文章编号:1004-0609(2008)03-0400-09

流变压铸YL112铝合金的微观组织特征

郭洪民1,杨湘杰2

(1. 南昌大学 材料科学与工程学院,南昌 330031;

2. 南昌大学 机电工程学院,南昌 330037)

摘 要:将剪切低温浇注半固态(LSPSF)浆料制备工艺与传统高压铸造工艺衔接,研究出一种半固态浆料直接成形工艺——流变压铸技术。结果表明:LSPSF工艺可在15~20 s制备出初生α(Al)形状因子为0.93,晶粒尺寸为70 μm且分布均匀,初生α(Al)内部没有夹裹液相的YL112铝合金半固态浆料;与传统压铸相比,流变压铸可改善YL112合金铸件的微观组织,半固态浆料在二次凝固中发生体积凝固,铸件微观组织细小且分布均匀。该LSPSF流变铸造工艺与传统压铸工艺衔接简便,半固态浆料输送平稳,具有较强的可操作性。

关键词:流变成形;半固态;微观组织;压铸;YL112铝合金

中图分类号:TG 146.2 文献标识码:A

Microstructures characteristics of YL112 aluminum alloy produced by rheo-diecasting process

GUO Hong-min1, YANG Xiang-jie2

(1. School of Materials Science and Engineering, Nanchang University, Nanchang 330031, China;

2. School of Mechanical and Electronic Engineering, Nanchang University, Nanchang 330031, China)

Abstract: A new one-step semi-solid processing technique, the rheo-diecasting (RDC) process, was exploited, in which the independently developed low superheat pouring with a shear field (LSPSF) process was combined with the existing cold chamber high pressure diecasting (HPDC) process. The experimental results show that the LSPSF can prepare sound semi-solid secondary diecasting aluminum alloy YL112 slurry in 15-20 s to fully meet the production rate of HPDC, the primary α(Al) presents in mean equivalent diameter of 70 μm and shape factor of 0.93 and features zero-entrapped eutectic. Compared with conventional HPDC process, RDC process can improve microstructures in castings. Secondary solidification of semi-solid slurry takes place uniformly throughout the entire cavity and produces an extremely fine and uniform microstructure. The advantages of the present RDC process include easy incorporation into existing HPDC machine without infrastructure changes, smooth transportation of semi-solid slurry from the LSPSF machine to the shot chamber, high operability for pouring temperature and thermal control.

Key words: rheoforming; semi-solid; microstructure; diecasting; YL112 aluminum alloy

高压铸造(High pressure diecasting, HPDC)是铝合金成形工艺中应用最广泛的技术之一,特别在汽车产业和运输业。高压铸造的显著特点是高生产效率、低能耗、能够生产薄壁结构零件。而气孔是压铸件最主要的缺陷,严重影响压铸件的力学性能、耐蚀性能、气密性、可焊性及可热处理性[1]。为了消除气孔缺陷,一些无气孔压铸技术,如真空压铸、挤压铸造和半固态压铸等应运而生。半固态压铸(包括流变压铸和触变压铸)充分应用了半固态浆料/坯料的特性,利用其触变特性实现充型,利用其高表观粘度降低自身的雷诺数实现实体平稳充型,减少甚至消除了气孔和缩松[2]。另外,半固态压铸在保持半固态成形特点的同时,还保留了高压铸造的高效率、低成本特征。与触变压铸相比,流变压铸仍然处于初期研究阶段,但由于流变压铸具有流变成形的基本特征[2-4],因此,其工业应用前景非常广阔。具有代表性的流变压铸技术主要有两类:以压射室制浆压铸技术[5]和流变射铸技术[6-8]为代表的制浆和成形结为一体的流变成形模式;以新流变铸造(New rheocasting,NRCTM)[9]和半固态流变铸造(Semi-solid rheocasting,SSRTM)[10]为代表的浆料制备和成形相分离的流变成形模式,但目前上述流变压铸的具体技术细节尚未公开。半固态浆料的快速制备和输送是制约流变压铸乃至流变成形发展的瓶颈。

