冲击热处理AW-7075-T6板材的成形过程

来源期刊:中国有色金属学报(英文版)2017年第10期

论文作者:M. KUMAR

文章页码:2156 - 2162

关键词:冲击热处理成形;AW-7075-T6板材;成形性能;析出动力学

Key words:shock heat treatment forming; AW-7075-T6 sheet; formability; precipitation kinetics

摘 要:研究AW-7075-T6板材在200~480 °C进行冲击热处理的成形行为。采用室温拉伸和深拉拔试验表征冲击热处理后样品的可成形性;采用差示扫描量热法(DSC)分析AW-7075板材冲击热处理前后的相沉积状态。结果表明,从300 °C起,随着冲击热处理温度的升高,板材的成形性开始提高;由η′析出物溶解导致的应变硬化以及剩余析出物的粗化有助于板材室温成形性能的提高;沉淀物的再析出和粗化是冲击热处理试样强度提高的主要原因。

Abstract: The forming behaviour of AW-7075-T6 sheet was studied across a range of shock heat treatment (SHT) temperatures of 200-480 °C. After SHT, formability of the samples was investigated by tension and deep drawing tests at room temperature. Differential scanning calorimetry (DSC) was used to study the precipitation states of the AW-7075 sheet in the as-received and shock heat treated conditions. Formability was started to improve with increasing shock heat treatment temperature from 300 °C onwards. Strain hardening resulted from the dissolution of η′ precipitates and the coarsening of remaining precipitates were found to contribute to the increase in formability at room temperature. Re-precipitation and coarsening of the precipitates were responsible for the post-paint baking strength of SHT samples.

Trans. Nonferrous Met. Soc. China 27(2017) 2156-2162

M. KUMAR1,2

1. LKR Leichtmetallkompetenzzentrum Ranshofen GmbH, Austrian Institute of Technology, Lamprechtshausnerstrasse 61, postfach 26,5282, Ranshofen, Austria;

2. EBNER Industrieofenbau GmbH, Ebner-Platz 1,4060, Leonding, Austria

Received 30 September 2016; accepted 1 March 2017

Abstract: The forming behaviour of AW-7075-T6 sheet was studied across a range of shock heat treatment (SHT) temperatures of 200-480 °C. After SHT, formability of the samples was investigated by tension and deep drawing tests at room temperature. Differential scanning calorimetry (DSC) was used to study the precipitation states of the AW-7075 sheet in the as-received and shock heat treated conditions. Formability was started to improve with increasing shock heat treatment temperature from 300 °C onwards. Strain hardening resulted from the dissolution of η′ precipitates and the coarsening of remaining precipitates were found to contribute to the increase in formability at room temperature. Re-precipitation and coarsening of the precipitates were responsible for the post-paint baking strength of SHT samples.

Key words: shock heat treatment forming; AW-7075-T6 sheet; formability; precipitation kinetics

1 Introduction

Nowadays, many investigations are carried out to include 7xxx-series alloys for automotive structural parts as these alloys exhibit a higher level of specific strength to satisfy the roof crush and side impact standards. AW-7xxx-series alloys are age hardenable alloys with strengthening arising from the formation of fine dispersed coherent/semi-coherent meta-stable precipitates including Guinier-Preston (GP) zone and η′ phase. Both are found as the strengthening phase in AW-7xxx alloys in the T6 temper. Formability of AW-7xxx alloys in T6-temper is the lowest as compared to the other industrially relevant tempers including W and O [1-3]. Both W and O-tempers provide higher formability but lower strength compared to conventional T6-temper due to the absence of hardening GP zone and η′ precipitates.

