DOI: 10.11817/j.issn.1672-7207.2019.09.029

机车多边形磨耗车轮镟修异常原因分析及改进措施

任德祥1,陶功权1,刘欢1,梁红琴2,陈国胜3,温泽峰1

(1. 西南交通大学 牵引动力国家重点实验室,四川 成都,610031;

2. 西南交通大学 机械工程学院,四川 成都,610031;

3. 大功率交流传动电力机车系统集成国家重点实验室,湖南 株洲,412000)

摘要:针对某型号不落轮镟床不能有效消除机车车轮多边形磨耗的问题,建立车轮镟修的几何关系模型,分析采用驱动轮定位镟床不能有效消除车轮多边形的原因。基于SolidWorks Motion模块建立该镟床镟修的仿真模型,仿真不同状态多边形车轮的镟修效果,并研究相应的改进措施。研究结果表明:当车轮与镟床驱动轮接触点之间的弧长约为车轮多边形波长的整数倍时,采用驱动轮定位镟修将产生极强的仿形效果,这是不能有效消除多边形磨耗的根本原因。采用多次进刀镟修无明显改善效果,通过改变驱动轮间距可有效改善车轮多边形的镟修质量。建议将传统不落轮镟床优化设计为驱动轮间距可调节的改进型镟床,或采用轴箱定位镟修。

关键词:机车车轮;车轮多边形磨耗;不落轮镟修

中图分类号:U279 文献标志码:A 文章编号:1672-7207(2019)09-2317-10

Analysis of abnormal turning repair for locomotive wheels with polygonal wear and improvement measures

REN Dexiang1, TAO Gongquan1, LIU Huan1, LIANG Hongqin2, CHEN Guosheng3, WEN Zefeng1

(1. State Key Laboratory of Traction Power, Southwest Jiaotong University, Chengdu 610031, China;

2. School of Mechanical Engineering, Southwest Jiaotong University, Chengdu 610031, China;

3. The State Key Laboratory of Heavy Duty AC Drive Electric Locomotive Systems Integration, Zhuzhou 412000, China)

Abstract: The on-site investigation of a certain type of underfloor wheel lathe indicates that the lathe cannot effectively eliminate the locomotive wheel polygonal wear. Aiming at this issue, the geometry model of wheel turning was established to analyze the reason why the wheel polygon cannot be effectively eliminated. The turning effects of wheels with different polygon states were simulated through a model established by SolidWorks Motion module, and the corresponding improvement measures were studied. The results show that when the arc length between contact points of wheel and driving wheels is about an integer multiple of the wheel polygon wavelength, the driving wheel positioning locomotive wheelset of the lathe will produce a strong imitation effect with wheels turning, which is the reason why the wheel polygon cannot be eliminated effectively. There is no obvious improvement effect with multiple feedings. The turning quality of wheel polygon can be effectively improved by changing the driving wheel distance to a proper one. It is recommended that the traditional underfloor wheel lathe be optimized with adjustable driving wheel distance, or an axle box positioning way be adopted.