本文作者将剪切低温浇注(Low superheat pouring with a shear field,LSPSF)半固态浆料制备工艺[11-12]和高压铸造相结合开发了流变压铸(Rheo-diecasting,RDC),以压铸专用合金YL112为研究对象,利用LSPSF工艺进行制浆进行了YL112合金的低固相率半固态浆料的直接压铸成型,重点研究了YL112合金半固态浆料制备和流变压铸的微观组织特征。

1 实验

1.1 实验材料

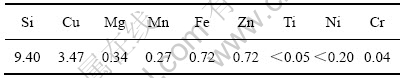

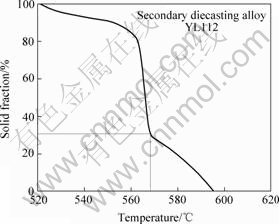

流变压铸研究的合金主要集中于A356、A357和AZ91D等铸造类合金,而对压铸专用合金的研究很少。本研究选用的实验合金为工业用压铸专用铝合金YL112,它具有较大的硬度和强度、较好的流动性能和铸造性能,广泛应用于压铸产业。合金锭由江西洪都航空工业集团铸造分厂提供,合金成分(质量分数,%)如表1所列。采用差热分析获得该合金固相率与温度之间的关系曲线如图1所示,确定其液相线温度为595℃。

表1 YL112压铸专用合金的化学成分

Table 1 Chemical compositions of YL112 alloy (mass fraction, %)

图 1 YL112合金固相率与温度关系

Fig.1 Relationship between solid fraction and temperature of YL112 alloy

1.2 流变压铸工艺RDC

本研究采用的流变压铸工艺将LSPSF工艺和传统压铸工艺相结合,实现半固态浆料直接成形,设备包括LSPSF浆料制备装置和普通压铸机两个部分。半固态浆料制备阶段(一次凝固)和浆料成形阶段(包括浆料充型、凝固和下一次压射的准备、二次凝固)是并行的。实践表明:浆料制备流程短于浆料成形流程,一个RDC流程由浆料成形流程所需时间决定。从整体流程而言,本研究的RDC属于制浆系统与成形系统相分离的思路,主要优点是无需对现有成形设备进行大的改动和调整,但必须解决浆料输送和定量浇注问题。

通过浆料制备前定量,进而实现浆料的定量浇注。浆料制备前定量指采用中间包对流入LSPSF机进料口的合金熔体进行定量。实际操作表明,这种定量方式对于制浆系统与成形系统相分离的流变成形技术是非常实用的。在半固态浆料输送方面,即制浆系统与成形系统间的衔接,本RDC工艺把浆料转移装置和浆料制备装置合为一体,即浆料蓄积器既是浆料制备装置的一部分,也是浆料输送装置,通过浆料蓄积器将半固态浆料转移到压射室或模具型腔。一方面,浆料的输送阶段为浆料制备过程的一部分,浆料蓄积器的预热温度接近于实验合金的液相线温度,浆料的冷却速度缓慢,有利于保证浆料质量;另一方面,浆料蓄积器具有特定的内腔结构和涂料涂敷,保证半固态浆料可顺利地从浆料蓄积器中倒出。

1.3 实验方案

将YL112合金锭在坩埚电阻炉内熔炼,熔炼温度为730 ℃,用六氯乙烷除气,扒渣静置15 min后待用。利用LSPSF工艺进行浆料制备实验,实验中浆料蓄积器温度为(560±1) ℃,输送管温度控制在450 ℃左右,研究浇注温度、输送管倾角及输送管转速对YL112合金半固态组织的影响,获得制备优质半固态浆料的工艺参数可选范围,并按照此参数进行流变压铸实验,重点分析了流变压铸YL112合金的微观组织特征。浆料成形设备为DCC280型 280 t 卧式冷室压铸机,本研究未对压铸机结构进行任何变动。在流变压铸过程中,模具温度保持在200 ℃左右,重点检查动模前后滑块的预热温度,以动模上型芯及前后滑块部位作为预热温度测量点。本研究中的增压压力为180 MPa。

