文章编号: 1004-0609(2005)07-1118-06

喷雾干燥法处理水合氧化锆

林振汉, 张玲秀, 吴 亮

(上海大学 锆材料研究中心 上海 200072)

摘 要: 比较了采用直接煅烧、 干燥后煅烧、 喷雾干燥等3种方法处理水合ZrO2, 再通过气流粉碎获得超微细粉ZrO2; 同时用激光衍射法、 光透法、 场发射扫描电镜和BET法测试了粉末的性能。 结果表明: 直接煅烧水合ZrO2获得的粉末团聚严重, 颗粒粗而均匀性差; 水合ZrO2通过低温静止干燥, 可以减少颗粒的团聚, 提高粉末颗粒分布的均匀性, 但效率低; 喷雾干燥法处理水合ZrO2, 通过动态反应, 易获得细晶粒的球状颗粒, 可避免粉末的团聚, 且粉末分散性好、 晶粒分布均匀。

关键词: 水合氧化锆; 喷雾干燥; 光透法; 场发射扫描电镜; 超微细粉 中图分类号: TQ134.1; TB383

文献标识码: A

Hydrous ZrO2 treated by spray drying method

LIN Zhen-han, ZHANG Ling-xiu, WU Liang

(Zirconium Materials Research Center, Shanghai University, Shanghai 200072, China)

Abstract: Three methods were used to treat hydrous ZrO2 such as direct sintering, sintering after drying, spray dring, then the ultra-fine ZrO2 powder was prepared by air-jet milling. The physical properties were tested by laser diffractrometry, light transmission, field emission scanning electron microscopy and Brunauer-Emmett-Teller(BET). The results that, the powder sintered directly are agglomerated greatly, rough and not well-distributed. The powder sintered after drying, through static reaction, has lower agglomeration and better distribution, but lower efficiency. The ultra-fine powder prepared by spray drying method, through the dynamic reaction, not only can prohibit the agglomeration and be obtained easily, but also has well-distributed and good dispersibility.

Key words: hydrous ZrO2; spray drying; light transmission method; field emission SEM; ultra-fine powder

微细粉氧化锆具有高活性, 是一种良好的催化剂, 在石油化工、 电子陶瓷和陶瓷釉料方面具有重要的用途。 氧化锆粒度的不均匀、 粗细差异大、 颗粒团聚严重等都将影响催化的效果。 制备微细氧化锆粉末的方法很多, 包括气相反应[1]、水热分解[2, 3]、 化学沉积[4]、 醇热法合成[5]、 草酸盐合成和分解[6]、 溶胶-凝胶法[7]等。 氢氧化锆一般通过氨沉淀获得[4], 而水合ZrO2是通过水热分解获得。 制备工艺不同, 所得产品的性能也不同, 这与沉积的时间和pH值有直接的关系。 水合ZrO2的原始颗粒成核、 晶体长大和二次颗粒的凝聚取决于水解溶液的H+和Cl-的浓度[2, 3]。 许多资料表明: 从ZrOCl2溶液水解合成的水合ZrO2的原始和二次颗粒尺寸, 不管添加HCl或NH4OH, 都由水溶液中H+离子浓度来控制[2]。 但二次颗粒尺寸主要依赖于Cl-的浓度。 一般认为通过低温水解来制备纳米ZrO2粉末[1], 减少颗粒之间的团聚, 但是, 低温很难排除残余的H+和Cl-。 所以, 在制备氢氧化锆或水合ZrO2时控制原始颗粒、 二次颗粒团聚和长[CM(22]大的同时, 对氢氧化锆或水合ZrO2进行再处理是[CM)] 高温下防止颗粒的团聚和长大的关键技术。 目前大多数研究是通过低温长时间干燥来处理氢氧化锆或 水合ZrO2。 由于该方法是在静止状态下进行, 效率很低, 而且会产生局部团聚。 但如果用喷雾干燥法处理前期锆的水合物, 不仅可以除去大部分的H+、 Cl-和挥发物, 而且可大大提高干燥的效率[8, 9]。

