DOI: 10.11817/j.ysxb.1004.0609.2021-37772

钴基高温合金GH5605热压缩变形行为

张 兵1, 3,赵芬芬1, 3,陈韩锋2,杨 艳2,马艳恒1, 3,祁 凯1, 3

(1. 西安建筑科技大学 冶金工程学院,西安 710055;

2. 金川集团股份有限公司,镍钴资源综合利用国家重点实验室,金昌 737100;

3. 功能材料加工国家地方联合工程研究中心,西安 710055)

摘 要:利用Gleeble-3500热模拟试验机对真空感应(VIM)+电渣重熔(ESR)所得的GH5605合金铸锭进行热压缩实验,研究其在变形温度为 950~1200 ℃、应变速率为0.001~10 s-1、真应变为0.65时的热变形行为。结果表明:铸态GH5605合金的真应力-应变曲线属于加工硬化+动态回复型,分为3个阶段,即Ⅰ剧烈加工硬化阶段、Ⅱ平缓加工硬化阶段、Ⅲ稳态流变阶段。建立的Arrhenius本构方程相关系数(Rr)和平均相对误差(δ)分别为0.95和11.99%,结合热加工图和变形组织分析得出GH5605合金良好的加工区域为变形温度1055~1200 ℃、应变速率0.01~0.1 s-1。

关键词:钴基高温合金;热变形行为;本构模型;热加工图;显微组织

文章编号:1004-0609(2021)-04-0879-11 中图分类号:TG132.3 文献标志码:A

引文格式:张 兵, 赵芬芬, 陈韩锋, 等. 钴基高温合金GH5605热压缩变形行为[J]. 中国有色金属学报, 2021, 31(4): 879-889. DOI: 10.11817/j.ysxb.1004.0609.2021-37772

ZHANG Bing, ZHAO Fen-fen, CHEN Han-feng, et al. Hot compression deformation of cobalt-based superalloy GH5605[J]. The Chinese Journal of Nonferrous Metals, 2021, 31(4): 879-889. DOI: 10.11817/j.ysxb.1004.0609.2021-37772

钴基高温合金在高温具有优良的稳定性和高强度,广泛应用于航空发动机的涡轮叶片及内部的导向叶片,又因其良好的生物相容性,在生物医学领域也备受关注[1-6]。GH5605合金是以20Cr、15W固溶强化的非磁性钴基高温合金,主要用于制造发动机导向叶片、涡轮外环、外壁、涡流器、封严片等零部件,国内外成分相近的有:L605,HS25,WF-11,ASTM F90,KC20WN[3, 7]。这些零件一旦发生故障,会带来非常严重的后果及损失,因而对GH5605合金进行热变形行为进行研究具有重要意义。

目前,对GH5605合金的研究主要集中在添加合金元素和热处理工艺对组织演变、析出相及热拉伸变形等方面的影响。裴丙红[8]研究了热处理工艺对GH5605合金碳化物组织分布的影响,采用含量中上限(0.12%)控制C元素,合金的室温性能和持久性能都能满足标准要求,其最佳固溶处理工艺参数为1230 ℃、60 min、水冷。FAVRE等[3, 9]采用平均场模型结合逆向工程方法研究了L605合金高温变形过程中的组织演变,在高温(>1100 ℃)和低应变速率(应变速率<0.1 s-1)下,动态再结晶会使晶粒从开始的100 μm细化到10 μm。NARUSHIMA等[10]探讨了在600~1450 ℃温度区间,C、N、Mn等微量合金元素对ASTM F90合金析出相的影响,发现在600~1000 ℃范围内,析出相为M23X6相;在1000~1450 ℃范围内,析出相为η相。SAMII等[11]研究了Nb对铸态HS25合金在950~1200 ℃温度范围内热拉伸变形行为的影响,发现Nb在合金中因形成NbC,从而提高了基体强度和伸长率,且材料在高温时(>1050 ℃)发生动态再结晶,在低温仅发生了动态回复。

材料热变形行为取决于变形温度、应变速率和变形程度等工艺参数[12],ZHANG等[13]研究了镍基高温合金GH4698合金在不同工艺参数下的热变形行为,分析了真应力-真应变曲线,在Arrhenius本构方程的基础上,建立了锻态GH4698合金的本构模型。宫润燕[14]研究了GH4169合金的高温变形行为,表明动态再结晶是合金高温塑性变形过程中的主要软化机制,并利用有限元数值模拟对合金叶片挤压、轧制过程进行模拟,结果表明GH4169合理的挤压工艺参数为:变形温度为1040 ℃、摩擦因数0.3、上模下压速度200 mm/s。LI等[15]研究了在恒定和阶梯应变速率下,时效镍基高温合金在热压缩变形过程中的组织演变,发现不连续动态再结晶和连续动态再结晶在恒定和阶梯应变速率下均会发生,其中不连续动态再结晶是主要的形核机制。

