采用混合智能方法评估球墨铸铁摩擦焊接接头的抗拉强度

来源期刊:中国有色金属学报(英文版)2013年第2期

论文作者:Rados?aw WINICZENKO Robert SALAT Micha? AWTONIUK

文章页码:385 - 391

关键词:摩擦焊接;抗拉强度;支持向量回归;遗传算法;经验竞争算法;球磨铸铁

Key words:friction welding; tensile strength; support vector regression; genetic algorithm; imperialist competitive algorithm; ductile iron

摘 要:采用混合智能方法评价球墨铸铁的最佳摩擦焊接工艺参数。在自动循环中使用支持向量回归(SVR)、遗传算法(GA)和帝国竞争算法(ICA)优化焊接工艺参数。该方法被用来确定焊接工艺参数, 得到了理想的球墨铸铁摩擦焊接抗拉强度。在加热力40 kN,加热时间300 s,顶锻压力10.12 kN条件下,使用SVR加上GA方法得到了最高抗拉强度为256.93 MPa。将摩擦焊接样品进行拉伸强度测试,并比较了采用混合智能方法得到的优化值与实验结果。结果表明,混合智能方法可以使ZT-14型摩擦焊机拉伸强度从211 MPa增加到258 MPa。

Abstract: A hybrid intelligent method for evaluation of near optimal settings of friction welding process parameters of ductile iron was presented. The optimization of welding parameters was carried out in automatic cycle with the use of support vector regression (SVR), genetic algorithm (GA) and imperialist competitive algorithm (ICA). The method suggested was used to determine welding process parameters by which the desired tensile strength was obtained in the friction welding of ductile iron. The highest tensile strength (TS) of 256.93 MPa was obtained using SVR plus GA method for the following friction welding parameters: heating force 40 kN, heating time 300 s and upsetting force 10.12 kN. The samples were welded by friction and subjected to the tensile strength test. The optimized values obtained by means of these hybrid techniques were compared with the experimental results. The application of hybrid intelligent methods allowed to increase the tensile strength joints from 211 to 258 MPa for the friction welder ZT-14 type.

Trans. Nonferrous Met. Soc. China 23(2013) 385-391

WINICZENKO, Robert SALAT,

WINICZENKO, Robert SALAT,  AWTONIUK

AWTONIUK

Department of Production Engineering, Warsaw University of Life Sciences, Nowoursynowska 164 St, 02-787 Warsaw, Poland

Received 12 March 2012; accepted 31 May 2012

Abstract: A hybrid intelligent method for evaluation of near optimal settings of friction welding process parameters of ductile iron was presented. The optimization of welding parameters was carried out in automatic cycle with the use of support vector regression (SVR), genetic algorithm (GA) and imperialist competitive algorithm (ICA). The method suggested was used to determine welding process parameters by which the desired tensile strength was obtained in the friction welding of ductile iron. The highest tensile strength (TS) of 256.93 MPa was obtained using SVR plus GA method for the following friction welding parameters: heating force 40 kN, heating time 300 s and upsetting force 10.12 kN. The samples were welded by friction and subjected to the tensile strength test. The optimized values obtained by means of these hybrid techniques were compared with the experimental results. The application of hybrid intelligent methods allowed to increase the tensile strength joints from 211 to 258 MPa for the friction welder ZT-14 type.

Key words: friction welding; tensile strength; support vector regression; genetic algorithm; imperialist competitive algorithm; ductile iron

1 Introduction

Ductile iron has been utilized as a structural material in many industries, such as, automotive, agriculture and pipe parts by virtue of its excellent strength and toughness.

Generally, welding of ductile iron is necessary for founders and end-user to rectify casting defect and machining errors, to attach lugs or join the casting part with other materials. The poor weldability of ductile iron in fusion welding is due to its high carbon content which leads to the formation of carbides in the fusion zone and martensite in the fusion zone and heat affected zone adjacent to the fusion zone. Carbides and martensite are brittle phases which can cause deterioration of the mechanical properties and machinability at the interface of joining materials [1-3]. Several methods have been employed successfully to join ductile iron to ductile iron and other materials such as stainless steels and mild steels with acceptable properties in the weld and base metal. These methods include manual metal arc welding (MMAW), flux cored arc welding (FCAW), metal inert gas welding (MIG), gas tungsten arc welding (GTAW), gas welding (GW), laser welding (LW) and friction welding (FW) [4-7].

