文章编号: 1004-0609(2005)05-0763-05

2618铝合金的热变形和加工图

黄光胜1, 汪凌云1, 陈 华2, 黄光杰1, 张所全1

(1. 重庆大学 材料科学与工程学院, 重庆 400044;

2. 西南铝业(集团)有限责任公司, 重庆 401326)

摘 要: 在Gleeble-1500D热模拟仪上进行热压缩实验, 研究了变形温度为573~773K、 应变速率为0.01~10s-1时2618铝合金的热变形行为。 热变形过程中的稳态流变应力可用双曲正弦本构关系式来描述, 平均激活能为181kJ/mol, 大于其自扩散激活能。 根据材料动态模型, 计算并分析了2618铝合金的加工图。 利用加工图确定了热变形的流变失稳区, 并且获得了试验参数范围内的热变形过程的最佳工艺参数, 其热加工温度为623~723K, 应变速率为0.01s-1, 温加工温度为573K左右, 应变速率为0.01s-1。

关键词: 2618铝合金; 流变应力; 加工图; 热变形 中图分类号: TG301

文献标识码: A

Hot deformation and processing maps of 2618 aluminum alloy

HUANG Guang-sheng1, WANG Ling-yun1, CHEN hua2,

HUANG Guang-jie1, ZHANG Suo-quan1

(1. College of Materials Science and Engineering, Chongqing University,

Chongqing 400044, China;

2. Southwest Aluminium Group Co., Ltd., Chongqing 401326, China)

Abstract: The deformation behaviour of 2618 aluminum alloy was investigated by compression tests with Gleeble-1500D thermal simulator system. The tests were performed in the temperature range between 573 and 773K and strain rates between 0.01 and 10s-1. The flow behaviour is described by the hyperbolic sine constitutive equation, and an activation energy of 181kJ/mol greater than the activation energy for self-diffusion in Al is calculated. The processing maps were calculated and analyzed according to the dynamic materials model. The process of hot deformation in the temperature range and different strain rate can be attained by the maps, which hot deformation temperature is 623-723K and strain rate is around 0.01s-1. The warm deformation temperature is approximately 573K and strain rate is also about 0.01s-1. The instability zones of flow behaviour can also be recognized by the maps.

Key words: 2618 aluminum alloy; flow stress; processing maps; hot deformation

国防工业和航空工业的高速发展对耐热铝合金提出了更高的要求, 2618铝合金属于Al-Mg-Cu-Fe-Ni系锻造铝合金, 是目前耐热性能最好的铝合金, 被广泛应用于航空发动机及其它较高温度条件下工作的零部件[1]。

热压缩试验可获得不同条件下流变应力的连续数据, 不仅可用于流变行为研究, 而且还可用于计算获得材料的加工图。 加工图是变形温度与应变速率空间中的功率耗散图与失稳图的叠印。 根据加工图可以判别材料变形过程中的流变失稳区, 还可根据非失稳区内最大功率耗散系数区与显微组织来制定材料的最佳加工工艺制度(变形温度与应变速率)。 关于加工图的理论在文献[2-5]中已有相关论述。

本文通过热压缩试验, 获得了2618铝合金的流变应力, 研究了流变应力模型及加工图, 分析了材料的最佳热加工条件, 为2618铝合金热加工工艺的制定与优化提供实验数据及理论依据。

1 实验

实验材料为2618合金, 属于Al-Cu-Mg-Fe-Ni合金, 其名义化学成分(质量分数)为: Cu 1.8%~2.7%, Mg 1.2%~1.8%, Fe 0.9%~1.4%, Ni 0.8%~1.4%。 将经均匀化处理后的铸锭加工成d10mm×12mm的小圆柱试样, 在Gleeble-1500D热模拟仪上进行圆柱体单向热压缩。 实验中在试样两端涂上高温石墨润滑剂(75%石墨+20%46#机油+5%硝酸三甲苯脂, 质量分数), 为了防止碳化钨压头与试件粘连, 在压头与石墨润滑剂之间放置一层厚度为0.1mm的钽片。 实验设计采用分类法, 压缩温度为573~773K, 间隔温度为40K, 应变速率分别为0.01、 0.1、 1.0、 10.0s-1。 压缩前升温速度为2K/s, 到温后保温5min。 相对压下量为70%。 试样变形后, 立即水冷凝固变形组织。 沿压缩轴线剖开压缩试样, 利用金相显微镜观察显微组织。