本文通过热压缩实验研究铸态GH5605合金在不同条件下的热变形行为,分析热变形过程中的真应力-真应变曲线,基于Arrhenius本构方程,建立了铸态GH5605合金热变形过程中的本构模型并绘制热加工图,结合变形后的微观组织,选定最佳加工工艺参数,为GH5605合金的热加工工艺参数优化提供数据支撑。

1 实验

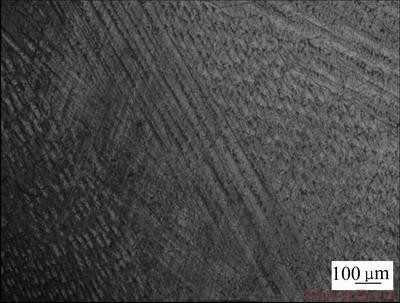

实验材料为真空感应及电渣重熔(VIM+ESR) GH5605合金铸锭(d 120 mm),化学成分见表1,其原始铸态组织形貌呈现出紧密分布的枝晶(如图1所示)。

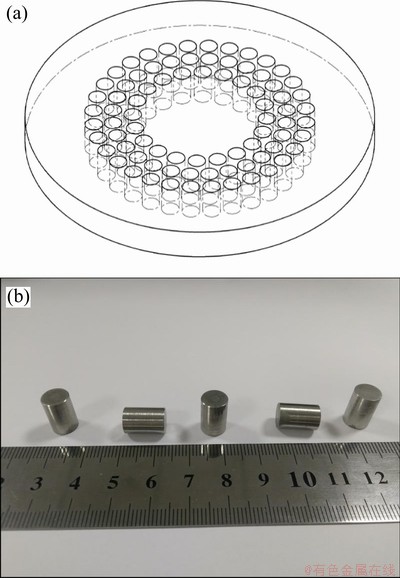

沿铸锭横截面R/2处切取d 8 mm×12 mm的标准圆柱体热压缩试样(如图2所示),在Gleeble-3500热模拟机上进行单道次热压缩实验,工艺参数为变形温度950~1200 ℃、应变速率0.001~10 s-1、真应变0.65,压缩结束后水冷,以保留高温变形时的组织。在变形过程中为减小试样两端与压头的摩擦,将试样两端面打磨光滑并涂抹石墨润滑剂。整个过程中温度的监测由焊接在试样上的热电偶完成,热压缩过程由计算机控制,并记录真应力-真应变曲线数据,分析真应力-真应变曲线,建立本构模型,再绘制热加工图。

金相试样采用线切割将压缩后的试样沿轴向对半切开,对试样进行研磨及抛光后使用10 g CuSO4+30 mL HCL的混合溶液进行腐蚀,之后用光学显微镜观察试样显微组织,结合热加工图分析找出合理加工区域。

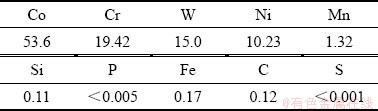

表1 铸态GH5605的化学成分

Table 1 Chemical composition of as-cast GH5605 alloy (mass fraction, %)

图1 铸态GH5605合金显微组织

Fig. 1 Microstructure of as-cast GH5605 alloy

图2 切样示意图和GH5605标准热压缩试样照片

Fig. 2 Schematic diagram of cutting sample(a) and photos of standard thermal compression specimens(b)

