达到19.35%。浸出液的硅量指数为30~40,且随浸出时间变化不大。

图6 浸出时间不同时C20A13M3S3中SiO2分解率

Fig.6 SiO2 decomposition rate of C20A13M3S3 under different leaching times

3 结论

1) 在1 500 ℃,保温1 h的条件下得到物相单一的四元化合物C20A13M3S3。

2) C20A13M3S3晶体的表面形貌主要以板条状形式立体堆积,并具有较多的沟壑和孔洞。

3) C20A13M3S3具有一定的氧化铝浸出率,其浸出率随着时间的延长而提高,并在浸出2 h后达到最大值,浸出率为68.87%,低于同条件下C12A7的氧化铝浸出率(92.78%)。

4) C20A13M3S3和Na2CO3的反应产物主要为NaAl(OH)4和CaCO3,并含有少量的Ca2SiO4和Mg(OH)2。生成的Ca2SiO4具有较强的活性,在浸出 2 h后,其分解率可达到19.35%。

REFERENCES

[1] 李殷泰, 毕诗文, 段振瀛, 杨毅宏, 张敬东. 关于广西贵港铝土矿综合利用工艺方案的探讨[J]. 轻金属, 1992(9): 6?15.

LI Yin-tai, BI Shi-wen, DUAN Zhen-ying, YANG Yi-hong, ZHANG Jing-dong. Discuss on comprehensive utilization of iron-bearing bauxite in Guigang Guangxi[J]. Light Metals, 1992(9): 6?15.

[2] 佟志芳, 毕诗文, 于海燕, 吴玉胜. 微波作用下铝酸钙炉渣非等温浸出动力学[J]. 中国有色金属学报, 2006, 16(2): 357?362.

TONG Zhi-fang, BI Shi-wen, YU Hai-yan, WU Yu-sheng. Leaching kinetics of non-constant temperature process of calcium aluminate slag under microwave radiation[J]. The Chinese Journal of Nonferrous Metals, 2006, 16(2): 357?362.

[3] 张敬东, 李殷泰, 毕诗文. 广西贵港高铁铝土矿综合利用研究[J]. 轻金属, 1992(8): 16?18.

ZHANG Jing-dong, LI Yin-tai, BI Shi-wen. Research on integrated utilization of high-ferrum bauxite in Guigang, Guangxi[J]. Light Metals, 1992(8): 16?18.

[4] 丁子上. 硅酸盐物理化学[M]. 北京: 中国建筑工业出版社, 1980: 259.

DING Zi-shang. Silicate physical chemistry[M]. Beijing: China Building Industry Press, 1980: 259.

[5] 姜奉华, 徐德龙. 微量组分对高铝水泥系统中Q相组成的影响[J]. 硅酸盐学报, 2005, 33(10): 1276?1279.

JIANG Feng-hua, XU De-long. Influence of trace compositions on the formation of Q phase in high-alumina cement system[J]. Journal of the Chinese Ceramic Society, 2005, 33(10): 1276?1279.

[6] 姜奉华, 郑少华. 高铝水泥系统中硅铝酸二钙向Q相的转变[J]. 硅酸盐学报, 2005, 33(4): 462?466.

JIANG Feng-hua, ZHEN Shao-hua. Transformation of gehlenite into Q phase in high-alumina cement system[J]. Journal of the Chinese Ceramic Society, 2005, 33(4): 462?466.

[7] 姜奉华, 杨利群, 徐先宇. Q相?CA?C12A7系列水泥烧成条件的研究[J]. 山东建材学院报, 1998, 12(4): 352?354.

JIANG Feng-hua, YANG Li-qun, XU Xian-yu. Research on sintering condition of Q phase-CA-C12A7 system cement[J]. Journal of Shandong Institute of Building Materials, 1998, 12(4): 352?354.

[8] KAPRALIK I, HANIC F. Studies of the system CaO-Al2O3- MgO-SiO2 in relation to the quaternary Q phase[J]. Transaction of Britain Ceram Society, 1980, 79(5): 128?133.

[9] 孟 涛, 杨利群, 徐先宇. CaO-Al2O3-MgO -SiO2系统中Q相的形成及其水化特性[J]. 硅酸盐通报, 1998(3): 31?34.

MENG Tao, YANG Li-qun, XU Xian-yu. Studies of CaO-Al2O3-MgO-SiO2 system in relation to the formation and hydration of Q phase[J]. Bulletin of the Chinese Ceramic Society, 1998(3): 31?34.

[10] EREMIN N I. Investigations on the complex processing of bauxites[C]// Symposium of ICSOBA. Budapest: Research Institute for Non-ferrous Metals, 1971: 329?335.

[11] 王 波, 于海燕, 苗 瑜. MgO对铝酸钙炉渣体系浸出和自粉性能的影响[J]. 轻金属, 2008(4): 11?13.

WANG Bo, YU Hai-yan, MIAO Yu. Effect of MgO on leaching and self-disintegrating property of calcium aluminate slag[J]. Light Metals, 2008(4): 11?13.

[12] 孙会兰, 涂赣峰, 毕诗文. 七铝十二钙的合成及其在高碳钠铝酸钠溶液中的溶出性能[J]. 轻金属, 2007(11): 17?19.

SUN Hui-lan, TU Gan-feng, BI Shi-wen. Synthesization of C12A7 and it’s leaching property in sodium aluminate solution with high-Na2Oc[J]. Light Metals, 2007(11): 17?19.

[13] 彭苏萍, 丁述理, 王贤君. 罕见矿物—六方球方解石的发现及特征[J]. 矿物学报, 2003, 23(1): 45?50.

PENG Su-ping, DING Shu-li, WANG Xian-jun. Discovery and charecteristics of the rare mineral—Vaterite in oil-pumping oil well[J]. Acta Mineralogica Sinica, 2003, 23(1): 45?50.

[14] 马红艳, 崔福斋. 淡水珍珠中球文石的XRD谱[J]. 矿物学报, 2003, 23(4): 371?373.

MA Yan-hong, CUI Fu-zhai. XRD patterns of vaterite in biomineralized freshwater pearls[J]. Acta Mineralogica Sinica, 2003, 23(4): 371?373.

[15] 毕诗文, 于海燕. 氧化铝生产工艺[M]. 北京: 化学工业出版社, 2006: 260.

BI Shi-wen, YU Hai-yan. Alumina production process[M]. Beijing: Chemical Industry Press, 2006: 260.

基金项目:国家自然科学基金资助项目(50674028);中国铝业股份有限公司资助项目(CHALCO-2007-KJ-03)

收稿日期:2008-05-26;修订日期:2008-08-26

通讯作者:于海燕,副教授,博士;电话:024-83686460;E-mail: wang_bo_2006@yahoo.com.cn

(编辑 李艳红)