文章编号: 1004-0609(2006)05-0786-07

镁合金AZ31B板材热拉深成形工艺参数优化

于彦东1, 2, 李彩霞1

(1. 哈尔滨理工大学 材料科学与工程学院, 哈尔滨 150040;

2. 上海交通大学 轻合金精密成型国家工程中心, 上海 200030)

摘 要: 在不同温度、 不同压边力和不同拉深速度下, 针对厚度为0.8mm的AZ31B镁合金板材的成形性能用有限元分析软件进行模拟与分析。 在25~220℃的温度范围内, 采用直径为140mm的坯料进行冲压成形, 研究成形温度、 拉深速度以及压边力对AZ31B镁合金板成形性能的影响。 结果表明: 成形温度为200℃时的极限拉深比达到了2.8; 成形温度在200℃以下时, 随着成形温度的升高, 镁合金板材的成形性能越来越好, 这证明AZ31B镁合金具有良好的热拉深性能; 此外, 拉深速度和压边力对AZ31B镁合金的拉深成形也有重要影响。

关键词: AZ31B镁合金; 拉深成形; 成形温度; 拉深速度; 压边力; 极限拉深比 中图分类号: TG146.2

文献标识码: A

Optimization of processing parameters for magnesium alloy AZ31B sheets in thermal deep-drawing process

YU Yan-dong1, 2, LI Cai-xia1

(1. School of Materials Science and Engineering,

Harbin University of Science and Technology, Harbin 150040, China;

2. Light Alloy Net Forming National Engineering Research Center,

Shanghai Jiao Tong University, Shanghai 200030, China)

Abstract: To investigate the formability, magnesium alloy AZ31B sheets with thickness of 0.8mm were simulated and analyzed by the finite element analysis software under different temperatures, different blank holder forces and different deep drawing speeds. During the range of 25-220℃, the blank with diameter of 140mm was used to proceed drawing to investigate the influences the forming temperature, deep drawing speed and blank holder force for the formability of magnesium alloy AZ31B sheets. The results show that: the limiting drawing ratio reaches 2.8 when the forming temperature is 200℃, and under 200℃, the higher the forming temperature is, the better of the formability for magnesium alloy sheets is. It is proved that magnesium alloy AZ31B has excellent thermal deep drawing formability. Furthermore the deep drawing speed and the blank holder force have important influences on the deep-drawing process of the magnesium alloy AZ31B sheets.

Key words: magnesium alloy AZ31B; deep drawing forming; forming temperature; deep drawing speed; blank holder force; limiting drawing ratio(LDR)

西方发达国家十分重视变形镁合金的研究与开发, 变形镁合金材料已开始向系列化发展, 产品应用领域不断扩展[1]。 制约变形镁合金发展的主要原因在于其较差的室温塑性变形能力, 如何在较大程度上改善镁合金的塑性已成为人们关注的焦点[2]。 近年来, 随着计算机技术和电子信息技术的飞速发展, 金属薄板冲压成形过程的计算机模拟技术正逐渐从实验室走向实际应用。 通过有限元模拟方法对镁合金进行成形分析, 找出改善其塑性的最佳参数成为一种趋势。

尽管人们对镁合金高温下的变形行为和成形极限进行了研究[3-8], 但有关成形温度、 变形速度以及压边力对镁合金成形性能影响的研究很少[9, 10]。 尹德良等[11]对AZ31镁合金的非等温拉深性能进行了研究, 确定了使AZ31镁合金具有最佳拉深性能的板料和冲头温度范围, 同时得出拉深速度和润滑条件对AZ31镁合金非等温拉深性能有重要影响; 张青来等[12]研究轧制方式对AZ31镁合金薄板组织和性能的影响, 得出交差轧制的AZ31镁合金薄板具有良好的深冲性能, 同时他还研究了AZ31B变形镁合金的压力成形, 总结了AZ31B变形镁合金挤压、 轧制和热冲压拉深的研究工作[13]。

本文作者就成形温度、 冲压速度、 压边力等工艺参数对镁合金板材热拉深成形的影响规律进行了数值模拟分析, 并对成形工艺进行完善及优化, 以期能进一步指导实践。

1 材料参数、 有限元模型的建立及计算中的关键问题

1.1 材料参数和有限元模型的建立

模拟过程中使用的是镁合金AZ31B板材, 厚度为0.8mm, 坯料直径为140mm, 成形温度为200℃, 压边力为8kN, 拉深速度为0.3mm/s。 模拟过程中的工艺参数: 弹性模量E为45GPa, 泊松比ν为0.35。