According to CROSSLAND [8], friction welding is an ideal method of joining materials which can be welded with difficulty. Thus, ductile iron can be welded and also joined to other materials such as steels with high alloy-content by friction welding. However, according to the American Welding Society (AWS) [9] and Paton Electric Welding Institute [10] the friction welding of ductile iron is not possible because graphite acts as a lubricant and prevents the generation of heat sufficient for joining. The structure of ductile iron is changed at the interface so that the mechanical properties of the parts which have been joined together are changed. Ductile iron-steel welded joints are particularly difficult to produce since carburization takes place on the low-carbon side with carbide formation. This can result in the formation of a brittle hard zone which cannot be eliminated by annealing. On the other hand, friction welding is a method of welding which has recently been used to connect grey cast iron with both the flake graphite and the nodular graphite. The aim of hitherto trials was to obtain a high mechanical tensile strength of joining during exploitation of a given element. SHINODA et al [11] joined ductile iron by friction welding without any special treatment such as preheating and/or post heating treatment. Some authors have used the interlayers made of low-carbon steel or other materials in order to connect the ductile iron with the use of friction heat [12-16]. MICHIURA et al [17] studied the friction welding of ductile cast iron pipes. OGARA et al [18] examined the relationship between tensile strength characteristics and the macrostructure of joint in friction-welded ductile cast iron. OCHI et al [19] investigated the macrostructure and temperature distribution near the weld interface in the friction welding of FC250 grade cast iron. The highest tensile strengths in the solid joints and pipe joints were 317 MPa (79 % joint efficiency) and 381 MPa (95 % joint efficiency), respectively. SONG et al [20] investigated the strength distribution at the interface of rotary-friction-welded aluminium to nodular cast iron. Regardless of type of material, these technologies complicate welding process, increase its duration and make the technology more expensive. To predict the welding parameters accurately without consuming time, materials and labour effort, various methods are available and evolutionary algorithms are one of such methods.

Many studies on viewing experiments, modeling and optimization for friction rotary welding (FRW) and friction stir welding (FSW) processes have been conducted. MURTI et al [21] developed statistical experimental design model in friction welding dissimilar materials. PAVENTHAN et al [22] used the response surface methodology to optimize the friction welding parameters for joining aluminium alloy and stainless steel. SATHIYA et al [23,24] optimized friction welding parameters for stainless steel using simulated annealing and evolutionary computational techniques. KUMARAN et al [25,26] optimized tube to tube plate using external tool by genetic algorithms and Taguchi method. CANYURT [27] estimated the welded joint strength using genetic algorithm approach. MERAN [28] predicted the optimized welding parameters for the joined brass plates using the genetic algorithms. BABU et al [29] optimized FSW parameters to maximize the tensile strength of aluminium alloy joints. LAKASHMINARAYANAN et al [30] compared response surface methodology (RSM) with artificial neural networks (ANN) in predicting tensile strength of FSW aluminium alloy joints. They predicted the tensile strength and optimized process parameters for FSW magnesium. Prediction of tensile strength and optimization of process parameters for friction stir welded AZ31B magnesium were conducted in Ref. [31]. GOSH et al [32] optimized FSW parameters for dissimilar aluminum alloys. Optimizations of FSW of aluminum alloy by using genetically optimized neural network were reported in Ref. [33]. MALINOV et al [34] modeled the correlation between processing parameters and properties in titanium alloys using ANN.

As it is mentioned above, the available knowledge on friction welding of ductile iron is focused on the structural and mechanical properties, phase formation and tensile strength evolution. These all investigations were carried out on trial and other basis to attain optimum welding conditions. No systematic study has been so far reported to optimize the friction welding parameters to attain the maximum tensile strength in ductile iron similar joints. Only other materials such as stainless steel, aluminum alloys, magnesium or titanium alloys were considered by many researchers. The main reason for this situation can be fact that ductile iron is generally considered a material difficult to weld. Therefore, in this work, an attempt was made to optimize the friction welding process parameters to attain the maximum tensile strength in similar joints of ductile iron using hybrid intelligent methods.

