文章编号:1004-0609(2013)10-2769-10

铝合金空心型材分流模挤压成形全过程温度场的数值模拟

侯文荣1,张志豪1,谢建新1,陈蕴博2

(1. 北京科技大学 材料先进制备技术教育部重点实验室,北京 100083;

2. 机械科学研究总院 先进制造技术研究中心,北京 100083)

摘 要:采用焊合区网格重构技术,解决包括分流与焊合过程的空心型材分流模挤压成形全过程温度场模拟问题,以一种典型大断面铝合金空心型材分流模挤压成形为实例,分析挤压速度和坯料温度对模孔出口处型材最高温度及型材横断面温度分布的影响,提出合理的坯料温度和挤压速度范围。结果表明:挤压速度对模孔出口处型材横断面温度分布不均匀性的影响较大,而坯料温度的影响较小:当挤压速度由0.6 mm/s增大到3.0 mm/s,坯料温度为500 ℃时,模孔出口处型材横断面上最高与最低温度的差值(最大温差)由28 ℃增大到60 ℃;而当挤压速度一定,坯料温度在480~520 ℃变化时,型材横断面上最大温差的变化不超过3 ℃。6005A型材的合理挤压条件:坯料温度520 ℃时,挤压速度范围为0.63~0.93 mm/s;坯料温度500 ℃时,挤压速度范围为0.87~1.14 mm/s;坯料温度480 ℃时,挤压速度范围为1.10~1.34 mm/s。

关键词:空心型材;分流模挤压成形;网格重构;温度场

中图分类号:TG379 文献标志码:A

Numerical simulation of temperature field during whole extrusion process of aluminum hollow profile with porthole die extrusion forming

HOU Wen-rong1, ZHANG Zhi-hao1, XIE Jian-xin1, CHEN Yun-bo2

(1. Key Laboratory for Advanced Materials Processing, University of Science and Technology Beijing, Beijing 100083, China;

2. Advanced Manufacture Technology Center, China Academy of Machinery Science and Technology, Beijing 100083, China)

Abstract: The precision simulation problem of the temperature field of hollow profile during the whole extrusion process, including the dividing and welding stages, was solved by mesh reconstruction technology of welding zone. Taking the porthole die extrusion of a typical aluminum hollow profile with large cross section as an example, the effects of billet temperature and extrusion speed on the maximum temperature of profile near the die exit and the temperature distribution on cross section were analyzed, and the reasonable billet temperature and extrusion speed were obtained. The results show that, the influence of the extrusion speed on the inhomogeneous temperature distribution of the cross section of the profile near the die exit is significant, while the influence of the billet temperature is not obvious. When the constant billet temperature is 500 ℃, the difference of the highest and lowest temperature (maximum temperature difference) on the profile cross-section increases from 28 ℃ to 60 ℃with the extrusion speed increasing from 0.6 mm/s to 3.0 mm/s. The changes of maximum temperature difference on the profile cross section are not more than 3 ℃ with the billet temperature varying from 480 ℃ to 520 ℃ at constant extrusion speed. The extrusion conditions are that when the billet temperatures are 520, 500 and 480 ℃, the reasonable extrusion speed ranges are 0.63~0.93 mm/s, 0.87~1.14 mm/s and 1.10~1.34 mm/s, respectively.

Key words: hollow profile; porthole die extrusion forming; meshes reconstruction; temperature field

在铝合金空心型材分流模挤压过程中,金属在分流和焊合过程中流动复杂,容易引起模具的局部温升和变形区金属温度的不均匀分布,显著影响挤压型材的质量和模具的强度。从挤压筒内经分流、焊合到从模孔挤出成形的过程中,金属温度不断变化,其变化行为主要受模具结构尺寸和坯料温度、工模具加热温度和挤压速度等条件的影响。因此,实现挤压全过程温度场的准确预测,是正确设计模具、合理选择工艺参数,实现对挤压产品组织性能精确控制的重要基础[1-2]。

有限元数值模拟技术广泛应用于挤压过程温度场模拟[3-6],但对于大多数空心型材分流模挤压成形的情形,由于焊合面与流动对称面不一致,焊合过程中网格容易发生穿透等严重畸变而导致计算自动终止问题,因而,只能对焊合开始前的分流过程或焊合室完全充满后的挤压成形过程(称为稳态挤压过程)进行模拟分析[7-9]。这一问题成为分析空心型材挤压成形时挤压筒内和分流、焊合过程中金属温度变化的相互影响及其对挤出产品温度影响的技术瓶颈。为此,ZHANG等[10]和黄东男等[11-13]开发了一种基于逆向工程的焊合区网格重构技术,有效解决了挤压焊合过程的网格分离和穿透导致的计算难题,实现了挤压全过程金属流动行为、应力应变分布和温度场变化的有效模拟,且采用该技术的模拟计算结果与实验结果基本吻合,从而为分流模的正确设计和模孔出口处型材温度的准确预测提供了一种有效的方法。