Key words: locomotive wheels; wheel polygonal wear; underfloor wheel turning

车轮多边形磨耗在铁路系统中普遍存在。据调查,国内外高速列车、地铁列车以及机车车轮上均有多边形磨耗现象发生[1-6]。车轮多边形会导致周期性的轮轨冲击,不仅显著增加机车车辆的噪声水平,还会导致异常振动和一些部件的损坏和故障,严重降低乘坐舒适性,甚至威胁行车安全[7-8]。目前,处理车轮多边形磨耗最有效和最直接的方式是车轮镟修。不同于机加工镟床采用两端中心孔顶尖安装的定位方式,不落轮镟床在轮对两侧各采用2个驱动轮作为定位元件与车轮踏面相接触从而起到类似于V形定位的作用。通过镟床驱动轮提供旋转动力使轮对旋转。轴向定位导轮作用于轮对内侧面,可保证轮对在轴向位置上的固定。刀具位于两驱动轮中心的中点位置,对车轮型面进行镟修。不落轮镟修的工作流程一般为:先对车轮进行测量,再根据测量结果合理地选择车轮型面进行镟修。镟修量根据车轮的实际外形制定,通常材料去除量小于1 mm,只镟修1刀。若镟修后测量检查出车轮某指标(比如轮缘厚度、轮缘高度和轮径差等)未满足要求,再考虑进行第2刀镟修。镟修速度根据现场操作经验确定为定值,在镟修过程中不变。不落轮镟修的优点是可以在列车不解编及转向架不拆解的状态下直接对磨损或擦伤的轮对进行镟修加工,工作量相对较少,效率较高。然而,不落轮镟修工艺最初的主要目的是为了恢复车轮型面,对于车轮多边形磨损的消除效果考虑较少。NIELSEN等[9]在研究车轮不圆和列车振动问题时指出,部分镟后车轮可能仍具有较高水平的初始不圆,会导致列车下一运行阶段内车轮非圆化的快速发展;并表示可考虑改变镟修时车轮的定位方式以降低车轮初始不圆[4],以及制定和完善基于车轮不圆和轮轨冲击载荷的车轮镟修标准[10]。JIN等[11]在研究地铁车辆车轮多边形机理时发现镟轮后多边形磨耗发展速率会变快,同时指出镟后车轮四边形是由镟修过程中轮对和镟床之间的共振造成的。文献[12-14]表明,不落轮镟修所采用的踏面定位方式会在镟轮过程中产生不可避免的仿形效果,使得镟修质量与被镟修车轮的踏面状态有很大关系。对于长时间运行已经严重磨耗的车轮踏面,其镟修质量更难得到保证[12]。韩光旭等[15]认为现有车轮镟修加工手段无法完全消除高速列车车轮已出现的高阶非圆化,导致镟后车轮继承部分或全部镟前的非圆化特性,并针对幅值较大的高阶非圆化车轮提出适当加大镟修深度的建议。苏建等[16]通过研究某动车组车轮非圆化及镟修情况指出,镟后车轮四边形的主要原因是镟床驱动轮偏心,且无法通过多次进刀得到缓解(驱动轮偏心势必造成轮对相对于镟床的垂向周期性振动);驱动轮偏心量与进刀次数对动车组20阶多边形车轮的镟修质量有较大影响。叶小明[17]对镟修造成地铁车轮多边形化的现场问题进行调查,认为切削过程中铁屑的混入造成车轮旋转时产生跳动,导致车轮多边形的形成。惠鹏举等[18]通过试验对镟后动车组车轮踏面的水波纹痕迹进行研究,发现镟床采用110%及以上驱动轮转速加工时产生的46 Hz左右的低频振动是导致113阶高阶多边形(水波纹痕迹)的主要原因;多次进刀时,低频振动和踏面已有波纹产生的同频振动叠加,会造成更严重的水波纹痕迹,进而提出控制驱动轮转速和加强设备运行状态监控等控制措施。为了减小车轮踏面损失、优化轮轨接触状态以及延长镟修周期内轮对使用寿命,目前关于不落轮镟修的研究多是基于踏面横向磨耗的镟修策略研究[19-23]。关于镟修过程中出现的车轮多边形问题主要聚焦于现象和原因描述,其解决方案主要依赖现场经验,对镟床的仿形效果及多边形磨耗车轮镟修质量缺乏深入的理论分析。本文作者针对某不落轮镟床不能有效消除机车车轮多边形这一问题,采用理论分析和数值仿真探究车轮多边形无法通过镟修得到消除的原因,研究进刀次数和驱动轮间距对车轮多边形镟修质量的影响,进而提出相应的改进措施,旨在为多边形磨耗车轮镟修质量改善及不落轮镟床改进设计提供理论参考。

1 机车多边形磨耗车轮镟修质量

1.1 车轮镟修质量现场调研

某型机车在运行一段时间后,车轮会出现明显的高阶多边形磨耗,其中以18边形磨耗居多[5-6]。对某采用驱动轮定位的不落轮镟床镟修效果进行调研,利用车轮不圆度测量仪获得机车车轮在镟修前后的车轮多边形状态[24]。调研发现,具有18边形磨耗的车轮在镟修后运营里程不到500 00 km时再次发展严重18边形磨耗。

