热压缩变形对Ni-20Cr-18W-1Mo高温合金碳化物析出行为的影响

来源期刊:中国有色金属学报(英文版)2016年第11期

论文作者:韩寅奔 薛祥义 张铁邦 胡锐 李金山

文章页码:2883 - 2891

关键词:Ni-20Cr-18W-1Mo高温合金;热压缩变形;晶界偏聚;碳化物析出

Key words:Ni-20Cr-18W-1Mo superalloy; hot compression; grain boundary segregation; carbide precipitation

摘 要:采用热模拟试验机、扫描电镜(SEM)和X射线衍射仪(XRD)等手段,研究热压缩变形对Ni-20Cr-18W-1Mo高温合金的元素晶界偏聚和M6C碳化物析出的影响。结果表明,热压缩变形后M6C碳化物含量明显增加;成分分析显示晶界中的M6C碳化物含有高含量的钨元素。同时,经过10%变形后晶界中的二次碳化物尺寸为3~5 μm,而经过900 和 1000 °C时效未变形的合金中晶界二次碳化物尺寸小于1 μm。根据热力学计算结果,γ基体相和碳化物的吉布斯自由能随变形温度升高而降低,富钨的M6C比富铬的M23C6稳定。与实验结果比较发现,压应力加速了钨元素在晶界区域的偏聚速率,进一步增加了富钨的M6C在晶界中的析出速率。

Abstract: The effect of hot compression on the grain boundary segregation and precipitation behavior of M6C carbide in the Ni-20Cr-18W-1Mo superalloy was investigated by thermomechanical simulator, scanning electronic microscope (SEM) and X-ray diffraction (XRD). Results indicate that the amount of M6C carbides obviously increases in the experimental alloy after hot compression. Composition analyses reveal that secondary M6C carbides at grain boundaries are highly enriched in tungsten. Meanwhile, the secondary carbide size of compressive samples is 3-5 μm in 10% deformation degree, while the carbide size of undeformed specimens is less than 1 μm under aging treatment at 900 and 1000 °C. According to the thermodynamic calculation results, the Gibbs free energy of γ-matrix and carbides decreases with increase of the compression temperature, and the W-rich M6C carbide is more stable than Cr-rich M23C6. Compared with the experimental results, it is found that compressive stress accelerates the W segregation rate in grain boundary region, and further rises the rapid growth of W-rich M6C as compared with the undeformed one.

Trans. Nonferrous Met. Soc. China 26(2016) 2883-2891

Yin-ben HAN, Xiang-yi XUE, Tie-bang ZHANG, Rui HU, Jin-shan LI

State Key Laboratory of Solidification Processing, Northwestern Polytechnical University, Xi’an 710072, China

Received 12 May 2016; accepted 30 August 2016

Abstract: The effect of hot compression on the grain boundary segregation and precipitation behavior of M6C carbide in the Ni-20Cr-18W-1Mo superalloy was investigated by thermomechanical simulator, scanning electronic microscope (SEM) and X-ray diffraction (XRD). Results indicate that the amount of M6C carbides obviously increases in the experimental alloy after hot compression. Composition analyses reveal that secondary M6C carbides at grain boundaries are highly enriched in tungsten. Meanwhile, the secondary carbide size of compressive samples is 3-5 μm in 10% deformation degree, while the carbide size of undeformed specimens is less than 1 μm under aging treatment at 900 and 1000 °C. According to the thermodynamic calculation results, the Gibbs free energy of γ-matrix and carbides decreases with increase of the compression temperature, and the W-rich M6C carbide is more stable than Cr-rich M23C6. Compared with the experimental results, it is found that compressive stress accelerates the W segregation rate in grain boundary region, and further rises the rapid growth of W-rich M6C as compared with the undeformed one.

Key words: Ni-20Cr-18W-1Mo superalloy; hot compression; grain boundary segregation; carbide precipitation

1 Introduction

The very high temperature gas-cooled reactor (VHTR) is being developed rapidly as one of the Generation-IV nuclear systems due to its much higher heat-electricity conversion efficiency than current light water reactors (LWRs) [1]. Currently, the outlet temperature of the VHTR has been designed as approximately 750 °C, but follow-up designs raise it to about 950 °C. These conditions are extremely demanding on the materials [2,3]. Nowadays, the Ni-Cr-W-based solid-solution-strengthened superalloys (especially HAYNES 230 alloy) become the primary candidate materials of high temperature components of intermediate heat exchanger (IHX) due to high temperature oxidation and corrosion resistance, excellent creep resistance at elevated temperatures [4-8].