The main objective of this study was to find the optimal welding combination that would maximize the tensile strength of ductile iron joints. The authors suggest the optimization of friction welding parameters to joining ductile iron with the use of unconventional hybrid methods (i.e. SVR plus GA and SVR plus ICA).

2 Experimental

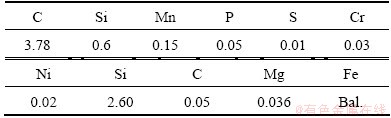

The ductile iron of EN-GJS-400-15 type was investigated. The chemical composition of the specimen material is presented in Table 1. The iron castings were fabricated in the Founding Department of Mechanical Plant PZL-Wola (Warsaw, Poland) according to the following method: the inductive crucible furnace of capacity 3 t, special low-manganese crude iron 30 % + process scrap 15 % and the rest steel scrap, spheroidizing at temperature 1530 °C, a spheroidizer type 611A of granulation 1÷10, modification at temperature of 1450 °C with the use of modifier ZL80ZN (0.4/2) of PECHINEY, putting the bottom of ladle with the use of a sinking device. Then, the samples of properly shaped fronts were welded in a friction welder ZT-14 at University of Technology and Life Sciences in Bydgoszcz (Poland). The heating force (HF) and upsetting force (UF) were in the range of 15-40 kN and 10-60 kN, respectively. The spindle rotating speed was kept constant at 1125 r/min and the welding was performed under the specified friction upset distance.

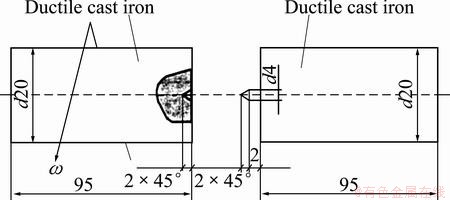

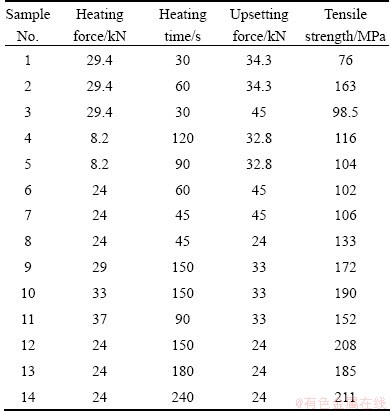

Because of the graphite appearance, the relatively large heating time (HT) 30-300 s was applied. Ductile iron specimens with a diameter of 20 mm and a length of 95 mm were used as parent materials in this study. Shape and size of specimens before friction welding are shown in Fig. 1. Similar ductile iron specimens were joined by friction welding process without any preheating. Friction joints were processed experimentally at randomly chosen parameter sets. Fourteen joints were processed for each parameter set. Tensile strength-related properties of the joints were tested and the average data were presented. Experimental values of friction processed joints are presented in Table 2.

Table 1 Chemical composition of specimen (mass fraction, %)

Fig. 1 Shape and size of specimens before friction welding (unit: mm)

Table 2 Experimental values of friction processed joints

3 Methods

3.1 Background in support vector regression (SVR)

Basically, the SVR [35,36] is a linear machine of one output, working in the high dimensional feature space formed by the nonlinear mapping of the N-dimensional input vector into a K-dimensional feature space (K>N) through the use of function φ(x). The learning task is transformed to the minimization of the error function, defined through the so-called ε -insensitive loss function Lε(d, y(x))

(1)

(1)

where ε is the assumed accuracy; d is the destination; x is the input vector; y(x) is the actual output of the network under excitation of x.

The actual output signal of the SVR network is defined by

(2)

(2)

where w=[ω0, ω1, …, ωK]T is the weight vector and φ(x)=[φ0(x), φ1(x), …, φK(x)]T is the basis function vector.

The learning task is defined as the minimization problem of the error function E:

(3)

(3)

at the following functional and boundary constraints:

(4)

(4)

where C and ε are user-specified constant; ξ and ξ* are slack variables; p is the number of learning data pairs (xi, di).

