Trans. Nonferrous Met. Soc. China 23(2013) 3643-3649

Effect of Zn and Ti mole ratio on microstructure and photocatalytic properties of magnetron sputtered TiO2-ZnO heterogeneous composite film

Li-jing BAI, Gang KOU, Zhen-yao GONG, Zhi-ming ZHAO

School of Materials Science and Engineering, Xi’an University of Technology, Xi’an 710048, China

Received 23 February 2013; accepted 5 July 2013

Abstract: Series of TiO2-ZnO heterojunction composite films with different n(Zn)/n(Ti) ratios were prepared by UDP450 magnetron sputter ion plating equipment, and the mole ratio of Zn to Ti was controlled by adjusting the current values of sputtering target. The effects of n(Zn)/n(Ti) on the microstructures of TiO2-ZnO films were investigated by SEM, AFM, Raman and XPS, and their photocatalytic decomposition of methyl orange solutions was evaluated. The results show that an increase in n(Zn)/n(Ti) typically results in a decrease in the grain size of composite films firstly and then an increase of grain size, while an increase in n(Zn)/n(Ti) leads to an increase in film roughness firstly and then a decrease in film roughness. Both grain size and roughness of TiO2-ZnO films reach the maximum and minimum at n(Zn)/n(Ti) of 1/9.3, respectively. The n(Zn)/n(Ti) shows little effect on the valences of Zn and Ti elements, which mainly exist in the form of TiO2 and ZnO phases. The n(Zn)/n(Ti) has influence on the amount of anatase/rutile TiO2 heterojunction in the film. With increase of the n(Zn)/n(Ti), the absorption intensity of the composite film increases and the absorption region extends to 450 nm, which is redshifted as much as 150 nm in comparison with the pure TiO2 films. However, the photocatalytic abilities of heterogeneous composite films do not depend on the n(Zn)/n(Ti) but rather on the microstructures of the TiO2-ZnO composite films. Degradation rate of the film reaches the maximum and the photocatalytic decomposition of pollutants works best when n(Zn)/n(Ti)=1:9.3.

Key words: magnetron sputtering; TiO2-ZnO thin films; Zn to Ti mole ratio; microstructure; photocatalytic

1 Introduction

The TiO2-ZnO heterogeneous composite films have received considerable attention due to their better physical, chemical and photocatalytic properties originated from the strong absorption of the ultraviolet light of nano-ZnO particles in films [1-4] in comparison with the pure TiO2 or ZnO film. Therefore, the incorporation of ZnO into TiO2 matrix film can improve the light absorption of TiO2 film dramatically. Moreover, ZnO and TiO2 have similar band gap and staggered band position. The molecule-level mixed ZnO-TiO2 heterojunction film possesses a narrower band gap as compared with single-phase TiO2 film, which makes the light-absorption red-shift and photocatalytic activity improve.

In addition, the sputtered films are amorphous, and the post-annealing is necessary to make the films crystallize. Unfortunately, grains grow and phase transformation takes place at the elevated annealing temperature, which results in the decrease of the photocatalytic activity of semiconductors. Incorporation of certain amount of ZnO into the TiO2 film could not only refine the TiO2 grains during the annealing process significantly, but also increase the anatase-to-rutile transition temperature of TiO2 phase and improve the thermal stability of TiO2. It was reported that the photocatalytic activities of some semiconductors are enhanced by addition of ZnO into TiO2 films [3-7].

However, there is an optimal value for the addition of ZnO. KANMANI and RAMACHANDRAN [5], TIAN et al [8], ZHANG et al [9] found that a small amount of additive could promote the photocatalytic degradation of methyl orange. The over-addition of ZnO could significantly decrease the photocatalytic activity because of the poor anti-light corrosion and chemical stability of ZnO itself. It is also found that the amount of ZnO phase has effects on the TiO2 grain growth, phase transformation and the film composition, which reflects the photocatalytic activities of the films in return [10]. Therefore, precise and effective control of n(Zn)/n(Ti) of the films is the key factor to achieve the high photocatalytic properties of TiO2-ZnO heterojunction composite films.

