磁铁矿球团煤基直接还原工艺中润磨的强化

朱德庆1,徐小锋1,潘 建1,欧应钦2,李 建1,唐艳云1

(1. 中南大学 资源加工与生物工程学院,湖南 长沙,410083;

2. 中冶长天国际工程有限公司,湖南 长沙,410001)

摘 要:以铁品位为69.21%(质量分数)的磁铁精矿为原料,采用预热球团“一步法”煤基直接还原工艺制取直接还原铁。为了降低该精矿成球时产生过多粉末,采用润磨工艺来预处理混合料,并在最优条件下进行了扩大型全流程试验。研究结果表明:在磁铁精矿配加1.0%复合粘结剂及润磨4 min的条件下,生球落下强度由未润磨时的3.8 次/(0.5 m)提高到13.7 次/(0.5 m);润磨后干球(<1 mm=粉末率由未润磨时的10.98%降低到2.98%;在预热温度为800 ℃和预热时间为10 min时,预热球团抗压强度由未润磨时的466 N/个提高到581 N/个。预热球团直接还原时,采用润磨预处理方案球团的金属化率与无润磨工艺球团的金属化率相差不大,但金属化球团抗压强度远远大于未润磨时的金属化球团抗压强度,且几乎不产生磁性粉末。通过链箅机-回转窑直接还原扩大试验,所得直接还原球团铁品位达93.43%,金属化率达95.88%,含硫量低于0.01%,磁性粉率为0.75%~0.96%,每吨直接还原铁所耗还原煤为808.5~859.3 kg。

关键词:磁铁精矿;润磨;干球粉末率;预热球强度;回转窑结圈;直接还原

中图分类号:TF551 文献标识码:A 文章编号:1672-7207(2007)05-0843-07

Improving coal-based direct reduction of magnetite pellets by damp milling

ZHU De-qing1, XU Xiao-feng1, PAN Jian1, OU Ying-qin2, LI Jian1, TANG Yan-yun1

(1. School of Mineral Processing and Bioengineering, Central South University, Changsha 410083, China;

2. Zhongye Changtian International Engineering Co.Ltd, Changsha 410001, China)

Abstract:The coal-based one-step direct reduction of magnetite concentrate, assaying 69.21% (mass fraction) total Fe, was conducted, where damp milling was utilized to pretreat the concentrate for increasing green balls strength, lowering binder dosage and reducing fines generated during drying and handling dried balls. The results show that with magnetite concentrate pretreated by damp milling for 4 min drop number of green balls increases from 3.8 times to 13.7 times from 0.5 m height, and fine fraction of dried balls reduces from 10.98% to 2.98%, when compared with that without pretreating magnetite concentrate before balling. The compressive strength of preheated pellets rises from 466 N to 581 N per pellet with the magnetite concentrate pretreated by damp mill and preheating pellets at 800 ℃ for 10 min. The metallized pellets made of magnetite concentrate pretreated by damp milling possess higher compressive strength than that without damp milling, while the metallization degree is close to each other. Based on small scale tests, pilot tests of direct reduction are performed to stimulate grate-kiln process. Main results are as follows: 93.43% total Fe of directly reduced iron (DRI), 95.88% metallization, sulphur content of lower than 0.01%, 0.75%-0.96% magnetic powder rate and reductive coal is 808.5-859.3 kg per 1 t DRI.

Key words: magnetite concentrate; damp milling; powder rate of dry balls; strength of preheated balls; accretion inside rotary kiln; direct reduction