The harsh environment of IHX causes the most vital damage, such as stress corrosion cracking [2] and hot corrosion [9,10], which primarily appear at the grain boundaries and on the surface, respectively. Therefore, much attention has been given to the grain boundaries quality for better service performance of superalloys. In the Ni-Cr-W-based superalloys, carbide is the major precipitate which affects mechanical properties due to its type, shape, size dimension and distribution [11]. For instance, PATAKY et al [12] have indicated that intense carbide-dislocation interactions are observed providing substantial resistance to dislocation motion and the M6C-type carbide has far less interaction with dislocations than the M23C6 carbide. Experimental results in Refs. [13,14] show that the decrease of both tensile and yield strengths of the aged Ni-Cr-W-based superalloy is mainly caused by the breaking of the lamellar M23C6 carbide. XU et al [15] have found that the addition of silicon can rise the dissolved temperature of M6C carbide up to 1335 °C. The silicon-rich M6C carbide particles, which act as cracking origin sites, always account the deterioration of mechanical properties at elevated temperatures. However, W-rich M6C type carbides have been proven to increase the strength and creep resistance at evaluated temperatures by blocking the movement of dislocations effectively and pinning grain boundaries to prevent sliding. It has been proven that the W-rich primary M6C carbides always form during solidification process [16,17] and the secondary M6C carbides form during heat treatment and thermal processing [18-20] in Ni-based superalloys.

Elements segregation at grain boundaries becomes a major factor in affecting mechanical properties of Ni-based superalloys [21]. Previous researches [22,23] have shown that high temperature plastic deformation can induce grain boundary segregation of Cr, Mo and P in an interstitial free steel, and this deformation-induced segregation increases with increasing deformation strain. ALLART et al [24] have indicated that plastic deformation accelerates the kinetics of sulphur grain boundary segregation. For Ni-based superalloys, thermomechanical working plays an important role in the fabricating process of thermostability components. Different components of Ni-based superalloys are generally fabricated by hot forging, hot rolling, and extrusion. Hence, it is necessary to study grain boundary segregation of Ni-based superalloys during hot deformation process. It is expected to illustrate the effect of grain boundary segregation on the carbide precipitation behavior and mechanical properties of Ni-based superalloys.

The present work aims to illustrate the deformation- induced grain boundary segregation in a solid-solution- strengthened Ni-20Cr-18W-1Mo superalloy. The effect of deformation conditions including temperature and deformation degree on grain boundary segregation of W and Cr elements was investigated by isothermal compression tests and deliberately focused on low levels of deformation (2.5% to 10%) to avoid dynamic recrystallization. The comparison of experimental data and thermodynamics calculation was discussed to illustrate the deformation effect on carbide precipitations at the serviceability temperature in nuclear power field.

2 Experimental

A nominal Ni-20Cr-18W-1Mo alloy was melted in the vacuum induction melting (VIM) furnace (with 1.3 MPa pressure) and remelted twice by vacuum arc remelting (VAR). The mass of the ingot was around 30 kg. The chemical composition of the alloy (mass fraction, %) was 19.82 Cr, 18.48 W, 1.24 Mo, 0.46 Al, 0.11 C, 0.0028 B, (0.026) La, <0.004 P, <0.004 S and balance Ni. The cast ingot was homogenized at 1200 °C for 24 h with furnace cooling and then hot forged and rolled at 1150 °C. Hot-rolled sheet with 10 mm in thickness was solution-annealed at 1260 °C for 0.5 h, followed by water quenching (WC). Cylindrical specimens of 8 mm in diameter and 12 mm in height were machined from the hot-rolled sheet. The isothermal compression tests were carried out on a Gleeble-3500 thermomechanical simulator with a constant strain rate of 10-4 s-1 at 900 and 1000 °C. The temperature control was within ±1 °C in the strain range of 2.5%-10%. All the specimens were heated at a heating rate of 20 °C/s and held for 30 s to secure temperature uniformity prior to deformation. Deformation conditions such as temperature and displacement velocity were automatically controlled by a computer system. The relevant data such as true stress and strain were also automatically recorded. The adiabatic temperature rise in the specimen during testing was measured by a thermocouple wire embedded in a 0.8 mm hole machined up to the center at mid-height of the specimen. In order to reduce the friction, a tantalum sheet was applied to specimen surface to ensure sufficient lubrication during each test. All the tests were carried out in high vacuum (133.322 mPa). After isothermal compression, the deformed specimens were quenched to room temperature immediately by water quenching.