The most important thing is the choice of coefficients ε and C. The constant ε determines the margin within which the error is neglected. The smaller its value, the more the support vectors will be found by the algorithm. The constant C is the weight, determining the tradeoff between the complexity of the network, characterized by the weight vector and the error of approximation, measured by the slack variables ξi(i=1, 2, …, p).

3.2 Background in genetic algorithm (GA)

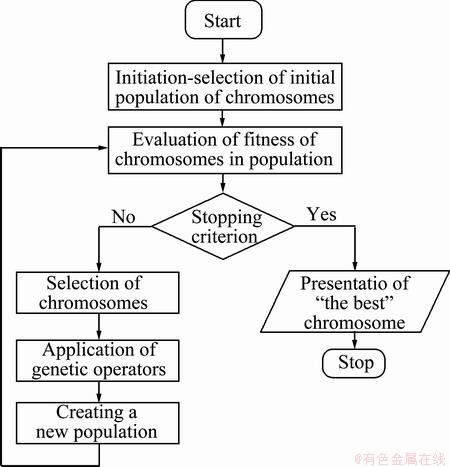

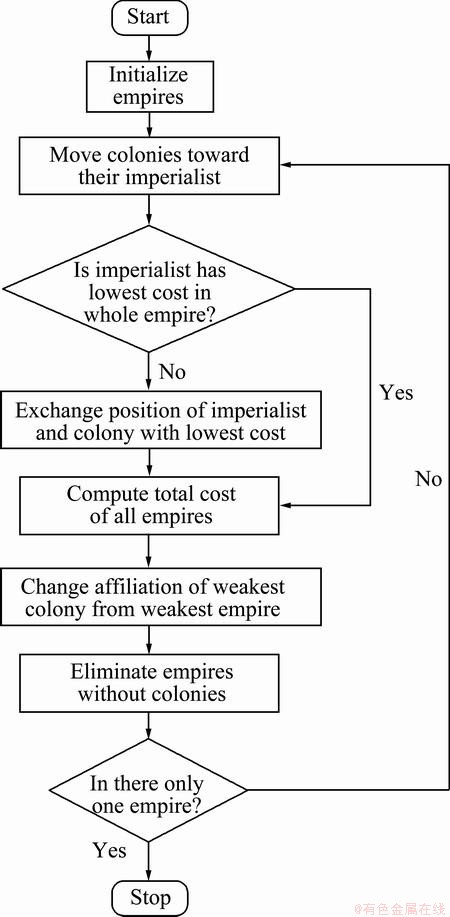

Genetic algorithms are computerized search and optimization algorithms based on the mechanics of natural genetics and natural selection. The general optimization procedure using a genetic algorithm is shown in Fig. 2. These algorithms encode a potential solution to a specific problem on simple chromosome string like data structure and apply specified operators to these structures so as to preserve critical information and to produce a new set of population with the purpose of generating strings which map to high function values [37-39].

Fig. 2 Flowchart for genetic algorithm [37]

The basic (classical) genetic algorithm, also called the elementary or simple genetic algorithm, comprises the following steps [37]:

Step 1: Initiation which is the selection of the initial population of chromosomes;

Step 2: Evaluation of the fitness of chromosomes in the population;

Step 3: Checking the stopping criterion;

Step 4: Selection of chromosomes;

Step 5: Using genetic operators;

Step 6: Creating a new population;

Step 7: Presentation of the “best” chromosome.

3.3 Background in imperialist competitive algorithm (ICA)

Imperialist competitive algorithm (ICA) is one of the evolutionary optimization methods. It was first presented in 2007 [40]. In the most cases, optimization algorithm is a kind of computer simulation of processes observed in the nature but ICA presents different points of view. It is algorithm motivated by the socio-politically mechanism.

In this case, solutions of optimization problem are called countries. Each country can play a role of colony or imperialist. The power of a country is represented by the value of cost function defined by the programmer. The strongest countries become imperialists and the others are considered as their colonies. Both of imperialist and its colonies create the empire. Total power of the empire is dependent on power of imperialist and all its colonies. It can be calculated by the following equation:

Tn=Cn+ζcn (5)

where Tn is the total cost of the nth empire; Cn is the cost of the nth imperialist; cn is the mean cost of all colony of the nth empire; ζ is a number from range (0,1).

