太阳能辅助喷射-蒸气压缩混合制冷循环的性能分析

刘肖,刘晔,鱼剑琳

(西安交通大学 能源与动力工程学院,陕西 西安,710049)

摘要:为了提高传统的单回路蒸气压缩制冷循环的性能,将常规的蒸气压缩制冷循环与太阳能驱动的喷射制冷循环相结合,提出一种新型太阳能辅助的混合喷射-蒸气压缩制冷循环。在该新型循环中,首先采用过冷器将喷射制冷循环与蒸气压缩制冷循环相结合,利用太阳能集热板收集太阳能,并利用太阳能驱动的喷射制冷循环增加蒸气压缩制冷循环的过冷度,通过增加循环的制冷量进而提高循环的综合性能;其次,建立热力学模型,利用REFPROP软件的数据库获取制冷剂物性参数并使用FORTRAN程序计算该新型循环性能;最后,研究蒸发温度等参数对循环性能的影响。研究结果表明:在设计工况范围内,混合制冷循环的性能系数和单位容积制冷量比常规的蒸气压缩制冷循环分别可提高10.4%和13.6%;混合制冷循环存在最佳中间温度,当中间温度为20 ℃时,循环性能系数达到最大值5.50;在设计工况范围内,喷射器的喷射系数和升压比最高可分别达到1.09和1.87;蒸发温度,冷凝温度与中间温度等循环参数均对喷射器的性能有非常显著的影响,降低蒸发温度和中间温度或者升高冷凝温度,均可以增大喷射器升压比,减小喷射系数。

关键词:混合制冷循环;喷射器;循环性能;太阳能

中图分类号:TB61 文献标志码:A 开放科学(资源服务)标识码(OSID)

文章编号:1672-7207(2021)06-1837-09

Performance analysis of a novel solar-assisted hybrid ejector-vapor compression refrigeration cycle

LIU Xiao, LIU Ye, YU Jianlin

(School of Energy and Power Engineering, Xi'an Jiaotong University, Xi'an 710049, China)

Abstract: In order to improve the performance of conventional single-loop vapor compression refrigeration cycle(VCRC), a novel solar-assisted hybrid ejector-vapor compression refrigeration cycle(ECRC) was proposed which combined with conventional VCRC and solar-driven ejector refrigeration. Firstly, a subcooler was applied to combine ejector cycle and VCRC in ECRC. Solar panels was utilized to collect solar energy, and then solar-driven ejector cycle was utilized to increase subcooling degree of main refrigeration cycle. As a result, the performance of ECRC was improved by increasing the refrigeration capacity. Secondly, a thermodynamic model was established for the ECRC. The physical property parameters of refrigerant were obtained by the database of REFPROP software and the performance of ECRC was calculated by FORTRAN program. Finally, the influence of evaporation temperature and other parameters on cycle performance was studied. The results show that compared with VCRC, the coefficient of performance(COP) and the volumetric refrigeration capacity of ECRC increases by 10.4% and 13.6% in the proposed operating conditions, respectively. There is an optimal intermediate temperature and COP of ECRC reaches the maximum of 5.50 when the intermediate temperature is 20 ℃. In the proposed operating conditions, the entrainment ratio and pressure lift ratio can reach the maximum value of 1.09 and 1.87, respectively. Evaporation temperature, condensation temperature and intermediate temperature have a significant impact on the performance of the ejector. Reducing evaporation temperature and intermediate temperature or increasing condensation temperature can increase pressure lift ratio and reduce entrainment ratio of ejector.

