HDPE微注射成型条件下非等温静态结晶

蒋炳炎1,尹湘林1,翁 灿1,王 进2

(1. 中南大学 机电工程学院,湖南 长沙,410083;

2. 株洲时代集团公司 橡塑弹性元件检测中心,湖南 株洲,412007)

摘 要:利用差示扫描量热仪(DSC),物理模拟HDPE微注射成型模腔中心层的静态非等温结晶过程,将样品从80 ℃以10 ℃/min升温速率升至180 ℃,并保温2 min。然后在液氮冷却作用下分别以5,10,15,20 ℃/min的恒降温速率,将温度降至80 ℃,得到静态非等温结晶DSC热流曲线,并利用Eopoxobeku方法对HDPE非等温结晶动力学参数进行解析。研究结果表明:当降温速率从5 ℃/min增大到20 ℃/min时,HDPE结晶起始温度从121.81 ℃下降到118.93 ℃,结晶度由86.19%增大到90.34%,非等温结晶动力学曲线在结晶初期基本上呈线性关系,而在后期不呈线性关系;结晶初期降温速率对晶体成核和生长机理的影响比较大,而结晶后期晶体成核和生长机理受降温速率的影响较小。

关键词:非等温结晶;微注射成型;HDPE;DSC

中图分类号:TQ320.66+2 文献标识码:A 文章编号:1672-7207(2007)05-0912-05

HDPE static non-isothermal crystallization in micro-injection molding process

JIANG Bing-yan1, YIN Xiang-lin1, WENG Can1, WANG Jin2

(1. School of Mechanical and Electrical Engineering, Central South University, Changsha 410083, China;

2. Test Center for Rubber and Plastics Elastomeric Component, Zhuzhou Times Electric Group, Zhuzhou 412007, China)

Abstract: Difference scanning calorimeter (DSC) was utilized to physically simulate the static non-isothermal crystallization in the center layer of micro-injection mold cavity, and the temperature of HDPE sample was raised from 80 ℃ to 180 ℃ with the speed of 10 ℃/min and held for 2 min. Afterward decrease the temperature to 80 ℃ with the invariable speed of 5, 10, 15, 20 ℃/min, respectively, when liquid nitrogen is cooled, and gain non-isothermal crystallization DSC curves, and HDPE non-isothermal crystallization kinetics parameters were resolved by Eopoxobeku method. The results show that the crystallization starting temperature decreases from 121.81 ℃ to 118.93 ℃ when the speed of decreasing temperature rises from 5 ℃/min to 20 ℃/min, and the degree of crystallization rises from 86.19% to 90.34%. The cooling speed strongly influences crystal nuclei forming and growing mechanism in initial stages of crystallization, but weakly in later stages.

Key words: non-isothermal crystallization; micro-injection molding; HDPE; DSC

结晶型聚合物熔体微注射成型结晶过程,根据模腔流动剪切速率分布的不同,可分为静态结晶和动态结晶。在微注射成型过程中,温度是聚合物结晶过程中最敏感的因素。聚合物在冷却过程所经历的温度场会影响到其结晶过程,从而影响到最终制品的机械性 能[1-4]。T. W. Chan等[5]用微分形式的Nakamura非等温结晶动力学方程计算了淬火条状PET试样沿厚度方向的结晶度分布,并考察了不同冷却速率对结晶度的影响;G. Titomanlio等[6]用Nakamura结晶动力学方程研究了非等温过程中密度的变化;T. Huang等[7]用Nakamura方程,将结晶时的比热容表示成熔体比热容和结晶潜热之和,用等价比热容法分析了结晶聚合物的固化过程。但是,Nakamura模式没有考虑诱导期的因素。目前,还有几种解析非等温动力学参数的方法,如Ozawa法、Ziabicki法、Jeziorny法等。但是,Ozawa法不能解析出与等温结晶有可比性的结晶速率常数,Ziabicki法仅可用于可测得等温结晶数据的温度范围,Jeziorny法所得到的结晶速率参数缺乏明确的物理意义。Eopoxobcku方法由于在冷却速率对结晶过程的修正上具有明确的物理意义,是一种较为可取的方法。在此,本文作者采用差示扫描量热仪(DSC),物理模拟微注射成型模腔中结晶型聚合物熔体的非等温结晶过程,进行HDPE静态非等温结晶动力学实验,探讨降温速率对结晶度的影响。