At present, TiO2-ZnO heterojunction composite film can be prepared by sol-gel, chemical vapor deposition(CVD) and various physical vapor deposition(PVD) methods [9,11,12]. The magnetron sputter ion plating technique is well known for the convenient preparation control and good repeatability of film performance. The TiO2-ZnO composite film obtained by magnetron sputter ion plating technique can effectively avoid the formation of titanium zinc due to its reactive sputtering process. Thus, the properties of TiO2-ZnO films prepared by this technique are better than those prepared by other techniques where titanium zinc can be generated [13].

In this work, the closed field magnetron sputter ion plating technology was used to prepare series of TiO2-ZnO heterojunction composite films with different n(Zn)/n(Ti). The contributions of addition of ZnO to photocatalytic activity of the composite films were studied by analyzing the effects of n(Zn)/n(Ti) on the microstructures and photocatalytic activities of the composite films.

2 Experimental

2.1 Preparation of TiO2-ZnO composite films

The TiO2-ZnO composite films were deposited on slides by UDP450/4 equipment. The targets were titanium and zinc with purity of 99.95%, and Ti target and Zn target were placed oppositely. The glass substrate voltage was -75 V. Working gas was Ar with a purity of 99.99%, and reactive gas was O2 with a purity of 99.99%, the initial vacuum was 4 mPa, the deposition pressure was controlled at 0.133 Pa, and the Ar/O2 flow volume ratio was 8/13. The different n(Zn)/n(Ti) ratios were controlled by regulating the target current.

2.2 Characterization of TiO2-ZnO composite films

After deposition, the films were annealed at 500 °C for 2 h. The surface morphologies and element content of the samples were observed by a scanning electron microscope (SEM JSM-6700) equipped with an energy disperse spectroscope (EDS Oxford INCA). The surface roughness was measured by an atomic force microscope (AFM PI3800-SPA-400). X-ray photoelectron spectroscopy (XPS) was conducted on an AXIS ULTRA DLD spectrometer with an Al (mono) Kα (1486.6 eV) source operated at 15 kV and 120 W. The phase identification of samples was conducted with a micro-Raman spectroscope (JOBIN YVON RAMANOR-V1000, Ar+ laser wavelength 514.5 nm, laser power 600 mW, temperature 25 °C).

2.3 Photocatalytic experiments of TiO2-ZnO composite films

Photocatalytic activity test of the TiO2-ZnO composite films was carried out by degradation of methyl orange solution under UV irradiation. The concentration of methyl orange solution was measured under irradiation by UV-756 spectrophotometer, and the initial concentration was 10 mg/L. A 40 W UV light with the wavelength of 253.7 nm was suspended above the degradation system with a distance of 10 cm. The solution was stirred during the reaction process. With proceeding of photocatalytic reaction, the decoloration occurred, and the absorption peak of methyl orange solution at 465 nm gradually decreased and even disappeared. The photocatalytic efficiency was evaluated with the degradation rate (K) by testing the corresponding absorption of solutions during photocatalytic reaction process [9]. The degradation rate K of methyl orange was calculated using the following expression:

K=[ln(c0/c)]/t=ln[(A0/A)]/t

where t is the reaction time; c is the concentration of methyl orange after reacting; c0 is the initial concentration; A is the absorbance of methyl orange solution after reacting; A0 is the initial absorbance.

3 Results and discussion

3.1 Effect of n(Zn)/n(Ti) on film surface structure

Generally, the grains of film grow and accordingly the surface roughness change during the annealing process. The grain size has an important effect on the light absorption and band gap of the semiconductor and further changes the photocatalytic properties of films. Figure 1 shows the surface morphology of composite films with different n(Zn)/n(Ti) ratios.

