文章编号:1004-0609(2007)09-1506-05

不同热喷涂技术制备镍基涂层的摩擦磨损性能

伍超群1, 2,周克崧2,刘 敏2,邓畅光2,邓春明1, 2

(1. 广东工业大学 材料能源学院,广州 510081;

2. 广州有色金属研究院 表面材料中心,广州 510650)

摘 要:利用超音速火焰喷涂技术和低压等离子喷涂技术,在铜基体上制备镍基涂层,研究涂层在室温下的摩擦磨损特性,探讨涂层的磨损机理。结果表明,HVAF制备的镍基涂层具有较好的耐磨性,主要原因是在涂层中存在Ni3B、M23C6、M7C3等硬质相,其磨损机理为磨粒磨损,而低压等离子喷涂技术制备的镍基涂层组织出现大量的非晶态,硬度低,磨损机理为磨粒磨损和疲劳磨损的综合作用,并以疲劳磨损为主。

关键词:镍基涂层;超音速火焰喷涂;等离子喷涂;摩擦磨损

中图分类号:TG 174 文献标识码:A

Wear properties of nickel-based coating sprayed by different thermal spraying technologies

WU Chao-qun1, 2, ZHOU Ke-song2, LIU Min2, DENG Chang-guang2, DENG Chun-ming1, 2

(1. College of Materials and Energy, Guangdong University of Technology, Guangzhou 510081, China;

2. Material Surface Center, Guangzhou Research Institute of Non-ferrous Metals, Guangzhou 510650, China)

Abstract: The Nickel-based coating was prepared on copper substrate by high velocity air-fuel (HVAF) thermal spraying and low pressure plasma spraying (LPPS). The wear properties and wear mechanisms of coating were studied. The results show that in the nickel-based coating deposited by HVAF, the hardness is high and the wear resistance is good. The wear mechanism is abrasive wear. The wear mechanism of Ni-based coating deposited by LPPS is mainly fatigue wear. This is attributed to low hardness and amorphous phase existed.

Key words: nickel-based coating; high velocity air-fuel; plasma spraying; friction and wear

热喷涂技术 [1?2]作为表面工程学的一个重要组成部分,具有操作简便、灵活高效,涂层材料种类多等特点,近年来得到越来越多的应用。低压等离子喷涂(LPPS)是在等离子喷涂的基础上发展起来的,它是将等离子喷涂工艺在低压保护性气氛中进行操作,减小喷涂过程中喷涂颗粒的氧化分解。超音速火焰喷涂(HVO/AF)技术[3?5]是继等离子喷涂后的又一发明,具有火焰速度高(可达1 500~2 000 m/s)、温度低(约3 000 ℃)的特点[6]。HVAF喷涂技术与普通的HVOF相比,具有粒子温度更低,速度更快的特点,获得的涂层氧化程度低,具有较高的沉积率,由于是以压缩空气作为助燃剂,其生产成本较低,从而被广泛用于制备高致密性、高结合强度、低孔隙率、耐磨损的涂层。

镍基自熔合金涂层[7]由于具有较好的耐磨损、抗腐蚀等性能,被广泛地应用于工业生产中。采用多种方法可获得镍基涂层[8?10],但目前大多数研究人员集中在对钢基体上的镍基涂层进行耐磨性研究,对铜基体上的镍基涂层研究鲜有报道。为提高结晶器等大型铜零部件的使用寿命,人们采用电镀及热喷涂等多种方法制备了各种涂层[11?13],并对涂层组织结构及性能进行了研究,文献[14]虽进行了不同热喷涂技术制备的镍基涂层结构性能的研究,但未对涂层耐磨性能进行详细分析。

本文作者主要用镍基自熔合金粉末作为喷涂材料,采用超音速火焰喷涂(HVAF)和低压等离子喷涂(LPPS)两种技术,在铜基体上制备镍基涂层,分析比较了两种喷涂技术对镍基涂层组织结构以及摩擦磨损性能的影响,以便确定合适的热喷涂技术流程,在铜基体上制备出较佳的耐磨涂层,为热喷涂技术在铜基体上的推广应用提供依据。