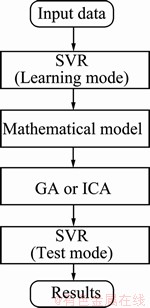

The essential of the ICA is competition of the empires. As a result of this competition, the weakest empires collapse and the most powerful ones take possession of their colonies. Another result of competition is changing position of countries by means of moving colonies toward their imperialist, changing coordinates of imperialist and eliminating the powerless empires. The working of algorithm is presented by the flowchart shown in Fig. 3.

Fig. 3 Flowchart of imperialist competitive algorithm [40]

4 Problem formulation

Conventional friction welding is divided into two basic phases: the friction phase and the upsetting phase. During the first phase, on the boundary of elements subjected to welding, heat is released during mutual friction. In the second phase (called the upsetting phase), the heated-up butting faces of both elements-bond and cool together and a durable connection are created [41]. To produce a good quality joint it is important to set up proper welding process parameters. Welding process is a multi-input and multi-output process in which joints are closely related to welding parameters. Therefore, identifying the suitable combinations of process input parameters to produce the desired output many experiments have to be carried out and this makes the process time-consuming and costly.

We suggest using two methods, namely SVR plus GA and SVR plus ICA which were compared to obtain the more accurate results (i.e., the maximum tensile strength) and friction welding parameters of ductile iron.

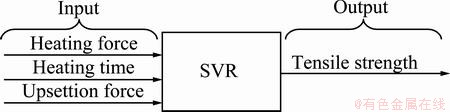

The general structure of the SVR used for hybrid methods is shown in Fig. 4.

Fig. 4 Block diagram of input vector and output of SVR

SVR was used because it is a proper method for regression problems of good generalization performance. In distinction to the classical neural networks, the formulation of learning problem of SVR leads to the quadratic programming with linear constraints whose solution achieves global minimum. Using SVR a mathematical model of welding phenomenon hidden in the form of weights can be easily written , whereas both GA and ICA are good tools for optimization. It seems reasonable to use SVR in connection with both GA and ICA as hybrid methods. Block diagram of the method used is shown in Fig. 5.

Fig. 5 Block diagram for general model usage with optimization algorithms

The algorithm is fully automatic. SVR network is learning the data shown in Table 2. Input data are heating force (HF), heating time (HT), and upsetting force (UF); and the tensile strength (TS) was taken as output data. SVR generates a mathematical model describing the complex relationship between the input and output parameters. The mathematical model is written as a fitness function for both GA and ICA. GA and ICA optimize the fitness function and calculate the input parameters for which the fitness function reaches its maximum tensile strength. These optimal parameters are given back to the SVR and the test mode theoretical maximum of tensile strength is calculated. Next, the experimental studies of friction welding of ductile iron with the parameters obtained from GA and ICA are conducted again. Finally, the results are compared with those of hybrid methods.

5 Parameters of learning

5.1 SVR

The learning process of the SVR network has been performed with the use of SMO-type algorithm implemented in toolbox LIBSVM [42]. We have used the Gaussian radial basis function as the kernel function  , where γ is the kernel parameter. The Gaussian radial basis function satisfied by SVR kernel described as the relation k(x,xi)=φT(x)φ(xi). The optimal value of the ε has been determined after a series of experiments and assumed as 0.001. The parameters C and γ used in experiments were 7×107 and 2×10-6, respectively.

, where γ is the kernel parameter. The Gaussian radial basis function satisfied by SVR kernel described as the relation k(x,xi)=φT(x)φ(xi). The optimal value of the ε has been determined after a series of experiments and assumed as 0.001. The parameters C and γ used in experiments were 7×107 and 2×10-6, respectively.

5.2 GA

The genetic algorithm parameters were as follows: Number of generations was 30, population size was 80, type of selection was roulette wheel probability of crossover and mutations were 0.77 and 0.0077, respectively.

5.3 ICA

The imperialist competitive algorithm parameters were as follows: the number of initial countries was 80, the number of initial imperialists was 8, the number of decades was 30 and parameter ζ was 0.02.