本文作者以一种典型大断面铝合金空心型材分流模挤压成形为实例,基于焊合区网格重构法分析了变形金属在分流、焊合和从模孔挤出成形各个阶段中的温度场变化,讨论挤压速度和坯料温度对模孔出口处型材断面温度不均匀性的影响,提出合理的坯料温度和挤压速度范围。

1 分流模挤压成形有限元模拟

1.1 几何模型

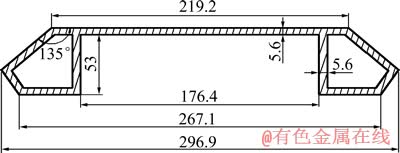

图1所示为一种工业用大断面铝合金空心型材的断面形状与尺寸,型材最大宽度为296.9 mm,断面面积为2 937.7 mm2,中间部分为悬臂梁,两端为对称分布的多边形孔,壁厚均为5.6 mm。

图1 铝合金空心型材断面形状及尺寸

Fig. 1 Shape and dimensions of cross section of aluminum hollow profile (Unit: mm)

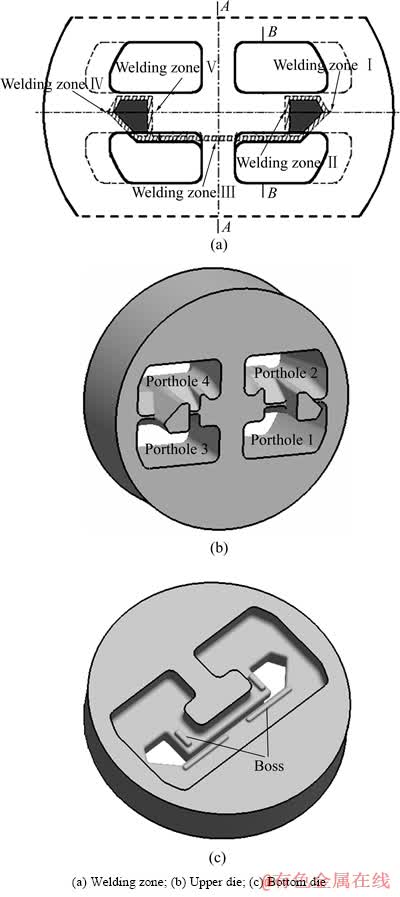

模具基本结构如图2所示。其中图2(a)中箭头所指的区域分别为型材的5个挤压焊合区的大致位置;图2(b)为上模仰视图,4个分流孔的编号分别为1~4;图2(c)为下模俯视图,设有4个调节(阻碍)金属流动的凸台。本文计算中,假定凸台对温度场分布的影响较小,可以忽略。考虑到模具和型材结构的对称性,为减少单元网格数量节省计算时间,取1/2模型进行计算,此时将焊合区Ⅲ所在的流动对称面A—A简化为刚性对称面,因此,实际计算中只存在Ⅰ和Ⅱ两个焊合区。

采用Deform-3D软件进行数值计算,挤压筒直径为320 mm、坯料长度为400 mm、挤压比为28.8、分流比为9.8。当焊合区两侧的网格单元开始接触后,随着挤压行程的增加,相互接触的网格单元将发生穿透或分离现象。因此,为了防止计算自动终止,保证模拟的顺利进行,必须对穿透的网格进行重构,具体方法参考文献[10]。在Deform-3D中对重构后的网格单元模型添加单元节点数据,继续计算,完成包括焊合和成形阶段挤压全过程的数值模拟。

1.2 材料参数和模拟条件

挤压材料为6005A铝合金,密度为2 700 kg/m3,比热容为940 J/(kg·℃),热导率为180 W/(m·℃)。工模具材料为H13热作模具钢,密度为7 850 kg/m3,比热容为407 J/(kg·℃),热导率为25 W/(m·℃)。6005A铝合金的流动应力应变曲线根据文献[11, 14]确定。

图2 焊合区位置及模具结构示意图

Fig. 2 Schematic diagrams of welding zone and porthole die mold

参考文献[15-16],设定挤压坯料初始温度为480~520 ℃,垫片初始温度30 ℃,挤压筒加热温度比坯料初始温度低30℃,模具初始温度比坯料初始温度低40 ℃。坯料与工模具之间的换热系数为1.1 kW/(m2·℃),工模具与空气之间的换热系数为60 W/(m2·℃)。

坯料与垫片、挤压筒和模具之间的摩擦设为剪切摩擦模型,表示为 (其中m为摩擦因子,σ为坯料的流动应力)。参考前期研究结果,本研究设定摩擦因子m=1。坯料与定径带之间的摩擦设为库伦摩擦模型,表示为τ=μσn(其中μ为摩擦因数,σn为坯料与定径带之间的接触法向应力)。本研究取摩擦因数μ=0.4。