2 实验结果

2618铝合金热变形过程中的真应力—真应变曲线如图1所示。 在一定的变形温度和应变速率下, 流变应力先随应变的增加迅速升高, 当真应变超过一定值后, 真应力并不随应变量的继续增大而发生明显的变化, 即呈现稳态流变特征。 绝大部分流变曲线为平滑直线, 说明变形过程中动态回复是主要的软化机制; 而有小部分流变曲线呈现出锯齿形, 为典型的动态再结晶特征。 在相同的变形温度下, 随着应变速率的增加, 材料的真应力水平升高, 该合金是一种应变速率敏感材料。

图1 不同温度时压缩的真应力—应变曲线

Fig.1 Compressive true stress—strain curves at different temperatures

3 高温流变应力

稳态流变应力的模型有多种, 双曲正弦模型已广泛用于金属材料的热变形研究中[6-8], 文献[5, 9, 10]表明, 对于许多铝合金的也能准确地描述其流变应力与变形温度和应变速率的关系, 因此本文在研究稳态流变应力时选用双曲正弦模型, 假设稳态流变应力满足双曲正弦模型, 即:

式中 Q为表观变形激活能; R为气体常数, 8.31J/mol; 并假设A、 α、 n为常数, 其中α可由指数关系模型 中的n1与幂指数模型(

中的n1与幂指数模型( )中的β共同确定, 即α=β/n1=0.01245。

)中的β共同确定, 即α=β/n1=0.01245。

Zener-Hollomon(Z)参数综合了材料的热变形条件, Z参数表达式如下[11]:

将式(2)代入式(1), 得

Z=A[sinh(ασ)]n(3)

对式(1)两边取偏微分可得:

图2和3所示分别表示在热压缩过程中的稳态流变应力与变形温度和应变速率的关系。

图2 ln(sinh(ασ))与温度的关系

Fig.2 Relation between ln(sinh(ασ)) and temperature

图3 ln(sinh(ασ))与 的关系

的关系

Fig.3 Relation between ln(sinh(ασ)) and

ln(sinh(ασ))分别与T-1和 成线性关系, 通过回归分析, 其线性相关系数均匀在0.97以上, 说明双曲正弦模型能准确描述流变应力与应变速率的关系。 通过图2和3中所示的直线的斜率可计算出合金的平均变形激活能为Q=181kJ/mol, 大于铝合金自扩散激活能。

成线性关系, 通过回归分析, 其线性相关系数均匀在0.97以上, 说明双曲正弦模型能准确描述流变应力与应变速率的关系。 通过图2和3中所示的直线的斜率可计算出合金的平均变形激活能为Q=181kJ/mol, 大于铝合金自扩散激活能。

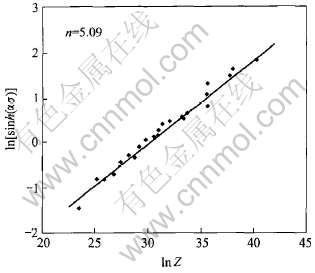

根据图3中直线的截距, 即Q/RT-lnA的值, 取其平均值可获得A=1.001×1013s-1。 而其斜率为1/n, 则可求得材料常数n的平均值为5.09。

对式(3)两边取自然对数得:

lnZ=lnA+nln[sinh(ασ)](5)

图4表明ln[sinh(ασ)]与lnZ成线性关系, 对其进行一元线性回归, 相关系数为0.99。 即可用双曲正弦模型来描述2618铝合金的稳态流变行为。

图4 ln(sinh(ασ))与lnZ的关系

Fig.4 Relation between ln(sinh(ασ)) and lnZ

4 加工图

材料的流变应力与应变速率的关系还可表示为[3]

式中 K为常数; m为应变速率敏感指数。 对于2618铝合金, 当温度不变时, lnσ与 的一元线性回归系数在96.3%~99.7%之间, 说明lnσ与

的一元线性回归系数在96.3%~99.7%之间, 说明lnσ与 之间存在线性关系(图5), 其关系也可用式(6)来描述。 m可由下式求得[3, 4]:

之间存在线性关系(图5), 其关系也可用式(6)来描述。 m可由下式求得[3, 4]:

图5 lnσ与 的关系

的关系

Fig.5 Relation between lnσ and

加工图是加工变量空间(应变速率, 温度)中的功率耗散图与失稳图的叠印图。 功率耗散图代表材料显微组织改变时功率的耗散, 其变化率可用一个无量纲参数表示, 即功率耗散系数η为[12]

失稳图是根据不可逆热力学极值原理, 用另一个无量纲参数 表示大塑性流变时的连续失稳判据[5, 12]

表示大塑性流变时的连续失稳判据[5, 12]

当 〈0时, 为非稳态流变。 含有温度与应变速率的变量

〈0时, 为非稳态流变。 含有温度与应变速率的变量 构成了失稳图, 重叠在功率耗散图上就能确定失稳区。

构成了失稳图, 重叠在功率耗散图上就能确定失稳区。

将式(8)计算出的功率耗散图与式(9)计算的失稳图重叠就可获得加工图, 图6所示是2618铝合金应变为0.3与0.5时的加工图, 图中的阴影区为流变失稳区, 图中等值线上的数字表示功率耗散系数。 加工图表明, 在变形温度为573~773K、 应变速率为0.01~10s-1范围内, 流变失稳区大, 可加工范围窄, 特别是在高应变速率区, 几乎都是失稳区, 表明该合金加工难度较大。

功率耗散图由功率耗散系数的等值线组成, 代表了材料中由显微组织耗散引起的熵增量相对变化速率。 功率耗散图由于实际代表热加工变形过程中的显微组织变化率, 因此又被称作“显微组织轨迹”。 加工图中局部区域存在功率耗散效率最大值, 它代表特殊的显微组织机制或流变失稳机制。 功率耗散图中高功率耗散区定义为具有最佳加工性能区, 然而由于楔形裂纹破坏机制通常也对应着高功率耗散系数, 因此分析加工图需要进一步的显微组织来佐证[2, 13, 14]。

2618铝合金的加工图中功率耗散系数较大的区域有3个, 每个区域的最大功率耗散系数均在0.4以上, 并且其应变速率都为0.01s-1左右时, 而温度分别为573K(低温)、 673K(中温)、 773K(高温)左右。 在高温区, 当应变速率高达1s-1时, 还保持较高的功率耗散系数。 但是在高温度变形时, 其变形组织粗大(图7), 将对其力学性能产生影响, 因此高温区很少进行该合金的热加工。 在中温区, 变形温度为623~723K、 应变速率约为0.01s-1时, 其功率耗散系数最大值达到0.45, 其组织细小(图8)。 中温区是该合金的热变形区域, 常进行热锻、 热挤压等变形[1]。 而在较低温度区域, 即变形温度为573K、 应变速率约为0.01s-1, 是该合金的温加工区域。 Cavaliere[13]的研究表明, 在523K可进行温锻, 获得的锻件与热锻的屈服强度与延伸率相当, 因此中温区的温度范围还可降至523K。通常热锻还要进行固溶时效处理, 而温锻只进行人工时效, 可节省大量的时间与热处理费用[13, 15]。

图6 不同应变时2618铝合金的加工图

Fig.6 Processing maps of 2618 aluminum alloy at different true strain

图7 变形温度为773K,应变速率为0.01s-1时2618铝合金的显微组织

Fig.7 Microstructure of 2618 Al alloy deformed at 773K and 0.01s-1

图8 变形温度为693K,应变速率为0.01s-1时2618铝合金的显微组织

Fig.8 Microstructure of 2618 Al alloy deformed at 693K and 0.01s-1

5 结论

1) 2618铝合金的稳态流变应力满足双曲正弦本构关系式, 其材料参数为α=0.01245, n=5.09, A=1.001×1013s-1, 其平均激活能为181kJ/mol。

2) 2618合金的失稳区为高应变速率区, 而可加工区仅为应变速率较低的区域。

3) 在中温区, 变形温度为623~723K、 应变速率为0.01s-1左右这个区域, 最大功率耗散系数为0.45, 可进行热锻、 热挤压等变形。

4) 较低温度区域, 即变形温度为573K、 应变速率为0.01s-1左右这个区域, 功率耗散系数最大值为0.40, 是该合金的温加工区域。

REFERENCES

[1]王祝堂, 田荣璋. 铝合金及其加工手册[M]. 长沙: 中南工业大学出版社, 1989.