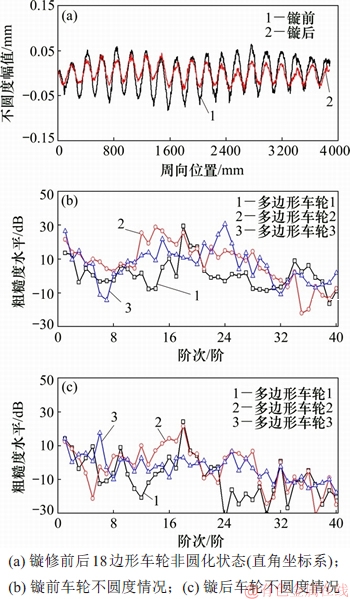

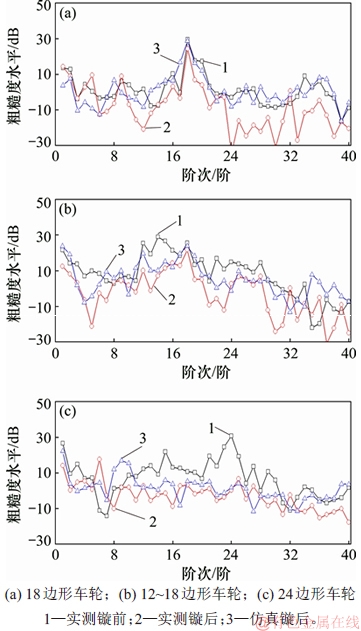

图1(a)所示为镟修前后车轮周向不平顺测试结果。镟修前车轮具有明显的18边形,其波深约为0.1 mm,虽然镟修后多边形幅值变小,但多边形现象并没有得到有效消除。在现场调研中,对镟修前后车轮非圆化状态进行了大量的测试。图1(b)和(c)所示为镟修前后3种典型多边形车轮非圆化状态的空间谱图,其纵坐标数值是根据1 μm粗糙度参考值求得的[16]。镟修前各车轮都具有不同程度的偏心现象,这与车轮的加工精度及质量偏心等因素有关。镟修前表现为18边形的车轮,镟修后车轮多边形特征未发生改变,仍表现为18边形,如多边形车轮1测试结果所示;镟修前表现为12~18边形的车轮,镟修后保留了18边形特征,如多边形车轮2测试结果所示;镟修前表现为24边形的车轮,镟修后其高阶多边形情况得到明显的改善和消除,如多边形车轮3测试结果所示。这表明该不落轮镟床可以消除车轮的24边形,却不能有效消除车轮的18边形;而且对于包含18边形在内几种多边形同时存在的车轮,镟后会滤出18边形。

1.2 多边形车轮镟修的理论分析

图1 镟修前后车轮非圆化状态测试结果

Fig. 1 Wheel out-of-round(OOR) measurement results before and after wheel turning

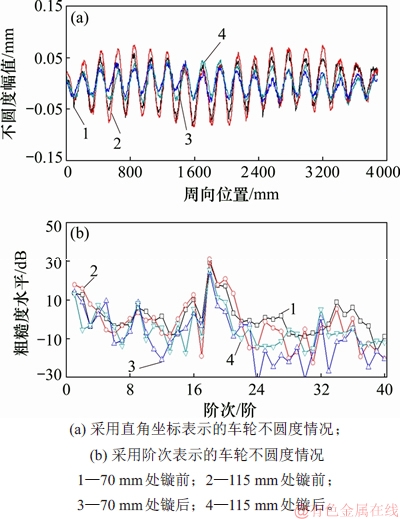

18边形车轮不圆度如图2所示。由图2可见:在车轮与驱动轮接触位置(距轮背115 mm处),车轮表现出与名义滚动圆(距轮背70 mm处)非常相似的18边形特征,两者幅值、相位差别不大。这表明在机车车轮踏面上18边形不圆有较宽的横向分布范围,车轮与驱动轮接触位置处的不圆状态将对车轮镟修质量产生直接影响。

图2 18边形车轮踏面不同位置处非圆化状态

Fig. 2 Wheel OOR with 18-order at different positons of tread

车轮镟修过程中,驱动轮圆心与车刀相对机架固定,驱动轮带动车轮旋转。理论上两驱动轮与车轮在接触点处应保持相切且线速度相同,然而车轮不圆会使2个接触点处车轮半径Rl和Rr始终处于动态变化之中,这必然造成车轮中心相对于车刀的浮动,令车刀切削处车轮半径无法维持恒定,从而使得镟床产生仿形效果,影响镟床的镟修质量。

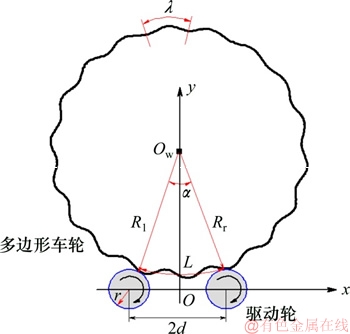

对多边形车轮与镟床驱动轮之间的几何关系进行理论推导,以深入分析不落轮镟床仿形作用的影响。车轮和镟床驱动轮之间的几何关系如图3所示。在车轮镟修过程中假设镟床驱动轮中心固定不动,而车轮的中心能够运动。以两驱动轮中心为坐标原点建立平面直角坐标系,该坐标系下驱动轮的外形可表示为

(1)

(1)

式中:xdw和ydw为驱动轮的圆周坐标;r为驱动轮的半径(r=132.5 mm);d为两驱动轮圆心间距的一半(d=255 mm);θ为驱动轮上某点与过驱动轮中心水平线的夹角, 。

。

具有谐波形式的多边形车轮在图3所示的坐标系中可表示为

(2)

(2)

式中:xw和yw为车轮圆周上某一点的坐标;R为车轮平均半径;A和n分别为车轮多边形的幅值和阶次;xwi和ywi为车轮圆心坐标;φ为车轮上某点与过车轮中心水平线的夹角, 。由于车轮是由驱动轮支承,如果在车轮与驱动轮接触位置存在多边形,那么,在车轮镟修过程中车轮中心将会随之运动。

。由于车轮是由驱动轮支承,如果在车轮与驱动轮接触位置存在多边形,那么,在车轮镟修过程中车轮中心将会随之运动。

根据车轮与2个驱动轮之间的约束关系,即在接触点处车轮与驱动轮相切,并且忽略车轮和驱动轮的弹性变形,可以得到如下方程:

(3)

(3)

式中:Rl和Rr分别为车轮与左右驱动轮接触点处的实际半径。

在车轮镟修过程中,轮对绕其主轴旋转,Rl和Rr随时间变化,其变化规律可表示为

(4)

(4)