Key words: hybrid refrigeration cycle; ejector; cycle performance; solar energy

随着社会发展,空调制冷系统在生产生活中的能耗问题越来越受关注。随着环保节能需求的日益增长,进一步开发可提高空调制冷系统效率、降低系统能耗的技术具有重要意义[1-2]。其中,能够利用不同制冷方式的混合制冷循环系统的研发与应用得到了广泛关注。尤其是可利用太阳能、汽车废热和工业废热等低品位热能的热驱制冷技术也成为近几十年来的热点研究领域之一[3-4]。喷射式制冷循环可充分利用低品位热能实现制冷,将常规蒸气压缩制冷循环与喷射式制冷循环相结合的喷射-压缩混合制冷循环在降低制冷空调能耗方面具有很大潜力。众多学者开展了喷射-压缩混合制冷循环的理论和实验研究[5-6]。

LIU等[7]提出了一种组合式压缩-喷射系统的控制模型,分析压缩机与喷射器之间的内在关系,基于热力学原理和集总参数法建立了压缩机与喷射器的混合模型;SANAYE等[8]提出了一种新型组合式喷射制冷循环,并进行了热力学建模,发现与另一种混合式喷射-压缩制冷循环相比,新型组合式喷射制冷循环新循环的性能系数提高18%,火用效率提高25%,耗电量降低31%,单位制冷量的年均成本降低8%;HOU等[9]提出了一种基于并联混合喷射器的冷却循环,在系统中利用带主轴的可调式喷射器满足变负荷的要求,发现带主轴的主喷嘴堵塞率对喷射器的性能有较大影响;XU等[10]首次提出了一种带有节能装置的新型压缩增效型喷射制冷循环,发现循环性能提升的主要原因是压缩机质量流量降低,而降低二次流流量和提升喷射系数对性能提升也有一定影响,但影响很小;黄潇治等[11]在喷射-压缩制冷循环中引入两相喷射器等面积混合模型和压缩机半经验模型,对以R1234ze为工质的喷射/压缩制冷循环进行能量和火用分析,发现喉部面积比对喷射器及循环的性能有重要影响,存在一个最优值;ZHU等[12]研究了一种结合蒸气压缩制冷循环和喷射制冷循环的制冷系统,喷射制冷循环由蒸气压缩制冷循环中冷凝器产生的余热驱动,虽然该制冷系统的压缩机排气温度较高,但采用R22制冷剂的系统性能系数可提高9.1%;WANG等[13]开发了一种基于喷射器的混合空调制冷系统,结合一个蒸气压缩循环和一个喷射器制冷循环,并将汽车的余热作为动力源应用于喷射式制冷循环,发现基于喷射器的混合空调系统的性能系数比常规系统的性能系数高34%,具有较高的节能潜力;吴勇平等[14]研究了一种太阳能喷射/压缩混合制冷循环,在该循环中存在一个最佳的喷射子系统蒸发温度,可以使混合制冷循环性能系数达到最大。

在以上研究基础上,为了进一步提高常规空调蒸气压缩制冷循环系统的性能系数,本文作者引入一个过冷器将太阳能驱动的喷射制冷循环与蒸气压缩制冷循环相结合,在新循环中利用太阳能驱动的喷射制冷循环产生的制冷量对蒸气压缩制冷循环中节流前的制冷剂进行过冷,从而提高混合制冷循环的制冷量和性能系数。