As shown in Fig. 1, the film surfaces are smooth and dense, and the particle sizes of all TiO2-ZnO composite films are smaller than that of TiO2 film. However, the particle sizes of the films with different n(Zn)/n(Ti) ratios are different. With increasing the n(Zn)/n(Ti), the particle size decreases firstly and then increases until reaches a minimum value (Table1). The particle sizes are 30-35, 16-20, 8-10, 14-17 and 20-25 nm, respectively. The film is the most uniform and the grain size is the smallest when the n(Zn)/n(Ti) is 1/9.3. ZnO is non-crystallized and exists as small cluster dispersed in the composite film, which increases the migration distance of Ti4+ during the growth of TiO2 particles and inhibits the growth of the TiO2 grains when the content of ZnO is small. The higher the Zn content, the more obvious the inhibitory effect, but the smaller the TiO2 grains as well. However, ZnO begins to crystallize when the ZnO content reaches a certain value. Excess ZnO may reduce the migration distance of Ti4+ and accelerate the growth of TiO2 particles, which leads to the increased grain size in films. When the n(Zn)/n(Ti) is 1/0.7, particle agglomeration appears. It is known that the film roughness reflects the particle size of films. Generally, a larger roughness leads to a bigger surface area and hence a better photocatalytic activity.

Fig. 1 Surface morphologies of composite films with different n(Zn):n(Ti) ratios

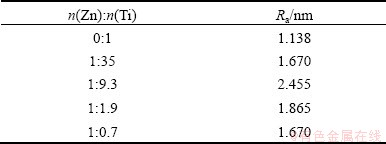

Table 1 lists the Ra values of the composite films measured by AFM with different n(Zn)/n(Ti) ratios (test area: 10 μm×10 μm).

With increasing the n(Zn)/n(Ti), the film surface roughness increases firstly, and then decreases. The roughness of the composite films reaches the maximum at n(Zn)/n(Ti)=1/9.3. This indicates that the grain growth and the film surface roughness are partly influenced by the n(Zn)/n(Ti). Such influence can play a certain role in the recombination rate of photo excited carriers, and then affect the photocatalytic property.

Table 1 Surface roughness of composite film with different n(Zn)/n(Ti) ratios

3.2 Effect of n(Zn)/n(Ti) on film phase structure

Figure 2 shows Zn 2p and Ti 2p XPS spectra of the composite films. As shown in Fig. 2(a), two intensity peaks at the binding energies of 1044.8 and 1021.9 eV are observed in all XPS spectra, which are assigned to Zn 2p3/2 and Zn 2p1/2, respectively. This indicates that the Zn exists as ZnO only in the composite films [14,15]. Thus, the addition of Zn increases the ZnO content and further increases the TiO2-ZnO heterojunction number with maintaining the valence state of the Zn element. Figure 2(b) shows the XPS spectra of Ti. Two asymmetrical Ti 2p peaks are observed, which indicates that Ti element exists as two kinds of oxidation states in the films. One corresponds to the  (457.55 eV) and

(457.55 eV) and  (463.30 eV) and the other corresponds to

(463.30 eV) and the other corresponds to  (458.30 eV) and

(458.30 eV) and  (464.05 eV). The difference of binding energy between TiⅢ and TiⅣ is similar (5.7 eV), which is consistent with the reported value in references [16,17]. These results indicate that Ti exists dominantly in the phases of TiO2 and fewer in the phase of the Ti2O3 in the composite films.

(464.05 eV). The difference of binding energy between TiⅢ and TiⅣ is similar (5.7 eV), which is consistent with the reported value in references [16,17]. These results indicate that Ti exists dominantly in the phases of TiO2 and fewer in the phase of the Ti2O3 in the composite films.

