J. Cent. South Univ. Technol. (2008) 15: 895-900

DOI: 10.1007/s11771-008-0163-z

Large-scale direct shear testing of geocell reinforced soil

WANG Yi-min(汪益敏), CHEN Ye-kai(陈页开), LIU Wei(刘 炜)

(School of Civil and Transportation Engineering, South China University of Technology,

Guangzhou 510640, China)

Abstract: The tests on the shear property of geocell reinforced soils were carried out by using large-scale direct shear equipment with shear-box-dimensions of 500 mm×500 mm×400 mm (length×width×height). Three types of specimens, silty gravel soil, geocell reinforced silty gravel soil and geocell reinforced cement stabilizing silty gravel soil were used to investigate the shear stress-displacement behavior, the shear strength and the strengthening mechanism of geocell reinforced soils. The comparisons of large-scale shear test with triaxial compression test for the same type of soil were conducted to evaluate the influences of testing method on the shear strength as well. The test results show that the unreinforced soil and geocell reinforced soil give similar nonlinear features on the behavior of shear stress and displacement. The geocell reinforced cement stabilizing soil has a quasi-elastic characteristic in the case of normal stress coming up to 1.0 GPa. The tests with the reinforcement of geocell result in an increase of 244% in cohesion, and the tests with the geocell and the cement stabilization result in an increase of 10 times in cohesion compared with the unreinforced soil. The friction angle does not change markedly. The geocell reinforcement develops a large amount of cohesion on the shear strength of soils.

Key words: direct shear test; geocell; reinforced soil; shear strength; cohesion

1 Introduction

Geocell reinforced soil has gained a considerable popularity in highway subgrade engineering in the recent past. It has been found to be useful for reinforcement of embankment, steep slopes, retaining walls and abutment backfills because of improving load-bearing capacity, increasing strength and stiffness, reducing settlement, and saving cost and time in construction[1-5].

Since the first use of cellular confinement systems to improve road bases over weak subgrades [6], the stability of geocell reinforced soil has required considerations on the interface shear strength between soil and geocell. A test method for determining the interface shear capacity of geosynthetic reinforced soil was first introduced by ASTM D 5321-92, a standard test method for determining the coefficient of soil and geosynthetic or geosynthetic and geosynthetic friction by the direct shear method, and current one is the revised edition ASTM D 5321-02[7].

The methods of test introduced above are now used to provide the shear parameters of a geosynthetic against soil, or a geosynthetic against another geosynthetic, under a constant rate of deformation. It is applicable for all kinds of geosynthetics including geotextile and geogrid, etc. However, because geocell is generally with single cell dimensions of 250 mm×250 mm×100 mm (length×width×height), the normal shear testing equipment is not large enough to simulate the shearing performance of multiple geocells reinforced soil. Limited investigations have been reported in literature on the shear behavior of geocell reinforced soil. BATHURST and KAPPURAPU[8] conducted a large-scale triaxial compression test for geocell reinforced granular soils. RAJAGOPAL et al[9] reported the behavior of sand confined with single and multiple geocells by a series of load-bearing-capacity tests. In a later study, LATHA et al[10-11] carried out the experimental and theoretical investigations on geocell-supported embankments. MENGEL[12] tested the resilient modulus and plastic deformation of soil confined in a geocell. LIU et al[13] reported large direct shear testings for sand. Up to date, limited studies on the shearing capacities of multiple geocell reinforced soil have been found. Recently, the geocell materials have been applied widely in highway engineering in China[14-16]. But, the studies on experiments and mechanism of geocell reinforced soil are highly lagged behind on its applications. Till now, the standard test method for determining the shear strength of geocell reinforced soil has not been issued yet[17].

This study aimed at developing a new shear apparatus for understanding the interface shear features of geocell reinforced soil. In this work, a set of large-scale direct shear facility was designed and applied. A series of large-scale direct shear tests on silty gravel soil confined with or without multiple geocells were carried out. The comparisons of large-scale shear test with triaxial compression test for the same type of soil were conducted to evaluate the influences of testing method on the shear strength. Meanwhile, the testing results of geocell reinforced cement stabilizing silty gravel soil were studied and analyzed.