2 结果和讨论

2.1 真应力-真应变曲线

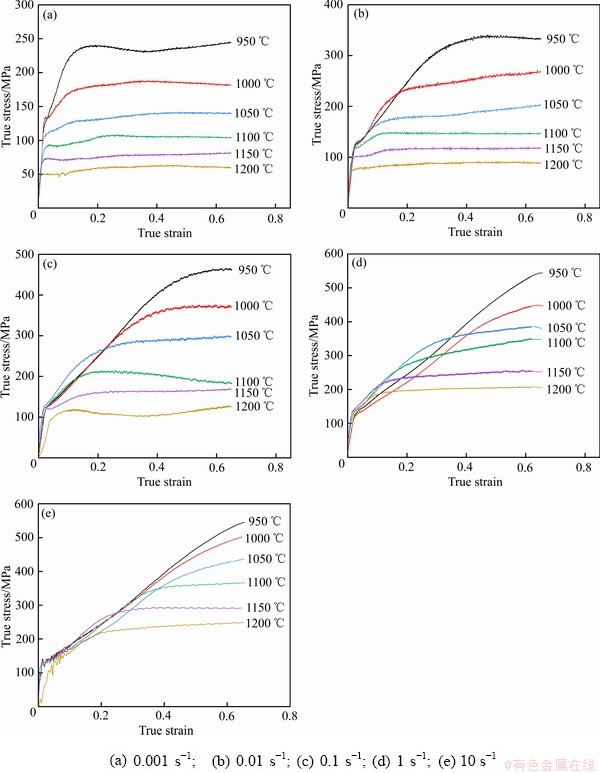

图3所示为GH5605合金在变形温度950~ 1200 ℃、应变速率0.001~10 s-1及真应变0.65的真应力-真应变曲线。从图3中可以看出,变形温度、应变速率以及应变对应力有显著影响。在应变速率为0.001 s-1、温度由950 ℃升高至1200 ℃时,达到稳态流变所需的真应变由0.168减小至0.018(见图3(a));在应变速率为0.01 s-1、温度由950 ℃升高至1200 ℃时,达到稳态流变所需的真应变由0.440减小至0.021(见图3(b));在应变速率为0.1 s-1、温度由950 ℃升高至1200 ℃时,达到稳态流变所需的真应变由0.587减小至0.105(见图3(c));在应变速率为1 s-1、温度为950 ℃和1000 ℃时,材料的真应力-真应变曲线整体呈加工硬化状态,没有达到稳态流变;在1200 ℃时,达到稳态流变所需的真应变为0.13(见图3(d));在应变速率为10 s-1、温度为950~ 1050 ℃时,材料的真应力-真应变曲线整体呈加工硬化状态,未达到稳态流变;在1200 ℃时,达到稳态流变所需的真应变为0.30(见图3(e))。因此,在热压缩变形过程中,铸态GH5605合金的真应力-真应变曲线属于加工硬化型和动态回复型。当变形温度一定时,应力值随应变速率的增加而增大;当应变速率一定时,应力值随变形温度的升高而减小。

图3 不同应变速率不同温度下的真应力-真应变曲线

Fig. 3 True stress-true strain curve of GH5605 alloy at different strain rates

以变形温度1200 ℃、应变速率1 s-1为例,如图4所示,依据真应力-真应变曲线的变化规律,铸态GH5605合金在各变形条件下的真应力-真应变曲线主要分为3个阶段:Ⅰ剧烈加工硬化阶段,在真应变为0~0.06范围内,加工硬化显著,真应力-真应变曲线接近直线,加工硬化率[16]  >500 MPa;Ⅱ平缓加工硬化阶段,在真应变0.06~0.22范围内,在达到屈服点后,曲线的上升趋势减缓,随着应变量的增大应力呈非线性增加,θ下降且趋势变缓;Ⅲ稳态流变阶段,随着变形量继续增加,在真应变大于0.22后应力值变化不大,真应力-真应变曲线及θ值均逐渐到达一个恒值,材料由于发生动态回复进入稳态流变阶段。当变形温度为1200 ℃、应变速率低于1 s-1时,加工硬化阶段在更短的应变内完成变形,稳态流变阶段变长;当变形温度低于1200 ℃、应变速率高于1 s-1时,随着温度的降低,应变速率的增大,加工硬化阶段变长,稳态流变阶段变短,甚至消失。

>500 MPa;Ⅱ平缓加工硬化阶段,在真应变0.06~0.22范围内,在达到屈服点后,曲线的上升趋势减缓,随着应变量的增大应力呈非线性增加,θ下降且趋势变缓;Ⅲ稳态流变阶段,随着变形量继续增加,在真应变大于0.22后应力值变化不大,真应力-真应变曲线及θ值均逐渐到达一个恒值,材料由于发生动态回复进入稳态流变阶段。当变形温度为1200 ℃、应变速率低于1 s-1时,加工硬化阶段在更短的应变内完成变形,稳态流变阶段变长;当变形温度低于1200 ℃、应变速率高于1 s-1时,随着温度的降低,应变速率的增大,加工硬化阶段变长,稳态流变阶段变短,甚至消失。

图4 GH5605合金的真应力-真应变曲线及加工硬化率曲线

Fig. 4 True stress-true strain curve and working hardening rate curve of GH5605 alloy