et al [2] studied the feasibility of forming a car B-pillar at room temperature from AW-7075 sheet in W-temper. In another investigation, CERETTI et al [3] formed a motorbike suspension arm from an extruded tube of AW-7003 in O-temper at room temperature. Both investigations have successfully manufactured the parts due to increased formability of AW-7xxx sheet in the W and O-tempers. But, the strength level of the formed part is significantly lower than that of T6-temper. Therefore, both require additional heat treatment steps to re-gain the T6-temper strength level. Additional heat treatment cost is higher in case of O-temper because it needs higher temperature and longer time with added complexity of distortion in the part as compared to W-temper.

et al [2] studied the feasibility of forming a car B-pillar at room temperature from AW-7075 sheet in W-temper. In another investigation, CERETTI et al [3] formed a motorbike suspension arm from an extruded tube of AW-7003 in O-temper at room temperature. Both investigations have successfully manufactured the parts due to increased formability of AW-7xxx sheet in the W and O-tempers. But, the strength level of the formed part is significantly lower than that of T6-temper. Therefore, both require additional heat treatment steps to re-gain the T6-temper strength level. Additional heat treatment cost is higher in case of O-temper because it needs higher temperature and longer time with added complexity of distortion in the part as compared to W-temper.

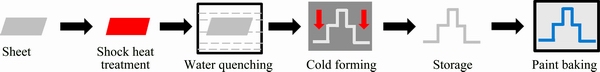

By comparison with above forming approaches, the shock heat treatment (SHT) forming process requires only a short-time heating of the blank and can form parts using cold tools. In this forming process, the aluminium achieves significantly higher ductility than at room temperature. This motivates the application of SHT forming to form structural parts. The process steps in the SHT forming process chain are shown in Fig. 1. The origin of SHT forming came from retrogression and reageing heat treatment (RRA).

BARUCH and RAMAT [4] invented a heat treatment for AW-7075-T6 known as retrogression and re-ageing (RRA). RRA was claimed to substantially reduce the susceptibility of the alloy to stress-corrosion cracking (SCC) while retaining its original strength. The material is retrogressed for a short period of time for 7-120 s at 200-260 °C, and subsequently re-aged at 121 °C for 16-48 h. As discussed above, the retrogression was performed in an oil bath where up to 10 K/s of heating rate can be realised. MARLAUD et al [5] have evaluated the mechanisms that prevail in the different stages of the RRA treatment of an AW-7xxx alloy using atom probe tomography (APT) and small- angle X-ray scattering (SAXS) experimental techniques. They showed that the retrogression step causes a strong decrease of the precipitate volume fraction due to rapid dissolution of precipitates with a limited increase in precipitate size. Dissolution of precipitates provides the extra solute to the Al matrix. During retrogression, strength falls very rapidly to reach a minimum before increasing again to a secondary peak and then decreasing again at long times as the material over-ages as shown by PARK and ARDELL [6] for AW-7075-T651 bar. Few seconds of retrogression time was not enough to produce the optimum SCC resistance for thicker sections as shown by RAJAN et al [7]. They have shown that 5 min of retrogression time requires at retrogression temperature of 220 °C producing best SCC resistance in AW-7075-T651 thick plate.

Since the short retrogression time (less than 60 s) is favourable for thin sheet, retrogression heat treatment can be applied to improve the cold formability of the sheet by softening. Based on this, Aleris Aluminium Duffel has published a European patent (EP 2581218 B1) in 2014 titled “Production of formed automotive structural parts from AA7xxx-series aluminium alloys” [8]. In their investigation, an AW-7021-T4 sheet is retrogressed at 180 °C for 6 s that leads to about 30% increase in drawing depth and about 60% decrease in yield strength of the sheet. The preferred heating rate was 20-60 K/s. JABUREK and MERKLEIN [9] have investigated the retrogression effect on the formability of AW-7020-T6 sheet as well. In their work, retrogression heat treatment at 320 °C for 60 s increased the total elongation and dome height by about 90% and about 15%, respectively. They reasoned that the partial dissolution of the hardening GP zone and η′ precipitates present in AW-7020-T6 sheet was responsible for the improvement in formability.