有限元计算模型如图1所示。 零件几何形状由pro/e软件建立, 直接生成片体, 转化成igs文件导入到有限元分析软件中。 该模型中坯料的有限元网格是用有限元分析软件的自动生成网格命令生成的。 在有限元分析软件中定义凸模、 凹模和压边圈等冲压工具以及毛坯, 并调整它们间的相对位置; 定义拉延和接触类型、 摩擦因数、 冲压速度和压边力等工艺参数; 给毛坯赋予材料和特性数据, 同时定义毛坯边界条件[14]。 模拟过程不考虑坯料与模具间的热交换问题(视为等温问题)。 模拟中涉及的性能参数见表1。

图1 有限元计算模型

Fig.1 Calculation model of finite element

板料塑性成形中主要的质量问题是开裂和起皱两大类缺陷。 开裂本质是拉伸失稳现象, 而起皱本质是板料压缩不稳定现象[15]。 本文将采用动态显式弹塑性有限元分析软件进行模拟及分析, 对镁合金板材的热拉深工艺进行计算机模拟, 通过成形温度、 冲压速度及压边力着重对起皱、 破裂等缺陷进行预测, 以实现相关工艺参数的优化。

1.2 计算中的关键问题

有限元数值模拟可用于分析板料的准静态大变形问题, 它基于增量理论, 采用修正的拉格朗日法来描述应力—应变关系, 运动方程采用中心差分动态显示法对时间进行积分, 能够利用壳单元较准确地模拟成形过程中板料的起皱、 破裂和回弹等变形行为[16, 17]。 由于主要对镁合金轧制板材的热拉深成形过程进行模拟, 因此模拟中选用Barlat-Lian三参数塑性模型作为材料模型, 该模型具体原理如下。

模型中平面应力的各向异性屈服准则定义为

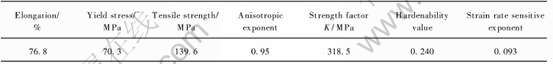

表1 模拟中使用的性能参数

Table 1 Performance parameters in simulation (200℃)

这里σs为屈服应力, Ki=1, 2通过式(2)、 (3)给出:

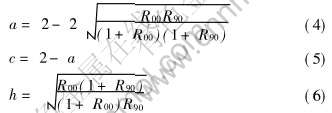

式中 a、 c、 h、 p为材料的各向异性常数, 其中a、 c和h可以由R00、 R45、 R90求出, 见式(4)~(6)。

使用指数应变强化模型, 其等效应力—应变关系为[18]

式中 σ为应力; K为强化系数; ε0为初始屈服应力的应变; εp为塑性应变; n硬化指数。

根据Barlat和Lian准则, 任意角度的宽度与厚度应变比计算如下:

式中 σ为角度方向上的单轴拉伸应力, 式(7)可用于迭代计算p值。

对于面心立方结构(fcc)的材料, 推荐m=8; 对于体心立方结构(bcc)的材料, 推荐m=6。 镁合金是密排六方结构, 对于有限元分析软件来说m为默认值8。 在冲压成形中材料塑性流动的计算依赖于材料的屈服准则和塑性流动准则, 所以, 材料本构关系的合理性及有关计算的准确性, 是直接影响冲压成形过程计算结果可靠性的最重要因素之一[19]。

2 工艺条件对拉深过程的影响

2.1 成形温度对拉深过程的影响

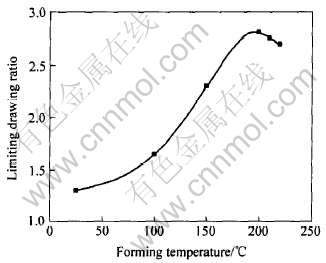

为了定量地确定成形温度对LDR的影响, 在25~220℃范围内, 以恒定的拉深速度0.3mm/s进行了拉深模拟, 得到了不同温度下的极限拉深曲线(见图2)。 可以看到, AZ31B镁合金板的LDR随着温度的上升不断增大, 到200℃达到最大值2.8, 当温度超过200℃例如210℃时, 极限拉深比降低, 但此时的成形性能仍是很好。 这说明在200℃时, 延伸率增加的促进作用与应变硬化能力降低的负面影响达到了平衡[20]。

图2 镁合金板材极限拉深比随温度的变化

Fig.2 Variation of limiting drawing ratio with

forming temperature for magnesium alloy sheet

从图2可以看到, 温度对镁合金板材拉深成形的影响很大, 成形温度在低于200℃时, 随着成形温度的升高, 镁合金板材的极限拉深比越来越大, 成形性能越来越好, 因此, 在实际生产中, 当镁合金板材在200℃以下拉深成形时, 应根据生产需要, 选取尽可能高的成形温度, 以保证镁合金成形件的质量, 使生产顺利进行。