本文作者根据动态反应原理, 利用喷雾干燥法处理水合ZrO2, 研究了ZrO2的制备工艺和粉末性能。

1 实验

采用ZrOCl2为原料溶解在水中, 用NH4OH作沉淀剂, 并添加分散剂(PEG)。 首先溶解配制成一定浓度的锆水溶液。 在水热和连续搅拌下缓慢地添加1∶1NH4OH(质量比), 调节水溶液的pH值为9~10, 使锆完全沉淀析出。 经过滤、 洗涤除去NH4Cl, 洗涤是制备水合ZrO2的关键工序[10]。 然后将水合ZrO2用QZR型高速离心喷雾干燥机处理得到含水的细干粉, 再将粉末分别在700和900℃下煅烧2h后通过气流粉碎制备ZrO2细粉。 用LS100型激光衍射粒度仪检测粉末粒度分布、 用JB-1比表面测定仪(BET)测定粉末比表面积、 用SKC2000型光透沉淀粒度分布测定仪测定粉末粒度大小, 用JSM6700F场发射扫描电镜观察粉末的SEM形貌。

2 结果和讨论

2.1 直接煅烧后水合氧化锆的粉末性能

将水合ZrO2直接在700℃下煅烧, 得到的块状物经球磨、 气流粉碎后, 变成细小的粉末。 粉末的颗粒尺寸和粒度分布结果如图1所示, 其比表面积SBET=3.82m2/g, 粉末的扫描电镜分析如图2所示。 粉末的粒度D50=37.32μm。

图1 700℃直接煅烧的水合ZrO2粉末的粒度分布曲线

Fig.1 Particle size distribution curve of hydrous ZrO2 directly calcinated at 700℃

图2 700℃直接煅烧的水合ZrO2粉末的SEM像

Fig.2 SEM morphology of hydrous ZrO2 directly calcinated at 700℃

所得水合ZrO2粉末含有大量的吸附水和游离水, 在粒子之间存在表面张力较高的水分子。 在煅烧过程中, 由于毛细管作用而使粒子间产生较强的结合力。 随着温度升高, 此结合力更为增强而出现硬团聚。 从图2中看出, 粉末颗粒虽细, 但团聚严重, 透气性差, 所以比表面积小。 图1所示表明其粒度分布是一条多峰曲线, 团聚粗颗粒多、 分散的细颗粒少, 均匀性差, 少量颗粒小于30μm, 大部分分布在30~100μm之间。 因此直接煅烧很难制备超微细粉ZrO2。

2.2 经低温干燥处理后水合氧化锆的粉末性能

将水合ZrO2在150~180℃和负压下干燥42h, 然后在700℃下煅烧2h, 获得的粉末经气流粉碎之后, 粉末的粒度D50=2.73μm , SBET=34.2m2/g。 粉末的粒度分布曲线及其SEM形貌分别如图3和4所示。

图3 水合ZrO2干燥粉末的粒度分布曲线

Fig.3 Particle size distribution curve of hydrous ZrO2 powder

图4 低温干燥粉末的SEM像

Fig.4 SEM morphologies of lower temperature drying powder

水合ZrO2在干燥期间, 游离水和结合水随温度的升高和时间的延长逐步变成气相从颗粒中间通过自扩散穿过蒸发到表面溢出[11], 从而除去游离水和部分的结晶水, 减少存在于粒子之间表面张力较高的水分子, 减弱粒子之间的结合力, 但是干燥粉末中仍含有H+、 Cl-、 H2O和挥发物(主要是NH4Cl), 这部分化合物在高温煅烧时才能除去。 很明显干燥处理的粉末比直接煅烧的粉末疏松, 粒度细、 分布均匀(图1和图3), 其粒度分布是一条单峰曲线, 且颗粒之间接触不很紧密, 所以比表面积大(约增大10倍)。 从图4可观察到粉末仍有少量团聚的现象。 结果表明, 低温干燥能够细化粉末颗粒、 减少粉末团聚、 提高粉末分布的均匀性、 增大粉末的比表面积。 但低温干燥时间太长, 能耗大, 效率低。