WANG Zhu-tang, TAN Rong-zhang. Hand Book of Aluminum Alloys and Their Processing[M]. Changsha: Central South University of Technology Press, 1989.

[2]Bozzini B, Cerri E. Numerical reliability of hot working processing maps[J]. Mater Sci Eng A, 2002, A328(1-2): 344-347.

[3]汪凌云, 范永革, 黄光胜, 等. 镁合金AZ31B高温塑性变形及加工图理论研究[J]. 中国有色金属学报, 2004, 14(7): 1068-1072.

WANG Ling-yun, FAN Yong-ge, HUANG Guang-sheng, et al. Research on plastic deformation at elevated temperature and processing maps of magnesium alloy[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(7): 1068-1072.

[4]Narayana-Murty S V S, Nageswara R B. On the development of instability criteria during hotworking with reference to IN 718[J]. Mater Sci Eng A,1998, A254(1-2): 76-82.

[5]Cerri E, Spigarelli S, Evangelista S E, et al. Hot deformation and processing maps of a particulate-reinforced 6061+20% Al2O3 composite[J]. Mater Sci Eng A, 2002, A324(1-2): 157-161.

[6]Gronostajski Z J. Model describing the characteristic values of flow stress and strain of brass M63 and aluminium bronze BA93[J]. Journal of Materials Processing Technology, 1998, 78(1-3): 84-89.

[7]Imbert C A C, McQueen H J. Peak strength, strain hardening and dynamic restoration of A2 and M2 tool steels in hot deformation[J]. Mater Sci Eng A, 2001, A313(1-2): 88-103.

[8]Li L X, Lou Y, Yang L B, et al. Flow stress behavior and deformation characteristics of Ti-3Al-5V-5Mo compressed at elevated temperatures[J]. Materials and Design, 2002, 23(5): 451-457.

[9]Bardi F, Cabibbo M, Evangelista E, et al. An analysis of hot deformation of an Al-Cu-Mg alloy produced by powder metallurgy[J]. Mater Sci Eng A, 2003, A339(1-2): 43-52.

[10]Cho J R, Bae W B, Hwang W J, et al. A study on the hot-deformation behavior and dynamic recrystallization of Al-5wt.% Mg alloy[J]. Journal of Materials Processing Technology, 2001, 118(1-3): 356-361.

[11]LIU Jian-tao, CHANG Hong-bing, WU Rui-heng, et al. Investigation on hot deformation behavior of AISI T1 high-speed steel[J]. Materials Characterization, 2000, 45(3): 175-186.

[12]Seshacharyulu T, Medeiros S C, Frazier W G, et al. Microstructural mechanisms during hot working of commercial grade Ti-6Al-4V with lamellar starting structure[J]. Mater Sci Eng A, 2002, A325(1-2): 112-125.

[13]Cavaliere P. Hot and warm forming of 2618 aluminium alloy[J]. Journal of Light Metals, 2002, 2(4): 247-252.

[14]Gronostajski Z. The deformation processing map for control of microstructure in CuAl9.2Fe3 aluminium bronze[J]. Journal of Materials Processing Technology, 2002, 125-126: 119-124.

[15]Bardi F, Cabibbo M, Spigarelli S. An analysis of thermo-mechanical treatments of a 2618 aluminium alloy: study of optimum conditions for warm forging[J]. Mater Sci Eng A, 2002, A334(1-2): 87-95.

收稿日期: 2004-11-12; 修订日期: 2005-03-08

作者简介: 黄光胜(1974-), 男, 讲师, 博士.

通讯作者: 黄光胜, 博士; 电话: 023-66978697; E-mail: gshuang@cqu.edu.cn

(编辑龙怀中)