The specimens for microstructure observation were sectioned parallel to the compression axis, and metallographic samples were prepared by standard metallographic techniques and the polished specimens were etched with aqua regia (V(HCl):V(HNO3)=3:1) for 60 s to reveal the microstructure. Microstructures were examined by a scanning electron microscope (SEM, Vega Tescan) equipped with an energy dispersive spectrometer (EDS, Oxford INCA PentaFET×3). The phase composition of this alloy was analyzed by DX-2700 X-ray diffraction (XRD) with a Cu Kα radiation source. Voltage and current were 40 kV and 30 mA, respectively. Rietveld method [25] based on the XRD patterns was used for qualitative and quantitative phase analyses. The full spectrum fitting was carried out to obtain a easy quantitative phase analysis by Rietveld refinement.

3 Results and discussion

3.1 Microstructure

3.1.1 Microstructure before thermal deformation

Figure 1 illustrates the SEM image of as-rolled Ni-20Cr-18W-1Mo alloy in the solution-annealed condition. The as-rolled microstructure preserves an average grain size of 60 to 70 μm. The plate-like and globular shaped primary carbides (bright color in SEM image in Fig. 1), which are typically fine with an average size below 10 μm, distributed randomly within the grain. In previous studies, these carbides have been proven as the primary W-rich M6C-type carbide in the form of Ni3W3C through TEM/SAD and EDS analyses [14,20,26]. Most of grain boundaries were observed to be straight or smoothly curved in their morphology and a low fraction of carbide precipitations along grain boundaries (see Figs. 1(a)). EDS analysis as shown in Figs. 1(b) indicates that carbide is rich in W element, with the composition of 9.39% Cr, 62.36% W, 14.87% Ni and 9.56% C (mass fraction). The EDS analysis further gives evidence that the particles are M6C carbide rich in W element.

Fig. 1 Low-magnification SEM image (a) and EDS data (b) of precipitate phase of as-rolled Ni-20Cr-18W-1Mo alloy in solution-annealed condition

Fig. 2 SEM images of Ni-20Cr-18W-1Mo alloy after 2.5% (a), 5% (b) and 10% (c) thermal deformation at 900 °C and carbide volume fraction statistics in deformed specimen at 900 °C (d)

3.1.2 Microstructure evolution during thermal deformation at 900 °C

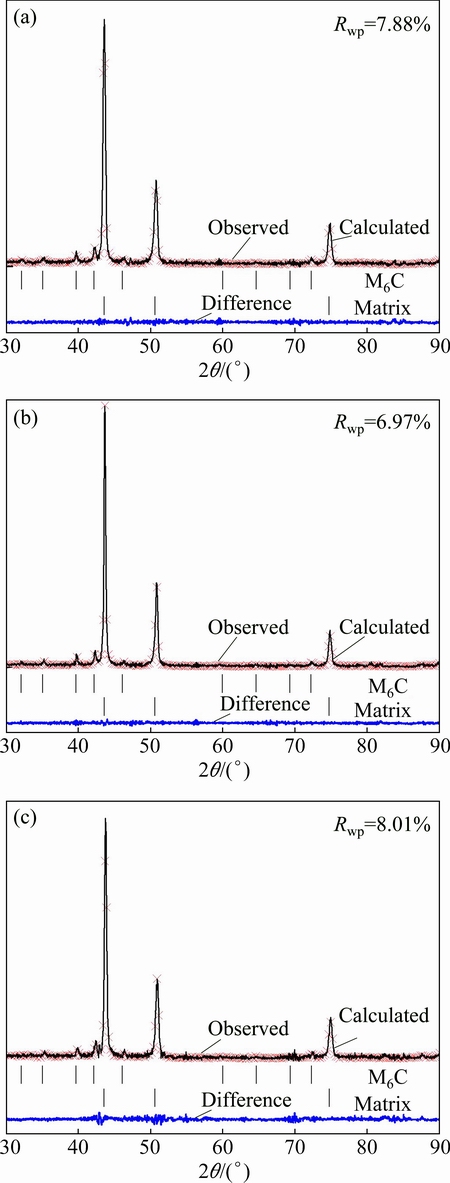

After thermal deformation at 900 °C, microstructure changes of different strains are observed as shown in Fig. 2. The precipitation is not significantly altered after low deformation strain (2.5%). The gray color granular precipitation of the carbides in Figs. 2(b) and (c) is observed at grain boundaries as well as within grains. In order to compare the amount of carbide, five regions from the deformed and undeformed specimen are randomly chosen and the area fraction of the carbide particles is calculated. The carbide volume fraction is significantly altered as shown in Fig. 2(d). It is obvious that the carbide volume fraction increases with the deformation strain increasing. When the deformation strain reaches 10%, the carbide volume fraction is about 6.5%. It has been shown that the volume fraction of carbide in HAYNES 230 alloy increases from 4% to 8% after aging at 900 °C for 20000 h [27]. This indicates that deformation of Ni-Cr-W-based superalloy can produce the similar amount carbide precipitation with the specimen which experiences long term aging at 900 °C. XRD analyses have been performed to identify the phases of Ni-20Cr-18W-1Mo alloy at 900 °C. Rietveld refinements for XRD patterns of different thermal deformations at 900 °C are presented in Fig. 3. Only Bragg peaks of M6C and γ-matrix can be observed in each sample. For different thermal deformations at 900 °C, the volume fractions of M6C-type carbides are ~5.2%, ~5.7% and ~6.3%, respectively. Clearly, there is quite a reasonable fit between XRD and SEM results. BAI et al [20] have reported that M6C carbides in Ni-20Cr-18W-1Mo alloy decompose dramatically into M23C6 carbides between 800 and 900 °C. After the hot compression at 900 °C, the amount of M6C-type carbides increases. This suggests that increase of M6C carbide volume fraction is associated with the effect of compressive deformation.