合金熔体流入输送管进料口时的温度为浇注温度,半固态浆料进入压铸机压室浇口时的温度为成形温度。由于YL112半固态浆料成形温度必须高于金属间化合物的析出温度,因此,本压铸实验的温度设定为580℃。半固态浆料的温度由直接插在浆料中的K型 热电偶直接测量,实验中浆料蓄积器温度恒为(560±1)℃,测得浆料在浆料蓄积器内的冷却速度约为0.6℃/s。整个浆料制备流程时间为15~20s,其中合金熔体流经输送管约历时2s,其余时间用于浆料在缓慢冷却过程中调整固相率,因此,有足够时间进行半固态浆料的输送,并保证输送平稳。

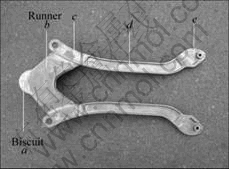

压铸零件为支架,支架壁厚变化范围为2~8mm (c部位厚8mm,其余厚2mm),料头a直径为50mm,浇道b厚7mm,内浇口厚1 mm(见图2)。在料头、浇道和压铸件(c、d和e)分别取样,通过对各取样部位进行微观组织观察,获得半固态浆料在压铸充型过程中的演变行为。通过SEM的背散射成像获得金属间化合物的形貌,用能谱分析定量获得金属间化合物的化学组成。通过SEM的二次电子成像获得压铸件共晶组织形貌。金相试样用混合酸浸蚀,利用光学显微系统进行显微组织观察、测量和分析。用晶粒等效圆直径D=2(A/π)1/2表征初生α(Al)的大小,用晶粒形状因子F=4πA/l2表征初生α(Al)的形貌,其中A和l分别代表初生α(Al)晶粒的面积和周长。在每个试样截面上选择10个不同视场测量上述两个表征参量。

图 2 YL112合金流变压铸支架及微观组织的取样位置

Fig.2 RDC bracket and sample positions of microstructure

2 结果及分析

2.1 YL112合金半固态浆料的制备

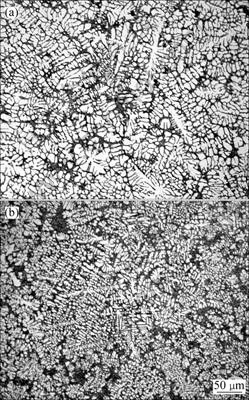

图3所示为LSPSF工艺流变铸造YL112合金的典型半固态组织。获得优质该合金半固态浆料的最佳工艺参数范围是:浇注温度为620~630 ℃;输送管倾角为20?~35?;输送管转速为90~150 r/min。在此工艺范围内,YL112合金中初生α(Al)的平均等效圆直径为70 μm,平均形状因子为0.93,初生α(Al)内没有夹裹液相,且在15~20 s内能够制备1.5 kg半固态浆料。

图3 LSPSF工艺条件下的YL112合金半固态组织特征

Fig.3 Semi-solid microstructures characteristics of YL112 alloy rheocast by LSPSF process: (a) 90 r/min, 20?, 640 ℃; (b) 90 r/min, 20?, 630 ℃; (c) 90 r/min, 20?, 620 ℃; (d) 30 r/min, 20?, 625 ℃; (e) 150 r/min, 20?, 625 ℃; (f) 150 r/min, 35?, 620 ℃

2.2 流变压铸YL112合金的铸态组织

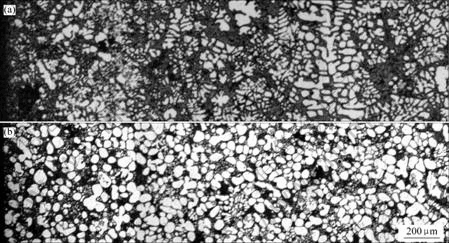

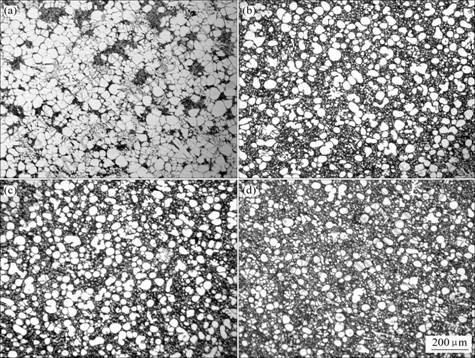

图4所示为HPDC和RDC工艺压铸YL112合金支架零件位置d处横断面的微观组织。图中白色的为初生α(Al)。在HPDC中,初生α(Al)的典型形态为树枝状,在整个断面上晶粒尺寸分布很不均匀。在靠近表面部位,初生α(Al)细小(急冷层组织);在中心部位,初生α(Al)较粗大。在RDC中,绝大部分初生α(Al)呈球形,均匀地分布在整个横断面上。