钢铁冶炼工艺的革新,特别是“短流程”工艺的兴起和发展,对冶炼的原料提出更高的要求,特别是电炉炼钢短流程工艺的蓬勃发展,为了保证钢材质量,生产优质、特殊钢,直接还原铁(DRI)成为必不可少的电炉炉料[1-5]。目前,国外直接还原的发展,气基直接还原法均占主导地位,其产量占直接还原铁总产量的90%;煤基直接还原法占10%左右。我国研究工作者研究了多种直接还原铁生产工艺,如:倒焰窑罐式法、隧道窑罐式法、链篦机—回转窑法、斜坡炉法(XSH-A法)等[6-10]。但能大规模投产且运转稳定的工艺仅为引进英国戴维公司的块矿回转窑直接还原及链篦机-回转窑“一步法”直接还原工艺[11-12]。针对我国资源条件的特点,非焦煤储量大及铁矿资源以贫矿为主,就必须以煤基球团直接还原法为主。我国新疆某地蕴藏大量的优质铁矿和非焦煤,中南大学以该原料为主开发出了煤基回转窑“一步法”直接还原新工艺。本文作者针对该磁铁精矿粒度较细但其成球性能不佳、生球表面极易脱落粉尘的特点,研究了润磨工艺的强化作用,并取得较为理想的结果,使入窑粉末量降至最低,防止回转窑结圈,以提高回转窑作业率和产量。

1 原料性能和研究方法

1.1 原料性能

铁精矿的化学成分见表1。精矿铁品位较高,总铁(TFe)达到69.21%,SiO2和Al2O3等有色金属杂质及P和S等有害元素含量很低,是生产直接还原铁的优质原料;铁精矿粒度小于74 μm粒级含量为82.74%,达到造球的一般标准。造球过程中添加的复合粘结剂由中南大学研制[13],该粘结剂具有粘结、放热、催化等多项功能,并且其铁品位较高,杂质成分低,对球团品位影响较小。

表1 铁精矿化学成分

Table 1 Chemical composition of iron concentrate w/%

还原煤工业分析结果见表2。由表2可知,本研究中采用的还原煤固定碳高、灰份低、挥发份高及结焦指数低,是比较好的还原剂。该还原煤的软熔特性为:变形温度1 100 ℃,软化温度1 170 ℃,半球温度1 190 ℃,流动温度1 260 ℃。可以看出其符合一般直接还原的要求。

表2 还原煤工业分析结果

Table 2 Industrial analysis results of reductive coal w/%

在还原过程中加入石灰石作脱硫剂,以防止还原煤中的硫与新生成的直接还原铁反应,其有效CaO含量为54.38 %,粒度小于3 mm。

1.2 研究方法

煤基“一步法”直接还原试验工艺流程如图1所示,主要包括配料、混匀、润磨混合料、造球、球团预热及球团矿煤基直接还原。混合料润磨采用直径×长度为500 mm×500 mm的无级调速润磨机,造球在直径为1 000 mm的圆盘造球机上进行,造球工艺参数为:造球水分7.2%,造球时间15 min。小型试验的生球经鼓风干燥箱干燥后备用,球团预热在直径为50 mm的卧式电阻管炉中进行,预热球在直径为70 mm的竖式炉内直接还原;扩大试验生球的干燥预热在链箅机模型中进行,预热球在直径×长度为1 000 mm×500 mm的回转窑火力模型中直接还原,以煤为还原剂。

图 1 煤基“一步法”直接还原试验工艺流程

Fig.1 Flow chart of coal based one step direct reduction experiment

如果铁精矿成球性差,生球干燥后表面会非常粗糙,极易产生粉末脱落,将会对回转窑的运转带来极大的隐患,极易引起回转窑结圈[14]。因此,研究了不同润磨条件下的生球强度、干燥球的粉末率、预热球强度及直接还原球团的抗压强度,以考查润磨在磁铁精矿球中的作用效果。其中,干燥球的粉末率是衡量润磨作用效果的一项重要指标,其测定方法为:将干燥球团用1 mm试样筛用振动筛筛分1 min,取筛下物,称量和计算。

2 结果及分析

2.1 小型试验研究

2.1.1 润磨对生球质量的影响

复合粘结剂对生球强度的影响见表3。可见,虽然生球落下强度随着复合粘结剂用量增加而明显升高,抗压强度均高于15 N/个,生球爆裂温度也高于580 ℃,但干球粉末率较高。提高复合粘结剂配比能提高生球球团强度,降低粉末率,但当复合粘结剂配比提高到1.4%(质量分数)时,粉末率仍然高达7.56%,会对回转窑安全运行带来很大隐患。混合料润磨4 min后效果很明显,生球强度大幅度上升,干球粉末率显著下降。在复合粘结剂用量仅为0.6%时,干燥球团 (粒度<1 mm)粉末率可降低到3.56%。