Fig. 3 XRD patterns for deformed samples of Ni-20Cr- 18W-1Mo alloy after 2.5% (a), 5% (b) and 10% (c) thermal deformation at 900 °C (Rwp is the reliability factor of Rietveld refinment)

3.1.3 Microstructure evolution during thermal deformation at 1000 °C

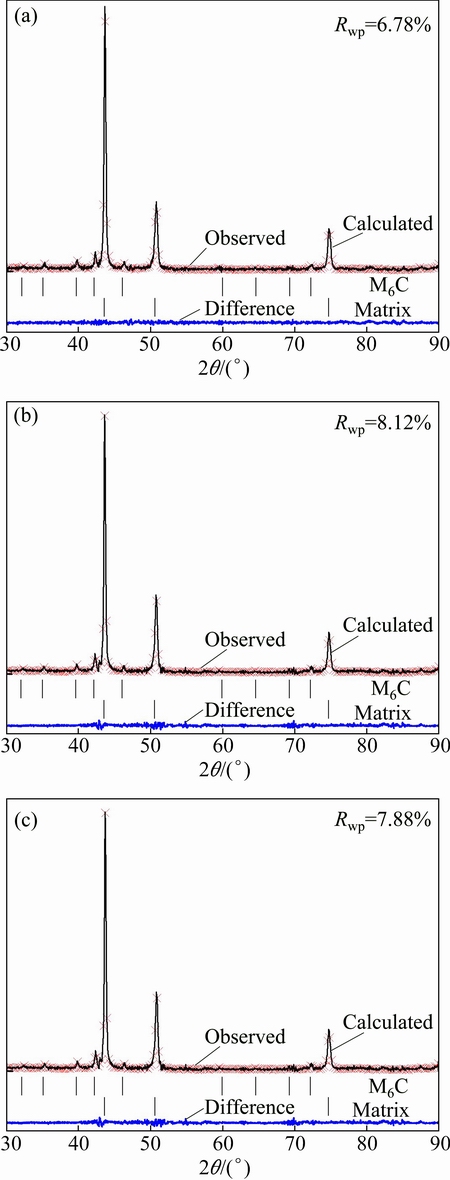

Microstructures of Ni-20Cr-18W-1Mo alloy after three different deformation degrees at 1000 °C are shown in Fig. 4. Like those after deformation at 900 °C, the volume fraction of precipitation also increases with the deformation strain increasing. With the deformation strain from 2.5% to 5%, the morphology of the granular carbides at grain boundary agglomerated changes into plate-like shape. When the deformation strain reaches 10%, the plate-like precipitate is broken and a lot of smaller carbide particles emerge near the large carbides. The carbide volume fraction is shown in Fig. 4(d). It is obvious that the volume fraction increases from 5.0% to 7.0 % with increasing the deformation strain. XRD patterns (Fig. 5) also indicate that M6C-type carbides are the major precipitate under different deformation conditions at 1000 °C. For different thermal deformations at 1000 °C, the volume fractions of M6C-type carbides are ~5.0%, ~5.8% and ~7.0%, respectively. There is quite a reasonable fit between XRD and SEM results. The corresponding data were taken from JCPDS card #01-089-4883.

3.2 Stress-strain curves

To illustrate the flow behavior of the present superalloy, true stress-true strain curves at deformation temperatures ranging from 900 to 1000 °C and deformation degrees ranging from 2.5% to 10% are given in Fig. 6. All shapes of true stress-true strain curves are sensitive to deformation degree and testing temperature. The stress exhibits an initial increase with the strain. With the increase of temperature, the stress level decreases significantly. It is obvious that the characteristics of the true stress-true strain curves are similar. As can be seen from Fig. 6, the work hardening effect plays a dominant rule so that stress increases very fast. The initial rapid rise of stress is associated with the increase of dislocation density. Dynamic recovery proceeded slowly in the alloys with low or intermediate stacking fault energy, such as nickel or stainless steel [28]. Figure 6 shows that the stress of the Ni-based superalloy decreases with the increasing temperature of deformation. Since the strain is very small (from 0.025 to 0.105), stress increases rapidly with the increase of strain, and it does not reach the peak value. At 900 °C, the stress (10% deformation degree) can be up to 231 MPa and the stress is 125 MPa when the temperature is 1000 °C. The former is about 2 times of the latter. This phenomenon is due to the fact that the increase of deformation temperature accelerates the dislocation annihilation, inducing the decrease of deformation resisting force [28].