(其中m为摩擦因子,σ为坯料的流动应力)。参考前期研究结果,本研究设定摩擦因子m=1。坯料与定径带之间的摩擦设为库伦摩擦模型,表示为τ=μσn(其中μ为摩擦因数,σn为坯料与定径带之间的接触法向应力)。本研究取摩擦因数μ=0.4。

2 分流和焊合过程中金属的温度变化

2.1 分流过程金属温度变化

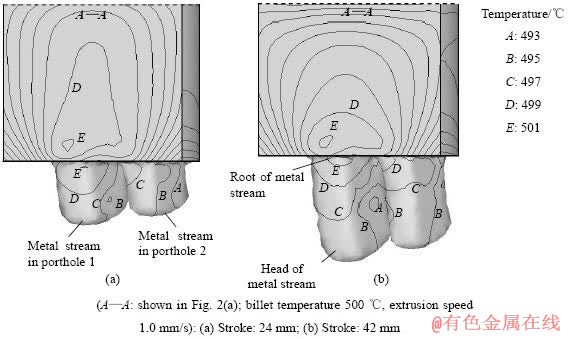

在分流阶段,变形金属被分流桥拆分为4股。在挤压行程分别为24 mm和42 mm时,分流孔1和2中的金属温度分布如图3所示。图中大平面为对应于图2(a)的A—A对称面。图3表明,分流阶段分流孔1内的金属流动快,且温度高于分流孔2内的金属温度,最高温度出现在金属流束的根部。

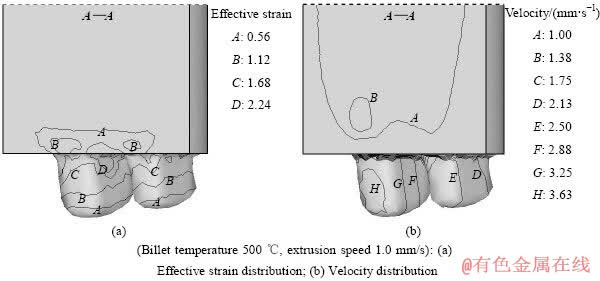

进一步对分流孔1和2中的金属等效应变和速度大小进行分析,结果如图4所示。由图4可知,当挤压行程为24 mm时,分流孔1内金属流动速度比分流孔2的高约45%,因而,单位时间内分流孔1内的金属与分流孔壁之间的摩擦生热较多。此外,分流孔1内金属流束根部的等效应变比分流孔2的高约33%,表明分流孔1入口处的金属塑性变形较剧烈,产生的变形热较多。因此,如图3所示,分流孔1内的金属温度较高。

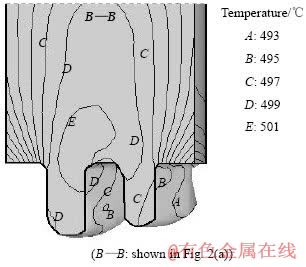

图3所示结果为分流阶段金属流束的表面温度分布,而金属流束内部(相当于图2(a) B—B剖面)的温度分布情况如图5所示。金属内部温度分布与表面温度分布的情况类似,也是分流孔1内的金属温度高于分流孔2内的金属温度,最高温度出现在金属流束的根部。但是总体来说,金属流束内部温度比表面温度要高,这主要是由于金属流束表面与模具直接接触从而散热较多导致的。

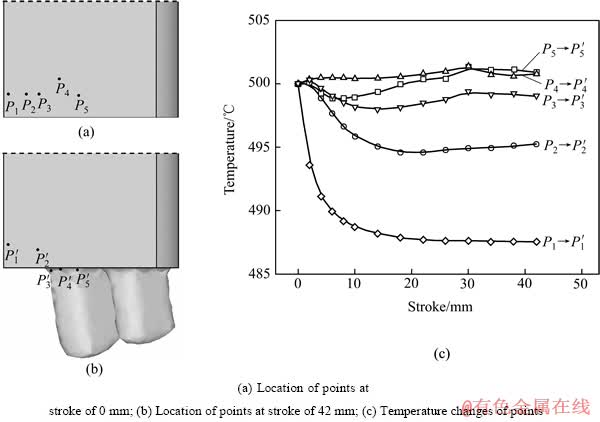

图6所示为挤压筒内金属不同位置质点的温度在分流阶段随挤压行程的变化情况。图6(a)为挤压开始前的质点位置,用P1~P5表示,图6(b)为挤压行程为42 mm时的质点位置,用P1′~P5′表示。