1 循环介绍

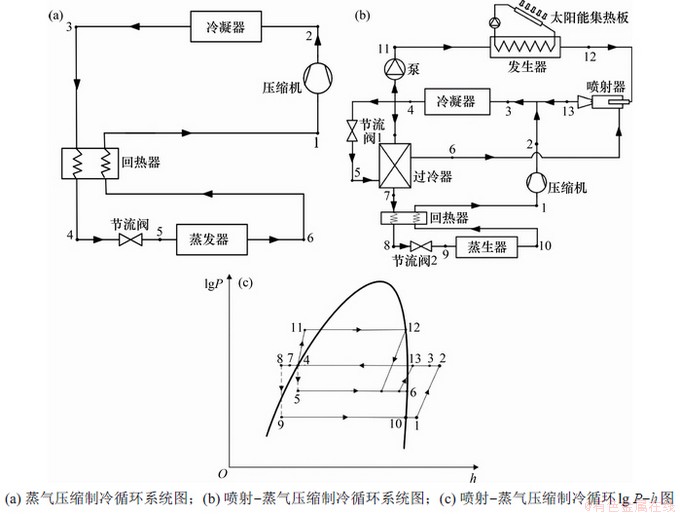

图1所示为常规蒸气压缩制冷循环(VCRC)和新型混合喷射-蒸气压缩制冷循环(ECRC)的流程图以及喷射-蒸气压缩制冷循环的压焓图。由图1(a)可见:常规蒸气压缩制冷循环主要由压缩机、冷凝器、回热器、节流阀和蒸发器组成。在蒸气压缩制冷循环的基础上,提出了1种新型混合喷射-蒸气压缩制冷循环,它还包括1个泵、1个发生器、1个喷射器和1个过冷器,如图1(b)所示。在这个新型循环中,利用过冷器将喷射循环和蒸气压缩循环结合起来,并且利用喷射制冷循环产生的制冷量对冷凝器产生的饱和液体制冷剂进行过冷。与此同时喷射-蒸气压缩制冷循环可利用平板式太阳能热水集热器产生的90 ℃以上的热水作为热源,驱动发生器工作,提升发生器内制冷剂温度,驱动喷射器完成喷射制冷循环,增大蒸气压缩制冷循环的过冷度,从而提高系统的制冷量和性能系数。

图1 循环系统图及lg P-h图

Fig. 1 Schematic diagram of cycle and lg P-h diagram

喷射-蒸气压缩制冷循环的工作原理如图1(c)所示,由图1(c)可见:压缩机排出的过热制冷剂气体(点2)与喷射器出口制冷剂气体(点13)混合(点3)被冷凝器冷凝为饱和液体后(点4)分为3路:

1) 第1路制冷剂液体在节流阀1中经过节流成为两相制冷剂(点5),在过冷器中吸热蒸发后(点6)成为喷射器的二次流体;

2) 第2路制冷剂液体进入过冷器,被上述节流过的制冷剂过冷后(点7)进入回热器进一步过冷(点8),然后经过节流阀2等焓节流后(点9)进入蒸发器吸热蒸发产生制冷效果(点10),然后经过回热器(点1)进入压缩机;

3) 第3路制冷剂液体被泵增压输送到发生器(点11),在发生器中吸收太阳能集热器中的太阳能,吸热蒸发为高压气体后(点12)作为一次流体进入喷射器,引射来自过冷器的制冷剂气体,二者混合后经喷射器出口排出(点13),再与压缩机排气的制冷剂(点2)混合进入冷凝器,完成整个循环。

需要注意的是,在喷射器中,一次流体通过喷嘴后变为高速低压流体,在压差的作用下引射二次流体,在混合室中充分混合后进入扩压段减速并恢复压力,从而实现了喷射器对二次流体的压力提升[15-16]。

2 热力学模型

本文采用热力学分析方法从理论上分析喷射-压缩混合制冷循环的性能。为了简化理论模型和便于分析,进行以下假设:

1) 制冷剂在循环各状态点均为稳态且为稳定流动过程;

2) 压缩机内的压缩过程不可逆,具有可变的等熵效率;

3) 节流装置的节流过程为等焓过程;

4) 制冷剂在发生器、蒸发器和冷凝器出口为饱和状态;

5) 忽略循环过程中的制冷剂压降和漏热;

6) 喷射器内的流动损失用喷嘴、混合段和扩压段的效率表示,且这些参数为常数;

7) 喷射器中的混合过程为等压过程,忽略喷射器入口和出口的流体速度。

基于以上假设,建立喷射-蒸气压缩制冷循环的热力学模型。对于喷射器来说,喷射系数μ和升压比rpj为最重要的2个性能参数,其定义为:

(1)

(1)

(2)

(2)

式中:msf和mpf分别为二次流和一次流的质量流量,kg/s;Pb和Psf分别为喷射器出口制冷剂压力和二次流入口制冷剂压力,kPa。

在假设喷射器入口和出口的速度可以忽略的情况下,喷射器的喷射系数也可以定义为[17-19]

(3)

(3)

式中:h12,n1为一次流进口比焓,J/g;h12,n2,is为等熵膨胀条件下喷嘴出口一次流体的理想比焓,J/g;h13,d,is为理想状态下等熵压缩时扩压段出口混合流体的比焓,J/g;h13,m2为混合流体在混合段出口的比焓,J/g;ηn,ηm和ηd分别为喷射器的喷嘴效率、混合效率和扩压效率,本文按照文献[20]选取数据。