In this work, an AW-7075-T6 alloy sheet is used to investigate the SHT forming behaviour. SHT temperatures at 200-480 °C have been chosen for this work. To shorten process time, faster heating rate was applied; that’s why the associated forming process was called “SHT forming”. Tensile samples were machined from the sheet and were exposed to different SHT using  deformation dilatometer. Afterwards, the samples were tensile tested as well as deep drawn at room temperature. Differential scanning calorimetry was also carried out to study the changes in the precipitation state of the sheet caused by the SHT.

deformation dilatometer. Afterwards, the samples were tensile tested as well as deep drawn at room temperature. Differential scanning calorimetry was also carried out to study the changes in the precipitation state of the sheet caused by the SHT.

Fig. 1 SHT forming process chain

2 Experimental

A commercial AW-7075 sheet in T6 condition with a thickness of 2 mm has been used in this work, having the following chemical composition given in Table 1.

Table 1 Chemical composition of commercial AQ-7075 sheet (mass fraction, %)

2.1 Tension test

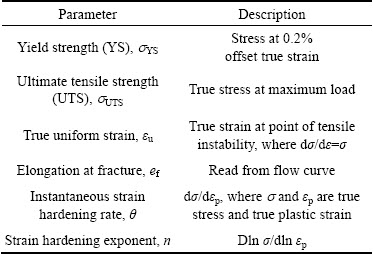

Tensile samples were machined from the 2 mm- thick AW-7075-T6 sheet in the direction of rolling. The samples were retrogressed and tensile tested using the  deformation dilatometer, as shown in Fig. 2(a). The details about the tensile sample geometry and deformation dilatometer were given in Ref. [10]. Each tensile sample was heated with heating rate of 100 K/s by induction coil to the SHT temperature of 200-480 °C for 30 s and subsequently quenched to room temperature using He gas. Then, tension tests were performed without any delay at room temperature and a strain rate of 0.1 s-1. Two horizontal fused silica push rods were attached to the sample within the gauge section and used to measure the change in length during deformation. Tests were repeated at least three times to ensure reproducibility. A detailed view of the test procedure is shown in Fig. 2(a). Table 2 gives the information about important parameters determined from the measured flow curves.

deformation dilatometer, as shown in Fig. 2(a). The details about the tensile sample geometry and deformation dilatometer were given in Ref. [10]. Each tensile sample was heated with heating rate of 100 K/s by induction coil to the SHT temperature of 200-480 °C for 30 s and subsequently quenched to room temperature using He gas. Then, tension tests were performed without any delay at room temperature and a strain rate of 0.1 s-1. Two horizontal fused silica push rods were attached to the sample within the gauge section and used to measure the change in length during deformation. Tests were repeated at least three times to ensure reproducibility. A detailed view of the test procedure is shown in Fig. 2(a). Table 2 gives the information about important parameters determined from the measured flow curves.

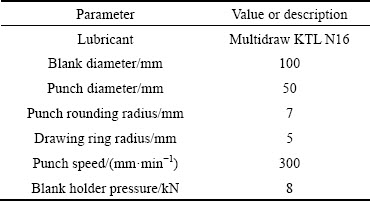

2.2 Swift cupping test

Swift cupping tests were performed on an Erichsen Model 142-40-Basic universal sheet metal testing machine. The test procedure and an inside view of the machine showing the axially symmetrical punch was shown in Ref. [10]. This test involves different deformation modes such as plane strain tension (cup wall), bending (punch and die corners), biaxial stretching (cup bottom) and pure shear (flange). Formability was determined from Swift cupping test by measuring the punch displacement at maximum force.

Fig. 2 Schematic of SHT and tension test procedure (a), contact heating tool for blanks (b) and temperature-time curve during heating to a SHT temperature of 400 °C (c)

Table 2 Important parameters from flow curve measured during tension test

In this test, blank of 100 mm in diameter was tested until cracks appeared in the drawn cup. Tests were carried out at room temperature. The blanks were processed firstly with SHT at 300-450 °C for 30 s using contacts heating (Fig. 2(b)) and subsequently water quenched to room temperature before deep drawing. A typical heating curve for SHT temperature of 400 °C is shown in Fig. 2(c). The test parameters for deep drawing are listed in Table 3.