图3 分流阶段金属的温度分布

Fig. 3 Temperature distribution of metals at dividing stage

图4 挤压行程为24 mm金属的等效应变和速度分布

Fig. 4 Distribution of effective strain and velocity at stroke of 24 mm

图5 挤压行程为24 mm时金属的内部温度场

Fig. 5 Inner temperature distribution of metals at stroke of 24 mm

由图6(c)可知,分流过程中不同位置质点的温度变化趋势不同。靠近挤压筒壁的质点温度首先产生较明显的下降,然后缓慢降低,如P1→P1′曲线。靠近心部的质点温度初期下降幅度较小,后期温度略有升高,如P3→P3′、P4→P4′、P5→P5′。这主要是由于挤压分流阶段金属经历复杂的传热过程,其中包括塑性变形功转化的热、摩擦产生的热、金属与工模具之间热传导散热以及金属内部不同温度区域的热传导。边部质点(如P1)靠近挤压筒壁,处于挤压死区位置,几乎不发生流动和变形,因此,塑性变形生热和摩擦生热较少,通过挤压筒和模具的散热导致其温度一直下降,且初期由于坯料与工模具的温差较大而产生较明显的温度下降。心部质点(如P3~P5)由于远离挤压筒壁,通过挤压筒和模具散失的热量较少,因此,初期温度不会出现明显下降,且由于进入分流孔时发生剧烈塑性变形产生较多变形热,后期温度呈升高趋势;介于金属坯料边部和心部的质点(如P2),在变形热、摩擦热和工模具散热的综合作用下,温度首先产生一定的下降,然后基本保持不变。

图6 挤压筒内金属坯料不同位置质点的温度随挤压行程的变化

Fig. 6 Temperature changes of different metal points on billet (Original temperature of point is 500 ℃)

上述分析表明,不同部位的金属质点在分流阶段经历了不同的热环境和热交换,从而产生了不同的温度变化,导致金属中存在温度不均匀分布。

2.2 焊合过程金属温度变化

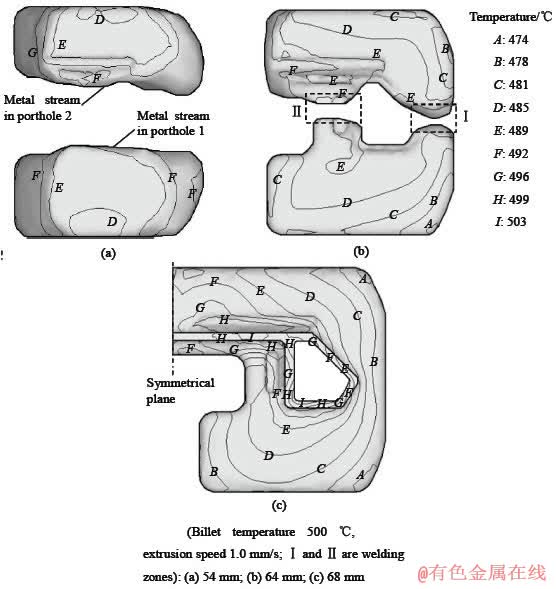

当流出分流孔的金属流束进入焊合室后,随挤压行程的增加,金属开始接触焊合室底部进而围绕模芯填充焊合室,直至金属流束之间完全实现焊合。图7(a)~(c)为焊合阶段金属表面温度分布,其中图7(a)为分流孔内流出的金属刚接触焊合室底面时的金属表面温度分布,图7(b)为焊合区Ⅰ开始焊合时的金属表面温度分布,图7(c)为焊合完成时的焊合室底面金属温度分布。

由于模具初始温度(460 ℃)低于分流孔内金属流束的头部温度(约495 ℃),金属流束接触焊合室底面后与模具之间进行传热,导致表面温度明显下降,最低降至480 ℃左右,如图7(a)所示。

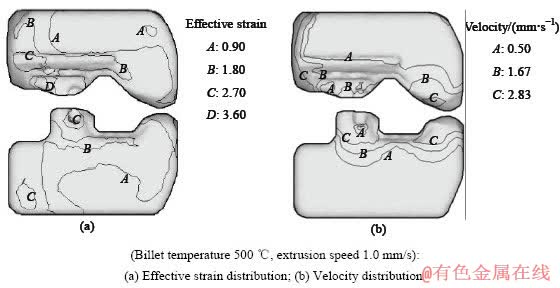

随着挤压的进行,金属围绕模芯填充焊合室。焊合区两侧的金属将要接触时的温度分布如图7(b)所示。由图7(b)可见,焊合区Ⅰ和Ⅱ附近的金属表面温度较高,为489~492 ℃,而边角处温度较低,约为474 ℃。该挤压行程时焊合室内金属的等效应变和速度大小分布如图8所示。由图8可以看到,焊合区Ⅰ和Ⅱ附近金属的等效应变和流动速度均较大,导致该处金属单位时间内的摩擦生热以及变形生热较多,因而温度较高;而焊合室边角部的金属几乎不流动,形成死区,因此摩擦生热和变形生热较少,且该处金属通过与模具传热导致散热较多,温度下降约20 ℃。