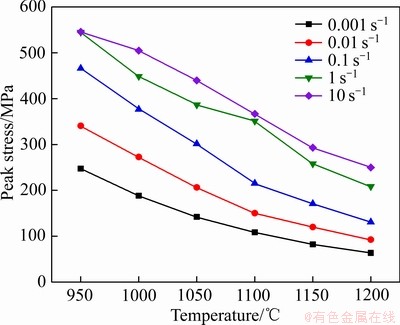

图5所示为GH5605合金的峰值应力曲线,可以看出GH5605合金的峰值应力随温度的升高而逐渐下降,随应变速率的增大而增大,表明GH5605合金为正应变速率敏感材料。在应变速率为10 s-1、变形温度由950 ℃升高至1200 ℃时,材料的峰值应力值降低了约295 MPa。在变形温度为950℃,应变速率由0.001 s-1升高至10 s-1时,材料的峰值应力值增大了约297 MPa。这主要是由于随着变形温度的升高,合金滑移所需的临界剪切应力降低,滑移系更易开动。此外,金属材料的高温变形是热激活过程,提高材料的变形温度相当于增加了热激活能,位错也更容易开动,并且运动速度明显提高,使动态回复消耗位错的能力提高,位错密度降低,合金的硬化作用减弱,降低合金的应力;随着应变速率的增加,变形过程缩短,金属内部的畸变程度加剧,继续变形困难,同时动态回复难以充分完成,因而导致合金变形抗力提高[17]。

图5 峰值应力变化关系曲线

Fig. 5 Relation curves of peak stress variation

2.2 本构模型

双曲正弦本构模型广泛用于描述高温下应变速率,变形温度和应力之间的关系。温度和应变速率对变形行为的影响可以通过指数方程中的Zener-Hollomon参数来表征[18],表达式如下:

(1)

(1)

式中 ,因此只要根据GH5605的热加工变形条件分别求出

,因此只要根据GH5605的热加工变形条件分别求出 、A、n和Q等材料参数值,并将其值分别代入式(1)即可得到GH5605的各个变形参数与应力之间关系的本构方程。

、A、n和Q等材料参数值,并将其值分别代入式(1)即可得到GH5605的各个变形参数与应力之间关系的本构方程。

计算时取真应变为0.1~0.65条件下的应力 。不同真应变

。不同真应变 和

和 的值分别由

的值分别由 和

和 曲线获得,以

曲线获得,以 为例如图6所示,经计算

为例如图6所示,经计算 =7.8039,

=7.8039, =0.034,则

=0.034,则 =0.004362。

=0.004362。

图6  和

和 的关系图

的关系图

Fig. 6 Relation curves of  (a) and

(a) and  (b)

(b)

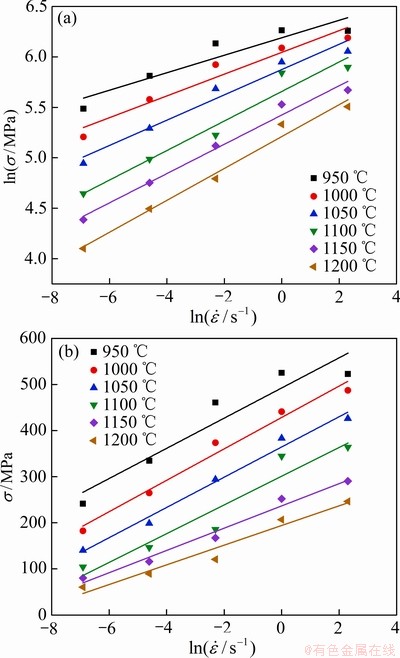

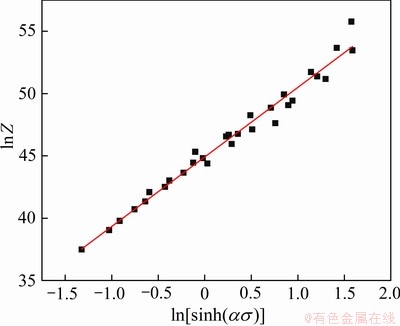

作 的关系图,如图7(a)所示,通过曲线斜率可求出n=5.65648。作不同应变的

的关系图,如图7(a)所示,通过曲线斜率可求出n=5.65648。作不同应变的 和

和 的关系图如图7(b)所示,通过曲线斜率均值求出m=11.5611,由Q=Rnm可求出变形激活能Q=543.6959 kJ/mol。

的关系图如图7(b)所示,通过曲线斜率均值求出m=11.5611,由Q=Rnm可求出变形激活能Q=543.6959 kJ/mol。

分别建立不同应变 与

与 关系曲线如图8所示,求得直线在

关系曲线如图8所示,求得直线在 坐标轴上的截距即为

坐标轴上的截距即为 44.91565。

44.91565。

图7  和

和

的关系图

的关系图

Fig. 7 Relation curves of  (a) and

(a) and

(b)

(b)