对于压缩机,其消耗功率Wc可以表示为

(4)

(4)

式中: 为压缩机吸气口的质量流量,kg/s;h2,is为在等熵压缩时压缩机出口制冷剂的比焓,J/g;

为压缩机吸气口的质量流量,kg/s;h2,is为在等熵压缩时压缩机出口制冷剂的比焓,J/g; 为压缩机的等熵效率,可由下式得到[21]

为压缩机的等熵效率,可由下式得到[21]

(5)

(5)

式中: 为压缩机压比;

为压缩机压比; 和

和 分别为压缩机吸气压力和排气压力。

分别为压缩机吸气压力和排气压力。

冷凝器热负荷Qc为

(6)

(6)

发生器负荷Qg为

(7)

(7)

蒸发器制冷量Qe为

(8)

(8)

单位容积制冷量qev为

(9)

(9)

式中: 为压缩机吸气口的制冷剂比体积,m3/kg。

为压缩机吸气口的制冷剂比体积,m3/kg。

系统的综合制冷性能系数 可以表示为

可以表示为

(10)

(10)

过冷器内的热平衡方程式为

(11)

(11)

喷射器进出口制冷剂的质量守恒方程为

(12)

(12)

冷凝器出口制冷剂的质量守恒关系式为

(13)

(13)

喷射器出口和压缩机排气混合段的质量守恒关系式为

(14)

(14)

式中:mi为各状态点制冷剂的质量流量,kg/s;hi为各状态点制冷剂的比焓,J/g。

基于上述模型方程,从REFPROP软件的数据库中获取制冷剂物性参数,利用FORTRAN语言编写程序计算蒸气压缩制冷循环和喷射-蒸气压缩制冷循环的循环性能。在理论计算过程中,选择R290制冷剂为循环工质,针对喷射-蒸气压缩制冷循环和蒸气压缩制冷循环,分别研究了蒸发温度te,冷凝温度tc,回热器过热度 (1点过热度)tsh以及中间温度(5点)tm对循环性能以及喷射器性能的影响规律。设定过冷器最小换热温差为5 ℃。选用能够提供90 ℃以上热水的平板式太阳能热水集热器通过板式换热器为发生器提供热能,因此可设定发生器出口制冷剂温度(12点)为80 ℃,选取喷射器各部件的效率ηn,ηm和ηd分别为0.85,0.90和0.80,假设压缩机进口制冷剂的质量流量为1.0 g/s。

3 结果与讨论

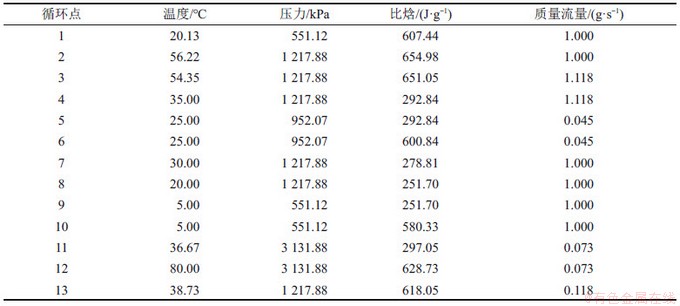

3.1 喷射-蒸气压缩制冷循环性能计算

在特定工况下计算喷射-蒸气压缩制冷循环性能,在循环中设定蒸发温度5 ℃,冷凝温度35 ℃,8点过冷度15 ℃,中间温度25 ℃,过冷器最小换热温差5 ℃,计算得出在此循环条件下喷射-蒸气压缩制冷循环中所有点的状态如表1所示。由表1可见:在ECRC中,循环最高压力为3 131.88 kPa,喷射器出口温度为38.73 ℃,由REFPROP软件可得此时制冷剂处于过热状态;压缩机压比为2.21,喷射器喷射系数和升压比分别为0.62和1.28;冷凝器出口的制冷剂在3个支路的流量分别为0.045,1.000和0.073 g/s,说明在喷射-蒸气压缩制冷循环中大部分制冷剂流经蒸发器产生制冷作用,制冷剂分流对总制冷量影响不大。

