文章编号:1004-0609(2013)S1-s0609-04

TA2/Q235轧制复合工艺

杨 哲,容 耀,刘润生,李向东

(宝钛集团有限公司,宝鸡 721014)

摘 要:论述TA2/Q235轧制复合法生产工艺,根据TA2、Q235材质的特点和复合技术要求,选取3种材料作为夹层,采取基层、复层、夹层材料对称组坯方式并做真空处理,对不同夹层材料、加热制度和轧制工艺进行了研究。综合分析结果表明:以1#材料为夹层,采取加热温度900℃、变形量大于80%的工艺,其贴合率、表面质量和力学性能均能满足标准GB/T8547—2006的要求。该生产方法可以有效地解决以往爆炸-轧制法生产方式板幅小、受外界条件制约的不足,为今后高效化生产宽幅钛钢复合板奠定了基础。

关键词:轧制复合工艺;组坯方式;夹层材料;宽幅钛钢复合板

中图分类号:TG392 文献标志码:A

TA2/Q235 rolling bonding technology

YANG Zhe, RONG Yao, LIU Run-sheng, LI Xiang-dong

(Baoji Titanium Group Co., Ltd., Baoji 721014, China)

Abstract: In order to study different interlayer material, heating schedule and hot rolling process, the TA2/Q235 rolling bonding technology was discussed and three kinds of interlining material were selected to take radical, complex, interlining material adopt symmetric assembly with vacuum treatment by considering the characteristic of two kinds material and technological requirements. The analysis results reveals that the fitting rate, surface quality and mechanical properties can meet the requirements of GB/T8547—2006 when material 1 was used as the sandwich at the heating temperature of 900 ℃ and deformation greater than 80%.The appropriate interlayer materials, process parameters and reliable process route were developed which can effectively solve the explosion-rolling process of plate width and small external condition that it is a foundation for efficient production of wide titanium clad steel plate.

Key words: rolling bonding technology; assembly method; interlining material; wide titanium clad steel plate

钛-钢复合板既具有钛的耐腐蚀性,又通过复合钢材提高了强度,改善了材料的综合性能,性价比高,从而扩展了钛材的适用范围,能够广泛应用于化工、电厂等的设备制造领域[1-2]。

目前,钛-钢复合板主要生产方式是爆炸法和爆 炸-轧制法,其生产效率受天气等外界环境影响很大,且由于爆炸技术局限性,能生产的复合板板幅有限[3-4]。随着现代大型设备的制造和需求,为了减少焊缝、提高安全系数和降低成本,对大面积复合板的需求日益增大,轧制复合工艺可以直接生产出满足要求的宽幅复合板。轧制复合生产工艺是有效的解决途径。但是这种工艺对设备、技术和人员操作技能要求很高,目前国内厂家很少采用此种工艺,只有国外一些企业技术较为成熟[5]。而宝钛集团具有德国进口的3.3 m热轧机的设备优势和技术优势以及多年复合板生产经验,完全可以对该产品进行开发,其对扩展公司产品结构、拓展市场空间有重要意义。

1 实验

TA2与Q235不能直接轧制复合,而采用合适的材料作为夹层是有效的解决途径。通过分析基、复层材质特点和复合工艺要求,试验初步设计了几种工艺路线,制定了不同的加热温度、变形量、夹层材料来进行对比试验,制定的工艺方案见表1。

表1 实验方案及试样编号

Table 1 Experiment program and sample number

实验以Q235为基层、TA2为复层,两者与夹层材料采取对称方式组坯,抽真空并处理。试验按照实验方案的工艺参数执行,空冷后将试验板切边、掀开后观察表面质量、贴合情况,取样分析界面金相和测试剪切强度等性能。将实验结果对照标准加以分析,确定夹层材料、加热温度和变形量,从而最终确定合理可行的工艺方案。