进入焊合室内的金属继续沿平行于焊合室底面流动,直至焊合区Ⅰ和Ⅱ完成焊合,如图7(c)所示。由于在焊合的同时不断有型材从模孔先行流出,导致模孔附近的金属塑性变形较大,金属表面温度明显升高,最高温度达503 ℃左右。

由图7和8可以看到,焊合阶段在多种热转换和热交换(塑性变形功转化的热、摩擦产生的热、金属与工模具之间热传导散热以及金属内部不同温度区域的热传导)的综合作用下,金属表面温度分布不均匀性较为明显,如图7(c)所示,焊合结束后焊合室边角部和模芯附近的温差高达25 ℃。这种温度不均匀分布还将遗传到挤压模孔出口处型材横断面上,导致型材横断面上的温度分布不均匀。

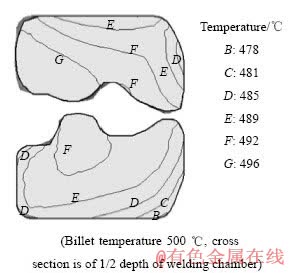

图7所示为焊合阶段焊合室内金属的表面温度分布,而焊合室内(取焊合室1/2深度处横断面)的金属内部温度分布情况如图9所示。由图9可见,金属内部温度分布与表面温度分布的情况类似,但总体上金属内部温度比表面温度要高。

图7 焊合阶段焊合室底面金属温度分布

Fig. 7 Temperature distributions of metals on bottom surface of welding chamber during welding stage

图8 挤压行程为64 mm时金属的等效应变分布和速度分布

Fig. 8 Effective strain and velocity distribution of metals at stroke of 64 mm

3 分流和焊合对模孔出口处型材温升与型材横断面温度分布的影响

3.1 模孔出口处型材温升

为了研究分流和焊合过程对模孔出口处型材温度的影响,本研究采用网格重构法和稳态模拟法(即以金属完全充满焊合室时的状态作为挤压初始状态,仅模拟型材稳定挤出的过程)两种方法,对空心型材分流模挤压成形过程温度变化进行了数值分析。

图9 挤压行程为64 mm时焊合室内的金属内部温度分布

Fig. 9 Inner temperature distribution of metals in welding chamber at stroke of 64 mm

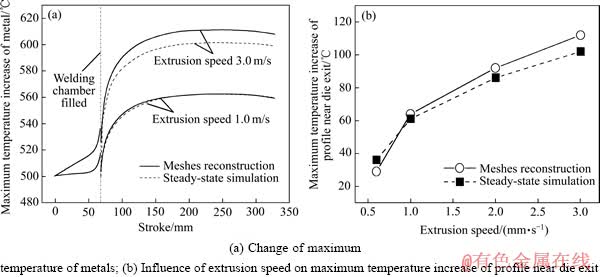

图10(a)为挤压速度1.0 mm/s和3.0 mm/s时采用两种模拟方法得到的挤压过程中不同阶段变形金属最高温度随挤压行程变化曲线的比较。在分流和焊合阶段,由采用网格重构法的计算结果可知,变形金属的最高温度始终在分流孔入口处金属流束根部(见图3),此处温度随挤压行程的变化曲线如图10(a)中焊合室充满之前实线所示;在稳定挤出阶段(挤压行程大于68 mm),两种模拟方法所得的结果均表明,变形金属的最高温度始终处于模孔出口处型材上,温度变化曲线如图10(a)中焊合室充满之后的实线和虚线所示。

图10(a)表明,焊合室充满前分流孔入口处金属温度随挤压行程的增大而逐渐升高。在稳定挤压阶段,随挤压的进行模孔出口处型材温度首先快速上升,然后趋于稳定。

采用网格重构法时,当挤压速度为1.0 mm/s,焊合室充满时(挤压行程68 mm)变形金属最高温度约为517 ℃,由于焊合过程中已有部分金属从模孔挤出,焊合室充满时模孔出口处型材的最高温度为503 ℃,随挤压行程继续增加,模孔出口处型材最高温度从503 ℃开始逐渐升高,然后趋于稳定。当挤压速度为3.0 mm/s时,焊合室充满时变形金属最高温度约为536 ℃,而此时模孔出口处型材上的最高温度为526 ℃,随挤压行程继续增加,模孔出口处型材的最高温度从526 ℃开始逐渐升高,然后趋于稳定。