2.2 压边力对拉深过程的影响

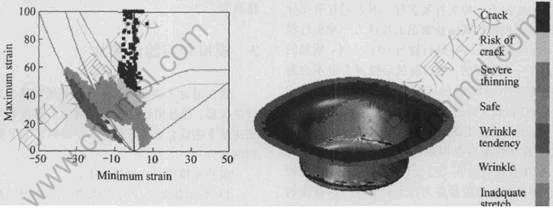

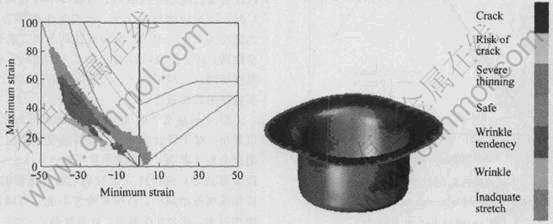

镁合金坯料产生破裂的影响因素较多, 包括成形温度的影响、 压边力的影响及冲压速度的影响等。 其中, 选取合适的压边力对避免缺陷的产生是相当重要的。 通过镁合金拉深件的成形极限图(FLD)也可看出压边力对成形质量的影响。 图3所示为压边力过大时的成形极限图。 此时部分节点超过最上面的一条线也就是破裂线, 拉深件破裂, 如图中最深色部分所示, 其成形件中最深色部分就是与之相对应的破裂部分; 而当压边力选取合理时, 所有节点均位于破裂线的下方, 未出现破裂的危险节点, 如图4所示。

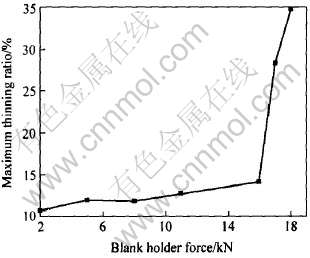

当冲压深度S=40mm时, 镁合金拉深件的最大减薄率随压边力的变化如图5所示。 在所取的深度内, 随着压边力的增大, 镁合金拉深件的最大减薄率增大。 如果压边力选取过大, 将会造成镁合金拉深件危险断面发生过度减薄, 等效应力超过抗拉强度而发生破裂缺陷。 实际工程中认为, 在数值模拟中, 当壁厚减薄量超过25%时, 拉深件已不能应用于生产, 视其为破裂。 可见, 选取合适的压边力对避免缺陷的产生是相当重要的。 通过数值模拟可以发现, 当压边力超过17kN时, 最大减薄率超过了25%, 拉深件产生过度减薄缺陷, 即说明件已破裂。

图3 压边力过大时的成形极限图及所对应的彩条图

Fig.3 Forming limit diagram and

color diagram under excessive blank holder force

图4 压边力选取合理时的成形极限图及所对应的彩条图

Fig.4 Forming limit diagram and

color diagram under appropriate blank holder force

图5 最大减薄率随压边力的变化

Fig.5 Variation of maximum thinning ratio with

blank holder force at punch stroke with 40mm

2.3 冲压速度对拉深过程的影响

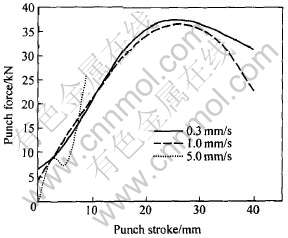

为确定冲压速度对镁合金AZ31B板材拉深的影响, 在200℃的成形温度(凹模温度), 压边力恒为8kN下, 分别采用3种恒定的速度0.3, 1和5mm/s对镁合金板进行拉深模拟。 模拟结果表明: 温度为200℃时, 根据不同速度下镁合金AZ31B的塑变曲线可以看出随着变形速度的增加, 塑变应力要求上升, 另外, 断裂处的应变随着变形速度也增加。

图6所示为在200℃, 拉深40mm时不同拉深速度下的拉深力-冲头行程曲线。 因为用有限元分析软件根据模拟结果所绘制出的拉深力-冲头行程曲线, 在拉深到最后一刻行程为40mm时, 所加的拉深力是一直存在的, 所以到最后拉深力也不会为零。 但从图中可以看出, 在拉深速度分别为0.3mm/s和1mm/s时进行拉深, 坯料均能完全拉进; 而以5mm/s的速度进行拉深时, 拉深力迅速升至27kN, 而导致板料拉深很浅时便发生断裂。 这是由于AZ31B镁合金在200℃时的应变速率强化效应, 使材料的初始屈服应力增加; 同时拉深速度的增加使凸缘的增厚加快, 拉深过程继续进行所需的拉深力迅速增大直至超出凹模圆角处金属材料的承受能力, 造成该处金属过早发生局部流动而失稳断裂[20]。