2 Experimental

2.1 Test instrumentations

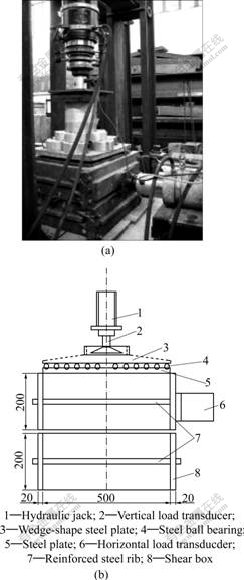

The general test arrangement of large-scale direct shear test is shown in Fig.1. The test system was built in the structure engineering laboratory at South China University of Technology, China. The shear box included two stacked parts. The inner size of each part had dimensions of 500 mm×500 mm×200 mm (length× width×height). Each part could be disassembled easily for installing and unloading soil specimen. During the directly shearing test, the bottom half was fixed on the ground, and the top half was driven by a 294 kN capacity horizontal loading system with force transducers collecting data constantly by computer software.

Fig.1 General arrangement of large-scale direct shear test system: (a) Overview of large-scale direct shear test system; (b) General arrangement of test instrumentations (unit: mm)

The vertical loading system was driven by a 980 kN capacity MTS hydraulic actuator. There were two steel plates placed at the top of the soil specimen to bear the vertical load. Two lines of steel linear bearings were seated between the two steel plates in order to reduce friction of plates caused by the horizontal movement of shear box. The normal load was measured by an electronic load transducer. Two 0.01 mm-sensitivity dial indicators were respectively located on the left side and right side of top-half shear box to measure the horizontal displacement manually.

2.2 Test materials

2.2.1 Soil

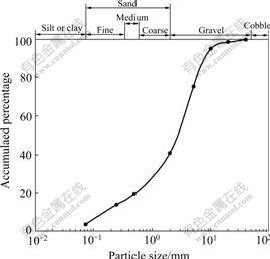

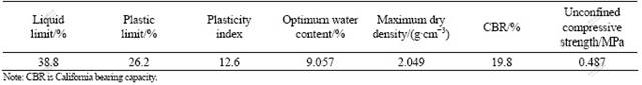

The soil used in the tests was well graded with a maximum particle size of 40 mm, coefficient of curvature of 2.98, coefficient of uniformity of 20.6 and fines mass fraction less than 4%. The particle size distribution is shown in Fig.2. The maximum dry density of the soil was 2.049 g/cm3. The optimum water content was 9.057 %. Soil properties are summarized in Table 1. This soil could be classified as GM according to the Unified Soil Classification System[18].

Fig.2 Particle size distribution of backfill soil

Table 1 Physical and mechanical properties of soil

2.2.2 Geocell

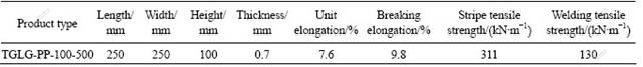

The geocell reinforcement material used in the test was a commercially available industrial product manufactured by Netlon China Limited. It consisted of polypropylene stripes welded together to give an open-cell construction that had a cell area of 625 cm2 and depth of 10 cm. The cellular materials came in panels expanded to cover an area of 4.0 m×12.5 m. The properties of geocell are summarized in Table 2.

Table 2 Physical and mechanical properties of geocell

2.2.3 Cement

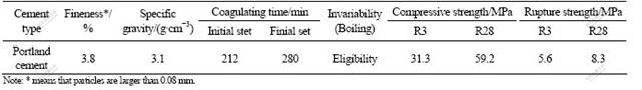

Portland cement has been used as stabilizer to increase the strength of coarse soil for a long time. In this study, the cement stabilized soil was used as backfill materials together with geocell reinforcement in the abutment. Table 3 shows properties of the cement used in the study.

Table 3 Physical and mechanical properties of Portland cement

2.3 Test procedures

2.3.1 Geocell reinforced soil

The test method for geocell reinforced soil in this work was large-scale direct shear test. The procedures of large-scale direct shear test were described as follows.

First, the large-scale direct shear device must be calibrated to measure the internal resistance to shear inherent to the device. Then, the geocell reinforced soil specimens were prepared. The geocell reinforced soil specimens were molded within the shear box with volume of 0.1 m3 (500 mm×500 mm×400 mm, length×width×high). Generally, three or four specimens are required in one direct shear test. After finishing the specimen molding, a confining stress was applied vertically to the specimen, and the upper box was pushed horizontally at a rate of 1 mm/min until the sample failed, or got to a general strain of 5%. Three specimens were tested at varying confining stresses to determine the shear strength parameters including the soil cohesion (c) and the friction angle (φ).

2.3.2 Unreinforced soil

Large-scale direct shear tests and triaxial com- pression tests were carried out to investigate the shear feature of unreinforced soil and the influence of different testing methods.