采用稳态模拟法时,由于将分流与焊合过程的金属温度近似为恒定的500 ℃,其温升曲线(图中虚线所示)从挤压行程68 mm时的500 ℃逐渐升高。

从图10(a)中还可以看到,挤压速度为1.0 mm/s时,两种方法计算的模孔出口处型材温升基本相同,而挤压速度为3.0 mm/s时,两种方法计算的模孔出口处型材温升有明显差别。对不同挤压速度下的模孔出口处型材最大温升进行分析,其结果如图10(b)所示。由图10(b)可以看到,在较低的速度下,采用稳态模拟法计算的模孔出口处型材最大温升高于网格重构法的计算结果,如挤压速度为0.6 mm/s时,稳态模拟法计算的模孔出口处型材温升比网格重构法高约7 ℃;而在较高的速度下情况恰好相反,当挤压速度增大至3.0 mm/s时,网格重构法计算的模孔出口处型材温升比稳态模拟法高约10 ℃。

图10 挤压过程中变形金属温升的计算结果

Fig. 10 Calculation results of temperature increase during extrusion process (Billet temperature 500 ℃)

网格重构法和稳态模拟法计算的模孔出口处型材温升不同的原因在于,变形金属在分流和焊合过程中产生较大的温度变化,并直接影响模孔出口处型材的温度。稳态模拟法不能反映变形金属在分流和焊合过程中的温度变化,忽略了挤压筒内和焊合室内的温度分布对模孔出口处型材温升的影响。一般来说,对于组织性能要求较高的挤压产品,模孔出口处产品的温度需控制在±5 ℃以内。可见,采用稳态模拟法计算的模孔出口处型材温度结果不利于精确指导挤压生产。

3.2 型材横断面温度分布

两种模拟方法获得的挤压中期(模孔出口处型材温升趋于稳定时)型材横断面温度分布结果如图11所示,其中图11(a)和(b)分别为挤压速度v=3.0 mm/s时网格重构法和稳态模拟法获得的型材横断面温度分布示意图,图11(c)为不同的挤压速度下型材横断面最大温差(最高温度和最低温度之差)的变化情况。可见,在不同挤压速度下,网格重构法计算的型材横断面最大温差均大于稳态模拟法的计算结果,当挤压速度为3.0 mm/s时,二者相差12 ℃。

采用两种模拟方法计算的型材横断面最大温差存在较大差别原因在于,变形金属在分流和焊合过程中经历了复杂的热交换过程,导致焊合室内不同部位的金属温度分布不均匀,这种温度不均匀分布直接遗留在模孔出口处的型材断面上,加剧型材横断面温度分布的不均匀。稳态模拟法不能反映分流和焊合过程中金属温度的变化,从而忽略焊合室内金属温度不均匀分布,因而无法准确反映型材横断面的温度分布不均匀性。上述分析表明,网格重构法相比于稳态挤压法能更准确地反映挤压型材横断面温度分布的不均匀性。

图11(c)的结果表明,挤压速度对型材横断面温度分布不均匀的影响较大。由网格重构法的分析可知,当挤压速度由0.6 mm/s增大到3.0 mm/s时,挤压型材横断面最大温差由28 ℃增大到60 ℃。

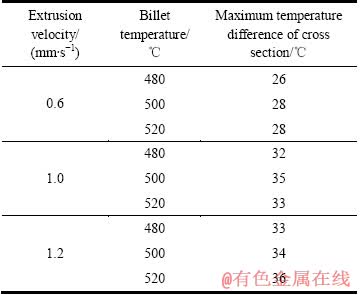

当挤压速度为0.6、1.0、1.2 mm/s、坯料温度为480、500和520 ℃时,挤压中期模孔出口处型材横断面最大温差结果如表1所列。由表1可以看出,在相同挤压速度下,当坯料温度在480~520 ℃范围内变化时,型材横断面上最大温差的变化不超过3 ℃,表明与挤压速度对型材横断面温度分布不均匀性的影响(见图11(c))相比,坯料温度对型材横断面温度分布不均匀性的影响较小。

综上所述,对铝合金空心型材分流模挤压成形进行模拟分析时,若忽略分流和焊合过程金属的温度变化,易导致温度场计算误差大、对模孔出口处型材温度及型材横断面温度分布的预测精度低,难以有效指导高性能铝合金产品的挤压生产。因此,本文作者开发的网格重构模拟方法对空心型材分流模挤压成形温度场分析也具有重要意义。

图11 稳定的型材横断面温度分布计算结果

Fig. 11 Calculation results of temperature distribution of stable profile during extrusion process (Billet temperature 500 ℃)

表1挤压速度和坯料温度对模孔出口处型材横断面温度分布的影响

Table 1 Effects of billet temperature and extrusion speed on temperature distribution of cross section of profile near die exit