图6 不同拉深速度下的拉深力—冲头行程曲线

Fig.6 Punch force—punch stroke curves at various punch speeds

3 模拟和实验的对比

现在通过实验和模拟两方面来研究镁合金板料冲压成形, 通过实验得到了不同成形温度和不同冲压速度下的镁合金冲压件, 其中得到了2.8的极限拉深比。

实验和模拟对比结果如下。

1) 不同温度下(25、 100、 150、 200℃)成形件照片的对比如图7所示。 从各成形件可看出, 随着温度的升高, 拉深深度越来越大, 在室温25℃时, 由于温度过低, 导致在拉深初始阶段就发生了断裂; 当温度升到100℃时, 拉深有一定的距离, 此时镁合金已经能拉深成形; 当温度继续升高到150℃时, 拉深深度继续加大, 没有发生断裂等缺陷; 当温度为200℃时, 拉深深度达到最大, 成形件完全拉满, 此时的极限拉深比为2.8。 图8所示为与温度相对应的模拟结果。 从模拟结果可以看出其与实验结果匹配良好。

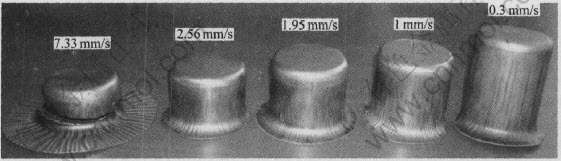

2) 不同速度下的成形照片对比如图9所示。 可以看出, 对于镁合金来说, 拉深速度不能过大, 否则就会发生断裂, 当速度非常小如为0.3mm/s时, 拉深很成功, 成形件完全拉满, 随着速度的增加, 拉深深度逐渐减小, 但拉深速度不能一直增加, 如增加过大, 就会发生断裂, 成为废品。

图7 实验中不同温度下的冲压成形件照片

Fig.7 Drawing components photos under various temperatures in experiment

图8 模拟中不同温度下的冲压成形件照片

Fig.8 Drawing components photos under various temperatures in simulation

图9 实验中不同速度下的冲压成形件照片

Fig.9 Drawing components photos under various speeds in experiment

4 结论

利用通用有限元分析软件对镁合金交叉轧制板材热拉深成形工艺进行了数值模拟分析, 优化的成形工艺参数如下:

1) 成形温度在200℃以下时, 随着成形温度的升高, 镁合金板材的成形性能越来越好, 板材在该温度范围内成形时, 尽可能选取高的成形温度。 一般情况下镁合金的最佳成形温度为200℃, 此时的极限拉深比为2.8。

2) 压边力越大, 镁合金拉深件越易破裂, 为避免破裂缺陷产生, 压边力F〈17kN。

3) AZ31B镁合金对冲压速度具有显著的敏感性。 因此对镁合金AZ31B进行冲压成形时, 冲压速度应该尽可能的小, 否则会导致板料拉深很浅时便发生断裂。

REFERENCES

[1]余琨, 黎文献, 王日初, 等. 变形镁合金的研究、 开发及应用[J]. 中国有色金属学报, 2003, 13(2): 277-288.

YU Kun, LI Wen-xian, WANG Ri-chu, et al. Research, development and application of wrought magnesium alloys[J]. The Chinese Journal of Nonferrous Metals, 2003, 13(2): 277-288.

[2]陈振华, 夏伟军, 程永奇, 等. 镁合金织构与各向异性[J]. 中国有色金属学报, 2005, 15(1): 1-11.

CHEN Zhen-hua, XIA Wei-jun, CHENG Yong-qi, et al. Texture and anisotropy in magnesium alloys[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(1): 1-11.

[3]Watanabe H, Tsutsui H, Mukai T, et al. Deformation Mechanism in a coarse-grained Mg-Al-Zn alloy at elevated temperatures[J]. International Journal of Plasticity, 2001, 17: 387-397.

[4]Shyong L, Chen Y H, Wang J Y. Isothermal sheet formability of magnesium alloy AZ31 and AZ61[J]. Journal of Material Processing Technology. 2002, 124: 19-24.

[5]Doege E, Droder K. Processing of magnesium sheet metals by deep drawing and stretch forming[J]. Mater Tech, 1997(7-8): 19-23.