表3 工艺参数对球团质量的影响

Table 3 Effect of processing parameter on green ball quality

当复合粘结剂用量为1.0%,造球时间为15 min,生球水分为7.2%时,润磨时间对生球质量的影响如图2所示。可见,随着润磨时间的延长,生球落下强度明显提高,干球粉末率大幅度下降,润磨能明显提高生球的质量。考虑到能耗等综合因素,在复合粘结剂配比为1.0%时,润磨时间选4 min左右为宜,生球落下和抗压强度分别达到13.7 次/(0.5 m)和26.66 N/个,远高于生产要求,同时干球粉末率为2%~3%。

图 2 润磨时间对生球质量的影响

Fig.2 Effect of milling time on green ball quality

润磨工艺现已被国内许多球团厂家认同并投入了生产,生产实践表明其能起到降低膨润土用量,提高球团产质量的效果。其主要原因是:润磨可使物料充分混合和细化,提高精矿表面活性。由于润磨机筒体内钢球的作用,润磨机的混合料效果远远优于普通混合机。润磨类似于干式磨矿,经过润磨处理后,铁矿粉细度降低,增大混合料颗粒的表面积,并暴露出很多新鲜表面,提高表面活性,使粘结剂可更好地与磁铁矿粉混合[15],并附在其表面上及间隙中。经过润磨之后,混合料的造球质量得到很大提高,在粘结剂配入量大幅度降低的条件下,所造的球粒度均匀,强度好,碎球少。经研究发现[16]:润磨后的原料细料级含量增多,粒级分布更接近对数正态分布;晶格扭曲,形成晶体缺陷,发生微塑性变形;颗粒表面自由能增大,从而增加了物料表面活性,提高其表面的吸附 能力。

2.1.2 润磨对预热球质量的影响

预热的主要目的是获得较高的球团强度,以保证回转窑中球团不破碎及尽可能少地产生粉末。预热球团入窑前有较高的抗压强度及耐磨强度是减少回转窑结圈的重要保证之一。入窑前球团强度越高、在还原过程中因相变结构削弱产生的粉末就越少,回转窑结圈的几率就越低,其产量越高,能耗越低。

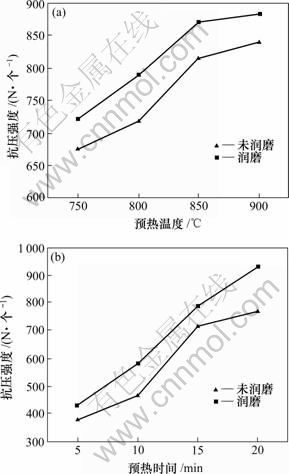

当复合粘结剂用量为1.0%,造球时间为15 min,生球水分为7.2%时,预热条件对预热球强度的影响如图3所示。可见,随着预热温度升高,预热球团抗压强度逐渐增大。磁铁精矿经润磨预处理,在所试验的预热温度范围内,预热球团的强度均高于不润磨所制备球团的强度。同时可以看出,随着预热时间延长,预热球团抗压强度显著增大。并且混合料经润磨预处理,在所研究的预热时间范围内,预热球团的抗压强度均高于不润磨所制备球团的抗压强度。

(a) 预热温度;(b) 预热时间

图3 预热条件对预热球团强度的影响

Fig.3 Effects of preheating parameters on green ball quality

润磨预处理有利于预热球强度的提高,主要是因为润磨后混合料成球性能得到改善,所造生球结构更加致密,有利于传质传热;此外,其表面活性很高,在较低温度及较短时间内就能很好固结。在预热800 ℃和10 min的条件下,未润磨球团预热球团抗压强度仅为466 N/个;经润磨工艺预处理后,预热球的抗压强度提高到581 N/个。