2 结果与分析

由于采取对称方式组坯,轧制后需将试验板切边掀板,然后观察贴合情况和表面质量。

对贴合良好的试验板取样检测,相关情况如下。

表2 实验结果

Table 2 Experiment result

2.1 轧制TA2/1#/Q235复合板

TA2/1#/Q235复合板组坯6块,取样测试剪切强度值,按照GB/T8547—2006标准规定复层厚度小于1.5 mm应取拉剪试样,其中轧制法钛钢复合板剪切强度值不小于140 MPa[6]。测试结果见表3。在A4和A6复合板取3个样,分别为A4-1、A4-2、A4-3、A6-1、A6-2和A6-3。A4的L2强度低于标准值,A6强度值均可以满足标准要求,且整体优于A4的结果。A6温度高于A4温度,但是不宜继续提高加热温度,有关研究表明;钛钢复合板在接近1 000 ℃的较高加热温度时会产生大量的金属间化合物,导致其结合强度降低,甚至无法贴合[7-8]。

TA2/1#/Q235复合板界面金相见图1所示。由图1可看出,A4结合界面平滑,A6结合界面呈现波浪状,而无论是平滑界面还是波状界面均可以良好结合[9]。由图1还可以看出,A4的界面化合物层较厚,钛侧晶粒内部存在片层状组织,Fe-Ti层较明显。且界面处化合物层厚度不一,观察较厚的化合物层均出现在铁素体晶粒周围,而直接影响钛钢复合板结合强度的主要是过渡层出现的金属间化合物Fe-Ti和Ti-C化合物层,这两种化合物越多,结合强度越低[10]。而A6整体组织形貌优于A4的,如图1(b)所示,界面化合物较少,钛钢两侧组织正常。

表3 TA2/1#/Q235轧制复合板剪切强度

Table 3 Shear strength of TA2/1#/Q235 clad plates

图1 TA2/1#/Q235复合板界面金相

Fig. 1 Interface metallographs of TA2/1#/Q235 clad plates

2.2 轧制TA2/2#/Q235复合板

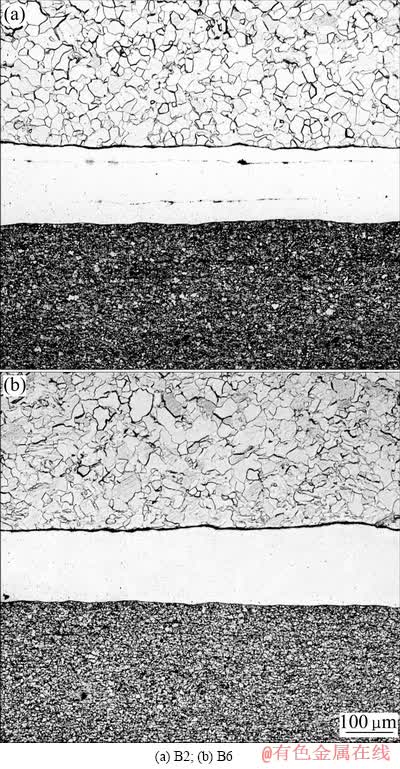

TA2/1#/Q235复合板的剪切强度见表4。由表4可看出,样品B2强度均不能满足标准,样品B6强度可以满足标准要求,但是偏低。

表4 TA2/2#/Q235轧制复合板剪切强度

Table 4 Shear strength of TA2/2#/Q235 clad plates

图2 TA2/2#/Q235复合板界面金相组织

Fig. 2 Interface metallographs of TA2/2#/Q235B clad plates

TA2/1#/Q235复合板结合界面组织见图2,B2夹层及界面化合物较多,B6结合处化合物层很薄,组织无明显异常,但是整体强度较低,且2#材质成本较高。多方考虑不建议以2#材质作为夹层。