Fig. 2 Zn 2p and Ti 2p XPS spectra of composite films

It is well known that the anatase/rutile TiO2 mixture shows a higher photocatalytic activity than the single anatase or rutile. The photocatalytic activity of anatase TiO2 is higher than rutile TiO2 [18,19]. However, the standard formation energy of rutile TiO2 phase is always lower than anatase phase at heat treatment temperature. Thus, the anatase TiO2 can easily transform into the rutile structure during the annealing process, which lowers the photocatalytic activity of the films. An effective method to hinder the anatase-to-rutile transformation of TiO2 is the incorporation of ZnO into the TiO2 film [6].

Fig. 3 Raman spectra of composite films with different n(Zn)/n(Ti) ratios

Figure 3 shows the Raman spectra of the composite films with different n(Zn)/n(Ti) ratios. From Fig. 3, when Zn content is small, the diffraction peaks of ZnO phase are not detected. But when the n(Zn)/n(Ti) is 1/9.3 or more, the peaks of ZnO are observed and the peak intensity gradually increases with increasing the n(Zn)/n(Ti). Moreover, with increasing n(Zn)/n(Ti), anatase TiO2 gradually transforms into rutile TiO2. This indicates that the phase composition of the mixed heterojunction films is dependent on the n(Zn)/n(Ti) again. When n(Zn)/n(Ti) is less than 1/9.3, the existence of ZnO can hinder the anatase-to-rutile transformation of TiO2. Once the n(Zn)/n(Ti) is more than 1/9.3, this effect becomes weak. As discussed above, a low content of Zn2+ decreases the probability of ZnO agglomerating apparently, and the ZnO peaks cannot be detected in Raman spectrometer shown in Fig. 3. In this situation, Zn ions exist as small clusters dispersed in anatase/rutile TiO2 matrix, and generate the Ti—O—Zn bonds [4,6]. These weak bonds limit the diffusion and transportation of atoms between TiO2 grains, thus preventing the formation of nucleation and the growth of the rutile phase. Namely, the anatase-to-rutile transformation of TiO2 is inhibited by this way effectively. This brings about the co-existence of anatase and rutile TiO2 in the films. With increasing the n(Zn)/n(Ti), the agglomeration of Zn elements is gradually promoted, and it causes the formation of ZnO phase. The number of Ti—O—Zn bonds decreases and makes they difficult inhibit the anatase-to-rutile transformation. Therefore, the more the amount of ZnO, the weaker the capability of stabilizing the TiO2 phase transformation, and the more the amount of rutile TiO2 exists in the film. During annealing process, the n(Zn)/n(Ti) has great influence on the phase transformation of TiO2. When the n(Zn)/n(Ti) is 1/9.3, the amount of TiO2-ZnO heterojunction shows the maximum. In contrast, excessive ZnO has little effect on the TiO2 phase transformation.

3.3 Effect of n(Zn)/n(Ti) on film photocatalytic activity

Figure 4 shows the effect of n(Zn)/n(Ti) on the UV-vis absorption of the composite films. It can be seen that the composite film has a wider UV-vis absorption edge compared with TiO2 film. The TiO2 film shows the smallest absorption edge, and the composite films with different n(Zn)/n(Ti) ratios have different absorption edges. The red-shift can also be observed clearly in Fig. 4. It shows that the larger the n(Zn)/n(Ti), the more obvious the red-shift. The maximum absorption edge is 450 nm, and the UV-vis absorption wavelength is increased by about 150 nm compared with the TiO2 film. This indicates that the addition of ZnO expands the light response range. And more TiO2-ZnO heterojunction can exhibit a wider light response range which makes the film absorb much light, and improves its photocatalytic activity significantly.

Fig. 4 UV-vis absorption spectra of composite films with different n(Zn)/n(Ti) ratios

Figure 5 shows the relationship between ln(c0/c) and reaction time for composite films degrading methyl orange with different n(Zn)/n(Ti) ratios.