2.1.3 润磨对直接还原球质量的影响

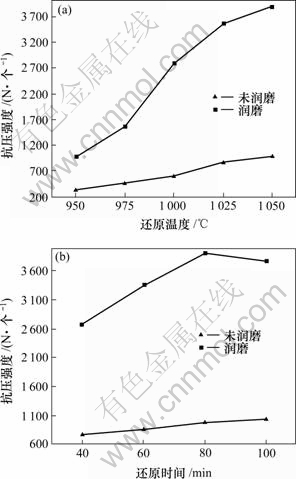

球团还原过程需要预热球有一定的空隙率,保证还原气体能较易进入球团内部从而使球团充分还原;但空隙率过高会导致球团强度降低,使球团在回转窑运转过程中产生粉末,造成结瘤等隐患。为此,研究了润磨工艺对预热球团还原焙烧的影响。当复合粘结剂用量为1.0%,预热温度为800 ℃、预热时间为10 min时,还原温度与时间对球团金属化率和还原过程球团抗压强度的影响如图4和图5所示。

(a) 还原温度;(b) 还原时间

图4 直接还原条件对直接还原球团金属化率的影响

Fig.4 Effects of reducing parameters on DRI metallization

(a) 还原温度;(b) 还原时间

图5 焙烧温度和时间对直接还原球团强度的影响

Fig.5 Effects of roasting temperature and time on DRI strength

由图4和图5可见,随着还原温度的升高,直接还原金属化率逐渐增加,抗压强度随之提高。未润磨球团相对润磨球团较易还原,但相同条件下的金属化率相差并不大,而抗压强度远远低于润磨球团的抗压强度。在还原温度为1 050 ℃和还原时间为80 min的条件下,未润磨时金属化球团抗压强度仅为983 N/个,而且观察到直接还原后的球团表面粗糙,裂纹很深,表面极易脱落;而增加润磨工艺后的直接还原球团抗压强度达到3 903 N/个,同时其表面光滑、结构致密。从图4还可以得出,当还原温度达到1 025 ℃时,直接还原球团矿金属化率已达到95.58%,已达到优质DRI的质量要求。综合考虑能耗及所用还原煤的软融性能,适宜的还原温度为1 050 ℃、焙烧时间为80 min左右。在此条件下生产的DRI的金属化率为95.87%,铁品位达到91.33%,球团抗压强度为3 903 N/个。

从图4及图5还可以看出,随着还原时间的延长,无论润磨或未润磨时球团金属化率随之增加。还原时间达到80 min时,再延长还原时间对球团还原程度的影响已非常微小(未润磨与润磨DRI的金属化率已分别达到96.30%和95.87%)。 虽然延长还原时间能提高未润磨球团的抗压强度,但在还原温度1 050 ℃、还原时间100 min的条件下金属化球团抗压强度仍只有1 025 N/个,远远低于润磨球团还原40 min时的强度。采用润磨工艺能明显提高DRI抗压强度,而还原过程中球团抗压强度低必然会导致其耐磨强度下降,从而产生碎片、粉料等,是导致回转窑结圈的重要隐患[17]。

由此可得:润磨工艺的增加对球团的还原率影响不大,但能明显提高其强度,减少粉化率,增强回转窑的安全运转性能,是必不可少的强化工艺。

2.2 煤基直接还原链篦机-回转窑扩大试验研究

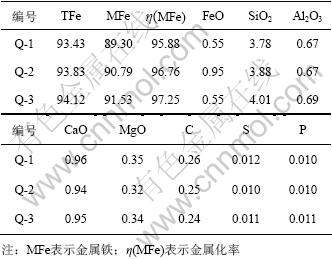

根据小型试验的最优工艺参数,利用高品位(70.86%)的新疆磁铁精矿,在中南大学直接还原扩大试验基地的链篦机-回转窑设备上进行半工业化试验研究。半工业试验通过优化链篦机干燥温度、风速、时间,预热温度、风速、时间,以及回转窑火力模型还原焙烧的温度、时间等参数,3次全流程试验得到的直接还原矿化学成分见表4。