2.3 Differential scanning calorimetry (DSC)

DSC samples were prepared from different SHT AW-7075 sheet material. These DSC tests were carried out using a Netzsch-DSC 204 F1 in which samples were continuously heated up to 480 °C with a heating rate of 10 K/min. The endothermic and exothermic peaks in the resulting temperature versus heat flow plots correspond to the dissolution and formation of precipitates, respectively. These results provide information about the precipitation state of the SHT sheet.

Table 3 Test parameters for swift cupping test

3 Results

3.1 Flow curves

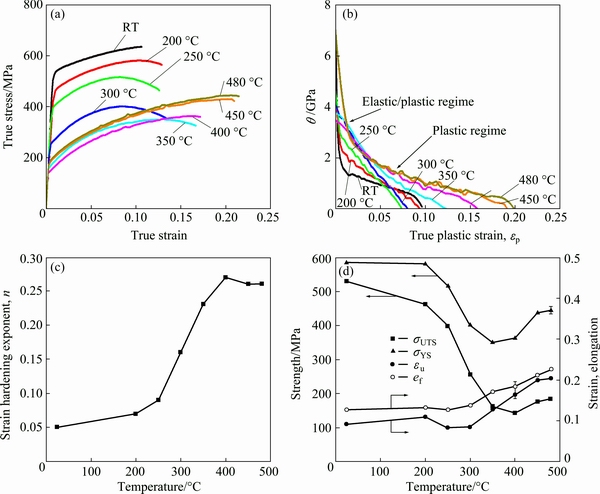

Figure 3(a) shows the true stress-true strain curves for the SHT AW-7075 sheet tested at room temperature and at strain rate of 0.1 s-1. A substantial decrease in true stress and increase in true strain can be observed with increasing SHT temperature from 200 to 480 °C.

Figure 3(b) shows the dependence of the instantaneous strain hardening rate θ on SHT state. Two distinct types of strain hardening behaviour can be observed, where θ decreases linearly with the true plastic strain, εp. The elastic/plastic transition regime starts with a higher value of θ which decreases rapidly. On the other hand in the plastic regime, the starting value of θ is lower but decreases slowly. It is clear that with increasing SHT temperature up to 400 °C, the elastic/plastic regime decreases while plastic regime increases. No significant difference in strain hardening behaviour is seen between SHT samples at 450 and 480 °C.

The strain hardening behaviour of SHT samples is also reflected on strain hardening exponent n (see Fig.3(c)). Value of n continuously increases with increasing SHT temperature up to 400 °C, thereafter slightly decreases.

σYS, σUTS, εu and ef have been extracted from the flow curves and plotted in Fig. 3(d). The σYS and σUTS both decrease with increasing SHT temperature up to 400 °C, thereafter increase again. εu decreases while ef increases slightly with increasing SHT temperature up to 300 °C as compared to the as-received AW-7075-T6 sheet. At SHT temperature above 300 °C, both εu and ef continuously increase.

Fig. 3 True stress-true strain curves of SHT AW-7075-T6 sheet at strain rate of 0.1 s-1 (a), plot between strain hardening rate θ and true plastic strain εp (b), strain hardening exponent (c) and σYS, σUTS, εu and ef (d)