Fig. 5 Relationship between ln(c0/c) and reaction time for composite films degrading methyl orange with different n(Zn)/n(Ti) ratios

As shown in Fig. 5 and Table 2, ln(c0/c) vs reaction time shows a good linear relationship. It is well accepted that the photocatalytic decomposition of organic pollutants fits the pseudo first-order kinetic rule. When n(Zn)/n(Ti) is 1/9.3, the K of the composite film degrading methyl orange is the largest. Whereas, when n(Zn)/n(Ti) is 1/0.7, the degradation of methyl orange evaluated by K is even lower than that of pure TiO2 film. The half-life, t0.5, of film degrading methyl orange exerts the same tendency as the K value. This indicates that the expansion of light response range caused by the TiO2-ZnO heterojunction is not the only factors which influence the photocatalytic properties.

However, the regular of K value depending on n(Zn)/n(Ti) is different from the relationship shown in Fig. 4. The reason is possible that: 1) the roughness of the composite film with the n(Zn)/n(Ti) of 1/9.3 is the largest, and it can absorb more methyl orange molecule on surface for photocatalysis reaction; 2) the high chemical activity of ZnO makes the composite films more easy corrode especially when the content of ZnO is more.

Table 2 First-order kinetic equation and parameter of film degrading methyl orange

As mentioned above, the grain size, surface roughness, and the n(anatase)/n(rutile) ratio of TiO2 phase are influenced by n(Zn)/n(Ti). Films with small grains and high surface roughness have an optimal n(anatase)/n(rutile) ratio of the TiO2 phase and a large surface area, and both of them are conducive to photo-induced carriers to move to the film surface and increase the separation efficiency of the photoexcited electron-hole pairs. Therefore, the efficiency of photocatalytic activity can be improved.

From Table 2, it shows that the surface hydroxyl content of the composite films is improved by the addition of ZnO. With increasing n(Zn)/n(Ti), the surface hydroxyl content increases to 13.86% (n(Zn):n(Ti)= 1:9.3). However, when n(Zn)/n(Ti) is more than 1/9.3, it decreases with increasing n(Zn)/n(Ti). The composite film with n(Zn)/n(Ti) of 1/9.3 has the maximum hydroxyl content. This is consistent with the film surface particle size and the n(anatase)/n(rutile) ratio of the TiO2 phase, as well as the K value. Therefore, the key reason that influences the photocatalytic activity of the composite films is that ZnO affects the microstructure of the composite films and the UV-vis absorption.

4 Conclusions

1) The grain size and surface roughness of TiO2– ZnO films vary differently with change of n(Zn)/n(Ti). With increasing the n(Zn)/n(Ti), the grain size of films decreases firstly followed by a increase, whereas the roughness of films first increases then decreases. Both grain size and surface roughness reach a maximum and minimum at n(Zn)/n(Ti) of 1/9.3, respectively.

2) The valence states of the Ti and Zn in the films are not affected by n(Zn)/n(Ti). The Ti and Zn atoms exist mainly as TiO2 and ZnO, respectively. The n(anatase)/n(rutile) ratio, however, is influenced by the n(Zn)/n(Ti). Moreover, n(Zn)/n(Ti) of 1/9.3 leads to a maximum amount of the heterojunction existing in the TiO2-ZnO films.

3) The value of the n(Zn)/n(Ti) correlates positively with the light response range and absorbance of the films. The absorption edge of TiO2-ZnO films is ca. 450 nm, which is redshifted as much as 150 nm in contrast to TiO2 film and moves from UV-light region to the visible-light region. But the photocatalytic capacities of composite films are not determined by the absorption band only.

4) The microstructure of ZnO-TiO2 films is the key factor which determines the photocatalytic activity of the composite films by the addition of ZnO to TiO2. The K value of composite films reaches the maximum at n(Zn)/n(Ti) of 1/9.3, and eventually results in the best photocatalytic activity.

References

[1] TAO Jie, DENG Jie, DONG Xiang, ZHU Hong, TAO Hai-jun. Enhanced photocatalytic properties of hierarchical nanostructured TiO2 spheres synthesized with titanium powders [J]. Transactions of Nonferrous Metals Society of China, 2012, 22(8): 2049-2056.