1 非等温结晶动力学处理方法

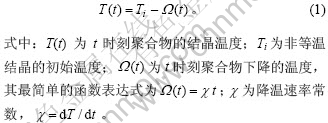

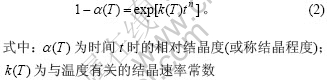

结晶型聚合物在注射成型过程中由于受到剪切作用,最终的制品在厚度方向上具有结构不同的多层结构[8-12],即所谓的“表-芯”结构(skin-core structure)。表层具有因剪切诱导作用形成的高度取向的晶体结构,典型的如串晶结构,而芯层受剪切作用很小可以忽略,其结晶过程可以认为是静态结晶。发生在连续降温的条件下的非等温结晶温度T与时间t的关系为:

通常等温结晶过程均可用经典的Avrami[13]方程描述如下:

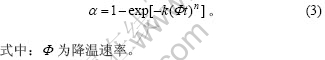

n为Avrami指数(在2~4之间[14]),与聚合物的成核机制和结晶形态有关。在等温结晶的Avrami方程的基础上,对于非等温结晶,Eopoxobeku采用如下公式表示t时刻的相对结晶度 :

:

对式(3)取对数后,可以表示为

。 (4)

。 (4)

在一定温度T下, 与

与 呈线性关系,其斜率为n,截距为

呈线性关系,其斜率为n,截距为 ,由实验参数曲线,可得到Avrami指数n和结晶速率常数k。

,由实验参数曲线,可得到Avrami指数n和结晶速率常数k。

2 实验方法与过程

实验设备为梅特勒-托利多(Mettler-Toledo)公司的DSC821e型差示扫描量热仪。实验材料为中国石油天然气股份有限公司抚顺石油分公司的高密度聚乙烯(HDPE),牌号为2909。样品在(23±2) ℃恒温24 h以上,然后在电子分析天平上称样7 mg(精确至10 ?g),用标准40 ?L的铝制坩埚制备完成。先将干燥氮气的气流量控制在100 mL/min左右,然后用高纯铟以10 ℃/min的升温速率对仪器进行校正,接着将样品从80 ℃以10 ℃/min升温速率升至成型温度180 ℃,并保温2 min以消除热的影响。然后,在液氮冷却作用下分别以5,10,15和20 ℃/min的恒降温速率将温度降至80 ℃,得到静态非等温结晶DSC热流曲线。

3 实验结果及分析

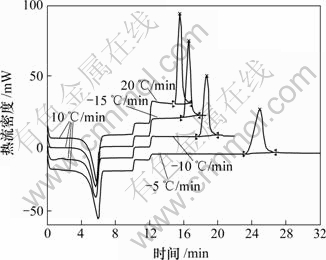

HDPE在不同降温速率下的静态非等温结晶DSC曲线及特征点分别如图1和表1所示。由图1和表1可见,HDPE熔体在结晶冷却过程中,不同降温速率下的结晶峰均为单峰,并且曲线的形状类似。当降温速率从5 ℃/min增大到20 ℃/min时,结晶峰温度(Tp)的位置由116.17 ℃下降到111.50 ℃,结晶峰的起始温度由121.81 ℃下降到118.93 ℃,结晶峰的面积也不断增大,结晶度由86.19%增大到90.34%。

图1 HDPE在不同降温速率下的静态非等温结晶DSC曲线

Fig.1 Static non-isothermal crystallization DSC curves with different cooling speeds

表1 不同降温速率下HDPE在DSC曲线上的特征点

Table 1 Characterization of DSC curves of HDPE with different cooling speeds

3.1 降温速率对HDPE熔体结晶度的影响

假设降温过程中,熔体所释放的热量都由结晶作用产生,在热流曲线上利用DSC设备配套的数据处理软件对结晶峰进行面积积分,可以计算出相应的结晶潜热(?Hc)。若已知单位质量的高聚物完全结晶时所释放的热量(?H),则用配套数据处理软件还可以计算对应的结晶度。结晶度是衡量物质内部结构规则程度的一个重要指标。对于HDPE,?H=290 J/g。通过下式来计算其结晶度:

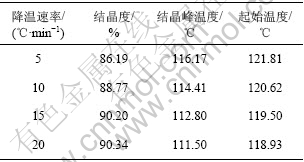

HDPE熔体在结晶冷却过程中,单位质量的结晶潜热、结晶度与降温速率的关系如表2所示。

表2 不同降温速率下的结晶潜热与结晶度

Table 2 Crystallization latent heat and degree of crystallization at different cooling speeds

由表2可知,当降温速率从5 ℃/min增大到20℃/min时,HDPE结晶度由86.19%增大到90.34%。结果表明,HDPE结晶度随着降温速率的增大而增大。

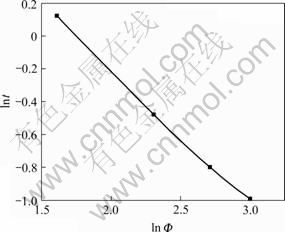

以ln Φ和ln τ1/2为坐标作图,如图2所示。图中ln Φ与ln τ1/2两者基本上呈线性关系。

图2 HDPE的ln Φ—ln t关系图

Fig.2 Relationship between ln Φ and ln t of HDPE

通过曲线拟合,得到两者的关系式如下:

。 (6)

。 (6)

。 (7)

。 (7)

3.2 非等温结晶动力学参数的确定

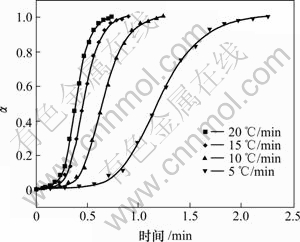

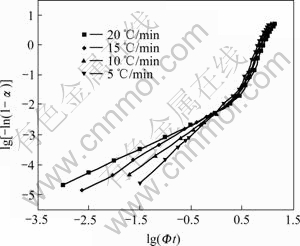

以5,10,15和20 ℃/min的恒降温速率冷却HDPE熔体,得到不同降温速率下HDPE结晶度与时间的关系,如图3所示。采用Eopoxobeku方法对HDPE非等温结晶动力学实验数据进行处理。根据式(4),对 和

和 作图,得到不同降温速率下的结晶动力学曲线,如图4所示。

作图,得到不同降温速率下的结晶动力学曲线,如图4所示。

图 3 HDPE不同降温速率下结晶度与时间的关系

Fig.3 Relationship between relative degree of crystallization and time with different cooling speeds of HDPE

图 4 HDPE非等温结晶动力学曲线

Fig.4 Non-isothermal crystallization kinetics curves of HDPE

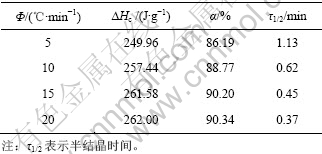

由图4可见,每条HDPE非等温结晶动力学曲线在结晶初期基本上都是呈线性关系,而在后期由于降温速率的差异而导致曲线的斜率发生变化,结晶动力学曲线不再保持线性关系。这说明在前期HDPE的结晶行为基本上符合Avrami方程,这与HDPE在结晶初期成核比较单一有关;后期斜率的变化有可能是晶体之间的相互碰撞而发生了二次结晶所致,同时有可能是HDPE后期成核和生长形态的复杂性[15]所致,即前期和后期的成核方式以及晶体的生长方式不同才导致了曲线斜率发生改变。

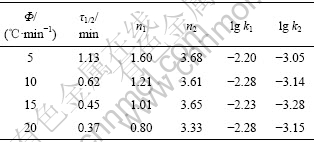

由图4分别求出非等温结晶前期与后期动力学曲线的斜率以及截距,结果见表3。

表3 HDPE非等温结晶动力学参数

Table 3 Non-isothermal crystallization kinetics parameters of HDPE

由表3可见,HDPE非等温结晶前期的Avrami指数n1随降温速率的增大而减小,说明结晶初期降温速率对晶体成核和生长机理的影响比较大;在结晶后期,n2随降温速率的变化不大,说明结晶后期晶体成核和生长机理受降温速率的影响较小。

4 结 论

a. HDPE熔体在结晶冷却过程中,不同降温速率下的结晶峰均为单峰,并且曲线的形状类似。当降温速率从5 ℃/min增大到20 ℃/min时,结晶峰的位置由高温向低温移动,结晶峰的面积也不断增大。

b. 当降温速率从5 ℃/min增大到20 ℃/min时,HDPE结晶起始温度从121.81 ℃下降到118.93 ℃,结晶度由86.19%增大到90.34%。

c. HDPE结晶初期降温速率对晶体成核和生长机理的影响比较大,而结晶后期晶体成核和生长机理受降温速率的影响较小。通过Eopoxobeku方法得到的HDPE非等温结晶动力学参数,较好地用于解释HDPE非等温结晶过程。

参考文献:

[1] Chan T W, Isayev A I. Quiescent polymer crystallization: modeling and measurement[J]. Polymer Engineering and Science, 1994, 34(6): 461-471 .