2.3 轧制TA2/3#/Q235复合板

TA2/1#/Q235复合板的剪切强度值见表5。由表5可看出,样品C2不能满足标准要求;样品C4-1的强度低于标准值不合,不能完全满足标准要求。

表5 TA2/3#/Q235轧制复合板剪切强度

Table 5 Shear strength of TA2/3#/Q235 clad plates

图3 TA2/3#/Q235复合板界面金相

Fig. 3 Interface metallographs of TA2/3#/Q235B clad plates

TA2/1#/Q235复合板结合界面金相组织见图3,C2化合物层厚,且界面存在明显夹杂物,其夹层内部缺陷也偏多。将C2放大倍率观察,见图3(b),夹层完成再结晶,且有孪晶存在。普钢侧组织无异常,为正常亚共析组织,但是纯钛侧组织发生明显变化,除去正常再结晶产生的等轴晶粒外,沿晶界生长出片层状、粗大针状组织,而且沿界面出现大尺寸晶粒,见图3(b)箭头处。认为是3#材质与钛在798 ℃发生共析转变,该组织是共析转变产物。C4结合界面也存在较多化合物,见图3(c)。综合考虑认为不应以3#材质作为夹层材料。

3 结论

1) 变形量是影响贴合的重要因素,本研究中变形量为50%的均未贴合,经过计算试验板实际变形量,结合实验结果和相关资料,为实现良好贴合,变形量应不低于80%。

2) 轧制TA2/Q235复合板以1#材料为夹层,对称组坯并真空处理后,采取加热温度900 ℃、变形量大于80%的工艺,其各项性能可以满足GB/T8547—2006标准的要求,且贴合情况和表面质量较好。

REFERENCES

[1] 闫 力. 钛钢复合板的特点及应用领域[J]. 中国钛业, 2011(3): 12-14.

YAN Li. Behaviotsard applications of Ti/steel composite sheets [J]. China Titanium Industry, 2011(3): 12-14.

[2] 黄淑梅. 热轧生产钛钢复合板的技术进展[J]. 钛工业进展, 2002(6): 49-50.

HUANG shu-mei. Titanium clad steel plate of hot-rolled production technology progress [J]. Titanium Industry Progress, 2002(6): 49-50.

[3] 李正华. 生产复合板的主要方法及其基本特点[J]. 稀有金属材料与工程, 1990(1): 72-75.

LI Zheng-hua. The main production method of composite plate and its basic characteristics [J]. Rare Metal Materials and Engineering, 1990(1): 72-75.

[4] 郝 斌. 轧制钛钢复合板的制造方法[J]. 钛工业进展, 1995(5): 50.

HAO Bing. Manufacturing method of rolling of titanium clad steel plate [J]. Titanium Industry Progress, 1995(5): 50.

[5] 黄金昌. NKK开发钛钢轧制复合板[J]. 稀有金属快报, 2002(6): 3-5.

HUANG jin-chang. NKK development of titanium steel clad sheet [J]. Rare Metal Letters, 2002(6): 3-5.

[6] GB/T8547—2006. 钛钢复合板[S].

GB/T8547—2006. Titanium clad steel plate [S].

[7] 王敬忠. 带夹层材料的爆炸-轧制钛钢复合板工艺研究[J]. 稀有金属材料工程, 2010, 39(2): 309-313.

WANG Jing-zhong. Summarization of the rolling Ti-steel composite plates process [J]. Rare Metal Materials and Engineering, 2010, 39(2): 309-313.

[8] 王敬忠. 轧制钛-钢复合板工艺综述[J]. 材料导报, 2005, 19(4): 61-63.

WANG Jing-zhong. Titanium cladding steel plates with interlayer by explosion and rolling bonding [J]. Rare Metal Materials and Engineering, 2005, 19(4): 61-63.

[9] 段卫东. 铜和铝作为钛钢爆炸焊接夹层时的复合工艺及焊接界面的实验研究[J]. 爆破器材, 2011, 30(1): 27-31.

DUAN Wei-dong. Experimental investigation on in to the interface and cladding technology while aluminum or brass as sandwich of Ti/steel compound plate in the explosive welding [J]. Explosive Materials, 2011, 30(2): 27-31.

[10] 李红. TAl/Q235循环累积变形复合界面的特性[J]. 有色金属, 2007, 59(3): 5-8.

LI Hong. Interface characteristic of TAl/Q235 clad plate by cyclic accumulated deformation process [J]. Nonferrous Metals, 2007, 59(3): 5-8.

(编辑 李艳红)

收稿日期:2013-07-28;修订日期:2013-10-10

通信作者:杨 哲,助理工程师; 电话: 13571759653; E-mail: baotailangzi@163.com