4 合理挤压温度和速度范围的确定

根据6005A合金的加工特性和性能要求,挤压模孔出口处型材温度应控制在520~570 ℃,温度过高,容易引起低熔点共晶化合物的熔化;温度过低,不利于挤压过程合金元素的充分固溶,影响在线淬火的效果[17-18]。而上述研究结果表明,不同的坯料温度和挤压速度对模孔出口处型材最高温度及型材横断面温度的分布有较大影响。因此,有必要综合考虑模孔出口处型材温升特点和型材横断面的温度分布不均匀性,确定合理的坯料温度和挤压速度范围,以确保型材横断面的最高和最低温度均在520~570 ℃的范围内。

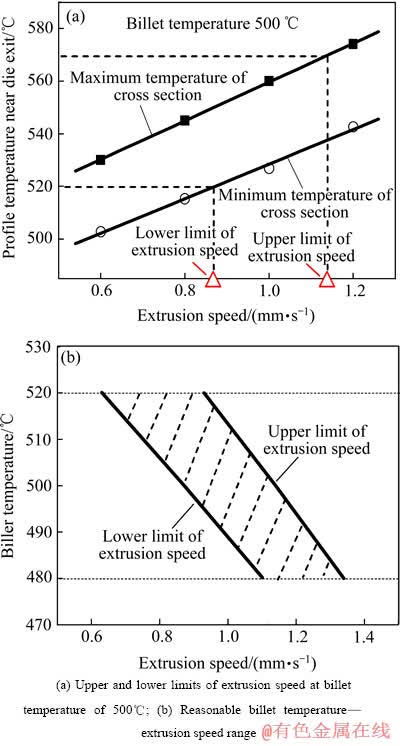

图12 速度对模孔出口处型材温度的影响与合理的挤压温度和速度范围

Fig. 12 Effects of extrusion speed on temperature of profile near die exit and reasonable billet temperature-extrusion speed ranges

图12(a)所示为坯料温度500 ℃、不同挤压速度下稳定挤压阶段模孔出口处型材横断面最高温度、最低温度与挤压速度的关系。由图12(a)可知,满足挤压模孔出口处型材温度要求的挤压速度上限为1.14 mm/s,挤压速度下限0.87 mm/s。

采用图12(a)所示的方法,可获得本文条件下空心型材合理的挤压速度和坯料温度范围,如图12(b)所示。图中阴影区域即为保证模孔出口处型材温度在520~570 ℃范围内的坯料温度和挤压速度窗口。由图12(b)可知,当坯料温度从480 ℃上升到520 ℃时,满足挤压模孔出口处型材温度要求的挤压速度范围分别由1.10~1.34 mm/s下降到0.63~0.93 mm/s。

5 结论

1) 分流和焊合过程中挤压坯料与工模具的热传导以及变形摩擦生热等复杂的热交换行为显著影响模孔出口处型材温升及型材断面温度分布不均匀性,与不考虑分流和焊合过程的稳态模拟法相比,网格重构模拟方法更有利于挤压过程温度场的精确计算。

2) 挤压速度对型材横断面温度分布不均匀性的影响较大,而坯料温度的影响较小。当坯料温度为500 ℃、挤压速度由0.6 mm/s增大到3.0 mm/s时,挤压型材横断面最高温度与最低温度的差值(最大温差)由28 ℃增大到60 ℃;当挤压速度一定、坯料温度由480 ℃增加到520 ℃时,型材横断面最大温差的变化不超过3 ℃。

3) 根据6005A挤压生产中模孔出口处型材温度应为520~570 ℃的要求,确定本研究条件下型材合理的挤压温度和速度关系:坯料温度520 ℃时,挤压速度范围为0.63~0.93 mm/s;坯料温度500 ℃时,挤压速度范围为0.87~1.14 mm/s;坯料温度480 ℃时,挤压速度范围为1.10~1.34 mm/s。

REFERENCES

[1] 谢建新, 刘静安. 金属挤压理论与技术[M]. 2版. 北京: 冶金工业出版社, 2012.

XIE Jian-xin, LIU Jing-an. Theory and technology for metal extrusion[M]. 2nd ed. Beijing: Metallurgical Industry Press, 2012.

[2] XIE J X, MURAKAMI T, IKEDA K, TAKAHASHI H. Experimental simulation of metal flow in porthole-die extrusion[J]. Journal of Materials Processing Technology, 1995, 49(1/2): 1-11.

[3] HE Z, WANG H N, WANG M J, LI G Y. Simulation of extrusion process of complicated aluminium profile and die trial[J]. Transactions of Nonferrous Metals Society of China, 2012, 22(7): 1732-1737.

[4] ZHOU J, LI L, DUSZCZYK J. Computer simulated and experimentally verified isothermal extrusion of 7075 aluminium through continuous ram speed variation[J]. Journal of Materials Processing Technology, 2004, 146(2): 203-212.