表1 喷射-蒸气压缩制冷循环各循环点性能

Table 1 Performance of each point of ECRC

3.2 蒸发温度对性能影响

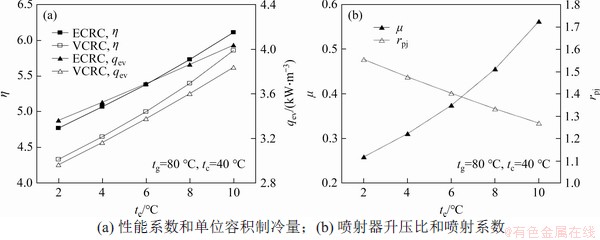

图2(a)所示为蒸发温度te变化时,蒸气压缩制冷循环与喷射-蒸气压缩制冷循环的性能系数和单位容积制冷量的对比关系。由图2(a)可见:在冷凝温度和中间温度不变的情况下,当蒸发温度由2 ℃增大至10 ℃时,蒸气压缩制冷循环与喷射-蒸气压缩制冷循环的性能系数均增大,但是喷射-蒸气压缩制冷循环的性能系数始终大于蒸气压缩制冷循环的性能系数;在所述的蒸发温度范围内,蒸气压缩制冷循环的性能系数为4.33~5.86,喷射-蒸气压缩制冷循环的性能系数为4.77~6.11,比蒸气压缩制冷循环高的性能系数4.3%~10.2%;当蒸发温度升高时,喷射-蒸气压缩制冷循环和蒸气压缩制冷循环的单位容积制冷量分别提升20.0%和29.6%,在所述的蒸发温度范围内,喷射-蒸气压缩制冷循环的单位容积制冷量比蒸气压缩制冷循环高5.2%~13.6%。这是因为引入喷射制冷循环对蒸气压缩制冷循环提供了额外的过冷度,导致喷射-蒸气压缩制冷循环的蒸发器入口干度降低,制冷能力增强,单位容积制冷量和系统性能系数均得到了提升。

图2(b)所示为蒸发温度变化时,喷射-蒸气压缩制冷循环的喷射器喷射系数和升压比的变化曲线。由图2(b)可见:当蒸发温度升高时,喷射系数从0.26升高至0.56,喷射器升压比从1.55降低至1.27。这是因为当蒸发温度升高时,蒸发器入口温度和过冷器出口制冷剂温度也会升高,导致喷射器二次流压力升高,在恒定发生压力(一次流压力)下,一次流和二次流之间的压差减小,从而导致喷射器的升压比降低,喷射系数升高。

图2 蒸发温度te对循环及喷射器性能的影响

Fig. 2 Influence of evaporation temperature te on performance of cycles and ejector

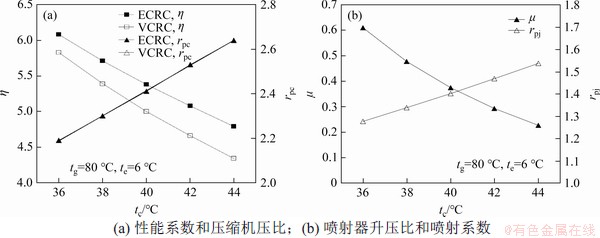

3.3 冷凝温度对性能影响

图3(a)所示为冷凝温度tc变化时,蒸气压缩制冷循环与喷射-蒸气压缩制冷循环的性能系数和压缩机压比的曲线关系。由图3(a)可见:随着冷凝温度升高,喷射-蒸气压缩制冷循环和蒸气压缩制冷循环的性能系数均降低,喷射-蒸气压缩制冷循环的性能系数从6.08下降至4.79,蒸气压缩制冷循环的性能系数从5.83下降至4.34,但是在相同的冷凝温度下,喷射-蒸气压缩制冷循环的性能系数始终大于蒸气压缩制冷循环,且比后者提高了4.3%到10.4%。随着冷凝温度升高,喷射-蒸气压缩制冷循环和蒸气压缩制冷循环的压缩机压比都增大,且2种循环的压比基本保持一致,均从2.19增大到2.64,增大了20.5%。这是因为冷凝压力随着冷凝温度升高而增大,在保持蒸发压力不变的情况下,压缩机的压比增大,进而导致压缩机输入功率增大,因此在制冷量不变的情况下性能系数降低。