表 4 链篦机-回转窑直接还原球团矿化学成分

Table 4 Chemical composition of DRI in grate-kiln pilot scale tests w/%

最优条件下的扩大试验得到了质量优良的直接还原铁:铁品位为93.43%~94.12%,金属化率为95.88%~97.25%,含硫量<0.010%,磁性粉率为0.75%~0.96%,每吨直接还原铁所耗还原煤为808.5~859.3 kg。

3 结 论

a. 润磨能使混合料粒度及粒度组成得到改善,能增加物料比表面积和提高表面活性,是一种减少粘结剂添加量、提高生球和干球强度及减少入窑粉末量的有效措施。新疆磁铁精矿在配加1.0%复合粘结剂及润磨4 min的条件下,使干球(粒度<1 mm)粉末率由10.98%降低到2.98%;生球落下强度由3.8 次/(0.5 m)提高到13.7 次/(0.5 m)。

b. 润磨预处理有利于提高预热球的质量,在预热温度为800 ℃和预热时间为10 min的条件下,增加润磨工艺能将预热球抗压强度由466 N/个提高到 581 N/个。

c. 还原焙烧过程中,增加润磨工艺对球团的金属化率影响不大,但能明显提高直接还原球团抗压强度,减少粉化率,增强回转窑的运转性能,是必不可少的强化工艺。

d. 链篦机-回转窑的扩大试验,所得直接还原球团铁品位为93.43%~94.12%,金属化率为95.88%~97.25%,含硫量<0.010%,磁性粉率为0.75%~0.96%,每吨直接还原铁所耗还原煤为808.5~859.3 kg。磁粉率很低,表明预热球团和还原球团具有很好的强度,进一步证实了润磨在直接还原中的强化作用。

参考文献:

[1] 方 觉. 非高炉炼铁工艺与理论[M]. 北京: 冶金工业出版社, 2003.

FANG Jue. Non-blast furnace technics and theory [M]. Beijing: Metallurgical Industry Press, 2003.

[2] D.C.梅瑟. 直接还原用铁矿的展望(一)[J]. 李 蒙, 孙立晏, 译. 国外金属矿山, 2000(3): 43-46.

Messy D C. Expectation of direct reduction iron ore(一)[J]. LI Meng, SUN Li-yan, transl. Foreign Metal Mining, 2000(3): 43-46.

[3] 游锦洲, 周国凡, 于仲洁, 等. 热态直接还原铁防再氧化初步研究[J]. 钢铁, 1999, 34(11): 5-6.

YOU Jin-zhou, ZHOU Guo-fan, YU Zhong-jie, et al. Preliminary study on preventing thermal state DRI to re-oxidize[J]. Iron and Steel. 1999, 34(11): 5-6.

[4] 刘育光. 直接还原法生产海绵铁的应用设想[J]. 包钢科技, 2006, 32(1): 8-10.

LIU Yu-guang. Thoughts of application of DRI process to produce spongy iron[J]. Science & Technology of Baotou Steel (Group) Corporation, 2006, 32(1): 8-10.

[5] 陈永国, 郭森魁, 何祥义. 铁直接还原技术的现状及发展[J]. 上海金属, 1999, 1(4): 40-42.

CHEN Yong-guo, GUO Sen-kui, HE Xiang-yi. The development and present situation of DR iron processes[J]. Shanghai Metals, 1999, 21(4): 40-42.

[6] 朱德庆, 邱冠周, 姜 涛, 等. 铁精矿冷固球团矿煤基回转窑直接还原新工艺[J]. 钢铁, 2001, 36(2): 4-7.

ZHU De-qing, QIU Guan-zhou, JIANG Tao, et al. Direct reduction of cold-bound pellets of iron concentrate with coal-based rotary kiln and Its theoretical basis[J]. Iron and Steel, 2001,36(2): 4-7.

[7] 张汉泉, 朱德庆. 直接还原的现状与发展[J]. 钢铁研究, 2002(2): 51-54.

ZHANG Han-quan, ZHU De-qing. Present situation and development of iron ore direct reduction[J]. Research on Iron & Steel, 2002(2): 51-54.