2.3 水合氧化锆喷雾干燥处理后的粉末性能

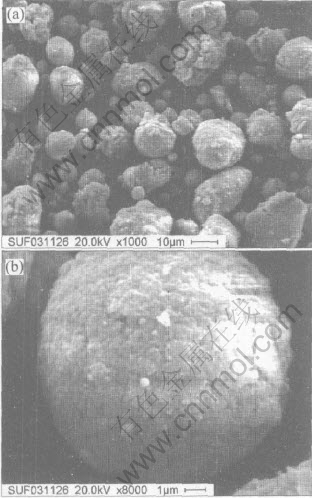

在水合ZrO2中添加3%~5%的分散剂(PEG)和粘结剂(PVA), 球磨调浆, 在350℃下用喷雾干燥法处理, 获得低温粉末。 粉末粒度为D50=16.41μm , SBET=32.6m2/g。 粉末的粒度分布曲线和SEM形貌分别如图5和6所示。

图5 喷雾干燥后水合ZrO2粉末的粒度分布曲线

Fig.5 Particle size distribution curve of hydrous ZrO2 powder after spray drying

图6 喷雾干燥后水合ZrO2粉末的SEM像

Fig.6 SEM morphologies of hydrous ZrO2 powder by spray drying

采用喷雾干燥技术处理水合ZrO2, 实际上是一个气相蒸发的物理过程: 喷雾干燥是在350℃的温度下在27000~30000r/min的高速高压下离心处理, 把胶体或胶液的料浆在一定温度下进行瞬时雾化、 浆中已形成ZrO2·nH2O化合物和水蒸气分离, 部分易挥发的物质也随之挥发, 获得含有机成分的细小颗粒, 在高速离心下变成圆球状颗粒。 分散剂和粘结剂实际上是高分子聚合物, 在喷雾干燥中, 分散剂和粘结剂填充、 包裹和渗合在ZrO2颗粒之间。 在热应力的作用下, 分子之间的基链在一定条件下, 不断发生断裂, 使之渗透在ZrO2分子之间[12]。

从图5中看出, 粒度分布是一个单峰曲线。 从图6中所示的SEM形貌可以看出, 喷雾干粉的二次颗粒呈球状, 粉末不发生团聚, 单颗粒是由非常细小的松散晶粒(原始颗粒)组成的, 并有微小的裂纹存在。 有利于应力作用使粉末进一步细化。 由于颗粒的分散性能很好, 颗粒之间接触面很小, 透气性好, 所以, 比表面积大。 比较低温干燥和喷雾干燥两种条件下粉末性能可知: 低温粉末粒度比较细, 但两种粉末的比表面积相差不大, 低温是在静态下进行, 颗粒之间接触紧密, 所以有团聚现象。 喷雾干燥是在驱动力作用下进行干燥, 温度比较高, 水蒸气挥发速度快, 结合水去除比较多, 也除去部分挥发物, 所以, 残留在干燥粉末颗粒中的表面张力高的物质减少。 分散剂和粘结剂填充、 包裹和渗合在ZrO2颗粒之间, 这有利于高温煅烧时分散粉末颗粒。

2.4 喷雾干燥粉末在不同温度煅烧后的粉末性能

喷雾干燥后的粉末颗粒内部含有分散剂、 粘结剂、 水合物和挥发物, 在高温下这些易挥发组份随温度升高而逐步除去。 喷雾干燥的粉末在不同的温度下煅烧, 观察粉末的变化, 其检测的结果列于表1和表2。 900℃温度下煅烧的粉末性能如图7和8所示。