式中:ω为车轮逆时针转动的角速度;α为车轮与两驱动轮接触点与车轮圆心连线的夹角,即Rl和Rr之间的夹角(见图3)。

图3 车轮和镟床驱动轮之间的几何关系

Fig. 3 Geometry relationship between wheel and driving wheels

通常车轮多边形的幅值都是毫米级,远小于车轮半径,因此,Rl和Rr之间的夹角α可认为是常数:

(5)

(5)

从式(3)可以得出车轮中心的坐标为

(6)

(6)

从式(6)可以看出,当xwi ≈ 0,即Rl ≈ Rr时,车轮圆心的垂向坐标可表示为

(7)

(7)

此时车轮将在垂向上以车轮多边形相同的形式上下波动(即镟床产生了极强仿形效果)。由于车轮镟修时车刀在给定的横向位置其垂向位置都是固定的,并且两驱动轮间距也是固定的,因此,当车轮多边形波长λ与两驱动轮与车轮接触点之间弧长L满足Nλ ≈ L(N为正整数)时,具有特别波长的车轮多边形将无法通过镟修得到有效消除。

以18边形车轮为例。车轮踏面115 mm处名义直径约为1 245 mm,可得18边形波长为217.2 mm。车轮与驱动轮2个接触点间的弧长为428.7 mm,约为18边形波长的2倍。根据上述推导,车轮将在其动态旋转过程中以18边形形式在垂直方向上下波动。当2个接触点同时达到不圆车轮的波峰时,车轮处于向上抬升的状态,此时车刀将车轮镟出一个新的波峰;当2个接触点同时达到不圆车轮的波谷时,车轮处于下降的状态,此时车刀将车轮镟出一个新的波谷。驱动轮带动车轮旋转1周后,车刀在整个车轮踏面上镟修出了1个新的18边形。这是该镟床不能通过镟修消除车轮18边形的根本原因。

同理,当车轮镟修中若能保证车轮圆心的垂向位置不动,即令Δywi ≈0时,车轮多边形能够得到有效消除。因此,将该镟床镟修定位方式改进为轴箱定位对车轮多边形镟修质量有改善效果(条件允许时改进为车轴中心孔定位[14]其效果会更显著)。此外,进一步分析发现,当(2N-1) λ≈2L时,Δywi能够最大程度地减小。若在车轮镟修之前能够获得车轮多边形占主导的波长,则通过改变两驱动轮之间的间距即可使(2N-1) λ ≈2L。

2 车轮镟修仿真模型及验证

2.1 仿真模型

上述几何关系推导只针对标准谐波形式多边形车轮的镟修效果进行了理论分析,实际车轮多边形并不是理想标准的谐波形式。因此,为进一步探究实际现场中镟床不能消除机车车轮某些阶次多边形和具有镟修滤波作用的原因,提出相应的改善措施,采用SolidWorks Motion对该镟床镟修过程进行仿真,仿真模型如图4所示。车轮与镟床驱动轮尺寸均根据现场实测数据确定。仿真轮对为带有大齿轮的机车轮对,忽略大齿轮的齿数特征,车轮名义滚动圆直径为1 250 mm。驱动轮名义直径为265 mm,与车轮接触处距轮背115 mm,两驱动轮间距为510 mm。

图4 不落轮镟床镟修仿真示意图

Fig. 4 Diagram of underfloor wheel turning simulation

对轮对和驱动轮进行装配,4个驱动轮中心位于同一水平面,且施加铰链约束,使其能够相对于大地旋转。车轮与驱动轮保持相切,确保运动过程中车轮与驱动轮不会相互脱离。添加共面约束使铅垂方向上车轮和驱动轮中心面重合,以取代轴向定位导轮的作用来保证轮对在轴向上固定,同时避免车轮在镟修过程中相对驱动轮出现前后错位。装配完成后进入SolidWorks Motion模块,为仿真环境添加9 806.65 mm/s2竖直向下的引力,为驱动轮添加匀速的旋转马达,并在车轮和驱动轮之间定义实体接触及摩擦。

利用车轮不圆度化数据创建车轮不圆外形,对于SolidWorks Motion来说实质上是一个外形生成问题。传统的方法是将极坐标系下的车轮不圆度数据转换到直角坐标系下进行绘图[16],相当于令“画笔”绕着车轴中心线既转动又平动,绘制一个不圆的车轮外形。该方法操作简单但耗时较多,因此,本文从相对运动的角度考虑,将“画笔”既转动又平动的运动拆分成“画笔”的平动和轮对的转动。在Motion中新建1个由线性马达驱动的从动件(即画笔),并向其输入1组位移数据(即车轮不圆度数据),同时添加1个旋转马达来驱动轮对,在轮对的旋转运动和从动件的直线运动过程中,跟踪记录从动件顶点相对于车轮旋转曲面的周向移动路径,由此获得不圆车轮的外形轮廓。