图4 HPDC和RDC成形YL112合金试样d处横断面的微观组织

Fig.4 Microstructures of cross-section of section d of YL112 alloy produced by HPDC (a) and RDC (b)

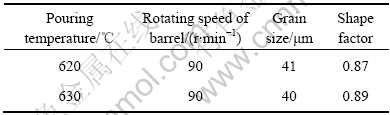

合金熔体的浇注温度不仅影响着半固态浆料和成形件的质量,还是流变压铸工艺在操作便捷和温度控制方面的主要影响因素。图5所示为输送管转速为 90 r/min、输送管倾角为20?,YL112合金熔体在620和630 ℃浇注时获得的流变压铸微观组织,且取样位置为支架d部位的横断面。表2所列为定量分析结果。由表2可看出,在不同浇注温度下,初生α(Al)均细小、呈球形、均匀分布,在尺寸和形态方面无明显差别。主要原因是LSPSF工艺具有较大的浇注温度空间,对YL112合金而言,620和630 ℃浇注可以获得相似的半固态浆料(见图3),因此,在成形温度相同的情况下,获得的压铸件的微观组织也相近。这就给RDC工艺带来了极大的实用性:工艺操作方便,温控精度可以适当放宽。另外,在工业生产中,由于浆料制备和压射都是间歇性的,随着生产的延续,合金熔体的成分必然会发生变化,合金的液相线温度也会随之改变,在本研究的RDC过程中,若合金成分变化没有超过LSPSF所允许的浇注温度范围,则都可以获得微观组织优良的流变压铸件。

图5 620和630 ℃温度浇注下的RDC YL112合金微观 组织

Fig.5 Microstructures of YL112 alloy produced by RDC process at pouring temperature of 620 ℃(a) and 630 ℃(b)

图6所示为传统压铸条件下YL112合金支架a部位和d部位横断面的微观组织。由图4(a)和图6可看出,随着支架壁厚的减薄,初生α(Al)由粗大发达的树枝晶演变成细小的树枝晶,在支架纵断面上组织分布不均匀。而在流变压铸条件下(见图7),初生α(Al)在支架纵断面上的分布明显不同于传统压铸的分布。在料头处,初生α(Al)一部分为较粗大的近球形晶粒,由半固态浆料中的原始初生α(Al)演变而来;另一部分为细小树枝晶,由浆料中剩余液相在二次凝固中形成。浇道部位和支架的纵断面上,初生α(Al)均为细小及分布均匀的球形晶粒。

图6 传统压铸下支架a和d部位横断面的微观组织

Fig.6 Microstructures of cross-section of section a(a) and d(b) of YL112 by HPDC

图7 流变压铸下YL112合金支架a、b、c和e部位横断面的微观组织

Fig.7 Microstructures of rheo-diecast YL112 alloy components on cross-section of sections a(a), b(b), c(c) and e(d)

表 2 620和630 ℃温度浇注下的RDC YL112合金的微观组织特征

Table 2 Microstructures characteristics of RDC YL112 alloy at different pouring temperatures

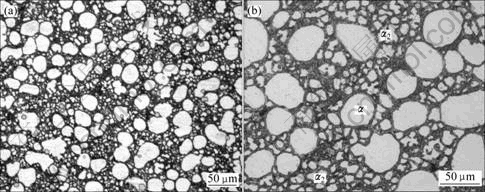

由于YL112合金中含有较多的杂质元素,会形成较多的金属间化合物,且该合金半固态浆料中含有接近70%的液相,因此,半固态浆料中的剩余液相在模具型腔中的凝固行为(二次凝固)是金属间化合物和共晶体形成的决定性因素。YL112合金浆料在二次凝固中形成的微观组织的整体形貌如图8所示。图8(b)所示为图8(a)中深色部位的放大图,揭示了二次凝固中形成的初生α(Al) (α2)的形态和分布。由图8可看出,二次凝固生成的初生α2(Al)增加了初生α(Al)的数量,呈细小颗粒状均匀地分布在基体中,其平均尺寸为13 μm。