图8  -

- 的关系图

的关系图

Fig. 8 Relationship between  and

and

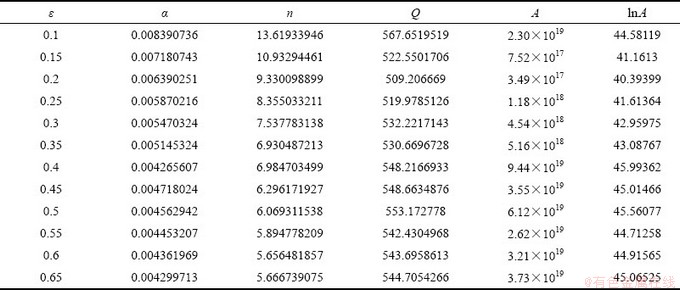

各值求解结果如表2所列。

可得到不同真应变下GH5605合金的本构方程,其在真应变为0.6时本构方程为

(2)

(2)

为了能够准确地衡量本构模型与试验数据的吻合度,现引入平均相对误差( )和相关系数Rr来进行误差分析,其表达式如式(3)~(4)所示:

)和相关系数Rr来进行误差分析,其表达式如式(3)~(4)所示:

(3)

(3)

(4)

(4)

式中: 为试验应力值(MPa);

为试验应力值(MPa); 为试验应力平均值(MPa);

为试验应力平均值(MPa); 为预测的应力值(MPa);

为预测的应力值(MPa); 为预测的应力平均值(MPa);

为预测的应力平均值(MPa); 为数据数量。

为数据数量。

表2 GH5605合金参数α、n、Q、A和ln A

Table 2 Alloy parameters α, n, Q, A and ln A of GH5605

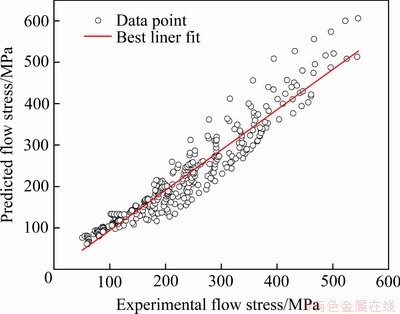

从所研究的本构方程中得出的应力的试验值与预测值的相互关系如图9所示。通过计算,整个温度下的 =11.99%,Rr=0.95。在各种加工条件下的本构方程试验值和预测值之间的比较如图10所示。图中曲线为Gleeble-3500热模拟机实测的应力值,散点为计算预测出来的理论应力值。可以看出,在大多数变形条件下,应力的预测值与实测值偏差较小,在1050~1200 ℃ 4个高温均有良好的相关性, 而在950、1000 ℃两个低温和高应变速率时有一定的偏差。这是一方面由于原始材料为铸态组织存在成分偏析和不均匀,另一方面由于在950、1000 ℃和高应变速率条件下,材料大部分处于加工硬化状态,并且变形区内变形不均匀,变形的不同步使得试验和预测应力值产生一定的偏差,易导致材料变形失稳。

=11.99%,Rr=0.95。在各种加工条件下的本构方程试验值和预测值之间的比较如图10所示。图中曲线为Gleeble-3500热模拟机实测的应力值,散点为计算预测出来的理论应力值。可以看出,在大多数变形条件下,应力的预测值与实测值偏差较小,在1050~1200 ℃ 4个高温均有良好的相关性, 而在950、1000 ℃两个低温和高应变速率时有一定的偏差。这是一方面由于原始材料为铸态组织存在成分偏析和不均匀,另一方面由于在950、1000 ℃和高应变速率条件下,材料大部分处于加工硬化状态,并且变形区内变形不均匀,变形的不同步使得试验和预测应力值产生一定的偏差,易导致材料变形失稳。

图9 试验应力值和预测应力值之间的相关性

Fig. 9 Correlation between experimental and predicted stress values

2.3 热加工图

热加工图可以直观反映出材料在不同变形参数时的变形机理,可对材料的可加工性进行预测评估。基于动态材料模型(Dynamic materials model,DMM)[19]构建了GH5605合金的热加工图。DMM是依据大塑性变形连续介质力学、物理系统模拟和不可逆热力学理论而建立的。DMM 模型将热变形过程作为一个能量单元,单位体积消耗的总能量(P)是由材料塑性变形消耗的能量G和组织转变消耗的能量J构成。这个过程的数学表达式为[20-21]

(5)

(5)

图10 不同应变速率下试验应力值和预测应力值的比较

Fig. 10 Comparison between experimental and predicted stress

描述功率耗散特征的参数 是由耗散协量J和材料处于理想线性耗散能量Jmax的比例来决定,即:

是由耗散协量J和材料处于理想线性耗散能量Jmax的比例来决定,即:

(6)

(6)

式中:m为应变速率敏感指数[22],

(7)

(7)