Fig. 4 SEM images of Ni-20Cr-18W-1Mo alloy after 2.5% (a), 5% (b) and 10% (c) thermal deformation at 1000 °C and carbide volume fraction statistics in deformed specimen at 1000 °C (d)

3.3 Quantitative analysis of grain boundary segregation

The present results show that the volume fraction of the W-rich M6C carbide increases after a compressive deformation below 10%. The mechanism for the precipitation of secondary M6C at grain boundary is suggested to be through a direct reaction: 6M+C→M6C [26]. Since M is rich in W, the phase transformation can also be triggered by the agglomeration of the W atoms from γ-matrix. According to the aforementioned results [14], the reaction of M23C6 carbides precipitation is described as 23M+6C→M23C6, M is rich in Cr, M may include some other elements such as W and Mo. Therefore, both secondary M6C and M23C6 carbides’ precipitations can be considered as the results of the transformation from γ to carbide.

In order to understand the effect of compressive deformation on the segregation of elements, Gibbs free energy and enthalpy of the phases in this alloy at different temperatures have been evaluated with the CALPHAD method. The main models used in the present work are the substitutional type model [29], which can broadly be represented by the general equation for a phase:

(1)

(1)

where △GΘ is the free energy of the phase in its pure form,  is the ideal mixing term and

is the ideal mixing term and  is the excess free energy of mixing of the components.

is the excess free energy of mixing of the components.

The free energy of the substitutional model (△Gm) for a many component system can be represented by the equation as follows:

(2)

(2)

where Xi is the mole fraction of component i,  defines the free energy of the phase in the pure component i, T is the temperature, R is the mole gas constant, Ωv is an interaction coefficient depending on the value of v. When v=0, it corresponds to the regular solution model, and when v=0 and 1, it corresponds to the sub-regular model. In practice, the value for v does not usually rise above 2. The JMatPro simulation results (Fig. 7) indicate that the Gibbs free energy of γ and carbides decreases with temperature increasing. It can be concluded that the stability of the γ and carbides is improved with temperature increasing in Ni-20Cr- 18W-1Mo alloy. Compared with the Gibbs free energy of M6C and M23C6 carbides, W-rich M6C carbide is more likely to precipitate at grain boundary at 900 and 1000 °C.

defines the free energy of the phase in the pure component i, T is the temperature, R is the mole gas constant, Ωv is an interaction coefficient depending on the value of v. When v=0, it corresponds to the regular solution model, and when v=0 and 1, it corresponds to the sub-regular model. In practice, the value for v does not usually rise above 2. The JMatPro simulation results (Fig. 7) indicate that the Gibbs free energy of γ and carbides decreases with temperature increasing. It can be concluded that the stability of the γ and carbides is improved with temperature increasing in Ni-20Cr- 18W-1Mo alloy. Compared with the Gibbs free energy of M6C and M23C6 carbides, W-rich M6C carbide is more likely to precipitate at grain boundary at 900 and 1000 °C.

Fig. 5 XRD patterns for deformed samples of Ni-20Cr-18W-1Mo alloy after 2.5% (a), 5% (b) and 10% (c) thermal deformation at 1000 °C

Fig. 6 True stress-true strain curves at strain rate of 1.0×10-4 s-1 after different deformation degrees at 900 °C (a) and 1000 °C (b)

Fig. 7 Gibbs free energy of γ and carbides in Ni-Cr-W alloy at different temperatures

Fig. 8 Enthalpy of γ and carbides in Ni-Cr-W alloy at different temperatures

The volume raise of W-rich M6C carbide under compressive deformation condition can be understood in terms of transformation of γ→M6C and the differences in densities of atomic packing of the γ and M6C carbides. The lattice parameters of the γ and M6C phases at room temperature are estimated to be a=3.58  for the γ phase and a=11.17

for the γ phase and a=11.17  for the M6C carbide based on JCPDS files, respectively. Also, BAI et al [14] have found the lattice constant of M23C6 carbide is 10.89

for the M6C carbide based on JCPDS files, respectively. Also, BAI et al [14] have found the lattice constant of M23C6 carbide is 10.89  which is similar to that of M6C carbide. The volume difference between the γ and carbide phases can be calculated by

which is similar to that of M6C carbide. The volume difference between the γ and carbide phases can be calculated by