图8 YL112合金流变压铸二次凝固组织特征

Fig.8 Microstructures characteristics of secondary solidification of primary α(Al) (α2) in die cavity: (a) Low-powered view; (b) Enlarged view of dark regions in (a)

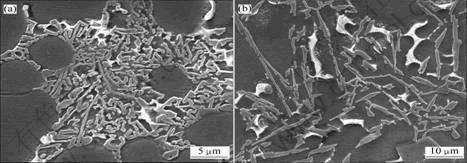

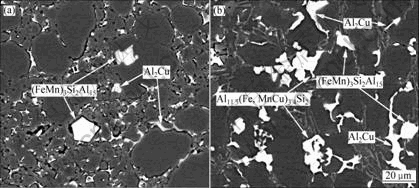

图9所示为流变压铸和传统压铸YL112合金的Al-Si共晶组织特征。由图9可看出,Al-Si共晶体呈连续网格状围绕在初生α(Al)周围,层片间距约1 μm (见图9(a));而传统压铸产生的YL112合金共晶Si相对粗大(见图9(b))。流变压铸二次凝固对YL112合金另一个重要影响体现在金属间化合物的形成。在YL112合金中主要存在两种Si、Fe和Mn金属间化合物,即多边形或球形的α-(FeMn)3Si2Al15和长条针状的β-AlFeSi。由于本研究中YL112合金中的Fe含量相对比较少,在流变压铸YL112合金中未发现β-AlFeSi,在传统HPDC中发现少量的长条针状的β-AlFeSi。α-(FeMn)3Si2Al15在两种工艺中大量存在,且多数呈多边形状,但在传统HPDC中发现少量形状复杂的α-(FeMn)3Si2Al15。除上述两种含Fe的主要金属统压间化合物外,在两种成形工艺条件下,YL112合金还含有少量的Al2Cu化合物,形态以近球形为主,在传统压铸条件下Al2Cu较粗大,有的形状很不规则(见图10)。另外,在传统压铸条件下,还发现数量很少形状复杂的Al11.5(Fe,MnCu)3.4Si2,但在RDC中未发现Al11.5(Fe,MnCu)3.4Si2。在流变压铸条件下,支架的不同部位各部位金属间化合物的分布比较均匀,在传统压铸条件下,金属间化合物的数量相差很大,在壁薄的地方数量很少,而在壁厚的地方(支架c部位) α-(FeMn)3Si2Al15成团出现。

图9 流变压铸和传统压铸YL112合金的Al-Si共晶组织特征

Fig.9 Eutectic structures of YL112 alloys formed in RDC(a) and HPDC(b)

图10 流变压铸与传统压铸YL112合金中的金属间化合物

Fig.10 Intermetallic compounds of YL112 alloys processed by RDC(a) and HPDC(b) process

3 讨论

根据本研究中RDC工艺流程,可将其分为浆料制备与浆料成形两个工序。因此,YL112合金在流变压铸中的凝固主要经历了一次凝固和二次凝固两个凝固过程。一次凝固发生在浆料制备阶段,包括快速冷却和缓慢冷却两个阶段。前者发生在合金熔体流经输送管的过程中。合金熔体在输送管内的流动是在自身重力和输送管转动共同作用下完成的。将合金熔体作为一个整体,则合金熔体在沿着输送管轴向运动的同时,由于输送管的转动及合金熔体对管壁的黏附作用,合金熔体具有与输送管旋转方向相同的旋转趋势。在自身重力产生的剪切力作用下,具有特定过热度的合