3.2 DSC curves

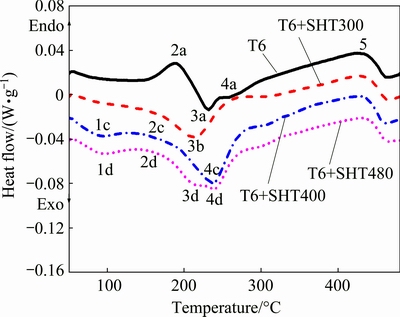

The DSC results were analysed based on the findings of HADJADJ et al [11] and JIANG et al [12] on AA7xxx alloys. They investigated the precipitation kinetics during non-isothermal heating of various heat treated Al-Zn-Mg alloy samples using the DSC, TEM and dilatometry techniques. They found that the interval temperatures 20-120 °C, 120-250 °C and 150-300 °C correspond, respectively, to the formation of GP zones, η′ and η phases. The interval temperatures 50–150 °C, 200-250 °C and 300-350 °C, respectively correspond to their dissolution. However, formation and dissolution interval temperatures depend on alloy composition, heating rate and initial temper of the material. Figure 4 shows DSC curves of the AW-7075-T6 sheets after their SHT conditions.

Fig. 4 DSC curves of AW-7075-T6 sheet

A total of 5 different peaks appear in the DSC curves, as shown in Fig. 4. While heating the AW-7075-T6 sample, an endothermic peak (2a) appears at approximately 186 °C related to the dissolution of η′ precipitates. This means that η′ precipitates were already present in the sample prior to the test. At 232 °C, these η′ precipitates grow and transform into η precipitates as indicated by peak 3a. On further heating, the η precipitates grow as indicated by exothermic bulge 4a at approximately 258 °C. And finally, remaining phases dissolve as shown by the broad endothermic peak 5 at 416 °C.

The endothermic peak related to the dissolution of η′ precipitates does not appear in the curve of the SHT sample at 300 °C. An earlier exothermic peak 3b appears at 213 °C. This means that η′ precipitates dissolve during SHT and re-precipitate as η′ and η precipitates during the measurements.

Exothermic peaks 1c and 1d (see Fig. 4) appear at 95 and 98 °C, respectively, for SHT samples at 400 and 480 °C. This is related to the precipitation of GP zones due to the presence of excess solutes in solid solution caused by SHT. On further heating, the re-precipitation of η′ and η precipitates occurred as indicated by peaks 4c and 4d at 237 and 238 °C, respectively. It becomes clear that dissolution of the η′ precipitate occurred at all SHT temperatures; the extent of this dissolution is controlled by the SHT temperature.

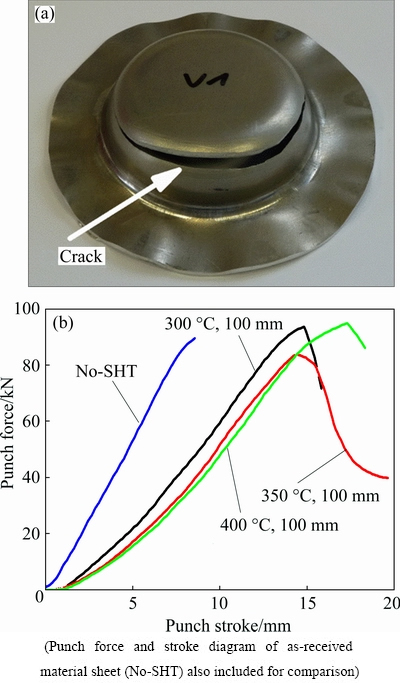

3.3 Deep drawing

Punch stroke at maximum punch force is considered in this work as a measure of formability. SHT sheet was deep drawn in a cup shape at room temperature and its punch stroke at maximum punch force is taken as the standard value to compare with the formability of the SHT sheets. Figure 5(a) shows a typical deep drawn cup with a crack from the SHT sheet at 400 °C. Figures 5(b)-(d) show the punch force versus punch displacement curves of different SHT samples of 100 mm in diameter. There was an increase of 8.8 mm in the punch stroke at maximum punch force after SHT at 400 °C compared to the room temperature value, as shown in Fig. 5(b).