[6]Kohzu M, Yoshida F, Somekawa H, et al. Fracture mechanism and forming limit in deep-drawing of magnesium alloy AZ31[J]. Mater Trans, 2001, 42 (7): 1273-1276.

[7]Kaneko J, Sugamata M, Numa M. Effect of texture on the mechanical properties and formability of magnesium wrought materials[J]. J Japan Inst Metals, 2002, 64(2): 141-147.

[8]Tozawa Y. Deep drawing of magnesium alloy sheets[J] .J Japan Inst Light Metals, 2001, 51(10): 492-497.

[9]Doege E, Droder K. Sheet metal forming of magnesium wrought alloys-formability and process technology[J]. Journal of Material Processing Technology, 2001(115): 14-19.

[10]Ohwue T, Sekiguchi F, Kikuchi M, et al. Formability of AZ31 magnesium alloy sheets under warm working conditions[J]. J Japan Soc Tech Plasticity, 2001, 42: 246-248.

[11]尹德良, 张凯峰, 吴德忠. AZ31镁合金非等温拉深性能的研究[J]. 材料科学与工艺, 2004, 12(1): 87-89.

YIN De-liang, ZHANG Kai-feng, WU De-zhong. Nonisothermal deep drawability of AZ31 magnesium alloy[J]. Materials Science and Technology, 2004, 12(1): 87-89.

[12]张青来, 卢晨, 朱燕萍, 等. 轧制方式对AZ31镁合金薄板组织和性能的影响[J]. 中国有色金属学报, 2004, 14(3): 391-392.

ZHANG Qing-lai, LU Chen, ZHU Yan-ping, et al. Effect of rolling method on microstructure and properties of AZ31 magnesium alloy thin sheet[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(3): 391-392.

[13]张青来, 李强, 卢晨, 等. AZ31B变形镁合金压力成形[J]. 轻合金加工技术, 2004, 32(1): 30-32.

ZHANG Qing-lai, LI Qiang, LU Chen, et al. Press forming in AZ31B wrought magnesium alloy[J]. Light Alloy Fabrication Technology, 2004, 32(1): 30-32.

[14]DYNAFORM-PC Applications Manual[M]. Engineering Technology Associates, Inc, 1999.

[15]苑世剑, 何祝斌. 板料成形性理论评价与深入研究[J]. 塑性工程学报, 2003, 10(3): 6-8.

YUAN Shi-jian, HE Zhu-bin. An overall review and comprehensive investigation into formability theory of sheet metal forming[J]. Journal of Plasticity Engineering, 2003, 10(3): 6-8.

[16]马占国. 拼焊板方盒件拉深不均匀变形的数值模拟与控制[D]. 呼和浩特: 内蒙古工业大学, 2001.

MA Zhan-guo. The Simulation and control of Non-uniform Deforming for Square Components Drawing of the Jointed Welding Sheets[D]. Huhehaote: Neimenggu Institute of Technology, 2001.

[17]周丽新. 板材零件液压成形及数值模拟[D]. 哈尔滨: 哈尔滨工业大学, 2001.

ZHOU Li-xin. Hydro Forming and Simulation of Sheet Components[D]. Harbin: Harbin Institute of Technology, 2001.

[18]LS-DYNA Keyword Manual[M]. Livermore: Livermore Software Technology Corporation, 1999.

[19]邱晓刚, 卢国清, 陈文龙, 等. 板材成形有限元仿真技术的应用[J]. 钢铁钒钛, 2003, 24(1): 54-60.

QIU Xiao-gang, LU Guo-qing, CHEN Wen-long, et al. Application of finite element analysis and simulation technique to sheet metal forming[J]. Iron Steel Vanadium Titanium, 2003, 24(1): 54-60.

[20]张凯锋, 尹德良, 吴德忠, 等. AZ31镁合金板的热拉深性能[J]. 中国有色金属学报, 2003, 13(6): 1505-1508.

ZHANG Kai-feng, YIN De-liang, WU De-zhong, et al. Deep drawability of AZ31 magnesium alloy sheets at elevated temperatures[J]. The Chinese Journal of Nonferrous Metals, 2003, 13(6): 1505-1508.

[18]Chun B K, Jinn J T, Wu W T. 3-D numerical simulation of sheet metal forming processes using solid element[J]. Numisheet, 2002: 543-548.

基金项目: 哈尔滨市科技攻关资助项目 (2005AA2CG029)

收稿日期: 2005-10-17; 修订日期: 2006-03-21

通讯作者: 于彦东, 教授; 电话: 0451-86392573; E-mail: yandongyu@yahoo.com.cn.

(编辑陈爱华)