The procedure of unreinforced soil large-scale direct shear test was similar to that of the geocell reinforced soil large-scale direct shear test except without paving the geocell material.

The triaxial compression tests were carried out through a LoadTrac II triaxial compression test apparatus made by Geocomp Company in US. The sizes of each specimen were 61.8 mm×132.7 mm (diameter×height). Consolidated-Undrained test method was taken with the triaxial apparatus. Three specimens were tested for each type of soil with confining pressures of 50, 200, and 400 kPa, respectively.

2.3.3 Geocell reinforced cement stabilizing soil

The test method for geocell reinforced cement stabilizing soil in this work was large-scale direct shear test. A dosage of 5% cement (by dry soil weight) was added into the well soaked soil and mixed fully with the soil before the soil mixture was molded to the specimen of large-scale direct shear test. Other procedures were the same as those described in section of geocell reinforced soil.

2.3.4 Unreinforced cement stabilizing soil

For the purpose of investigating the influence of geocell on cement stabilizing soil, several unreinforced cement stabilized soil triaxial compression tests were carried out. The test procedures are similar to the above. A total of 15 tests including 9 large-scale direct shear tests and 6 triaxial compression tests were carried out in this study. Considering silty gravel and cement stabilizing silty gravel which reinforced with geocell or not, if the soil is stabilized with cement, the dosage of cement is 5%.

3 Test results and comparison

3.1 Large-scale direct shear tests

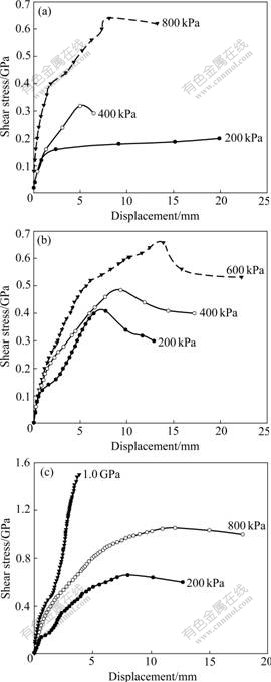

The shear stress—displacement behaviors observed from large-scale direct shear tests on different reinforcement soils are shown in Fig.3. The results of unreinforced soil show that the shear stress increases with increasing shear displacement when the normal stress is 200 kPa. As increasing normal stress to 400 kPa and above, the shear stress—displacement response is softening pattern which shows an increase in shear stress with increasing shear displacement at the beginning and a decrease in shear stress with increasing shear displacement in the end. In the case of geocell reinforced soil (Fig.3(b)), all the curves of shear stress—displacement with different normal stresses appear in softening pattern. There is a characteristic that the shear stress increases to a peak with increasing shear displacement from zero to a certain magnitude and thereafter, it decreases gradually to the residual shear stress with the increase of the displacement. The reason for this correspondence is that there is a considerable degree of interlocking on dense soil and there is an additional friction on the interface between soil and geocell reinforcement. Therefore, before shear failure can take place this interlocking and additional friction must be overcome in addition to the frictional resistance at contact points. As the interlocking and additional friction are progressively overcome, the shear stress necessary for additional deformation decreases. However, the result of geocell reinforced cement stabilizing soil shows different features when the normal stress comes up to 1.0 GPa (Fig.3(c)). The shear failure takes place with a relatively high shear stress and low deformation. It is clear from the data in this figure that there is a quasi-elastic characteristic on the behavior of shear stress and displacement. This is mainly due to the 5% cement stabilizing soil possessing a considerable degree of rigidity. Each plot in Fig.3 shows that there is a transformation in shear stiffness. It increases with increasing the normal stress for all tests.

Fig.3 Shear stress—displacement behaviors of different rein- forcement soils: (a) Unreinforced soil; (b) Geocell reinforced soil; (c) Geocell reinforced cement stabilizing soil