(3)

(3)

Because the elastic modulus of Ni-20Cr-18W- 1Mo alloy is as high as 210 GPa [30], high internal stress concentration and high strain energy will be induced the γ→carbide transformation. This stress and strain energy cannot be relieved during the hot compression, and the total Gibbs energy will increase correspondingly. Therefore, element W segregation at grain boundary region is accelerated by the increased energy, and the γ→carbide transformation is facilitated during hot compression. The Clausius-Clapeyron relation describes the pressure-dependant equilibrium of the phases with different cell volumes, and the equation is expressed as [31]

(4)

(4)

where Δp, ΔTeq, ΔH, ΔV correspond to the change in the pressure, the temperature, the enthalpy and the volume, respectively. According to Eq. (3), the cell volume of M6C is greater than that of γ matrix ( ), the cell volume of M23C6 has approximate value of M6C carbide (

), the cell volume of M23C6 has approximate value of M6C carbide ( ). The change in enthalpy of γ to carbides transformation is shown in Fig. 8, the calculated result is

). The change in enthalpy of γ to carbides transformation is shown in Fig. 8, the calculated result is  and

and  at 900 and 1000 °C. The (△p/△T) can be referred to be negative, which indicates that an increase in pressure causes the decrease of transformation temperature. Since the enthalpy of γ to M6C transformation is larger than that of M23C6 (

at 900 and 1000 °C. The (△p/△T) can be referred to be negative, which indicates that an increase in pressure causes the decrease of transformation temperature. Since the enthalpy of γ to M6C transformation is larger than that of M23C6 ( ), the change in the temperature can be derived as

), the change in the temperature can be derived as  . Therefore, under compressive stress, the γ→M6C transformation causing carbide volume increasing occurs preferentially at 900 and 1000 °C. Meanwhile, the compressive stress accelerates the γ→M6C transformation.

. Therefore, under compressive stress, the γ→M6C transformation causing carbide volume increasing occurs preferentially at 900 and 1000 °C. Meanwhile, the compressive stress accelerates the γ→M6C transformation.

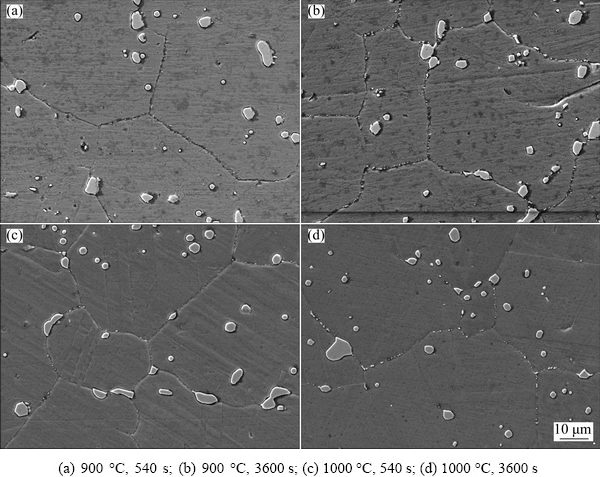

In order to illustrate the relationship between compressive stress and carbide precipitation, we introduced a parallel test. The undeformed specimens were held at 900 and 1000 °C for 280, 540 and 1080 s, respectively. The heat-treated time of undeformed specimens corresponds to that of deformed samples. Samples after 3600 s aging treatment have been added to illustrate the effect of temperature on carbide precipitation at 900 and 1000 °C. The result is shown in Fig. 9, showing the micrographs of as-aged Ni-20Cr- 18W-1Mo alloy in undeformed condition. As shown in Figs. 9(a) and (c), the samples aged for a long time have approximate precipitation volume comparing with that of the specimens aged for a short aging time. The secondary precipitation size of undeformed samples is less than 1 μm in all conditions. However, from Fig. 2 and Fig. 4, the secondary precipitation size of deformed samples is 3 to 5 μm. By comparing Figs. 2(d), 4(d) and Fig. 10, it can be found that the grain boundary precipitation volume for the undeformed simples is less than that for the compressive deformed ones both at 900 and 1000 °C. The temperature range for the secondary M6C formation is reported from 850 to 1210 °C, and the best precipi- tation temperature range is from 950 to 1100 °C [32]. At the elevated temperature, the secondary M6C has a granular morphology at grain boundary and its precipitation rate depends on the assembling, coarsening and fusing of carbide particles. Above all, stress-induced phase transformation can be confirmed at elevated temperature and the stress provides a profuse supply of energy to accelerate the carbide growth rate at grain boundaries.