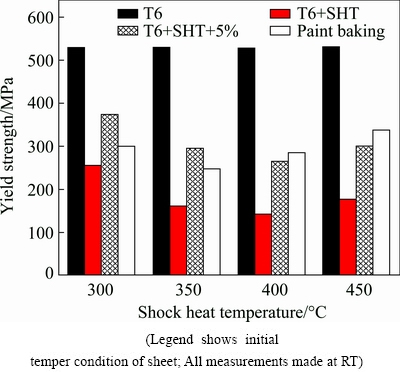

3.4 Yield Strength

It can be expected that process steps such as SHT, quenching, forming and storage, and finally the paint baking treatment would alter the mechanical properties of the sheet. Since it was not possible to machine out samples from the deep drawn cup, the process steps were applied on tension samples taken from the as-received AW-7075-T6 sheet. To simulate the forming steps, the tension samples were stretched by 5% in the deformation dilatometer after the SHT and quenching. Figure 6 shows the influence of the process steps on the yield strength of the sheet.

As expected, the SHT considerably decreases the yield strength of the as-received sheet by 274, 368, 387 and 353 MPa at SHT temperatures of 300, 350, 400 and 450 °C, respectively (Fig. 6). Yield strength of SHT samples increases after stretching by 5%. Paint baking was applied at the same day within 1-2 h on the stretched samples. So, storage time would have only minor influence on the yield strength. However, the author does believe that there may be significant influence on the yield strength if longer storage time will be considered. It can be seen that yield strength of paint baked samples decreases for SHT temperatures of 300 and 350 °C, and increases for SHT temperatures of 400 and 450 °C. The highest yield strength of 337 MPa was achieved for SHT sample at 450 °C. However, this value is far more less (about 192 MPa) than that of the as-received sheet. Therefore, it is shown that the yield strength of the sample is very much sensitive on the SHT temperature.

Fig. 5 Cracked deep drawn cup (a) and punch force and stroke diagrams (b) of SHT AW-7075-T6 blanks of 100 mm in diameter

Fig. 6 Effect of process steps on yield strength of AW-7075-T6 sheet in SHT forming process chain

4 Discussion

From the DSC curves (Fig. 4), it was clearly shown that η′ precipitates were present in the as-received AW-7075-T6 sheet. In general, the peak height/area and peak width in DSC curves are correlated to volume fraction and size distribution of the existing precipitates [13]. It can be seen that the peak height/area of the endothermic peak 2a of T6 sample is drastically reduced in the DSC curves of the SHT samples (Fig. 4). This occurs due to the dissolution of the smaller (unstable) and the coarsening of the larger (stable) precipitates.

With increasing SHT temperatures, a minimum yield strength value is obtained when the dissolution process ends and coarsening process may continue for remaining precipitates if present [5,14]. This condition is achieved for AW-7075-T6 sheet at 350 °C, as shown in Fig. 3(d). Dissolution is also facilitated by higher heating rate during shock heat treatment as it promotes faster dissolution of η′ precipitates rather than η′→η transformation in an Al-Zn-Mg-Cu alloy [15].

Strain hardening behaviour is of significant relevance to industrial sheet metal forming. It is seen from the flow curves of SHT samples that the strain hardening rate is extended to large plastic strain with increasing SHT temperatures. As discussed above, the dissolution and coarsening of η′ precipitate occurred during SHT. They increase the solute concentration in the matrix and subsequently the size of the un-dissolved precipitates. It is assumed that transition from shearable to non-shearable precipitates takes place in T6 condition [16,17]. As dissolution and coarsening progress, the existing precipitates become more non-shearable. This is particularly important because a higher dislocation storage rate is possible at the non-shearable precipitates. With increasing SHT temperatures, the strain-hardening rate increases due to the precipitation hardening from shearable and/or non-shearable precipitates as well as solid solution hardening from solutes. Therefore, increased εu, ef and n were obtained. Improvement in strain hardening was also responsible for 100% increase in the punch stroke at maximum punch force of SHT AW-7075 sheet at 400 °C compared to as-received sheet.