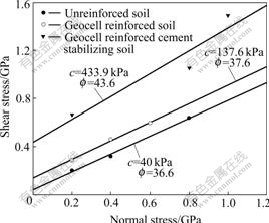

The linear shear capacity envelops deduced from the peak or the maximum recorded shear stress versus normal stress data for different reinforcement soils are plotted together in Fig.4. It shows that there is a good correspondence for unreinforced soil and geocell reinforced soil. But in the case of geocell reinforced cement stabilizing soil, there is scatter of the data points about the linear regression line. This is due to the unavoidable small variations in the setup of the shear surface between the two parts of shear boxes exactly at the interface between geocell reinforcement soil and unreinforced soil. The correlation coefficient of the linear regression on geocell reinforced cement stabilizing soil is 0.91, and those on both unreinforced soil and geocell reinforced soil are all 0.99. Based on the linear regression lines presented in Fig.4 the parameters of shear strength including cohesion “c” and friction angle “ ” can be derived. The results show that there is a considerable increase on cohesion from unreinforced soil to geocell reinforced soil. Comparing the cohesion of unreinforced soil with that of geocell reinforced soil, the cohesion of geocell reinforced soil increases by 244%, and the cohesion of geocell reinforced cement stabilizing soil is 11 times as large as that of unreinforced soil. However, the friction angle does not change dramatically. Based on the data presented in Fig.4 it can be argued that the geocell reinforced soil develops a large amount of cohesion on the interface shear strength but the friction angle.

” can be derived. The results show that there is a considerable increase on cohesion from unreinforced soil to geocell reinforced soil. Comparing the cohesion of unreinforced soil with that of geocell reinforced soil, the cohesion of geocell reinforced soil increases by 244%, and the cohesion of geocell reinforced cement stabilizing soil is 11 times as large as that of unreinforced soil. However, the friction angle does not change dramatically. Based on the data presented in Fig.4 it can be argued that the geocell reinforced soil develops a large amount of cohesion on the interface shear strength but the friction angle.

Fig.4 Shear capacity envelops for large-scale direct shear tests

3.2 Comparison of results with triaxial compression tests

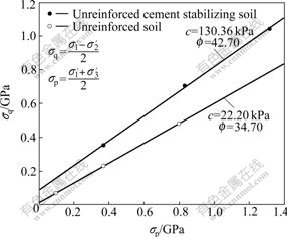

Fig.5 shows the behavior of principle stress difference versus vertical strain of consolidated- undrained triaxial compression tests for unreinforced soil and unreinforced cement stabilizing soil. Comparing the results of unreinforced soil with those of unreinforced cement stabilizing soil, it seems that the two types of soils have different features of stress—strain. With the same vertical strain of 2%, the principal stress difference of unreinforced cement stabilizing soil reaches the peak point of the curve, but the principal stress difference of unreinforced soil increases with increasing vertical strain and after that, the stiffness becomes less. Nevertheless, the linear shear failure strength envelopes deduced from the maximum recorded effective principal stress ratio are plotted in Fig.6. The σp and σq in this diagram are the mean effective normal stress and effective shear stress, respectively. It appears a very good correlation for both unreinforced soil and unreinforced cement stabilizing soil. Based on the regression linear lines and test data, the consolidated undrained shear strength parameters are interpreted and summarized in Table 4.

Fig.5 Triaxial behaviors of principle stress difference versus vertical strain: (a) Unreinforced soil; (b) Unreinforced cement stabilizing soil

Fig.6 Failure strength envelopes for triaxial compression tests

Table 4 Shear strength parameters with different test methods

It is observed that the effective cohesion of unreinforced cement stabilizing soil is nearly 6 times as larger as that of unreinforced soil, while the frictional angle increases by 19.2%. Comparing the results of triaxial compressive shear test with those of large-scale direct shear test on unreinforced soil, it shows that there is a significant difference in the cohesion. The triaxial compressive shear tests give cohesion of 22.2 kPa, and the large-scale direct shear tests exhibit a relatively larger result of 40 kPa. However, there is only a marginal decrease in the friction angle which is from 34.7? to 36.6?, respectively. This result can be attributed to the different specimen sizes used in the tests. With a dimensions of 500 mm×500 mm×400 mm (length× width×height), the large-scale shear test specimen has much more area of soil confined by shear box. Therefore, the degree of interlocking in the soil can be developed to a higher lever, which results in the increase of cohesion. Based on the test results in this study, it may be concluded that the cohesion of soil is mainly responsible for the increase of shear strength due to the influence of test methods. Comparing the results of triaxial compression test, the large-scale direct shear test provides a higher cohesion and an approximate friction angle.

4 Conclusions

1) The use of large-scale direct shear test device provides a valuable method to gain the shear strength parameters for geocell reinforced soil.

2) The behaviors of stress—strain on both un- reinforced soil and reinforced soil by large-scale direct shear tests are nonlinear. When the normal stress comes up to 1.0 GPa, there is a quasi-elastic characteristic on the behavior of shear stress and displacement for the geocell reinforced cement stabilizing soil. The shear stiffness increases with increasing normal stress for all tests.