[8] 阴继翔. 煤基直接还原技术的发展[J]. 太原理工大学学报, 2005, 31(3): 314-315.

YIN Ji-xiang. Development of coal-based direct reduction technologies[J]. Journal of Taiyuan University of Techonology, 2005, 31(3): 314-315.

[9] 冯燕波, 曹维成, 杨双平, 等. 中国直接还原技术的发展现状及展望[J]. 中国冶金, 2006, 16(5): 10-13.

FENG Yan-bo, CAO Wei-cheng, YANG Shuang-ping, et al. Development and prospect on direct reduction technology in China[J]. China Metallurgy, 2006, 16(5): 10-13.

[10] 魏 国, 赵庆杰, 董文献, 等. 直接还原铁生产概况及发展[J]. 中国冶金, 2004(9): 16-20.

WEI Guo, ZHAO Qing-jie, DONG Wen-xian, et al. Present status and development trends of world direct reduction processes[J]. China Metallurgy, 2004(9): 16-20.

[11] 董 方, 王 南, 那树人, 等. 回转窑直接还原铁生产的试验研究[J]. 包头钢铁学院学报, 1999, 18(2): 151-155.

DONG Fang, WANG Nan, NA Shu-ren, et al. Experimental investigation on rotary kiln DRI production[J]. Journal of Baotou University of Iron and Steel Technology, 1999, 18(2): 151-155.

[12] 叶匡吾. 铁矿资源优势的发挥与“一步法”直接还原[J]. 冶金矿山设计与建设, 1998, 30(3): 3-5.

YE Kuang-wu. Development of advantage of iron-ore reserves and “one-step process” direct reduction[J]. Metal Mine Design and Construction, 1998, 30(3): 3-5.

[13] ZHU De-qing, QIU Guan-zhou, JIANHG Tao, et al. An innovative process for direct reduction of cold-bound pellets from iron concentrate with a coal-based rotary kiln[J]. J Cent South Unvi Technol, 2000, 7(2): 68-71.

[14] 王治卿, 赵庆杰, 董文献. 球团强度对回转窑内铁收得率的影响[J]. 钢铁, 2000, 35(10): 13-15.

WANG Zhi-qing, ZHAO Qing-jie, DONG Wen-xian. Effect of pellet strength on iron yield on DR kiln[J]. Iron and Steel, 2000, 35(10): 13-15.

[15] 黄柱成, 李 骞, 杨永斌, 等. 混合料润磨预处理对氧化球团矿质量的影响[J]. 中南大学学报: 自然科学版, 2004, 35(5): 753-758.

HUANG Zhu-cheng, LI Qian, YANG Yong-bin, et al. Effect of wet-grinding of mix on quality of iron ore concentrate pellet[J]. J Cent South Univ: Science and Technology, 2004, 35(5): 753-758.

[16] 王昌安, 朱德庆. 润磨活化机理初探[J]. 钢铁研究, 2003(6): 23-27.

WANG Chang-an, ZHU De-qing. Study on the mechanism of activation of magnetite concentrate pretreated by damp mill[J]. Research on Iron & Steel, 2003(6): 23-27.

[17] 朱德庆, 陈 荩, 蔡汝卓, 等. 铁精矿冷固球团矿在工业性回转窑内的还原行为[J]. 中南工业大学学报: 自然科学版, 1995, 26(4): 470-474.

ZHU De-qing, CHEN Jin, CAI Ru-zhuo, er al. Reduction behavior of cold bond pellets of iron ore concentrate in a commercial rotary kiln[J]. J Cent South Univ Technol: Natural Science, 1995, 26(4): 470-474.

收稿日期:2006-12-18;修回日期:2007-01-25

基金项目:国家教育部高等学校优秀青年教师教学科研奖励基金资助项目(教人司[2000]26)

作者简介:朱德庆(1964-),男,湖南安乡人,博士,教授,从事直接还原与熔融还原、资源综合利用与环境保护、烧结球团理论和技术等研究

通信作者:朱德庆,男,教授;电话:0731-8836041(O);E-mail: dqzhu@mail.csu.edu.cn