4 Conclusions

1) After compression at 900 and 1000 °C with different deformation degrees, extensive precipitation of the secondary W-rich M6C carbides is observed at the grain boundaries. In addition, the carbide volume fraction increases with the deformation degree increasing.

2) The grain boundary precipitation volume for the undeformed simples is less than that for the compressive deformed ones both at 900 and 1000 °C. Also, the secondary precipitation size of undeformed samples is less than that of deformed ones in all experimental conditions.

3) Stress-induced phase transformation can be confirmed and the stress provides energy to accelerate the carbide growth rate at grain boundaries.

Fig. 9 SEM images of Ni-20Cr-18W-1Mo alloy after aging treatment at different temperatures

Fig. 10 Carbide volume fraction statistics in undeformed specimen

References

[1] HAYNER G O, BRATTON R L, MIZIA R E, WINDES W E, CORWIN W R, BURCHELL T D. Next generation nuclear plant materials research and development program plan [R]. Idaho: Idaho National Laboratory, 2006.

[2] ZINKLE S J, WAS G S. Materials challenges in nuclear energy [J]. Acta Materialia, 2013, 61: 735-758.

[3] TUNG H M, MO K, STUBBINS J F. Biaxial thermal creep of Inconel 617 and Haynes 230 at 850 and 950 °C [J]. Journal of Nuclear Materials, 2014, 447: 28-37.

[4] YOON J G, JEONG H W, YOO Y S, HONG H U. Influence of initial microstructure on creep deformation behaviors and fracture characteristics of Haynes 230 superalloy at 900 °C [J]. Materials Characterization, 2015, 101: 49-57.

[5] PATAKY G J, SEHITOGLU H, MAIER H J. Creep deformation and mechanisms in Haynes 230 at 800 °C and 900 °C [J]. Journal of Nuclear Materials, 2013, 443: 484-490.

[6] KIM D, SAH I, JANG C. Effects of high temperature aging in an impure helium environment on low temperature embrittlement of Alloy 617 and Haynes 230 [J]. Journal of Nuclear Materials, 2010, 405: 9-16.

[7] BOEHLERT C J, LONGANBACH S C. A comparison of the microstructure and creep behavior of cold rolled HAYNES 230 alloy and HAYNES 282 alloy [J]. Materials Science and Engineering A, 2011, 528: 4888-4898.

[8] CHIEN F R, BROWN R. Cyclic oxidation of Haynes-230 alloy [J]. Journal of Materials Science, 1992, 27: 1514-1520.

[9] ZHANG Tie-bang, DONG Rui-feng, HU Rui, KOU Hong-chao, LI Jin-shan. Hot corrosion characteristics of Ni-20Cr-18W superalloy in molten salt [J]. Transactions of Nonferrous Metals Society of China, 2015, 25: 3840-3846.

[10] YUAN Liang, HU Rui, ZHANG Tie-bang, LI Jin-shan, ZHANG Xiao-qing. Oxidation behavior of Hastelloy C-2000 superalloy at 800 °C and 1000 °C [J]. Transactions of Nonferrous Metals Society of China, 2015, 25: 354-362.

[11] XIE Jun, YU Jin-jiang, SUN Xiao-feng, JIN Tao. Thermodynamics analysis and precipitation behavior of fine carbide in K416B Ni-based superalloy with high W content during creep [J]. Transactions of Nonferrous Metals Society of China, 2015, 25: 1478-1483.

[12] PATAKY G J, SEHITOGLU H, MAIER H J. High temperature fatigue crack growth of Haynes 230 [J]. Materials Characterization, 2013, 75: 69-78.

[13] HU R, BAI G, LI J, ZHANG J, ZHANG T, FU H. Precipitation behavior of grain boundary M23C6 and its effect on tensile properties of Ni-Cr-W based superalloy [J]. Materials Science and Engineering A, 2012, 548: 83-88.

[14] BAI G, LI J, HU R, TANG Z, XUE X, FU H. Effect of temperature on tensile behavior of Ni-Cr-W based superalloy [J]. Materials Science and Engineering A, 2011, 528: 1974-1978.

[15] XU Z, JIANG L, DONG J, LI Z, ZHOU X. The effect of silicon on precipitation and decomposition behaviors of M6C carbide in a Ni-Mo-Cr superalloy [J]. Journal of Alloys and Compounds, 2015, 620: 197-203.

[16] TAWANCY H, KLARSTROM D, ROTHMAN M. Development of a new nickel-base superalloy [J]. Journal of Metals, 1984, 36: 58-62.

[17] ZHENG L, GU C Q, ZHENG Y R. Investigation of the solidification behavior of a new Ru-containing cast Ni-base superalloy with high W content [J]. Scripta Materialia, 2004, 50: 435-439.