图3 冷凝温度tc对循环及喷射器性能的影响

Fig. 3 Influence of condensation temperature tc on performance of cycles and ejector

图3(b)所示为不同冷凝温度下喷射-蒸气压缩制冷循环中喷射器的喷射系数和升压比变化曲线图。由图3(b)可见:当冷凝温度从36 ℃升高至44 ℃时,喷射器的喷射系数从0.61减小至0.23,升压比从1.28增大至1.54。这是由于升高冷凝温度会导致冷凝压力和喷射器背压升高,在一次流压力和二次流压力均不变的情况下,喷射器引射能力减弱,导致喷射器的喷射系数减小,升压比增大。

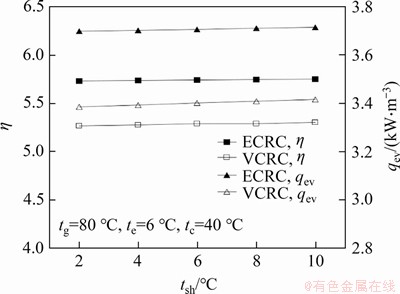

3.4 回热器过热度对性能影响

图4所示为回热器过热度tsh变化时,蒸气压缩制冷循环与喷射-蒸气压缩制冷循环的性能系数和单位容积制冷量的变化情况。由图4可见:随着回热器过热度升高,喷射-蒸气压缩制冷循环和蒸气压缩制冷循环的性能系数均略微增大,因此回热器过热度对喷射-蒸气压缩制冷循环和蒸气压缩制冷循环的性能系数影响很小,但是由于喷射-蒸气压缩制冷循环中引入了喷射器可以降低压缩机和整个系统的耗功,因此其性能系数比蒸气压缩制冷循环高7.1%~7.4%;在给定的回热器过热度范围内,喷射-蒸气压缩制冷循环和蒸气压缩制冷循环的单位容积制冷量均略有增大,这是因为随着回热器过热度增大,回热器中换热量增大,导致节流后蒸发器入口处制冷剂干度降低,液相制冷剂组分增多,因此单位容积制冷量增大;同样由于喷射器的过冷作用,喷射-蒸气压缩制冷循环的单位容积制冷量比蒸气压缩制冷循环增大8.8%~9.2%。

图4 回热器过热度tsh对性能系数和单位容积制冷量qev的影响

Fig. 4 Influence of superheat of IHX tsh on coefficient of performance and qev

3.5 中间温度对性能影响

图5(a)所示为喷射-蒸气压缩制冷循环在不同中间温度tm下性能系数和单位容积制冷量的变化情况。从图5(a)可见:随着中间温度升高,喷射-蒸气压缩制冷循环的性能系数先升高后降低;当中间温度为20 ℃时,喷射-蒸气压缩制冷循环的性能系数达到最大值5.50。当中间温度大于20 ℃时,性能系数随着中间温度升高而急剧减小。喷射-蒸气压缩制冷循环的单位容积制冷量随着中间温度升高而减小,中间温度从15 ℃升高至35 ℃时,单位容积制冷量减小16.8%。这是因为中间温度升高时,进入蒸发器的制冷剂在过冷器中放出的热量较少,过冷度较小,因此其制冷效果较差。

图5(b)所示为不同中间温度下喷射-蒸气压缩制冷循环中喷射器的喷射系数和升压比的变化曲线。由图5(b)可见:随着中间温度升高,喷射器的喷射系数由0.13快速升高至1.09,升压比由1.87下降至1.12。这是因为二次流的温度和压力都随着中间温度升高而增大,而一次流的压力和温度保持不变。因此,一次流和二次流之间的压差减小,导致升压比减小,喷射系数增大。

图5 中间温度tm对喷射-蒸气压缩制冷循环及喷射器性能的影响

Fig. 5 Influence of intermediate temperature tm on performance of ECRC and ejector