3) With the reinforcement of geocell, the cohesive strength of silty gravel soil considerably increases and it increases much more highly for the cement stabilizing soil.

4) The friction angle of the geocell reinforced soil does not change obviously. The failure envelops of both the unreinforced soil and the reinforced soil are nearly parallel to each other.

5) The large-scale direct shear test gives a higher cohesion and an approximate friction angle compared with the results of triaxial compression test.

References

[1] DASH S K, SIREESH S, SITHARAM T G. Model studies on circular footing supported on geocell reinforced sand underlain by soft clay [J]. Geotextiles and Geomembranes,2003, 21(4): 197-219.

[2] YAN Chang-gen, YANG Xiao-hua, SHI Yu-ling, QI Sheng-wen. Testing and application of geocell in loess slopes of highway [J]. Chinese Journal of Rock Mechanics and Engineering, 2006, 25(S1): 3235-3238. (in Chinese)

[3] DASH S K, KRISHNASWAMY N R, RAJAOPAL K. Bearing capacity of strip footings supported on geocell-reinforced sand [J]. Geotextiles and Geomembranes,2001, 19(4): 235-256.

[4] BATHURST R J, CROWE R E. Recent case histories of flexible geocell retaining walls in North America [C]// TATSUOKA F, LESHCHINSKY D. The International Symposium on Recent Case Histories of Permanent Geosynthetic-reinforced Soil Retaining Walls. Rotterdam: Balkema, 1994: 17-29.

[5] MHAISKAR S Y, MANDAL J N. Investigations on soft clay subgrade strengthening using geocells [J]. Construction and Building Materials, 1996, 10(4): 281-286.

[6] BATHURST R J, JARRETT P. Large-scale model tests of geocomposite mattresses over peat subgrades [C]// ASTM Transportation Research Record 1188. Washington: Transportation Research Board, 1989: 28-36.

[7] ASTM D 5321-02. Standard Test method for determining the coefficient of soil and geosynthetic or geosynthetic and geosynthetic friction by the direct shear method [S]. Pennsylvania: West Conshohocken, 2002.

[8] BATHURST R J, KAPPURAPU R. Large-scale triaxial compression testing of geocell-reinforced granular soils [J]. Geotechnical Testing Journal, 1993, 16: 296-303.

[9] RAJAGOPAL K, KRISHNASWAMY N R, LATHA G M. Behavior of sand confined with single and multiple geocells [J]. Geotextiles and Geomembranes, 1999, 17(3): 171-184.

[10] LATHA G M, RAJAGOPAL K, KRISHNASWAMY N R. Experimental and theoretical investigations on geocell-supported embankments [J]. International Journal of Geomechanics, 2006, 6(1): 30-35.

[11] LATHA G M, MURTHY T G. Effects of reinforcement form on the behavior of geosynthetic reinforced sand [J]. Geotextiles and Geomembranes,2007, 25(1): 23-32.

[12] MENGELT M. Resilient modulus and plastic deformation of soil confined in a geocell [J]. Geosynthetics International, 2006(13): 195-205.

[13] LIU Xiao-li, LUO Jin-tian, MIN Hong, DENG Jian-hui, THAM L G. A new large direct shear apparatus for field and laboratory test (II) [J]. Rock and Soil Mechanics, 2006, 27(2): 336-340. (in Chinese)

[14] CHEN R H, CHIU Y M. Model tests of geocell retaining structures [J]. Geotextiles and Geomembranes, 2008, 26(1): 56-70.

[15] BAO Cheng-gang. Principle and application of geosynthetics in engineering [M]. Beijing: China Water Power Press, 2008. (in Chinese)

[16] FAN Zhen-hui, WANG Yong-he. Elastic finite element analysis of reinforcing geogrids applied in high embankment slope [J]. Journal of Central South University: National Science, 2005, 36(5): 904-910. (in Chinese)

[17] JT/T 669-2006. geosynthetics in highway engineering—Sort, capability demand and test methods of compositive materials [S]. Beijing: People’s Transportation Press, 2006. (in Chinese)

[18] CRAIG R F. Soil mechanics [M]. London: Spon Press, 2001.

Foundation item: Project(40672178) supported by the National Natural Science Foundation of China; Project(2004844009) supported by the Chinese Scholarship Council

Received date: 2008-04-19; Accepted date: 2008-06-26

Corresponding author: WANG Yi-min, Professor, PhD; Tel: +86-20-87111030; E-mail: ctymwang@scut.edu.cn

(Edited by YANG Hua)