6 Results and discussion

Most of the researchers use traditional optimization techniques for solving engineering problems. The traditional methods of optimization do not perform well over a broad spectrum of domains. Traditional techniques are not efficient. These algorithms are not robust. Conventional techniques such as linear programming, dynamic programming and branch or bound techniques are sometimes insufficient to solve these problems and they are inclined to obtain a local optimal solution [24]. Therefore, authors proposed two hybrid methods, consisting of support vector regression and genetic algorithm (SVR+GA) and support vector regression and imperialist competitive algorithm (SVR+ICA) as a new approach to the friction welding of ductile iron.

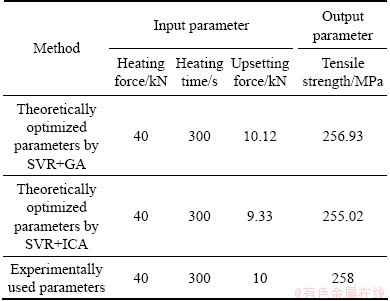

The experiments were conducted with a random change of parameters within the range specified in section 2. The processed joints were subjected to tensile testing in order to evaluate the strength-related aspects of joints. The process parameters for the joints and the associated strength are listed in Table 2. These experimental input and output values were utilized to train the general SVR model. Learning set was equal to 85%, test set contained 15 % of the data. Relative learning error and relative test error were 5.8% and 2.6%, respectively. Both SVR and evolutionary methods have been implemented in Matlab R2010a. The welding optimized parameters (i.e. HF, HT, UF) by both GA and ICA methods are given in section 2. The program is constructed in such a way that the trained SVR takes random input parameters from the optimization GA or ICA algorithms and the output of SVR is again presented to algorithm for optimization. The results obtained from the optimization algorithms are presented in Table 3.

Table 3 Comparison between theoretical and experimental input and output values

Table 3 presents the theoretical and experimental input and output parameters of the friction-processed similar ductile iron joints. The parameters are optimized for the maximized tensile strength. The optimized parameters obtained through GA, were used to process of the friction welding. The highest tensile strength of connection, 256.93 MPa, was obtained using SVR plus GA method for the following friction welding parameters: HF=40 kN, HT=300 s and UF=10.12 kN. The highest tensile strength of connection was found for samples welded with the longest heating time, the highest heating force and the smallest upsetting force. The very close agreement between theoretical and experimental data (less than 1% difference) confirms the potential applicability of these evolutionary computational techniques for the industrial problems. It is noteworthy that for these friction-processed joints, among the optimization techniques used, GA gives the better results than ICA in terms of the maximized tensile strength.

7 Conclusions

1) The application of hybrid intelligent methods allowed to increase the tensile strength joints from 211 MPa to 258 MPa for the friction welder ZT-14 type.

2) The best theoretical tensile strength 256.93 MPa was achieved by SVR+GA method with following parameters: HF=40 kN, HT=300 s and UF=10.12 kN. The results are higher than those achieved by SVR+ICA method.

3) The coherence between the theoretically optimized and the experimentally obtained values of the process parameters ensures the high potential of applying SVR+GA or SVR+ICA evolutionary methods to the friction welding process.

References

[1] PASCUAL M, CEMBRERO J, SALAS F. Analysis of the weldability of ductile iron [J]. Mater Lett, 2008, 62: 1359-1362.

[2] EL-BANNA E M. Effect of preheat on welding of ductile cast iron [J]. Mater Lett, 1999, 41: 20-26.

[3] POURANVARI M. On the weldability of grey cast iron using nickel based filler metal [J]. Mater Des, 2010, 31: 3253-3258.

[4] OZDEMIR N, AKSOY M, ORHAN N. Effect of graphite shape in vacuum-free diffusion bonding of nodular cast iron with gray cast iron [J]. J Mater Process Technol, 2003, 14: 228-233.

[5] MATSUGI K, KONISHI M, YANAGISAWA O, KIRITANI M. Joining of spheroidal graphite cast iron to stainless steel by impact- electric current discharge joining [J]. J Mater Process Technol, 2004, 150: 300-308.

[6] ALABEEDI K F, ABBOUD J H, BENYOUNIS K Y. Microstructure and erosion resistance of nodular cast iron by laser melting [J]. Wear, 2009, 266: 925-933.