仿真时,驱动轮带动车轮旋转,并输出竖直方向上车轮中心的坐标跳动量,根据仿真时间将其截取为轮对刚好旋转1周的数据,将该段数据减去仿真初始时车轮中心竖直方向坐标即为车轮中心的相对跳动量。由于仿真模型中各物体均可视为刚性体,且驱动轮中心固定,车刀位于两驱动轮中心的中点位置,故车轮中心点铅垂方向的跳动量可视为车轮在车刀切削处的瞬时跳动量。若车轮向上跳动,则车刀切削量减小,切削处车轮瞬时半径增大,所以,车轮中心跳动量即为镟后车轮的非圆化幅值。将所得车轮非圆化数据表示为关于圆周长度x的函数f(x),并对f(x)进行阶次分析。将第1次镟修后的车轮中心相对跳动量输入线性马达,再次跟踪记录从动件顶点相对于车轮旋转曲面的周向路径,即可绘制出镟后车轮的形状。

2.2 模型验证

采用上述模型及非圆化车轮对该镟床的车轮镟修过程进行仿真。为验证所建模型的准确性,将仿真结果与现场实测结果进行对比。用阶次表示的仿真与实测结果对比如图5所示。可见:对于18边形车轮,镟后其18边形并没有得到消除;对于12~18边形车轮,镟后保留了其18边形特征;对于24边形车轮,镟后高阶多边形基本上得到消除。仿真结果与实测结果在趋势上基本相符,尤其对于需要关注的高阶多边形,吻合度较高,表明该仿真模型是较为可靠的。

仿真与实测结果在数值上并没有完全相同,这是因为模型无法考虑现场镟修过程中所有的因素,车轮镟修的进刀量、切削速度以及切削过程中材料的弹性变形等因素会对镟床镟修结果产生影响,但这些因素并不影响镟修后车轮多边形的变化趋势。

3 数值结果与分析

图5 仿真结果和实测结果对比

Fig. 5 Comparison between simulation results and measurement results

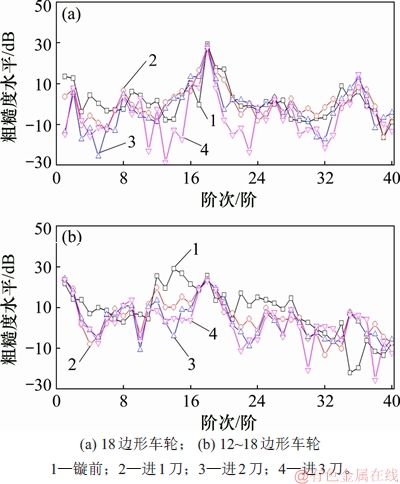

3.1 进刀次数对多边形车轮镟修质量的影响

利用所建立的镟修仿真模型分析进刀次数对多边形车轮镟修质量的影响。图6(a)所示为不同进刀次数对18边形车轮镟修质量的影响。由图6(a)可知,多次进刀可以改善其偏心水平,但对车轮18边形水平的改善效果不佳,在3次进刀后,车轮依然表现为较为突出的18边形。这与1.2节理论分析结果相符合,即2个接触点间的弧长与多边形波长之间的整数倍关系导致镟修仿形效果的增强。

图6(b)所示为不同进刀次数对12~18边形车轮镟修质量的影响。由图6(b)可知,1次进刀后滤出了车轮18边形,其原因是对于12~18边形车轮,在该驱动轮间距下其他阶次的波长并不存在这种整数倍关系,因此,该镟床可以镟掉12~17边形,而唯独滤出18边形。2次与3次进刀对车轮18边形水平的改善效果同样非常有限,在3次进刀后车轮仍表现为较为明显的18边形。

机车运行的既有线路上,小半径曲线比例较高,这导致车轮多边形在整个踏面上有较宽的分布范围。镟修时,驱动轮与车轮踏面距轮背115 mm附近相接触,为产生仿形作用提供前提条件。当驱动轮间距设置不合理时,镟床仿形效果变强,即使增加进刀次数,仍会在上次镟修的基础上仿形出相似的高阶多边形。

图6 不同进刀次数镟修效果对比

Fig. 6 Comparison of turning effects with different numbers of feeding

3.2 驱动轮间距对多边形车轮镟修质量的影响

根据上述几何关系推导已找出采用驱动轮定位镟修时车轮多边形无法消除的原因。从本质上解决该问题需要使轮心垂向位置尽量保持恒定,除了可以通过改善轮对镟修定位的方式来限制轮心在镟修过程中的垂向位移外,还可从驱动轮间距入手,研究驱动轮间距对多边形车轮镟修质量的影响。

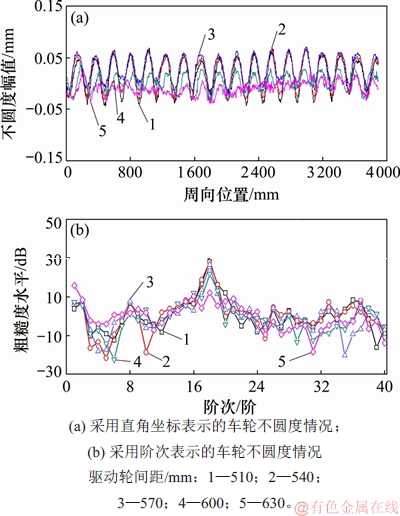

以30 mm为步长,仿真驱动轮间距为510~630 mm时18边形车轮镟修效果,仿真结果如图7所示。间距630 mm时,2个接触点间的弧长为535.6 mm,约为车轮18边形波长的2.5倍。由图7可知:随着驱动轮间距增加,镟后18边形的粗糙度水平逐渐降低,由30 dB降至10 dB左右。