The decrease in yield strength from the as-received condition to the SHT strength was found to be the greatest for the SHT of 350 °C (Fig. 6). After stretching (forming) and short storage (less than 2 h), yield strength was found to be increased in all SHT conditions. After a subsequent paint baking at 185 °C for 20 min, the yield strength of SHT300 and SHT350 samples was found to be decreased while yield strength of SHT400 and SHT450 was found to be increased. This is related to the extent of dissolution of η′ precipitates in SHT condition. The increased solute concentration and reduced volume fraction of coarse precipitates enhance re-precipitation of fine η′ precipitates in case of SHT400 and SHT450. The highest yield strength of 337 MPa was achieved for SHT sample at 450 °C after the paint baking treatment, but this is still only 64% of the initial T6-temper yield strength. Therefore, there is a need for further optimisation of the paint bake treatment to achieve the peak-aged strength in the completed part. Alternatively, a heat treatment may be given after forming to stabilize the GP zone precipitates that may form during storage in order to prevent them from dissolving, allowing them to act as nucleation sites for η′ precipitates.

5 Conclusions

1) Increasing SHT temperature of the sheet up to 400 °C decreases the yield strength, σYS and ultimate tensile strength, σUTS. While the εu, ef and n increase significantly at SHT temperature of 300-480 °C.

2) Tensile test results show that the strain hardening behaviour of SHT AW-7075-T6 alloy is sensitive to SHT temperature. The strain hardening rate was found to be extended to large plastic deformation with increasing SHT temperature.

3) The punch stroke at maximum punch force was found to be increased with increasing SHT temperature at 300-450 °C. SHT AW-7075-T6 sheet at 400 °C has increased the punch stroke value by 100% as compared to the as-received sheet.

4) Dissolution of η′ precipitates and the coarsening of remaining precipitates were responsible for the decrease of the yield and ultimate tensile strength during SHT.

5) During SHT, dissolution of η′ precipitates increases the solute concentration in the matrix responsible for solid solution hardening as well as re-precipitation during pain baking.

6) The highest yield strength of 337 MPa was achieved for SHT sample at 450 °C after the paint baking treatment, but this is still only 64% of the yield strength of the as-received AW-7075-T6 sheet.

Acknowledgements

The authors would like to gratefully acknowledge the Austrian Federal Ministry for Transport, Innovation and Technology (BMVIT) and the federal state of Upper Austria for funding this research work within the frame work of Independent research UF2015.

References

[1] KUMAR M, ROSS N G. Influence of temper on the performance of a high-strength Al-Zn-Mg alloy sheet in the warm forming processing chain [J]. Journal of Materials Processing Technology, 2015, 231: 189-198.

[2] de  E S, GALDOS L, ORTUBAY R, MENDIGUREN J, AGIRRETXE X. Room temperature forming of AA7075 aluminium alloys: W-temper process [J]. Key Engineering Materials, 2015, 651-653: 199-204.

E S, GALDOS L, ORTUBAY R, MENDIGUREN J, AGIRRETXE X. Room temperature forming of AA7075 aluminium alloys: W-temper process [J]. Key Engineering Materials, 2015, 651-653: 199-204.

[3] CERETTI E, CONTRI C, GIARDINI C. Tube-hydroforming experiments on an Al 7003 extruded tube [J]. Journal of Materials Processing Technology, 2006, 177: 672-675.

[4] BARUCH M C, RAMAT G I. Reducing the susceptibility of alloys, particularly aluminium alloys, to stress corrosion cracking [P]. United States Patent 3856584. 1974.

[5] MARLAUD T, DESCHAMPS A, BLEY F, LEFEBVRE W, BAROUX B. Evolution of precipitate microstructures during the retrogression and re-ageing heat treatment of an Al-Zn-Mg-Cu alloy [J]. Acta Materilia, 2010, 58: 4814-4826.