[7] EBRAHIMNIA M, MALEK GHAINI F, GHOLIZADE S H, SALARI M. Effect of cooling rate and powder characteristic on the soundness of heat affected zone in powder welding of ductile cast iron [J]. Mater Des, 2012, 33: 551-556.

[8] CROSSLAND B. Friction welding [J]. Contemp Phys, 1971, 12(6): 559-574.

[9] American Welding Society. Recommended practice for friction welding [M]. Miami: AWS, 1989.

[10] LEBEDEV V K, CHERNENKO I A. Welding and surface reviews Friction welding [M]. Amsterdam: Harwood Academic Publishers, 1992.

[11] SHINODA T, ENDO S, KATO Y. Friction welding of cast iron and stainless steels [J]. Weld Int, 1991, 13(2): 89-95.

[12] RICHTER H, PALZKILL A. Applicability of test result from miniature friction welded specimens to full-size specimens as demonstrated by the combination of constructional steel and spheroidal graphite cast iron [J]. Weld Cutting, 1985, 37: 60-5.

[13] DETTE M, HIRSCH J. Reibschweissen von Konstruieren aus Kugelgraphitguss mit Stahlteilen [J]. Schw Und Schn, 1990, 11(42): 188-190.

[14] KACZOROWSKI M, WINICZENKO R. The microstructure and mass transport during friction welding of ductile cast iron [J]. Ind Lub Tribo, 2013, 65(4).

[15] WINICZENKO R, KACZOROWSKI M. Friction welding of ductile cast iron using interlayers [J]. Mater Des, 2012, 34: 444-451.

[16] WINICZENKO R. Structures and mechanical properties of friction welding of ductile cast iron [D]. Warsaw: Warsaw University of Technology, 2001.

[17] MICHIURA Y, MAEKAWA K, TAKAHARA W, KITAGAWA M, HORIE H. Friction welding of ductile cast iron pipes [J]. Jpn J Foundry Eng Soc, 1998, 70: 873-877.

[18] OGARA T, KOJOH K, NAGAYOSHI N. Relation between tensile characteristics and macrostructure of joint in friction welded ductile cast iron [J]. Jpn J Foundry Eng Soc, 2005, 77: 39-43.

[19] OCHI H, KAWAI G, MORIKAWA K, YAMAMOTO Y, SUGA Y. Macrostructure and temperature distribution near the weld interface in friction welding of cast iron [J]. Strength Fracture and Complexity, 2009, 5: 79-88.

[20] SONG Yu-lai, LIU Yao-hui, ZHU Xian-yong, YU Si-rong, ZHANG Ying-bo. Strength distribution at interface of rotary-friction-welded aluminium to nodular cast iron [J]. Transactions of Nonferrous Metals Society of China, 2008, 18(1): 14-18.

[21] MURTI K G K, SUNDARESAN S. Parameter optimization in friction welding dissimilar materials [J]. Metal Construct, 1983, 331-335.

[22] PAVENTHAN R, LAKSHMINARAYANAN P R, BALASUBRAMANIAN V. Prediction and optimization of friction welding parameters for joining aluminium alloy and stainless steel [J]. Transactions of Nonferrous Metals Society of China, 2011, 21(7): 1480-1485.

[23] SATHIYA P, ARAVINDAN S, NOORUL HAQ A. Optimization of friction welding parameters using simulated annealing [J]. Indian Journal of Engineering and Material Science, 2006, 13: 37- 44.

[24] SATHIYA P. Optimization of friction welding parameters using evolutionary computational techniques [J]. J Mater Process Technol, 2009, 5: 2576-2584.

[25] KUMARAN S S, MUTHUKUMARAN S, VINODH S. Optimization of friction welding of tube to tube plate using an external tool by hybrid approach [J]. Journal of Alloys and Compounds, 2011, 509: 2758-2769.

[26] KUMARAN S S, MUTHUKUMARAN S, VINODH S. Optimization of friction welding of tube to tube plate using an external tool [J]. Struct Multidisc Optim, 2010, 42: 449-457.

[27] CANYURT O. Estimation of welded joint strength using genetic algorithm approach [J]. Int J Mech Sci, 2005, 47: 1249-1261.

