快速凝固Al-Li-Cu-Mg-Zr合金的时效特征

来源期刊:中南大学学报(自然科学版)1992年第3期

论文作者:黄钧声 金头男 张新明 左铁镛

文章页码:323 - 327

关键词:快速凝固; 铝俚合金; 力学性能; 微观组织; 时效

Key words:rapid solidification; aluminum-lithium alloy; aging; microstructure; mechanical property

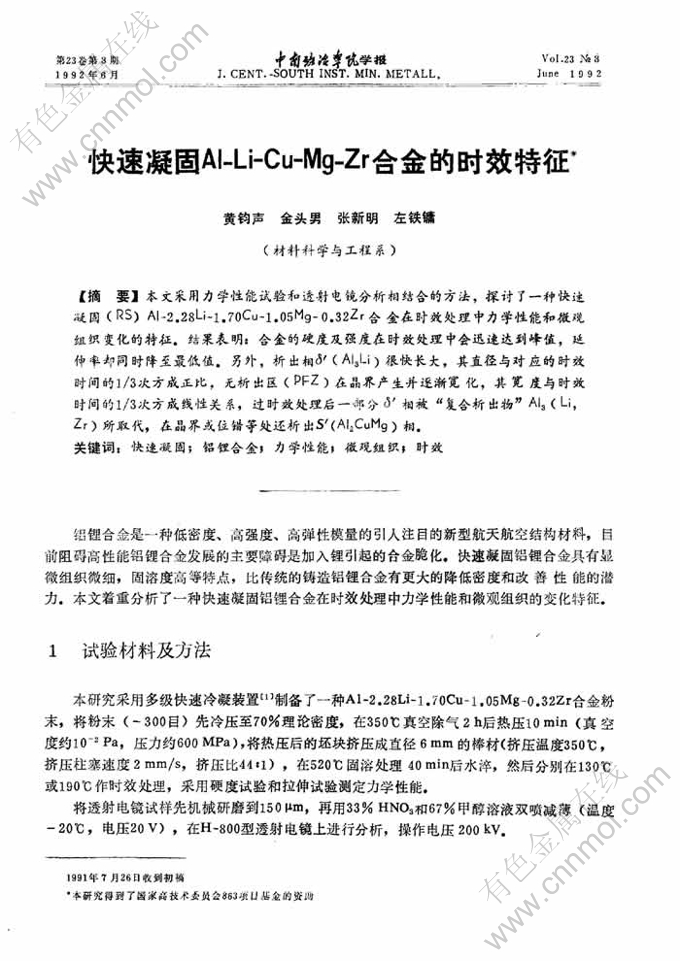

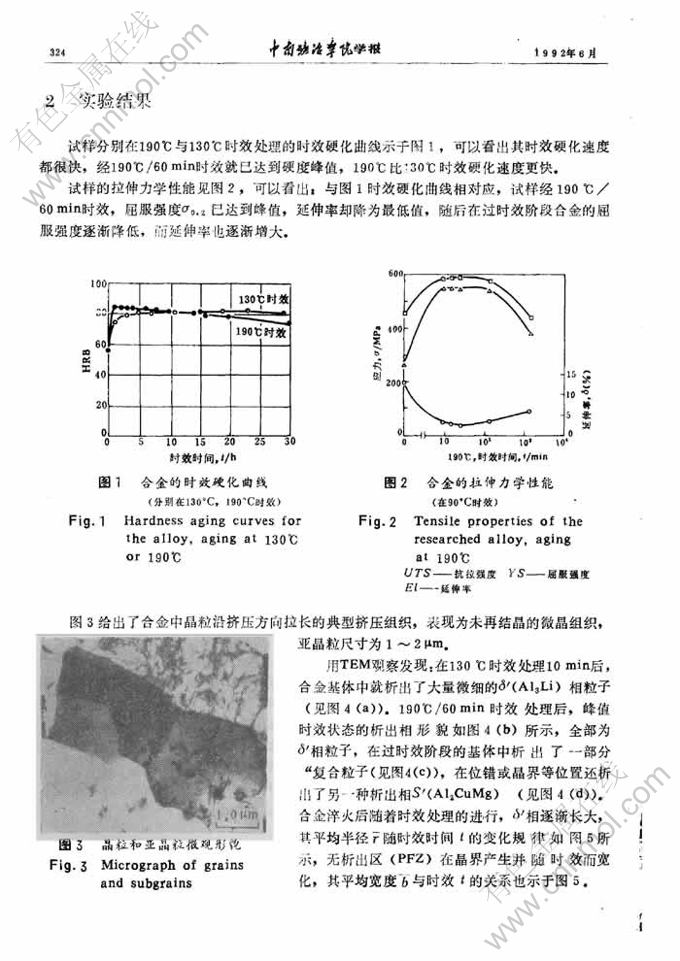

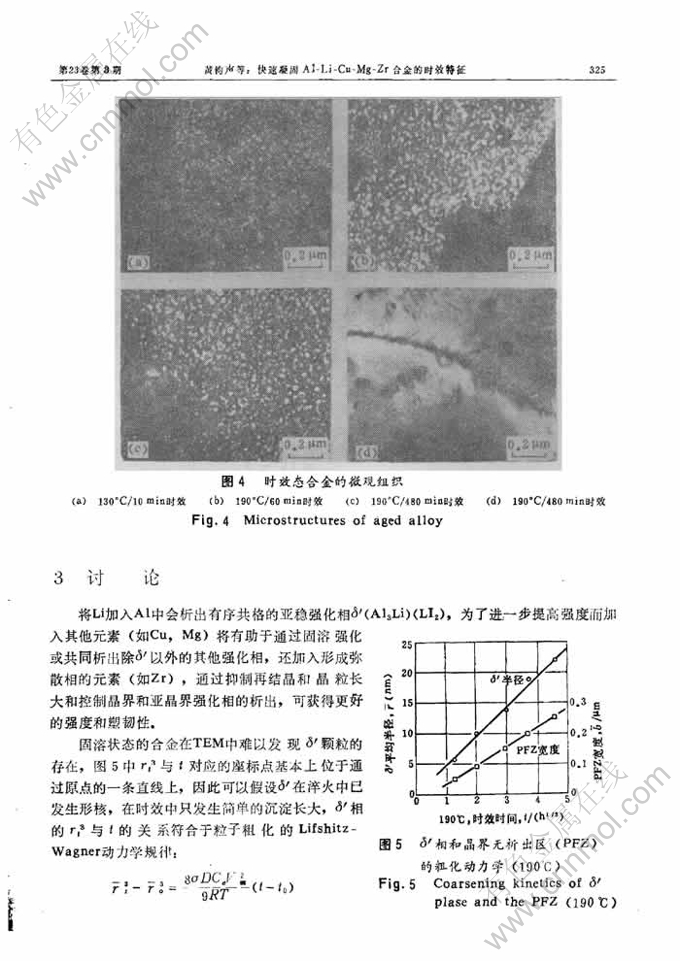

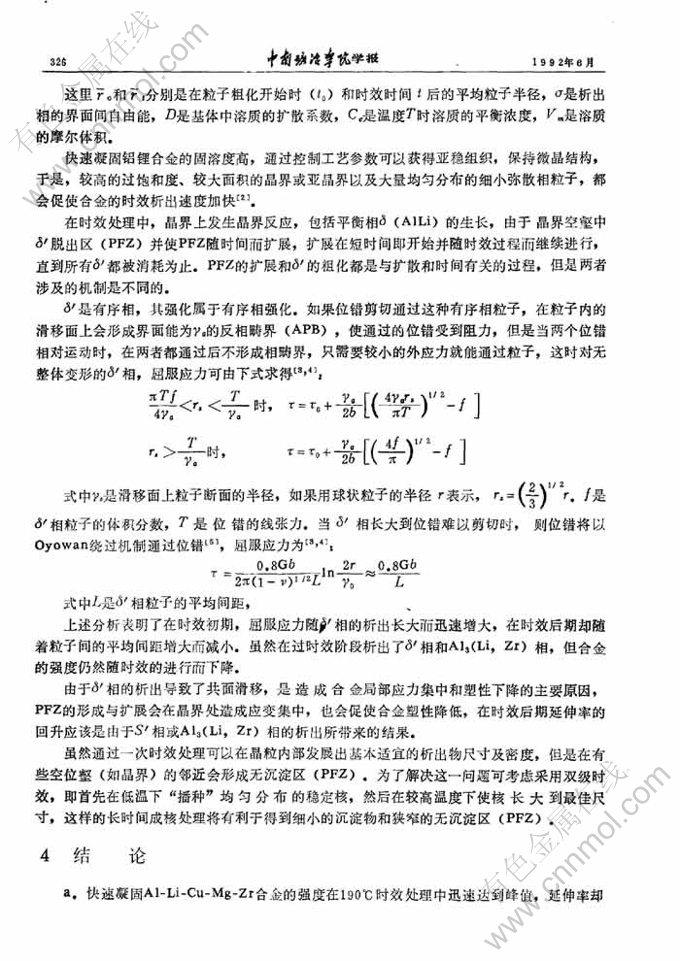

摘 要:本文采用力学性能试验和透射电镜分析相结合的方法,探讨了一种快速凝固(RS)Al-2.28Li-1.70Cu-l.05Mg-0. 32Zr合金在时效处理中力学性能和微观组织变化的特征。结果表明:合金的硬度及强度在时效处理中会迅速达到峰值,延伸率却同时降至最低值。另外,析出相δ’(A13Li)很快长大,其直径与对应的时效时间的1/3次方成正比,无析出区(PFZ)在晶界产生并逐渐宽化,其宽度与时效时间的1/3次方成线性关系,过时效处理后一部分δ’相被“复合析出物”Al3(Li,Zr)所取代,在晶界或位错等处还析出S’(Al2CuMg)相。

Abstract: The mechanical properties and microstructures of a rapidly solidified Al-2. 28Li-1. 70Cu-1. 05Mg-O. 32Zr alloy during the aging process have been inves-tigated. The results show that its hardness and strenghth rapidly increase topeak values, but its elongation simutaneously decreases to the lowest valuewhen aging at 190℃. Furthermore, the precipitates δ'(Al3Li) phases grow continuously and its average diameters are proportional to the one-third power of corresponding aging time. The precipitate free zone (PFZ) appears and widens generally in grain boundaries; its width increases with the one-third power of aging time on linear relationship. In over-aged alloy, some δ'phases are replaced by "composite precipitates" Al3(Li, Zr) phases, and S'(Al2CuMg) phases also precipitate mostly at grain boundaries or dislocations.