图7 510~630 mm驱动轮间距对多边形车轮镟修效果影响

Fig. 7 Influence of driving wheel distance of 510-630 mm on turning effects of polygonal wheel

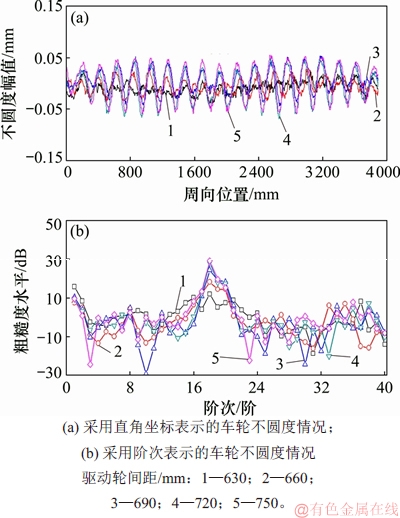

以30 mm为步长,仿真驱动轮间距为630~750 mm时18边形车轮镟修效果,仿真结果如图8所示。当间距为750 mm时,两接触点间的弧长为646.8 mm,约为车轮18边形波长的3倍。由图8可知:随着驱动轮间距的增加镟后18边形粗糙度水平又逐渐上升,最终回升至与间距510 mm时的相当。这是因为2个接触点间的弧长约为多边形波长的3倍时,镟床同样具有较强的仿形效果(根据1.2节理论推导),驱动轮带动车轮旋转1周后车刀仍会仿形出新的18边形。

图8 630~750 mm驱动轮间距对多边形车轮镟修效果影响

Fig. 8 Influence of driving wheel distance of 630-750 mm on turning effects of polygonal wheel

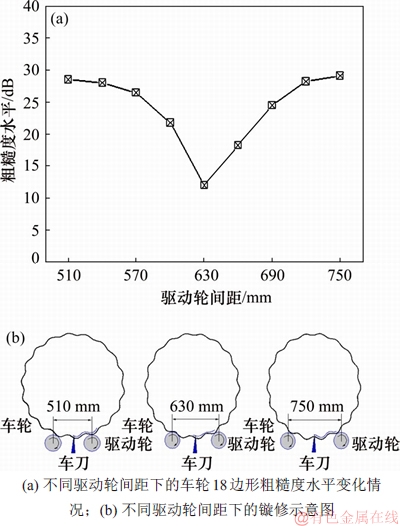

驱动轮间距对18边形车轮镟修质量的影响如图9所示。

由图9(a)可见:镟后车轮18边形粗糙度水平随着驱动轮间距变大呈现先下降后上升的变化趋势,结合图9(b)驱动轮间距从510 mm增至630 mm再增至750 mm的过程进行分析可见:当驱动轮间距为630 mm时镟修效果最佳,18边形粗糙度水平降低幅度可达57.8%。因为在此间距下,2个接触点间的弧长为18边形波长的2.5倍,避免了实际镟修过程中车轮在垂向上发生大幅度起伏。由此可见:在实际镟修时,为了尽量减轻仿形作用的影响,需避免接触点弧长与高阶多边形波长产生整数倍关系。

图9 驱动轮间距对18边形车轮镟修质量的影响

Fig. 9 Effects of driving wheel distance on turning quality for polygonal wheel with 18-order

3.3 针对机车车轮多边形特征的镟修改进措施

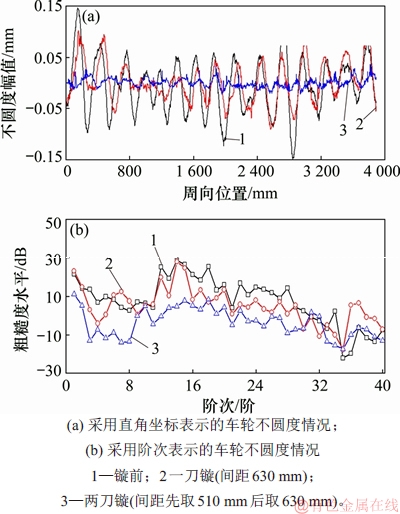

将不落轮镟床的驱动轮间距改进为630 mm可改善机车18边形车轮的镟修质量,但也会影响其他阶次多边形车轮的镟修质量。

经计算,车轮踏面115 mm处14边形车轮波长为279.2 mm,15边形车轮波长为260.6 mm,630 mm驱动轮间距下2个接触点间的弧长约为14边形和15边形车轮波长的2倍,会使镟床在镟修14边形和15边形车轮时产生较强的仿形效果。以12~18边形为例,在630 mm驱动轮间距下进行仿真,仿真结果如图10所示。仿真结果表明:由于强仿形性,镟后车轮仍表现为明显的14边形和15边形,这不利于保证乘坐舒适性和运行安全性。因此,针对包含14边形和15边形的车轮,可以采用变间距两刀镟的方案,第1刀采取510 mm间距以消除14边形和15边形,第2刀采取630 mm间距以消除18边形,经过2刀镟修后车轮的高阶多边形得到了明显的消除。