能耗因子 值表明组织演变耗散能量所占理想线性耗散能量的比例,

值表明组织演变耗散能量所占理想线性耗散能量的比例, 值越大即组织耗散功率越大,但这并不完全意味着材料的加工性越好,还需结合失稳判据来分析。

值越大即组织耗散功率越大,但这并不完全意味着材料的加工性越好,还需结合失稳判据来分析。

PRASADY等[20]根据不可逆力学极值原理,认为耗散函数和应变速率满足不等式:

<

< (8)

(8)

则系统不稳定,其失稳判据表达式为

<0 (9)

<0 (9)

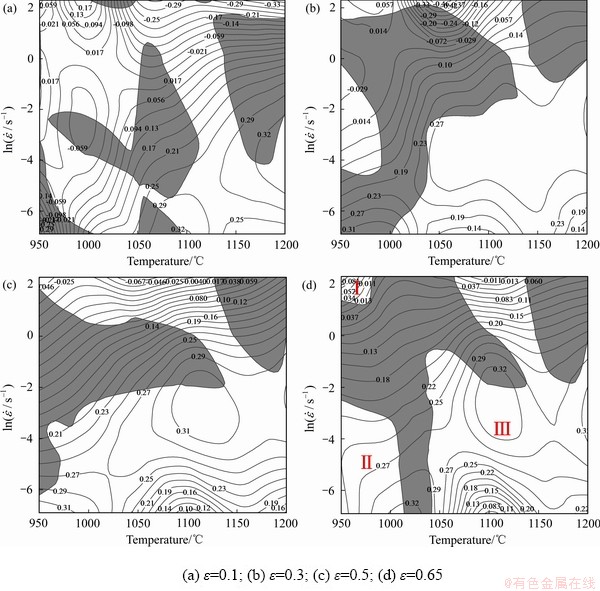

根据式(9)可绘制出材料的能耗因子图和失稳图,将二者叠加后即可获得材料的热加工图。基于动态材料模型构建了GH5605合金的热加工图,图11所示分别为真应变为0.1、0.3、0.5和0.65时的加工图,对应于热压缩过程的初级阶段、中间阶段和最终阶段。其中阴影部分为加工失稳区。

在GH5605合金塑性变形过程中,可以观察到,在真应变为0.1时加工图失稳区的分布较乱,随着应变量增大在真应变为0.3、0.5时失稳区只要集中在低温、高应变速率区域,当真应变增大到0.65时失稳区开始向高温移动。以压缩终态ε=0.65为例,图中可以看出有3个可加工区Ⅰ、Ⅱ、Ⅲ。Ⅰ区温度为950~980 ℃,应变速率为10 s-1;Ⅱ区温度950~1015 ℃,应变速率为0.001~0.01 s-1;Ⅲ区温度1040~1200 ℃,应变速率为0.001~0.1 s-1。但Ⅰ可加工区范围小且功率耗散值低(<0.1),不是最佳加工区域。Ⅱ、Ⅲ区功率耗散值最大达到0.3左右,适合GH5605热加工。为了验证加工图判断的正确性,对变形后的显微组织进行观察。

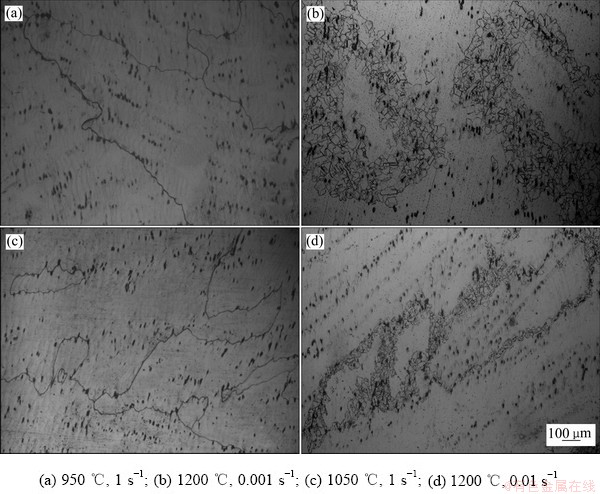

图12所示为GH5605合金对应图11(d)下不同区域的显微组织,图12(a)和(c)所示分别为(950 ℃,1 s-1)和(1050 ℃,1 s-1)合金的显微组织,在热加工图中为不可加工区,可以看出其组织粗大。结合真应 力-应变曲线可以看出在低温和高应变速率时真应力-应变曲线为加工硬化型,材料变形不均匀,几乎未发生动态回复,材料处于加工硬化状态;图12(b)和(d)所示分别为(1200 ℃,0.001 s-1)和(1200 ℃,0.01 s-1)合金的显微组织,在热加工图中为良好的加工区,可以看出在大晶粒晶界附近有大量细小的晶粒,这种微观组织有助于提高材料的强度与韧性。结合显微组织和加工图确定的最佳加工区域温度为1055~1200 ℃,应变速率为0.01~0.1 s-1。