[6] PARK J K, ARDELL A J. Effect of retrogression and reaging treatments on the microstructure of Ai-7075-T651 [J]. Metallurgical Transactions A, 1984, 15: 1531-1543.

[7] RAJAN K, WALLACE W, BEDDOES J C. Microstructural study of a high-strength stress-corrosion resistant 7075 aluminium alloy [J]. Journal of Material Science, 1982, 17: 2817-2824.

[8] SMEYERS A A M, KHOSLA S. Production of formed automotive structural parts from AA7xxx-series aluminium alloys [P]. EU Patent EP 2 581 218 B1. 2013.

[9] JABUREK N, MERKLEIN M. Influence of a regression heat treatment on the material properties of a copper-free 7xxx series aluminium alloy [J]. Procedia CIRP, 2014, 18: 108-113.

[10] KUMAR M, SOTIROV N, CHIMANI C M. Investigations on warm forming of AW-7020-T6 alloy sheet [J]. Journal of Materials Processing Technology, 2014, 214: 1769-1776.

[11] HADJADJ L, AMIRA R, HAMANA D, MOSBAH A. Characterization of precipitation and phase transformations in Al-Zn-Mg alloy by the differential dilatometry [J]. Journal of Alloys and Compounds, 2008, 462: 279-283.

[12] JIANG X J, TAFTO J, NOBLE B, HOLME B, WATERLOO G. Differential scanning calorimetry and electron diffraction investigation on low-temperature aging in Al-Zn-Mg alloys [J]. Metallurgical and Materials Transactions A, 2000, 31: 339-348.

[13] STARINK M J. The analysis of Al-based alloys by calorimetry: Quantitative analysis of reactions and reaction kinetics [J]. International Material Review, 2004, 49: 191-226.

[14] MA T, den OUDEN G. Softening behaviour of Al-Zn-Mg alloys due to welding [J]. Materials Science and Engineering A, 1999, 266: 198-204.

[15] NICOLAS M. Precipitation evolution in an Al-Zn-Mg alloy during non-isothermal heat treatments and in the heat-affected zone of welded joints [D]. Institut National Polytechnique de Grenoble - INPG, France, 2009.

[16] DESCHAMPS A, BRECHET Y. Influence of predeformation and ageing of an Al-Zn-Mg alloy—II. Modelling of precipitation kinetics and yield stress [J]. Acta Materilia, 1998, 47: 293-305.

[17] WESTERMANN I, HOPPERSTAD O S, MARTHINSEN K, HOLMEDAL B. Work-hardening behaviour of a heat-treatable AA7108 aluminium alloy deformed to intermediate strains by compression [J]. Journal of Materials Science, 2010, 45: 5323-5331.

M. KUMAR1,2

1. LKR Leichtmetallkompetenzzentrum Ranshofen GmbH, Austrian Institute of Technology, Lamprechtshausnerstrasse 61, postfach 26, 5282, Ranshofen, Austria;

2. EBNER Industrieofenbau GmbH, Ebner-Platz 1,4060, Leonding, Austria

摘 要:研究AW-7075-T6板材在200~480 °C进行冲击热处理的成形行为。采用室温拉伸和深拉拔试验表征冲击热处理后样品的可成形性;采用差示扫描量热法(DSC)分析AW-7075板材冲击热处理前后的相沉积状态。结果表明,从300 °C起,随着冲击热处理温度的升高,板材的成形性开始提高;由η′析出物溶解导致的应变硬化以及剩余析出物的粗化有助于板材室温成形性能的提高;沉淀物的再析出和粗化是冲击热处理试样强度提高的主要原因。

关键词:冲击热处理成形;AW-7075-T6板材;成形性能;析出动力学

(Edited by Bing YANG)

Corresponding author: M. KUMAR; Tel: +61-436646279509; E-mail: mkm.iitr@gmail.com

DOI: 10.1016/S1003-6326(17)60241-3