图10 12~18边形车轮的镟修方案对比

Fig. 10 Comparison of wheel turning strategy for polygonal wheel with 12-18-order

因此,针对所调研机车的车轮多边形特征和不落轮镟床出现的问题,建议对镟床进行改进设计,使得驱动轮间距可根据实际情况进行调整。此外,建议在镟修前将车轮不圆列为测试项,根据不圆状态选取合适的驱动轮间距。

4 结论

1) 当车轮与镟床驱动轮接触点间的弧长约为车轮多边形波长的整数倍时,采用驱动轮定位镟修将产生极强的仿形效果,因此,某些阶次的多边形磨耗无法通过镟修得到有效消除。

2) 当驱动轮间距为510 mm时,多次进刀对机车车轮18边形镟修质量的改善效果非常有限,仍会在上次镟修的基础上仿形出1个相似的高阶多边形。

3) 改变驱动轮间距可有效改善车轮多边形的镟修质量。针对18边形车轮,建议驱动轮间距采取630 mm进行镟修。对包含14边形和15边形的车轮,建议采取变间距两刀镟的方案,第1刀驱动轮间距采取510 mm,第2刀驱动轮间距采取630 mm。

4) 建议对镟床进行改进设计,使得驱动轮间距可根据实际情况进行调整,或采用轴箱定位甚至车轴中心孔定位。同时建议在镟修前将车轮不圆列为测试项。

参考文献:

[1] 金学松, 吴越, 梁树林, 等. 车轮非圆化磨耗问题研究进展[J]. 西南交通大学学报, 2018, 53(1): 1-14.

JIN Xuesong, WU Yue, LIANG Shulin, et al. Mechanisms and countermeasures of out-of-roundness wear on railway vehicle wheels[J]. Journal of Southwest Jiaotong University, 2018, 53(1): 1-14.

[2] JOHANSSON A. Out-of-round railway wheels: assessment of wheel tread irregularities in train traffic[J]. Journal of Sound and Vibration, 2006, 293(3/4/5): 795-806.

[3] TAO Gongquan, WEN Zefeng, LIANG Xiren, et al. An investigation into the mechanism of the out-of-round wheels of metro train and its mitigation measures[J]. Vehicle System Dynamics, 2019, 57(1): 1-16.

[4] NIELSEN J C O, LUNDEN R, JOHANSSON A, et al. Train-track interaction and mechanisms of irregular wear on wheel and rail surfaces[J]. Vehicle System Dynamics, 2003, 40(1/2/3): 3-54.

[5] 柳炜, 颜宁, 蒲全卫, 等. HXD1型机车轮对多边形发展趋势探讨[J]. 电力机车与城轨车辆, 2017, 40(6): 55-59.

LIU Wei, YAN Ning, PU Quanwei, et al. Development trend of wheel set polygon on type HXD1 locomotive[J]. Electric Locomotives & Mass Transit Vehicles, 2017, 40(6): 55-59.

[6] TAO Gongquan, WANG Linfeng, WEN Zefeng, et al. Experimental investigation into the mechanism of the polygonal wear of electric locomotive wheels[J]. Vehicle System Dynamics, 2018, 56(6): 883-899.

[7] TAO Gongquan, WEN Zefeng, GUAN Qinghua, et al. Experimental investigation of the abnormal vibration of the electric locomotive[C]//2016 18th International Wheelset Congress (IWC). New York, USA: IEEE, 2016: 44-49.

[8] BARKE D W, CHIU W K. A review of the effects of out-of-round wheels on track and vehicle components[J]. Proceedings of the Institution of Mechanical Engineers, Part F: Journal of Rail and Rapid Transit, 2005, 219(3): 151-175.

[9] NIELSEN J C O, MIRZA A, CERVELLO S, et al. Train induced ground vibration-optimized rolling stock mitigation measures and their parameters[R]. Gothenburg: Chalmers University of Technology, 2013: 1-81.

[10] NIELSEN J C O, JOHANSSON A. Out-of-round railway wheels: a literature survey[J]. Proceedings of the Institution of Mechanical Engineers, Part F: Journal of Rail and Rapid Transit, 2000, 214(2): 79-91.

[11] JIN Xuesong, WU Lei, FANG Jianying, et al. An investigation into the mechanism of the polygonal wear of metro train wheels and its effect on the dynamic behaviour of a wheel/rail system[J]. Vehicle System Dynamics, 2012, 50(12): 1817-1834.

[12] 李秀艳, 王雪岭, 刘军, 等. 铁路车辆轮对踏面旋修加工的质量差异分析[J]. 制造技术与机床, 2017(1): 162-165.