金熔体不会黏附在输送管壁,即不会跟随输送管一起旋转,而是以特定的速度自身旋转。因此,合金熔体在输送管内,流向快速变化,具有自搅拌混合的流动特性。管壁局部激冷与合金熔体自搅拌混合的综合作用,增强了合金凝固时的能量起伏、结构起伏和浓度起伏,使合金熔体整体或局部在液相线附近波动,从而使合金熔体有类似于反复进行熔化和凝固的效果(管壁局部激冷增强了此效果),有利于结晶团簇的形成,即有利于液态金属在过冷区域中的形核。因此,随着合金熔体温度的降低,搅拌混合间接地增加了异质形核的核心界面、晶胚数和能量起伏,从而降低了临界形核功[13]。在输送管转动与合金熔体自身重力作用下,不断地有合金熔体与新的管壁相接触,作为形核衬底的输送管管壁在转动作用下可无限延伸,即LSPSF工艺显著增多了新生晶核可利用的形核衬底面积。浇注和重力作用使得合金熔体具有较高的流动速度,对输送管壁具有较大的冲刷作用,有利于晶粒游离[14]。另外,由于输送管的转动作用,使得晶粒具有随同管壁转动的趋势,而周围的液态金属必然阻止其转动,对晶粒产生剪切作用,有利于晶粒游离。因此,在LSPSF工艺中,低过热浇注与凝固初期的激冷和搅拌混合可有效地激发熔体形核,促进晶粒游离,提高游离晶的存活率,是半固态组织细化的本质所在。而半固态组织细化效果主要取决于浇注温度、输送管转速和倾角3个工艺参数,三者均有一个合理的选择范围,只有三者良好匹配时才能获得最佳的细化效果(见图3)。

半固态浆料流入浆料蓄积器后,进入缓慢冷却阶段,初生α(Al)在静止状态下进行形态演变。对于YL112合金,合金熔体流出输送管后的温度为 591 ℃,对应的固相率约为3%,因此,初生α(Al)主要在静止状态下进行形态演变。实验和模拟结果均表明[15-16],影响初生α(Al)在第二个生长阶段形态演变的主要因素为浆料中自由晶的数量和浆料的冷却强度,高晶粒密度、低冷却强度有利于球晶的形成。在高晶粒密度和缓慢冷却条件下,晶粒周围溶质扩散层的叠加可明显降低液固界面前沿的浓度梯度;在浆料蓄积器中,半固态浆料整体处于过冷状态,所有初生α(Al)均处于生长状态,凝固潜热集中释放,晶粒周围温度场的叠加使得液固界面前沿的温度梯度降低。因此,温度梯度和浓度梯度负面作用得到抑制,界面能的正面效应得到加强,有利于提高液固界面的稳定性。另外,晶粒周围溶质扩散层和温度扩散层的叠加使得晶粒周围溶质和温度分布更为均匀,抑制晶粒的择优生长,使得晶粒在各个方向上几乎均匀生长。这些因素均有利于初生α(Al)保持球状生长到较大的尺寸。

二次凝固主要发生于模具型腔内。厚大的模壁吸热能力很强,且半固态浆料含热量比较少,需释放的凝固潜热少,因此二次凝固的主要特征是极高的冷却速度(数量级为103 ℃/s[6])。在一次凝固的缓慢冷却阶段,半固态浆料的温度场和浓度场非常均匀,在强冷却条件下,整个半固态浆料中的剩余液相将爆发形核,且近100%的晶核会存活,而晶粒的长大程度很小,二次凝固生成的初生α2(Al)非常细小;产生非常细小的共晶Si、金属间化合物,形态发生改变;充满模具型腔的半固态浆料将处于整体式的体积凝固状态,而不会发生逐层凝固,因此,流变压铸件在纵断面和横断面上的微观组织都非常均匀。

4 结论

1) 将LSPSF浆料制备工艺和传统压铸HPDC工艺相结合,开发了流变压铸工艺RDC。RDC属于浆料制备与零件成形相分离的流变成形系统,无需对冷室卧式压铸机进行改动,RDC生产周期由半固态浆料成形时间限制。

2) LSPSF可以高效地制备低固相率半固态浆 料。获得优质YL112合金半固态浆料的最佳工艺参数范围是:浇注温度为620~630 ℃;输送管倾角为20?~ 35?;输送管转速为90~150 r/min。在此工艺范围内,初生α(Al)的平均等效圆直径为70 μm,平均形状因子为0.93,初生α(Al)内部没有夹裹液相。

3) 流变压铸二次凝固中,半固态浆料在模具型腔内发生体积凝固,铸件横断面和纵断面微观组织分布很均匀。初生α2(Al)非常细小,均匀分布在基体中。金属间化合物和共晶Si细小。

REFERENCES

[1] 潘宪曾. 压铸工艺与模具[M]. 北京: 电子工业出版社, 2006.