[2] BEHNAJADY M A, MODIRSHAHLA N, SHOKRI M, ZEININEZHAD A, ZAMANI H A. Enhancement photocatalytic activity of ZnO nanoparticles by silver doping with optimization of photo-deposition method parameters [J]. Journal of Environmental Science and Health, 2009, 44(7): 666-672.

[3] GAO Jing-qun, LUAN Xiao-yu, WANG Jun, WANG Bao-xin, LI Kai, KANG Ping-lie, HAN Guang-xi. Preparation of Er3+:YAlO3/Fe-doped TiO2-ZnO and its application in photocatalytic degradation of dyes under solar light irradiation [J]. Desalination, 2011, 268(1-3): 68-75.

[4] ZHOU Yi, SHI De-hui, LI Hong, DANG Ming-ming,  Cai-xia, HUANG Ke-long. Preparation and photoelectric effect of Zn2+-TiO2 nanotube arrays [J]. Transactions of Nonferrous Metals Society of China, 2010, 20(9): 2320-2325.

Cai-xia, HUANG Ke-long. Preparation and photoelectric effect of Zn2+-TiO2 nanotube arrays [J]. Transactions of Nonferrous Metals Society of China, 2010, 20(9): 2320-2325.

[5] KANMANI S S, RAMACHANDRAN K. Synthesis and characterization of TiO2/ZnO core/shell nanomaterials for solar cell applications [J]. Renewable Energy, 2012, 43: 149-156.

[6] FIRDAUS C M, SHAH RIZAM M S B, RUSOP M, RAHMATUL HIDAYAH H. Characterization of ZnO and ZnO:TiO2 thin films prepared by sol-gel spray-spin coating technique [J]. Procedia Engineering, 2012, 41: 1367-1373.

[7] WANG He-feng, SHU Xue-feng, LI Xiu-yan, TANG Bin. Photocatalytic activities of N doped TiO2 coatings on 316L stainless steel by plasma surface alloying technique [J]. Transactions of Nonferrous Metals Society of China, 2012, 22(1): 120-126.

[8] TIAN Jin-tao, CHEN Li-juan, DAI Jin-hui, WANG Xin, YIN Yan-sheng, WU Ping-wei. Preparation and characterization of TiO2, ZnO, and TiO2/ZnO nano-films via sol–gel process [J]. Ceramics International, 2009, 35(6): 2261-2270.

[9] ZHANG Wen-jie, ZHU Sheng-long, LI Ying, WANG Fu-hui. Photocatalytic Zn-doped TiO2 films prepared by DC reaction magnetron sputtering [J]. Vacuum, 2008, 82(3): 328-335.

[10] LIAO Yi-chuan, XIE Chang-sheng, LIU Yuan, CHEN Hao, LI Hua-yao, WU Jun. Comparison on photocatalytic degradation of gaseous formaldehyde by TiO2, ZnO and their composite [J]. Ceramics International, 2012, 38(6): 4437-4444.

[11] KU Young, HUANG Ying-Hau, CHOU Yiang-Chen. Preparation and characterization of ZnO/TiO2 for the photocatalytic reduction of Cr(VI) in aqueous solution[J].Chemical, 2011, 342-343: 18-22.

[12] CHOI Won-Seok, KIM Eui-Jung, SEONG Seung-Gie, KIM Yong- Soo, PARK Chinho, HAHN Sung. Optical and structural properties of ZnO/TiO2/ZnO multi-layers prepared via electron beam evaporation [J]. Vacuum, 2009, 83(5): 878-882.

[13]  N, AIT AMAR H. Photocatalytic oxidation of methyl orange in presence of titanium dioxide in aqueous suspension. Part II: Kinetics study [J]. Desalination, 2005, 185(1-3): 439-448.