喷雾干燥的粉末中含有未挥发的分散剂、 粘结剂、 NH4Cl和其他易挥发的物质, 渗透在ZrO2分子之间, 这些物质在不同温度下挥发, 温度升高时, 基链不断断裂, 挥发冲散ZrO2之间的聚合, 易挥发的物质在球状颗粒之间起着隔离、 偏离和活化表面的作用, 利用有机物的挥发性把无机颗粒分开[12]。 比较图3和7可看出: 经煅烧之后的粉末,粉末颗粒度明显变细。 颗粒呈不规则状(图8)。 比较在低温(700℃)和高温(900℃)下煅烧的成分变化可知: 杂质含量变化不明显, 而Cl-和灼烧损失变化很大, 在700℃下煅烧Cl-含量很高(0.021%), 灼烧损失很大(1.12%), 说明ZrO2中挥发性物质含量比较高; 而在900℃下煅烧, 残留在ZrO2粉末中的挥发物(NH4Cl等)进一步除去, 使Cl-和灼烧损失进一步下降。 比较不同温度下煅烧的粉末粒度变化得知, 在700℃下煅烧, 粉末比较细, 随着温度升高, 二次颗粒聚合, 晶粒有所长大, 但不明显, 而颗粒的聚集度增大, 所以比表面积随着温度升高明显地降低。

表1 不同温度下煅烧样品的化学成分

Table 1 Chemical composition of calcinated sample at various temperatures(mass fraction, %)

表2 不同温度下煅烧粉末的粒度、松装密度和比表面积

Table 2 Particle size, bulk density and SBET of calcinated powder at various temperatures

图7 煅烧粉末的粒度分布曲线

Fig.7 Particle size distribution curve of calcinated powder

图8 煅烧粉末的SEM像

Fig.8 SEM morphology of calcinated powder

2.5 煅烧粉末经气流粉碎后的粉末性能

图9所示为喷雾干燥粉末经900℃温度下煅烧的ZrO2粉末的SEM形貌, 从图中看出, 颗粒之间有一定的聚合, 但有明显的分离空间, 颗粒和颗粒之间结合并不紧密, 颗粒表面有微裂纹和重叠现象, 颗粒尺寸小于1μm。

图9 喷雾干燥粉末经900℃煅烧后粉末的SEM像

Fig.9 SEM morphology of sprayed powder after calcinated at 900℃

气流粉碎是利用高速气流的能量, 使颗粒相互冲击、 碰撞、 摩擦而实现超细粉碎, 因此, 通过气流粉碎的作用, 可以使粉末进一步细化[13, 14]。 气流粉碎后粉末的SEM形貌表示于图10中。

经气流粉碎后的粉末的粒径检测结果(激光法)为: D10=0.56μm, D50=1.34μm, D90=2.34μm, SBET=34.97m2/g , 松装密度0.47cm3/g。

用光透法测定的粉末粒度结果列于表3, 粉末的D50为0.6μm。

比较煅烧和气流粉碎后粉末的性能(图7和图11)及SEM形貌(图9和10)可知: 气流粉碎粉末的颗粒更细, 粒度分布更狭窄, 晶粒细而均匀, 松装[CM(22]密度降低, 比表面积明显增大。 表明喷雾干燥、 温度和气流粉碎起着细化和分散的作用。 颗粒虽有聚合现象, 但颗粒之间有明显的独立性, 颗粒中晶粒粒径介于0.1~1.0μm之间。

表3 光透法测定的粉末粒度分布

Table 3 Particle size distribution of examined powder by light transmission method

图10 气流粉末的场发射扫描电镜像

Fig.10 Field emission SEM morphologies of air-flow pulverization powder

图11 气流粉末的粒度分布曲线

Fig.11 Particle size distribution curve of air-flow pulverization powder

3 结论

1) 水合ZrO2经低温干燥予处理后煅烧, 可直接获得氧化锆微细粉, 低温干燥是制备细微粉的关键工序。

2) 用喷雾干燥法预处理水合ZrO2, 比用低温干燥处理效果好, 不仅干燥速度快, 而且获得的ZrO2粉末疏松、 分散性好、 分布均匀、 不团聚且比表面积大。

3) 喷雾干燥法预处理的水合ZrO2, 其粉末颗粒都是亚微米级, 其粒度分布是一条狭窄单峰的曲线, 表明粒度分布均匀。因此, 该方法预处理水合ZrO2制备超微细粉氧化锆是可行和有效的。

REFERENCES

[1]XIA Bin, DUAN Lian-yun, XIE You-chang. ZrO2 nanpowders prepared by low-temperature vapor-phase hydrolysis [J] . J Am Ceram Soc, 2000, 83(5): 1077-1080.