图11 GH5605的热加工图

Fig. 11 Processing map of GH5605

图12 不同条件下GH5605的显微组织

Fig. 12 Microstructures of GH5605 under different conditions

3 结论

1) 在热压缩变形过程中,GH5605合金的真应力-真应变曲线属于加工硬化型+动态回复型,真应力-真应变曲线主要分为3个阶段,即Ⅰ剧烈加工硬化阶段、Ⅱ平缓加工硬化阶段、Ⅲ稳态流变阶段。

2) 利用Arrhenius本构模型计算获得GH5605合金本构模型的相关系数(R)和平均相对误差( )分别为0.95和11.99%,并预估其应力在高温时有良好的相关性。

)分别为0.95和11.99%,并预估其应力在高温时有良好的相关性。

3) 在动态材料模型的基础上构建了GH5605合金的热加工图,并结合显微组织验证了加工图的准确性,结果表明应变速率为0.01~0.1 s-1、温度为1055~1200 ℃是GH5605合金的良好加工区。

REFERENCES

[1] 郭建亭. 高温合金材料学[M]. 北京: 北京科学出版社, 2008.

GUO Jian-ting. Superalloy material science[M]. Beijing: Beijing Science Press, 2008.

[2] 中国金属学会高温材料分会. 高温合金手册(全2册)[M]. 北京: 中国标准出版社, 2011.

High-temperature Materials Branch of the Chinese Metal Society. High-temperature alloy (Manual 2 volumes)[M]. Beijing: China Standard Press, 2011.

[3] FAVRE J, KOIZUMI Y, CHIBA A, et al. Deformation behavior and dynamic recrystallization of biomedical Co-Cr-W-Ni (L-605) alloy[J]. Metallurgical and Materials Transactions A, 2013, 44(6): 2819-2830.

[4] ANILKUMAR V, GUPTA R K, NARAYANA MURTY S V S, et al. Hot workability and microstructure control in Co20Cr15W10Ni cobalt-based superalloy[J]. Journal of Alloys and Compounds, 2016, 676: 527-541.

[5] SORENSEN D, LI B Q, GERBERICH W W, et al. Investigation of secondary hardening in Co-35Ni-20Cr-10Mo alloy using analytical scanning transmission electron microscopy[J]. Acta Materialia, 2014, 63: 63-72.

[6] UEKI K, UEDA K, NARUSHIMA T. Microstructure and mechanical properties of heat-treated Co-20Cr-15W-10Ni alloy for biomedical application[J]. Metallurgical and Materials Transactions A: Physical Metallurgy and Materials Science, 2016, 47(6): 2773-2782.

[7] 刘 超, 江 河, 董建新, 等. 钴基高温合金GH5605铸态组织及高温扩散退火过程中元素再分配[J]. 工程科学学报, 2019, 41(3): 359-367.

LIU Chao, JIANG-he, DONG Jian-xin, et al, As-cast microstructure and redistribution of elements in high- temperature diffusion annealing in cobalt-base superalloy GH5605[J]. Chinese Journal of Engineering, 2019, 41(3): 359-367.

[8] 裴丙红. 热处理制度对GH605合金碳化物组织分布影响研究[J]. 特钢技术, 2017, 23(1): 4-11.

PEI Bing-hong. Effect of heat treatment regime on distribution of carbides in alloy GH605[J]. Special Steel Technology, 2017, 23(1): 4-11.

[9] FAVRE J, FABREGUE D, YAMANAKA K, et al. Modeling dynamic recrystallization of L-605 cobalt superalloy[J]. Materials Science and Engineering A, 2016, 653: 84-92.

[10] NARUSHIMA T, MINETA S, KURIHARA Y, et al. Precipitates in Biomedical Co-Cr Alloys[J]. JOM, 2013, 65(4): 489-504.

[11] SAMII ZAFARGHANDI M, ABBASI S M, MOMENI A. Effects of Nb on hot tensile deformation behavior of cast Haynes 25 Co-Cr-W-Ni alloy[J]. Journal of Alloys and Compounds, 2019, 774: 18-29.

[12] WANG K, LI M Q, LUO J, et al. Effect of the δ phase on the deformation behavior in isothermal compression of superalloy GH4169[J]. Materials Science & Engineering A, 2011, 528(13/14): 4723-4231.