4 结论

1) 提出了一种可应用于空调系统的新型太阳能辅助混合喷射-蒸气压缩制冷循环。该循环利用过冷器将喷射制冷循环与蒸气压缩制冷循环相结合,并利用喷射器对蒸气压缩制冷循环提供了额外的过冷度。

2) 喷射-蒸气压缩制冷循环相比蒸气压缩制冷循环在循环性能上有明显改善,尤其是蒸发温度、冷凝温度、回热器过热度和中间温度等工况参数对循环系统与喷射器性能都有着非常重要的影响。当蒸发温度从2 ℃升高至10 ℃时,喷射-蒸气压缩制冷循环的性能系数和单位容积制冷量分别比蒸气压缩制冷循环提高了4.3%~10.2%和5.2%~13.6%;当冷凝温度从36 °C升高至44 °C时,喷射-蒸气压缩制冷循环的性能系数比蒸气压缩制冷循环提高了4.3%~10.4%。

3) 喷射-蒸气压缩制冷循环的性能在本文给出的所有设定工况条件下均优于蒸气压缩制冷循环,且在蒸发温度较低时喷射-蒸气压缩制冷循环所能提供的性能改善程度更高。除此之外,在喷射-蒸气压缩制冷循环中存在最佳中间温度20 ℃,导致喷射-蒸气压缩制冷循环的性能系数存在最大值5.50。

参考文献:

[1] YAN Jia, CAI Wenjian, ZHAO Lei, et al. Performance evaluation of a combined ejector-vapor compression cycle[J]. Renewable Energy, 2013, 55: 331-337.

[2] CHEN Yi, HAN Wei, JIN Hongguang. Analysis of an absorption/absorption-compression refrigeration system for heat sources with large temperature change[J]. Energy Conversion and Management, 2016, 113: 153-164.

[3] CHEN Jianyong, JARALL S, HAVTUN H, et al. A review on versatile ejector applications in refrigeration systems[J]. Renewable and Sustainable Energy Reviews, 2015, 49: 67-90.

[4] ABDULATEEF J M, SOPIAN K, ALGHOUL M A, et al. Review on solar-driven ejector refrigeration technologies[J]. Renewable and Sustainable Energy Reviews, 2009, 13(6/7): 1338-1349.

[5] 胡开永, 张自强, 张海礁, 等. 喷射过冷制冷系统热力学性能分析[J]. 低温与超导, 2020, 48(10): 68-72.

HU Kaiyong, ZHANG Ziqiang, ZHANG Haijiao, et al. Thermodynamic performance analysis of subcooled refrigeration system with ejector[J]. Cryogenics & Superconductivity, 2020, 48(10): 68-72.

[6] 耿利红, 马新灵, 魏新利, 等. 喷射器几何结构对压缩/喷射制冷循环性能的影响研究[J]. 高校化学工程学报, 2015, 29(5): 1073-1081.

GENG Lihong, MA Xinling, WEI Xinli, et al. Effects of Ejector Geometry on Performance of Compression/Ejection Refrigeration Cycle[J]. Journal of Chemical Engineering of Chinese Universities, 2015, 29(5): 1073-1081.

[7] LIU Jiapeng, WANG Lei, JIA Lei, et al. A control oriental model for combined compression-ejector refrigeration system[J]. Energy Conversion and Management, 2017, 138: 538-546.

[8] SANAYE S, EMADI M, REFAHI A. Thermal and economic modeling and optimization of a novel combined ejector refrigeration cycle[J].International Journal of Refrigeration, 2019, 98: 480-493.

[9] HOU Wenxiu, WANG Lei, YAN Jia, et al. Simulation on the performance of ejector in a parallel hybrid ejector-based refrigerator-freezer cooling cycle[J]. Energy Conversion and Management, 2017, 143: 440-447.

[10] XU Yingjie, JIANG Ning, HAN Xiaohong, et al. Performance evaluation and energy-saving potential comparison of a heat-powered novel compression-enhanced ejector refrigeration cycle with an economizer[J]. Applied Thermal Engineering, 2018, 130: 1568-1579.