[2]Matsui K, Ohgai M. Formation mechanism of hydrous-zirconia particles produced by hydrolysis of ZrOCl2 solutions: Ⅱ[J]. J Am Ceram Soc, 2000, 83(6): 1386-1392.

[3]Matsui K, Ohgai M. Formation mechanism of hydrous-zirconia particles produced by hydrolysis of ZrOCl2 solutions(Ⅲ): kinetics study for the nucleation and crystal-growth processes of primary particles [J]. J Am Ceram Soc, 2001, 84(10): 2303-2312.

[4]HUANG Chuang-yong, TANG Zi-long, ZHAN Zhong-tai. Differences between zirconium hydroxide (Zr(OH)4·nH2O) and hydrous zirconia (ZrO2·nH2O)[J]. J Am Ceram Soc, 2000, 84(7): 1637-1638.

[5]Kongwudthiti S, Praserthdam P, Silveston P, et al. Influence of synthesis conditions on the preparationof zirconia powder by The glycothermal method[J]. Ceramics International, 2003, 29: 807-814.

[6]Vasylkiv O, Sakka Y. Nonisothermal synthesis of yttria-zirconia nanopowder through oxalate processing: I, Characteristics of Y-Zr oxalate systhesis and decomposition[J]. J Am Ceram Soc, 2000, 83(9): 2196-2202.

[7]Wu A Y, Vilarinho P M, Isabel M, et al. Baptista, sol-gel preparation of lead zirconate titanate powders and ceramics: effect of alkoxide stabilizers and lead precursors[J]. J Am Ceram Soc, 2000, 83(6): 1379-1385.

[8]林振汉, 张玲秀. 喷雾干燥法制备PSZ-3Y粉末的粒度性能研究[J]. 稀有金属, 2001, 25(5): 336-339.

LIN Zhen-han, ZHANG Lin-xiu. Study of properties of particle of PSZ-3Y powder prepared by spray drying method[J]. Rare Metals, 2001, 25(5): 336-339.

[9]林振汉, 吴亮, 林钢, 等. 用喷雾干燥法制备PSZ-3Y粉末颗粒的形貌研究[J]. 稀有金属, 2003, 27(1): 144.

LIN Zhen-han, WU Liang, LIN Gang, et al. Study on particle appearance of PSZ-3Y powder prepared by spray drying method[J]. Rare Metals, 2003, 27(1): 144.

[10]Hatton B D, Sakka Y. Influence of washing on zirconia powder for electrophoretic deposition[J]. J Am Ceram Soc, 2001, 84(3): 666-668.

[11]Maglia F, Anselmi-Tamburini U, Spinolo G, et al. Zirconia-based metastable solid solutions through self-propagating high-temperature synthesis, characterization, and mechanistic investigations[J]. J Am Ceram Soc, 2000, 83(8): 1935-1941.

[12]吴亮, 林振汉, 张玲秀, 等. 粘结剂和分散剂对喷雾干燥PSZ-3Y粉末性能的影响[J]. 稀有金属, 2004, 28(6): 983-986.

WU Liang, LIN Zhen-han, ZHANG Lin-xiu, et al. Effect of binder and dispersant on spray-dried PSZ-3Y powders[J]. Rare Metals, 2004, 28(6): 983-986.

[13]郑水林. 超细粉碎[M]. 北京: 中国建材工业出版社, 1999. 137-144.

ZHENG Shui-lin. Ultrafines Shatter[M]. Beijing: China Building Materials Industry Press, 1999. 137-144.

[14]卢寿慈. 粉体加工技术[M]. 北京: 中国轻工业出版社, 2000. 165-175.

LU Shou-ci. Powder Processing Technology[M]. Beijing: China Light Industry Press, 2000.165 -175.

基金项目: 国家重点新产品试制计划资助项目(2000G041D680023)

收稿日期: 2004-10-28; 修订日期: 2005-04-06

作者简介: 林振汉(1938-), 男, 教授.

通讯作者: 林振汉; 电话: 021-56331986; E-mail: utzircob@etang.com

(编辑 龙怀中)