[13] ZHANG Peng, HU Chao, ZHU Qiang, et al. Hot compression deformation and constitutive modeling of GH4698 alloy[J]. Materials & Design, 2015, 65: 1153-1160.

[14] 宫润燕. GH4169合金高温塑性变形行为及组织演变规律研究[D]. 辽宁: 东北大学, 2014.

GONG Run-yan. Research of microstructure evolution law and hot plastic deformation behavior for alloy GH4169[D]. Liaoning: Northeastern University, 2014.

[15] LI Kuo-kuo, CHEN Ming-song, LIN Y C, et al. Microstructural evolution of an aged Ni-based superalloy under two-stage hot compression with different strain rates[J]. Materials & Design, 2016, 111: 344-352.

[16] 周 舫, 张思倩, 张浩宇, 等. GH79合金高温变形行为及变形机理研究[J]. 稀有金属材料与工程, 2019, 48(12): 3939-3947.

ZHOU Ge, ZHANG Si-qian, ZHANG Hao-yu, et al. Elevated temperature compression deformation behavior and mechanism of GH79 superalloy[J]. Rare Metal Materials and Engineering, 2019, 48(12): 3939-3947.

[17] 王淑娟. TiNiFe形状记忆合金的变形行为及微观组织演变规律的研究[D]. 北京: 有色金属研究总院, 2012.

WANG Shu-juan, Deformation behavior and microstructure evolution of TiNiFe shape memory alloy[D]. General Research Institute for Nonferrous Metals, 2012.

[18] ZENER C, HOLLOMON J H. Effect of strain rate upon plastic flow of steel[J]. Journal of Applied Physics, 1944, 15(1): 22-32.

[19] SUZUKI A, POLLOCK T M. High-temperature strength and deformation of γ/γ′ two-phase Co-Al-W-base alloys[J]. Acta Materialia, 2008, 56(6): 1288-1297.

[20] PRASAD Y, RAO K P, SASIDHARA S. Hot working guide: A compendium of processing maps[M]. Materials Park, OH: ASM International, 1997.

[21] HAN Ying, ZOU De-ning, CHEN Zhi-yu, et al. Investigation on hot deformation behavior of 00Cr23Ni4N duplex stainless steel under medium-high strain rates[J]. Materials Characterization, 2011, 62(2): 198-203.

[22] CAVALIERE P, CERRI E, LEO P. Hot deformation and processing maps of a particulate reinforced 2618/Al2O3/20p metal matrix composite[J]. Composites Science and Technology, 2004, 64(9): 1287-1291.

Hot compression deformation of cobalt-based superalloy GH5605

ZHANG Bing1, 3, ZHAO Fen-fen1, 3, CHEN Han-feng2, YANG Yan2, MA Yan-heng1, 3, QI Kai1, 3

(1. College of Metallurgy Engineering, Xi’an University of Architecture and Technology, Xi’an 710055, China;

2. State Key Laboratory of Nickel and Cobalt Resource integrated utilization, Jinchuan Group Co., Ltd., Jinchang 737100, China;

3. National & Local Engineering Researching Center for Functional Materials Processing, Xi’an 710055, China)

Abstract: Hot compression deformation tests of cobalt base superalloy 5605 alloy by vacuum induction electroslag remelting were performed on Gleeble-3500 thermal simulator. The deformation behavior of as-cast GH5605 alloy was studied at the temperature ranging from 950-1200 ℃, strain rate ranging from 0.001 to 10 s-1 with true strain of 0.65. The results show that the true stress-strain curve of GH5605 alloy belongs to the working hardening type + dynamic recovery type. The true stress-strain curve of GH5605 alloy is mainly divided into three stages: Ⅰ severe work hardening stage; Ⅱ gentle work hardening stage; Ⅲ steady stage. The average relative error (δ) of the constitutive model is 11.99%, the correlation coefficients (Rr) is 0.95, the optimum hot working domain for GH5605 alloy is 1055-1200 ℃ and 0.01-0.1s-1.

Key words: cobalt-based superalloy; hot compression deformation; constitutive modeling; processing map; microstructure

Foundation item: Project(51874226) supported by the National Natural Science Foundation of China; Project (301170504) supported by State Key Laboratory of Nickel and Cobalt Resources Comprehensive Utilization, China

Received date: 2020-07-06; Accepted date: 2021-03-11

Corresponding author: ZHANG Bing; Tel: +86-13691363825; E-mail: r.zhang1112@163.com

(编辑 王 超)

基金项目:国家自然科学基金资助项目(51874226);镍钴资源综合利用国家重点实验室开放课题(301170504)

收稿日期:2020-07-06;修订日期:2021-03-11

通信作者:张 兵,教授,博士:电话:13691363825;E-mail:r.zhang1112@163.com