[11] 黄潇治, 李风雷, 李蓉蓉. 喷射/压缩制冷循环的能量与分析[J]. 低温与超导, 2020, 48(2): 63-69.

HUANG Xiaozhi, LI Fenglei, LI Rongrong. Energy and exergy analyses of ejector/compression refrigeration cycle[J]. Cryogenics & Superconductivity, 2020, 48(2): 63-69.

[12] ZHU Yinhai, JIANG Peixue. Hybrid vapor compression refrigeration system with an integrated ejector cooling cycle[J]. International Journal of Refrigeration, 2012, 35(1): 68-78.

[13] WANG Hao, CAI Wenjian, WANG Youyi, et al. Experimental study of the behavior of a hybrid ejector-based air-conditioning system with R134a[J]. Energy Conversion and Management, 2016, 112: 31-40.

[14] 吴勇平, 郝新月, 陈光明, 等. 太阳能喷射/压缩复合制冷循环性能研究[J]. 热科学与技术, 2020, 19(5): 503-510.

WU Yongping, HAO Xinyue, CHEN Guangming, et al. Study on the performance of combined compression refrigeration and solar-driven ejector cooling system[J]. Journal of Thermal Science and Technology, 2020, 19(5): 503-510.

[15] RUSLY E, LU Aye, CHARTERS W W S, et al. CFD analysis of ejector in a combined ejector cooling system[J]. International Journal of Refrigeration, 2005, 28(7): 1092-1101.

[16] 李金梦, 郑宏亮, 刘霞, 等. 基于计算流体力学模拟的蒸汽喷射器结构优化[J]. 流体机械, 2016, 44(7): 42-46.

LI Jinmeng, ZHENG Hongliang, LIU Xia, et al. Optimal design of steam ejector by computational fluid dynamics simulation[J]. Fluid Machinery, 2016, 44(7): 42-46.

[17] SUMERU K, NASUTION H, ANI F N. A review on two-phase ejector as an expansion device in vapor compression refrigeration cycle[J]. Renewable and Sustainable Energy Reviews, 2012, 16(7): 4927-4937.

[18] CHEN Jiaheng, YU Jianlin. Theoretical analysis on a new direct expansion solar assisted ejector-compression heat pump cycle for water heater[J]. Solar Energy, 2017, 142: 299-307.

[19] 陈华, 鱼剑琳, 任云锋, 等. 一种新型喷射制冷循环的理论分析[J]. 西安交通大学学报, 2005, 39(11): 55-58, 80.

CHEN Hua, YU Jianlin, REN Yunfeng, et al. Theoretical analysis on new ejector refrigeration cycle[J]. Journal of Xi'an Jiaotong University, 2005, 39(11): 55-58, 80.

[20] MCGOVERN R K, PRAKASH N G, LIENHARD J H V. Analysis of reversible ejectors and definition of an ejector efficiency[J]. International Journal of Thermal Sciences, 2012, 54: 153-166.

[21] SARKAR J. Geometric parameter optimization of ejector-expansion refrigeration cycle with natural refrigerants[J]. International Journal of Energy Research, 2010, 34(1): 84-94.

(编辑 秦明阳)

收稿日期: 2001 -01 -31; 修回日期: 2020 -03 -20

基金项目(Foundation item):国家自然科学基金资助项目(51776147)(Project(51776147) supported by the National Natural Science Foundation of China)

通信作者:刘晔,博士研究生,工程师,从事制冷与低温过程节能新技术研究;E-mail: liuye52t@xjtu.edu.cn

DOI: 10.11817/j.issn.1672-7207.2021.06.013

引用格式:刘肖, 刘晔, 鱼剑琳. 太阳能辅助喷射-蒸气压缩混合制冷循环的性能分析[J]. 中南大学学报(自然科学版), 2021, 52(6): 1837-1845.

Citation:LIU Xiao, LIU Ye, YU Jianlin. Performance analysis of a novel solar-assisted hybrid ejector-vapor compression refrigeration cycle[J]. Journal of Central South University(Science and Technology), 2021, 52(6): 1837-1845.