PAN Xian-zeng. Die casting technology and its moulds[M]. Beijing: Electronic Industry Press, 2006.

[2] FAN Z. Semisolid metal processing[J]. International Materials Reviews, 2002, 47(2): 1-37.

[3] MIDSON S P. Rheocasting processes for semi-solid casting of aluminum alloy[J]. Die Casting Engineer, 2006, 50(1): 48-51.

[4] JORSTAD J L. SSM processes-an overview[C]//APELIAN D, ALEXANDROU A, GEORGIOU G, JORSTAD J, MAKHLOUF M. Proceedings of the 8th International Conference on Semi-Solid processing of Alloys and Composites. Limassol: The Worcester Polytechnic Institute and the Metals Processing Institute, 2004: 15-24.

[5] SHIBATA R, KANEUCHI T, SOUDA T, YAMANE H. Formation of spherical solid phase in die casting shot sleeve without any agitation[C]//BHASIN A K, MOORE J J, YOUNG K P, MIDSON S. Proceedings of the 5th International Conference on Semi-Solid Processing of Alloys and Composites. Colorado: Colorado School of Mines, 1998: 465-470.

[6] FAN Z. Development of the rheo-diecasting process for magnesium alloys[J]. Mater Sci Eng A, 2005(413/414): 72-78.

[7] KANG Yong-lin, XU Yue, WANG Zhao-hui. Study on microstructure and mechanical properies of rheo-die casting semi-solid A356 aluminum alloy[J]. Solid State Phenomena, 2006(116/117): 453-456.

[8] XIAO Ze-hui, LUO Ji-rong, WU Shu-sheng, et al. Performing for semi-solid slurry produced by twin-screw stirring mixer and rheo-diecasting process of AZ91D alloy[J]. Journal of Wuhan University of Technology-Materials Science Edition, 2004, 19(4): 81-85.

[9] KAUFMANN H, WABUSSEG H, UGGOWITZER P J. Metallurgical and processing aspects of the NRC semi-solid casting technology[J]. Aluminum, 2000, 76(1/2): 70-75.

[10] YURKO J A, FLEMINGS M C, MARTINEZ R A. Semisolid rheocasting (SSR)-increasing the capabilites of die casting[J]. Die Casting Engineering, 2004, 48(1): 50-52.

[11] GUO H M, YANG X J, HU B. Rheocasting of aluminum alloy A356 by low superheat pouring with a shearing field[J]. Acta Metallurgica Sinica (English Letters), 2006, 19(5): 328-334.

[12] GUO Hong-min, YANG Xiang-jie. Continuous fabrication of sound semi-solid slurry for rheoforming[J]. Solid State Phenomena, 2006, 116/117: 425-428.

[13] 胡汉起. 金属凝固原理[M]. 北京: 机械工业出版社, 2001: 80-164.

HU Han-qi. Solidification principles of metal[M]. Beijing: Mechanical Industry Press, 2001: 80-164.

[14] OHNO A. Solidification-the separation theory and its practical applications[M]. Germany: Springer-Verlag Press, 1987: 1-82

[15] GUO Hong-min, YANG Xiang-jie. Morphology evolution of primary alpha phase in rotated duct process[C]//APELIAN A, ALEXANDROU A, GEORGIOU G, JORSTAD J, MAKHLOUF M. Proceedings of the 8th International Conference on Semi-Solid processing of Alloys and Composites. Limassol: The Worcester Polytechnic Institute and the Metals Processing Institute, 2004: 695-703.

[16] GUO H M, YANG X J. Efficient refinement of spherical grain by LSPSF rheocasting process[J]. Materials Science and Technology, 2008, 24(1): 55-63.

基金项目:国家自然科学基金资助项目(50474007);江西省教育厅科技计划资助项目(GJJ08006);江西省科技支撑计划资助项目

收稿日期:2007-05-20;修订日期:2007-12-24

通讯作者:郭洪民,博士;电话:0791-3969611;E-mail: hmguo_email@163.com

(编辑 李艳红)