1 实验

1.1 实验材料与喷涂设备

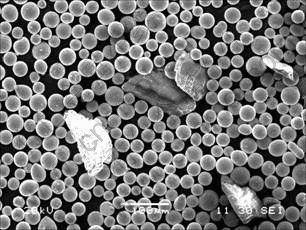

热喷涂实验粉末选用美国Uniquecoat公司生产的NiCrWB粉末和Al2O3粉末的机械混合物,其组成为NiCrWB+50%Al2O3(体积分数),粉末形貌如图1所示。其中NiCrWB的化学成分为(质量分数):Cr 14.73%,W 8.76%,Fe 3.58%,Si 2.87%,B 2.49%,C 0.62%,Ni余量。基体材料采用紫铜,喷涂前铜基体表面进行 去油喷砂处理,采用超音速火焰喷涂技术(HVAF)和 低压等离子喷涂技术(LPPS)制备涂层,涂层厚度约 0.3 mm。

图1 原始喷涂粉末形貌

Fig.1 Morphology of thermal spray powders

超音速火焰喷涂(HVAF)采用美国Uniquecoat公司生产的SB50型超音速火焰喷涂枪,经测试其火焰温度约为1 800 ℃左右,粒子温度约为1 400 ℃,而粒子飞行速度为700~800 m/s;低压等离子喷涂(LPPS)采用广州有色金属研究院自行制造的MPF?1000型低压等离子喷涂设备。两种喷涂技术所采用的工艺参数列于表1。

表1 HVAF和LPPS喷涂工艺参数

Table 1 Thermal spray parameters of HVAF and LPPS

1.2 分析检测设备

采用JSM?5910型扫描电镜(SEM)进行涂层组织形貌观察,采用JCXA?733电子探针(EPMA)进行涂层成分分析,用D/Max-RC型X射线衍射仪对涂层进行物相分析,用HXD?1000B数字计显微硬度计测量涂层硬度,载荷1 N,加载时间15 s。在MM?200型磨损实验机上进行润滑状态下的涂层耐磨性实验,将试样加工成10 mm×13 mm×7 mm大小,对磨件采用d 45 mm的GCr15钢,硬度为HRC62,转速为200 r/min,对磨时间4 h,载荷150 N。

2 结果与讨论

2.1 涂层组织结构

图2所示为HVAF喷涂涂层和LPPS喷涂涂层的表面(SEM)和纵截面光学显微镜(OP)形貌。可以看出,涂层呈现出热喷涂涂层特有的层状结构,由变形的颗粒相互堆积而成。HVAF制备的镍基涂层中存在大量的未熔颗粒,截面观察(腐蚀后)涂层出现明暗交替的区域,由熔融颗粒与部分未熔颗粒组成,出现部分腐蚀孔洞和极少量的Al2O3颗粒。而LPPS制备的镍基涂层无论表面还是截面,喷涂颗粒大多发生熔融变形,且涂层中出现大量的Al2O3颗粒。采用电子探针EPMA分析镍基涂层不同区域的化学成分,在HVAF镍基涂层中未熔区域(灰色)仍保留颗粒的大致形态,其Cr、W含量(Cr 14.74%、W 8.88%)与原始喷涂颗粒的成分基本相似,高于熔融区域(灰白色)的Cr、W含量(Cr 12.03%、W 7.41%)。在LPPS制备的镍基涂层中,涂层颗粒大多呈熔融状,其熔融区域(白色)的Cr、W含量分别为13.07%和7.42%,灰色变形区含少量的Cr、W,棱角分明呈颗粒状的为Al2O3颗粒。

图2 不同热喷涂技术制备的镍基涂层形貌

Fig.2 Morphologies of Ni-base coating deposited by different spraying technologies: (a), (c) SEM images of surface coating; (b), (d) OP photos of cross-section coating (after etch); (a), (b) Deposited by HVAF; (c), (d) Deposited by LPPS

图3所示为两种喷涂技术制备的涂层与原始喷涂粉末的X射线衍射谱。采用HVAF喷涂技术制备的镍基涂层仍保持了原始喷涂粉末的结构,相组成与原始喷涂粉末类似,主要由镍基相组成,出现少量的Ni3B、M23C6、M7C3等相,在2θ为44?附近衍射峰出现宽化,存在少量的非晶相。而采用LPPS技术制备的镍基涂层衍射峰强度明显降低,在2θ为44?附近出现明显的宽化的漫散射峰,无明显的尖锐峰,表明涂层主要由非晶相组成,同时涂层中出现明显的Al2O3衍射峰。

图3 两种工艺制备的涂层及原始喷涂粉末的X射线衍射谱

Fig.3 XRD patterns of spray powder and Ni-base coatings deposited by two spraying technologies: (a) Spray powder; (b) Deposited by HVAF; (c) Deposited by LPPS