[2] Heckele M, Schomburg W K. Review on micro molding of thermoplastic polymers[J]. Journal of Micromechanics and Microengineering, 2004, 14(3): 1-14.

[3] Huang T, Kamal R. Morphological modeling of polymers solidification[J]. Polymer Engineering and Science, 2000, 40(8): 1796-1808.

[4] 蒋炳炎, 翁 灿,罗建华, 等. 考虑结晶潜热的LDPE微结构注射成型模内温度场[J]. 中南大学学报: 自然科学版, 2006, 37(3): 532-536.

JIANG Bing-yan, WENG Can, LUO Jian-hua, et al. Cavity temperature of LDPE injection molded parts with microstructure region considering latent heat[J]. Journal of Central South University: Science and Technology, 2006, 37(3): 532-536.

[5] Chan T W, Isayev A I. Quiescent polymer crystallization: modeling and measurement[J]. Polymer Engineering and Science, 1994, 34(6): 461-471.

[6] Titomanlio G, Speranza V, Brucato V. On the simulation of thermoplastic injection molding process: Ⅱ Relevance of interaction between flow and crystallization[J]. International Polymer Processing, 1997, 12(1): 45-53.

[7] Huang T, Kamal R. Morphological modeling of polymers solidification[J]. Polymer Engineering and Science, 2000, 40(8): 1796-1808.

[8] Kantz M R. Effects of melt processing variables on the morphology and properties of injection molded polypropylene[J]. International Journal of Polymeric Materials, 1974, 3(3): 245-258.

[9] Kamal M R, Moy F H. Microstructural characterization of injection-molded articles[J]. Journal of Applied Polymer Science, 1983, 28(5): 1787-1804.

[10] Katti S S, Schultz J M. Microstructure of injection-molded semicrystalline polymers—a review[J]. Polymer Engineering and Science, 1982, 22(16): 1001-1007.

[11] Pantani R, Coccorullo I, Speranza V, et al. Modeling of morphology evolution in the injection molding process of thermoplastic polymers[J]. Progress in Polymer Science, 2005, 30: 1185-1222.

[12] 戴文利, 薛 良, 王鹏驹. 结晶性塑料在注射成型条件下的形态结构与性能[J]. 塑料, 1997, 26(1): 16-20.

DAI Wen-li, XUE Liang, WANG Peng-ju. Microstructures and properties of injection-molded crystalline plastics[J]. Plastics, 1997, 26(1): 16-20.

[13] Avrami M. Kinetics of phase change: II Transformation-time relations for random distribution of nuclei[J]. The Journal of Chemical Physics, 1940, 8(2): 212-224.

[14] 姚 微, 黄宝琛, 孙云芳, 等. 反1, 4-聚丁二烯结晶形态和结晶动力学[J]. 高分子材料科学与工程, 1999, 15(3): 99-101.

YAO Wei, HUANG Bao-chen, SUN Yun-fang, et al. Crystal morphology and kinetics of trans-1, 4-polybutadiene[J]. Polymer Materials Science and Engineering, 1999, 15(3): 99-101.

[15] 余 坚, 何嘉松. 聚合物熔体结晶的方式(Regime)理论[J]. 高分子通报, 2001(1): 25-33.

YU Jian, HE Jia-song. Regime theory of polymer melt crystallization[J]. Polymer Bulletin, 2001(1): 25-33.

收稿日期:2007-03-29;修回日期:2007-05-08

基金项目:国家自然科学基金资助项目(50475140)

作者简介:蒋炳炎(1963-),男,浙江浦江人,教授,从事微注射成型理论和应用研究

通信作者:蒋炳炎,男,教授;电话:0731-8836035;E-mail:jby@mail.csu.edu.cn