[18] LIU L R, JIN T, ZHAO N R, SUN X F, GUAN H R, HU Z Q. Formation of carbides and their effects on stress rupture of a Ni-base single crystal superalloy [J]. Materials Science and Engineering A, 2003, 361: 191-197.

[19] YANG J X, ZHENG Q, SUN X F, GUAN H R, HU Z Q. Topologically close-packed phase precipitation in a nickel-base superalloy during thermal exposure [J]. Materials Science and Engineering A, 2007, 465: 100-108.

[20] BAI G, LI J, HU R, ZHANG T, KOU H, FU H. Effect of thermal exposure on the stability of carbides in Ni-Cr-W based superalloy [J]. Materials Science and Engineering A, 2011, 528: 2339-2344.

[21] HAN Y B, XUE X Y, ZHANG T B, HU R, LI J S. Grain boundary character correlated carbide precipitation and mechanical properties of Ni-20Cr-18W-1Mo superalloy [J]. Materials Science and Engineering A, 2016, 667: 391-401.

[22] CHEN X M, SONG S H. Plastic deformation-induced phosphorus segregation to ferrite grain boundaries in an interstitial free steel [J]. Materials Science and Engineering A, 2010, 527: 7580-7584.

[23] CHEN X M, SONG S H, WENG L Q, LIU S J. Solute grain boundary segregation during high temperature plastic deformation in a Cr-Mo low alloy steel [J]. Materials Science and Engineering A, 2011, 528: 7663-7668.

[24] ALLART M, CHRISTIEN F, LE GALL R. Ultra-fast sulphur grain boundary segregation during hot deformation of nickel [J]. Acta Materialia, 2013, 61: 7938-7946.

[25] RIETVELD H M. A profile refinement method for nuclear and magnetic structures [J]. Journal of Applied Crystallography, 1969, 2: 65-71.

[26] ZHANG J Q, HU R, WANG J, LI J S. Secondary M6C precipitation in Ni-20Cr-18W-1Mo superalloy [J]. International Journal of Innovative Technology and Exploring Engineering, 2013, 3: 48-51.

[27] LEE H J, KIM H, KIM D, JANG C. Microstructure evolution of a Ni-Cr-W superalloy during long-term aging at high temperatures [J]. Materials Characterization, 2015, 106: 283-291.

[28] WANG K, LI M Q, LUO J, LI C. Effect of the delta phase on the deformation behavior in isothermal compression of superalloy GH4169 [J]. Materials Science and Engineering A, 2011, 528: 4723-4731.

[29] ANSARA I. Comparison of methods for thermodynamic calculation of phase diagrams [J]. International Materials Reviews, 1979, 24: 20-53.

[30] TANG Z, LI J, HU R, YAO C. Study on properties of solid solution nickel-based superalloy Ni-20Cr-18W-Mo [J]. Materials Review, 2012, 26: 1-4.

[31] BOLES M A, CENGEL Y A. Thermodynamics: An engineering approach [M]. 5th ed. New York: Mc Graw-Hill, 2006.

[32] ZHENG Yun-rong, ZHANG De-tang. Color metallographic investigation of superalloys and steels [M]. Beijing: Beijing National Defense Industry Press, 1999. (in Chinese).

韩寅奔,薛祥义,张铁邦,胡 锐,李金山

西北工业大学 凝固技术国家重点实验室,西安 710072

摘 要:采用热模拟试验机、扫描电镜(SEM)和X射线衍射仪(XRD)等手段,研究热压缩变形对Ni-20Cr-18W-1Mo高温合金的元素晶界偏聚和M6C碳化物析出的影响。结果表明,热压缩变形后M6C碳化物含量明显增加;成分分析显示晶界中的M6C碳化物含有高含量的钨元素。同时,经过10%变形后晶界中的二次碳化物尺寸为3~5 μm,而经过900 和 1000 °C时效未变形的合金中晶界二次碳化物尺寸小于1 μm。根据热力学计算结果,γ基体相和碳化物的吉布斯自由能随变形温度升高而降低,富钨的M6C比富铬的M23C6稳定。与实验结果比较发现,压应力加速了钨元素在晶界区域的偏聚速率,进一步增加了富钨的M6C在晶界中的析出速率。

关键词:Ni-20Cr-18W-1Mo高温合金;热压缩变形;晶界偏聚;碳化物析出

(Edited by Xiang-qun LI)

Foundation item: Project (51171150) supported by the National Natural Science Foundation of China

Corresponding author: Tie-bang ZHANG; Tel: +86-29-88491764; Fax: +86-29-88460294; E-mail: tiebangzhang@nwpu.edu.cn

DOI: 10.1016/S1003-6326(16)64417-5