2.2 涂层硬度

两种喷涂技术制备的镍基涂层显微硬度分析表明,两种涂层具有不同的硬度。HVAF制备的涂层显微硬度HV介于579~1 089之间,平均值831,最高硬度可达1 089;LPPS制备的涂层显微硬度HV介于488~657之间,平均值559,最高硬度可达657。HVAF制备的镍基涂层由熔融及未熔融的颗粒组成,显微组织为镍相软基体上分布碳化物、硼化物等硬质相构成,其硬度变化较大。整体而言,采用HVAF工艺制备的镍基涂层比LPPS制备的镍基涂层具有更高的显微硬度。

2.3 涂层摩擦磨损特性

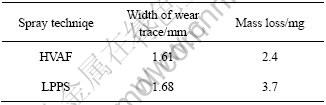

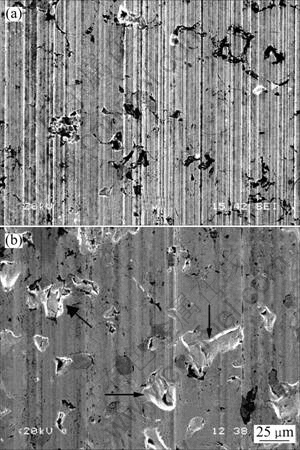

表2所列为两种喷涂技术制备的镍基涂层在润滑状态下150 N载荷下的磨损质量损失,图4所示为两种涂层在润滑状态下的摩擦磨损形貌。从表可知,HVAF喷制的涂层磨痕宽度和磨损后的质量损失均小于LPPS喷制的涂层,显示出较好的耐磨性。从摩擦磨损表面形貌图中可见,两种喷涂技术制备的涂层磨损表面形貌存在明显差异,表明两者占主导地位的磨损机理不同。HVAF涂层磨损表面出现明显的平行擦痕,以犁沟为主,表明其磨损机理主要为磨粒磨损。而LPPS涂层磨损表面除出现少量的犁沟痕迹外,还存在大量的鳞片状的剥落凹坑(如箭头所示),表现出磨粒磨损和疲劳磨损的复合磨损形式。

表2 不同热喷涂技术制备的涂层耐磨实验结果

Table 2 Wear results of coating deposited by different spraying technologies

图4 不同热喷涂技术制备的镍基涂层摩擦磨损的表面 形貌

Fig.4 Surface morphologies of Ni-base coating deposited by different spraying technologies: (a) HVAF; (b) LPPS

3 讨论

在HVAF喷涂过程中由于喷涂温度相对较低,速度快,喷涂颗粒在喷射到基体时大多仍保留了原始喷涂颗粒的形状,少量发生氧化熔融,在镍基软基体上分布了大量弥散的Ni3B、M23C6、M7C3等硬质相,硬质相的弥散分布,增加了涂层硬度,由于喷涂温度较低, Al2O3颗粒未融化,在喷涂过程中撞击到基体后大多作为刚性粒子反弹脱落,极少量沉积在涂层中。而在LPPS过程中喷涂温度高,在真空状态下,氧含量较低,熔融的喷涂颗粒未发生氧化,原始颗粒中镍基固溶体及大量硼化物以及碳化物发生熔融,在撞击到铜基体时,快速凝固形成非晶相,喷涂颗粒熔融非晶化导致涂层硬度降低,同时部分Al2O3颗粒随着熔融颗粒在喷涂过程中沉积到涂层中,从而造成涂层中存在明显的Al2O3颗粒。

镍基涂层在喷涂过程中为较软的镍基体上分布硬质相的耐磨涂层。在润滑状态下的摩擦磨损过程中,HVAF喷涂技术喷制的涂层除部分镍基合金发生熔融外,基本保持原始喷涂颗粒的结构,存在大量弥散分布的硬度高的质点相。硬质相的弥散强化使得涂层难以发生塑性变形,大大提高了涂层的硬度和耐磨性,在载荷的反复作用下,硬质相部分剥落,成为摩擦副之间的磨粒在涂层摩擦表面产生切削犁沟,从而形成以磨粒磨损为主的磨损机理。而LPPS制备的涂层由于喷涂时温度高,镍基合金熔化,在沉积到基体时快速凝固,硬质相熔融分解,涂层发生非晶化,涂层的强化机制主要为固溶强化,涂层硬度偏低。摩擦磨损过程中涂层表面在循环变化的接触应力作用下,表面涂层发生塑性变形,产生脆性剥落,导致涂层表面的疲劳破坏[15],使涂层磨损量明显加大,其磨损机理为磨粒磨损和疲劳磨损结合的复合型磨损,并以疲劳磨损为主。