N, AIT AMAR H. Photocatalytic oxidation of methyl orange in presence of titanium dioxide in aqueous suspension. Part II: Kinetics study [J]. Desalination, 2005, 185(1-3): 439-448.

[14] PATIL ASHOKRAO B, PATIL KASHINATH R, PARDESHI SATISH K. Ecofriendly synthesis and solar photocatalytic activity of S-doped ZnO [J]. Journal of Hazardous Materials, 2010, 183(1-3): 315-323.

[15] WANG Hai-qiang, WU Zhong-biao, LIU Yue. The characterization of ZnO-anatase-rutile three-component semiconductor and enhanced photocatalytic activity of nitrogen oxides [J]. Journal of Molecular Catalysis A: Chemical, 2008, 287(1-2): 176-181.

[16] NASERI N, YOUSEFI M, MOSHFEGH A Z. A comparative study on photo-electrochemical activity of ZnO/TiO2 and TiO2/ZnO nanolayer systems under visible irradiation [J]. Solar Energy, 2011, 85(9): 1972-1978.

[17] KIM Myoung-Joo, KIM Kwang-Dae, SEO Hyun-Ook, LUO Yuan, DEY Nilay-Kumar, KIM Young-Dok. Improvement in the photocatalytic activity of TiO2 by the partial oxidation of the C impurities [J]. Applied Surface Science, 2011, 257(7): 2489-2493.

[18] OUYANG Mi, BAI Ru, XU Yi, ZHANG Cheng, MA Chun-an, WANG Mang, CHEN Hong-zheng. Fabrication of polypyrrole/TiO2 nanocomposite via electrochemical process and its photoconductivity [J]. Transactions of Nonferrous Metals Society of China, 2009, 19(6): 1572-1577.

[19] SPUUR R A, MYERS H. Quantitive analysis of anatase-rutile mixtures with an X-ray diffractometer [J]. Analytical Chemistry, 1957, 29(5): 760-762.

Zn与Ti摩尔比对磁控溅射TiO2-ZnO异质复合薄膜微观结构及光催化性能的影响

白力静,寇 钢,龚振瑶,赵志明

西安理工大学 材料科学与工程学院,西安 710048

摘 要:利用磁控溅射离子镀技术制备系列TiO2–ZnO异质复合薄膜,通过调节溅射靶材电流的大小控制薄膜中n(Zn)/n(Ti)值。采用AFM﹑SEM﹑Raman和XPS手段表征薄膜的微观形貌和结构,并以甲基橙作为光催化污染物,研究n(Zn)/n(Ti)对TiO2-ZnO复合薄膜微观结构及光催化性能的影响。结果表明:随着n(Zn)/n(Ti)的增大,复合薄膜的晶粒尺寸先减小而后增大,其粗糙度也先增大而后减小,且均在n(Zn)/n(Ti)为1/9.3时达到极值;n(Zn)/n(Ti)对薄膜中元素Ti和Zn的价态无明显影响,均以TiO2和ZnO形式存在,但比值的大小影响薄膜退火后TiO2中锐钛矿/金红石异质结的数量;n(Zn)/n(Ti)越大,复合薄膜的光响应范围及吸光度越大,其响应光谱最大可扩展150 nm,波长可至450 nm,但异质复合薄膜光催化效果与其并不对应,取决于ZnO对TiO2复合薄膜微观结构的影响,当n(Zn)/n(Ti)为1/9.3时,薄膜的降解速率最大,光催化能力最好。

关键词:磁控溅射;TiO2-ZnO薄膜;Zn与Ti摩尔比;微观结构;光催化

(Edited by Xiang-qun LI)

Foundation item: Project (2010JQ6008 ) supported by the Natural Science Foundation of Shaanxi Province, China

Corresponding author: Li-jing BAI; Tel: +86-29-82312592; E-mail: bljlxm@xaut.edu.cn

DOI: 10.1016/S1003-6326(13)62912-X