[5] JO H H, LEE S K, JUNG C S, KIM B M. A non-steady state FE analysis of Al tubes hot extrusion by a porthole die[J]. Journal of Materials Processing Technology, 2006, 173(2): 223-231.

[6] LI L X, LOU Y. Ram speed profile design for isothermal extrusion of AZ31 magnesium alloy by using FEM simulation[J]. Transactions of Nonferrous Metals Society of China, 2008, 18(1): s252-s256.

[7] 邸利青, 张士宏. 分流组合模挤压过程数值模拟及模具优化设计[J]. 塑性工程学报, 2009, 16(2): 123-127.

DI Li-qing, ZHANG Shi-hong. Porthole die extrusion process numerical simulation and optimal die design[J]. Journal of Plasticity Engineering, 2009, 16(2): 123-127.

[8] WU X H, ZHAO G Q, LUAN Y G, MA X W. Numerical simulation and die structure optimization of an aluminum rectangular hollow pipe extrusion process[J]. Materials Science and Engineering A, 2006, 435/436: 266-274.

[9] LI L, ZHANG H, ZHOU J, DUSZCZYK J, LI G Y, ZHONG Z H. Numerical and experimental study on the extrusion through a porthole die to produce a hollow magnesium profile with longitudinal weld seams[J]. Materials and Design, 2008, 29(6): 1190-1198.

[10] ZHANG Z H, HOU W R, HUANG D N, XIE J X. Mesh reconstruction technology of welding process in 3D FEM simulation of porthole extrusion and its application [J]. Procedia Engineering, 2012, 36: 253-260.

[11] 黄东男, 李静媛, 张志豪, 谢建新. 方形管分流模双孔挤压过程中金属的流动行为[J]. 中国有色金属学报, 2010, 20(3): 488-495.

HUANG Dong-nan, LI Jing-yuan, ZHANG Zhi-hao, XIE Jian-xin. Metal flowing behaviors during diplopore extrusion of square tube with porthole die[J]. The Chinese Journal of Nonferrous Metals Society, 2010, 20(3): 488-495.

[12] 黄东男, 张志豪, 李静媛, 谢建新. 焊合室深度及焊合角对方形管分流模双孔挤压成形质量的影响[J]. 中国有色金属学报, 2010, 20(5): 954-960.

HUANG Dong-nan, ZHANG Zhi-hao, LI Jing-yuan, XIE Jian-xin. Influences of welding chamber depth and welding angle on forming quality of extrusion of square tube by porthole die[J]. The Chinese Journal of Nonferrous Metals Society, 2010, 20(5): 954-960.

[13] 谢建新, 黄东男, 李静媛, 张志豪. 一种空心型材分流模挤压焊合过程数值模拟技术: 中国, ZL 20091008896.7[P]. 2009-12-16.

XIE Jian-xin, HUANG Dong-nan, LI Jing-yuan, ZHANG Zhi-hao. A numerical simulation technology for hollow profile extrusion by porthole die: China, ZL 20091008896.7[P]. 2009-12-16.

[14] 黄东男. 模具结构对铝合金型材挤压流动变形行为的影响[D]. 北京: 北京科技大学材料科学与工程学院, 2010: 23-28.

HUANG Dong-nan. Investigation of die-structure effects on Al-alloy flowing behaviours during extrusion process[D]. Beijing: School of Materials Science and Engineering, University of Science and Technology Beijing, 2010: 23-28.

[15] 肖亚庆, 谢水生, 刘静安, 王 涛. 铝加工技术实用手册[M]. 北京: 冶金工业出版社, 2004.

XIAO Ya-qing, XIE Shui-sheng, LIU Jing-an, WANG Tao. Aluminum processing technology practical manual[M]. Beijing: Metallurgical Industry Press, 2004.

[16] FANG G, ZHOU J, DUSZCZYK J. FEM simulation of aluminium extrusion through two-hole multi-step pocket dies[J]. Journal of Materials Processing Technology, 2009, 209(4): 1891-1900.

[17] 刘静安, 盛春磊, 王文琴. 铝合金挤压在线淬火技术[J]. 轻合金加工技术, 2010, 38(2): 7-15.

LIU Jing-an, SHENG Chun-lei, WANG Wen-qin. Online quenching technology of aluminium extrusion[J]. Light Alloy Fabrication Technology, 2010, 38(2): 7-15.

[18] LAUE K, STENGER H. Extrusion[M]. Ohio: American Society for Metals, 1981.

(编辑 李艳红)

基金项目:金属挤压与锻造装备技术国家重点实验室(中国重型机械研究院有限公司)开放基金课题(20111101);新金属材料国家重点实验室北京科技大学开放基金课题资助(2011Z-12)

收稿日期:2012-11-24;修订日期:2013-05-26

通信作者:张志豪,副教授,博士;电话:010-62332253;E-mail: ntzzh2279@163.com