4 结论

1) HVAF喷涂技术和LPPS喷涂技术制备的镍基涂层具有明显的热喷涂涂层的层状结构,涂层组织致密。HVAF喷涂制备的涂层仍保留原始喷涂颗粒的相组成,在镍基相基础上分布大量的硬质相,出现少量非晶相;LPPS喷涂制备的涂层喷涂颗粒发生明显的熔融,涂层以非晶相为主。

2) 在摩擦磨损实验中,采用HVAF喷涂技术制备的镍基涂层主要以磨粒磨损为主,采用LPPS喷涂技术制备的镍基涂层呈磨粒磨损和疲劳磨损综合的复合型磨损,并以疲劳磨损为主。

REFERENCES

[1] Herman H, Sampath S, Mccune R. Thermal spray: current status and future trends[J]. Material Resource Society Bull, 2000, 25(7): 17?25.

[2] 戴达煌, 周克崧, 袁镇海. 现代材料表面技术科学[M]. 北京: 冶金工业出版社, 2004: 126?148.

DAI Da-huang, ZHOU Ke-song, YUAN Zhen-hai. Surface techqunic science on modern materials[M]. Beijing: Metallurgy Industry Press, 2004: 126?148.

[3] Browing J B. Hypersonic velocity impact fusion spraying[C]// Proc of the 13th ITSC. Orlando, Florida, USA: 1992, 123?125.

[4] Dolatabadi A, Pershin V, Mostaghimi J. New attachment for controlling gas flow in the HVOF process[J]. Journal of Thermal Spray Technology, 2005, 14(1): 91?99.

[5] He J, Ice M, Lavernia E. Particle melting behavior during high-velocity oxygen fuel thermal spraying[J]. Journal of Thermal Spray Technology, 2001, 10(1): 83?93.

[6] Shipway P H, McCartney D G, Sudaprasert T. Sliding wear behaviour of conventional and nanostructured HVOF sprayed WC–Co coatings[J]. Wear, 2005, 259: 820?827.

[7] Otsubo F, Era H, Kishitake K. Structure and phases in nickle-base self-fluxing alloy coating containing high Cromium and Boron[J]. Journal of Thermal Spray Technology, 2000, 9(1): 107?113.

[8] 斯松华, 何宜柱. 离子堆焊合金层组织及磨蚀磨损性能[J]. 焊接学报, 2002, 23(2): 40?42.

SI Song-hua, HE Yi-zhu. Structures and corrosive wear property of alloy coating by ion-solder[J]. Transactions of the China Welding Institute, 2002, 23(2): 40?42.

[9] 丁彰雄, 曾庆健. 自熔合金喷焊层耐磨粒磨损特性[J]. 机械工程材料, 1994, 18(5): 48?51.

DING Zhang-xiong, ZENG Qingjian. Abrasive wear characteristics of self-fluxing alloy spraywelding overlay[J]. Materials for Mechanical Engineering, 1994, 18(5): 48?51.

[10] Rodríguez J, Martín A, Fernández R, et al. An experimental study the wear performance of NiCrBSi thermal spray coatings[J]. Wear, 2003, 255: 950?955.

[11] Sanz A. Tribological behavior of coatings for continuous casting of steel[J]. Surf Coat Technol, 2001, 146/147: 55?64.

[12] Allcock B W, Lavin P A. Novel composite coating technology in primary and conversion industry applications[J]. Surface and Coating Technology, 2003, 163/164: 62?66.

[13] Miguel J M, Guilemany J M, Vizcaina S. Tribological study of NiCrBSi coating obtained by different processes[J]. Tribology International, 2003, 36: 181?187.

[14] Planche M P, Liao H, Normand B, et al. Relationships between NiCrBSi particle characteristics and corresponding coating properties using different thermal spraying process[J]. Surface and Coating Technology, 2005, 200: 1?9.

[15] 温诗铸, 黄 平. 摩擦学原理[M]. 北京: 清华大学出版社, 2002: 302?330.

WEN Shi-zhu, HUANG Ping. Principle of tribology[M]. Beijing: Tsinghua University Press, 2002: 302?330.

基金项目:国家高技术研究发展计划资助项目(2002AA331040)

收稿日期:2007-02-16;修订日期:2007-06-19

通讯作者:伍超群,高级工程师,博士;电话:020-37239421; E-mail: qun95@126.com

(编辑 陈爱华)