[28] MERAN C. Prediction of the optimized welding parameters for the joined brass plates using genetic algorithm [J]. Mater Des, 2006, 27: 356-363.

[29] BABU S, ELANGOVAN K, BALASUBRAMANIAN V, BALASUBRAMANIAN M. Optimizing friction stir welding parameters to maximize tensile strength of AA2219 aluminum alloy joints [J]. Metals and Materials International, 2009, 15: 321-330.

[30] LAKASHMINARAYANAN A K, BALASUBRAMANIAN V. Comparison of RSM with ANN in predicting tensile strength of friction stir welded AA7039 aluminium alloy joints [J]. Transactions of Nonferrous Metals Society of China, 2009, 19(1): 9-18.

[31] PADMANABAN G, BALASUBRAMANIAN V. Prediction of tensile strength and optimization of process parameters for friction stir welded AZ31B magnesium [J]. Proceedings of the Institution of Mechanical Engineers, Part B: J Eng Manuf, 2010, 1: 1519-1528.

[32] GOSH M, KUMAR K, KAILAS S V, RAY A K. Optimization of friction stir welding parameters for dissimilar aluminum alloys [J]. Mater Des, 2010, 31: 3033-3037.

[33] TANSEL I N, DEMETGUL M, OKUYUCU H, YAPICI A. Optimizations of friction stir welding of aluminum alloy by using genetically optimized neural network [J]. Int J Adv Manuf Technol, 2010, 48: 95-101.

[34] MALINOV S, SHA W, MCKEOWN J J. Modeling the correlation between processing parameters and properties in titanium alloys using artificial neural network [J]. Comput Mat Sci, 2001, 21: 375-394.

[35] SMOLA A, SCHOLKOPF B. A tutorial on support vector regression [J]. STAT COMPUT, 2004, 14: 199-222.

[36] SALAT R, OSOWSKI S. Support vector machine for soft fault location in electrical circuits [J]. J Intell Fuzzy Syst, 2011, 22(1): 21-31.

[37] RUTKOWSKI L. Computational intelligence, methods and techniques [M]. Berlin: Springer, 2008.

[38] DEB K. Optimization for engineering design [M]. New Delhi: Prentice-Hall, 1998.

[39] GEN M, CHENG R. Genetic algorithms and engineering design [M]. New York: Wiley, 1997.

[40] ATASHPAZ GARGARI E, LUCAS C. Imperialist competitive algorithm: an algorithm for optimization inspired by imperialistic competition [C]//IEEE Congress on Evolutionary Computation. Singapore, 2007: 4661-4667.

[41] VILL V I. Friction welding of metals [M]. New York: AWS, 1962.

[42] CHANG C C, LIN C J. LIBSVM: A library for support vector machines [J]. ACM Trans on Intell Syst and Technol, 2011, 2(27): 1-27.

WINICZENKO, Robert SALAT,

WINICZENKO, Robert SALAT,  AWTONIUK

AWTONIUK

Department of Production Engineering, Warsaw University of Life Sciences, Nowoursynowska 164 St, 02-787 Warsaw, Poland

摘 要:采用混合智能方法评价球墨铸铁的最佳摩擦焊接工艺参数。在自动循环中使用支持向量回归(SVR)、遗传算法(GA)和帝国竞争算法(ICA)优化焊接工艺参数。该方法被用来确定焊接工艺参数, 得到了理想的球墨铸铁摩擦焊接抗拉强度。在加热力40 kN,加热时间300 s,顶锻压力10.12 kN条件下,使用SVR加上GA方法得到了最高抗拉强度为256.93 MPa。将摩擦焊接样品进行拉伸强度测试,并比较了采用混合智能方法得到的优化值与实验结果。结果表明,混合智能方法可以使ZT-14型摩擦焊机拉伸强度从211 MPa增加到258 MPa。

关键词:摩擦焊接;抗拉强度;支持向量回归;遗传算法;经验竞争算法;球磨铸铁

(Edited by Xiang-qun LI)

Corresponding author: Robert SALAT; Tel: +48-225-934-608; Fax: +48-225-934-618; E-mail: robert_salat@sggw.pl

DOI: 10.1016/S1003-6326(13)62474-7