LI Xiuyan, WANG Xueling, LIU Jun, et al. Quality difference analysis of lathing process of railway vehicle wheel tread[J]. Manufacturing Technology and Machine Tool, 2017(1): 162-165.

[13] 周鸣语, 洪浩. 数控不落轮机床轮对定位装置分析[J]. 电力机车与城轨车辆, 2005, 28(6): 53-55.

ZHOU Mingyu, HONG Hao. Analysis on the wheelset positioning device of CNC underfloor wheel lathe[J]. Electric Locomotives & Mass Transit Vehicles, 2005, 28(6): 53-55.

[14] 周殿买, 徐彬, 孔瑞晨, 等. 高速动车组轮对旋修技术研究[C]//铁路车辆轮轴技术交流会论文集. 大连: 中国铁道学会车辆委员会, 2016: 163-166.

ZHOU Dianmai, XU Bin, KONG Ruichen, et al. Research on wheelset repair technology of high speed EMU[C]// Proceedings of Railway Vehicle Axle Technology Exchange Conference. Dalian, China: Vehicle Committee of China Railway Society, 2016: 163-166.

[15] 韩光旭, 宋春元, 李国栋, 等. 高速列车车轮非圆化与振动噪声关系跟踪试验研究[J]. 城市轨道交通研究, 2017, 20(2): 1-9.

HAN Guangxu, SONG Chunyuan, LI Guodong, et al. Tracing test of the relationship between high-speed train wheel OOR and vibration noise[J]. Urban Mass Transit, 2017, 20(2): 1-9.

[16] 苏建, 李立, 崔大宾. 不落轮旋修工艺对初始车轮多边形的影响研究[J]. 铁道学报, 2017, 39(5): 57-61.

SU Jian, LI Li, CUI Dabin. Study on influence of turning repair operations on wheels with initial polygonal state[J]. Journal of the China Railway Society, 2017, 39(5): 57-61.

[17] 叶小明. 地铁车辆车轮多边形问题分析及处理措施探讨[J]. 现代城市轨道交通, 2018(4): 35-38.

YE Xiaoming. Analysis and measures of metro vehicle wheel polygon problem[J]. Modern Urban Transit, 2018(4): 35-38.

[18] 惠鹏举, 李波. 不落轮镟修车轮踏面异常分析[J]. 机车车辆工艺, 2017(6): 45-46, 48.

HUI Pengju, LI Bo. Wheel tread anomaly analysis of underfloor wheel turning[J]. Locomotive & Rolling Stock Technology, 2017(6): 45-46, 48.

[19] 董孝卿, 王悦明, 王林栋, 等. 高速动车组车轮踏面镟修策略研究[J]. 中国铁道科学, 2013, 34(1): 88-94.

DONG Xiaoqing, WANG Yueming, WANG Lindong, et al. Research on the reprofiling strategy for the wheel tread of high-speed EMU[J]. China Railway Science, 2013, 34(1): 88-94.

[20] 许宏, 员华, 王凌, 等. 基于高斯过程的地铁车辆轮对磨耗建模及其镟修策略优化[J]. 机械工程学报, 2010, 46(24): 88-95.

XU Hong, YUAN Hua, WANG Ling, et al. Modeling of metro wheel wear and optimization of the wheel re-profiling strategy based on Gaussian processes[J]. Journal of Mechanical Engineering, 2010, 46(24): 88-95.

[21] CUI Dabin, LI Li, WANG Hengyu, et al. High-speed EMU wheel re-profiling threshold for complex wear forms from dynamics viewpoint[J]. Wear, 2015, 338/339: 307-315.

[22] WANG Ling, XU Hong, YUAN Hua, et al. Optimizing the re-profiling strategy of metro wheels based on a data-driven wear model[J]. European Journal of Operational Research, 2015, 242(3): 975-986.

[23] 张宝安, 陆正刚, 唐辰. 高速动车组车轮型面多目标优化镟修[J]. 同济大学学报: 自然科学版, 2013 (3): 437-442.

ZHANG Baoan, LU Zhenggang, TANG Chen. Wheel reprofiling of high-speed EMU based on multi-objective optimization strategy[J]. Journal of Tongji University(Natural Science), 2013 (3): 437-442.

[24] TAO Gongquan, WANG Linfeng, WEN Zefeng, et al. Measurement and assessment of out-of-round electric locomotive wheels[J]. Proceedings of the Institution of Mechanical Engineers, Part F: Journal of Rail and Rapid Transit, 2018, 232(1): 275-287.

(编辑 赵俊)

收稿日期: 2018 -12 -03; 修回日期: 2019 -02 -25

基金项目:国家自然科学基金资助项目(51875484);大功率交流传动电力机车系统集成国家重点实验室开放课题资助项目(2017ZJKF01)

Foundation:(Project(51875484) supported by the National Natural Science Foundation of China; Project (2017ZJKF01) supported by the Open Project of the State Key Laboratory of Heavy Duty AC Drive Electric Locomotive Systems Integration)

通信作者:梁红琴,博士,讲师,从事基于仿真的产品设计与制造研究;E-mail:sugargl@163.com