DOI: 10.11817/j.issn.1672-7207.2019.11.001

天然磁黄铁矿机械活化强化除砷技术

张荥斐1, 2,刘屾淼1, 2,曹学锋1, 2,韩海生1, 2,孙伟1, 2,成朋飞1, 2,王丽1, 2

(1. 中南大学 资源加工与生物工程学院,湖南 长沙,410083;

2. 中南大学 战略含钙矿物资源清洁高效利用湖南省重点实验室,湖南 长沙,410083)

摘要:以天然磁黄铁矿为净化剂,研究As(III)在磁黄铁矿表面的吸附、转化行为;基于机械活化原理,开发高质量浓度含砷废水净化除砷技术。研究结果表明:As(III)吸附在磁黄铁矿表面,并与表面S2-发生作用生成As2S3,矿物表面同时发生氧化反应生成少量As2S5,As2O3和As2O5,表面含砷组分及单质硫在一定程度上阻碍磁黄铁矿与溶液中砷的进一步反应。通过对磁黄铁矿进行机械活化处理,一方面,可减小磁黄铁矿粒度、增大比表面积,另一方面,暴露具有较高活性的新鲜表面,极大地提高磁黄铁矿的除砷效率;当pH为3.0~3.5、温度为80 ℃、反应时间为24 h、磁黄铁矿初始质量浓度为12 g/L时,砷的去除率大于97%。

关键词:磁黄铁矿;As(III);水处理;机械活化

中图分类号:TD923 文献标志码:A 文章编号:1672-7207(2019)11-2623-10

Arsenic removal technology based on mechanical activation of natural pyrrhotite

ZHANG Xingfei1, 2, LIU Shenmiao1, 2, CAO Xuefeng1, 2, HAN Haisheng1, 2,SUN Wei1, 2, CHENG Pengfei1, 2, WANG Li1, 2

(1. School of Minerals Processing and Bioengineering, Central South University, Changsha 410083, China;

2. Key Laboratory of Hunan Province for Clean and Efficient Utilization of Strategic Calcium-containing Mineral Resources, Central South University, Changsha 410083, China)

Abstract: Natural pyrrhotite was used as a purifying agent to study the adsorption and transformation behavior of As(III) on the surface of pyrrhotite. Based on the mechanical activation, the arsenic removal technology of acid wastewater with high mass concentration of arsenic was developed. The results show that As(III) adsorbs on the surface of pyrrhotite and reacts with surface S2- to form As2S3. The surface of the mineral is simultaneously oxidized to form a small amount of As2S5, As2O3 and As2O5. The presence of arsenic-containing components and elemental sulfur on the surface hinder the further reaction of pyrrhotite with arsenic in the solution to some extent. On the one hand, activated treatment of pyrrhotite by mechanical activation reduces the size of pyrrhotite and increases the specific surface area. On the other hand, it exposes the fresh surface with higher activity, and greatly improves the arsenic removal efficiency of pyrrhotite. The removal rate of arsenic is over 98% when pH is 3.0-3.5 and temperature is 80 ℃, with reaction time being 24 h, and an initial dosage of pyrrhotite being 12 g/L.

Key words: pyrrhotite; As(III); water treatment; mechanically activated

砷(As)是一种有毒非金属元素,在自然界中主要以硫化物的形式存在,在还原环境下,微量的砷可转入地下水中,经过迁移和富集可使地下水中的砷含量增加,长期饮用将会严重影响人的身心健康[1]。在有色冶金行业的生产中,往往会产生高质量浓度的强酸性含砷废水,给环境和社会的可持续发展带来严重危害。国内外研究者对含砷废水的处理进行了大量研究。对于低质量浓度含砷废水,吸附法是处理含砷废水最常用的方法之一[2]。大量的文献报道了不同吸附材料(主要包括铁(氢)氧化物[3]、零价铁[4]、红泥[5-6])对砷的吸附作用及其机理,其中天然硫化物和合成硫化物对砷的吸附成为研究的热点之一[7-9]。早在20世纪70年代,铁的硫化物因其与溶液中的重金属离子有较强的亲和力,被用来净化水溶液中的重金属离子[10]和含砷废水[11]。KATSOYIANNIS等[9, 12]分别研究了黄铁矿对砷的吸附以及天然黄铁矿和FeS(马基诺矿)对砷的吸附,并得到了各矿物对As(III)和As(V)的线性吸附系数,发现分配系数的差距是由黄铁矿颗粒粒径不同造成的。史亚丹[14]在最佳条件下煅烧天然黄铁矿,使其转化为磁黄铁矿,其结果表明煅烧后的黄铁矿对As(III)和As(V)的去除都优于煅烧前的去除效果,即单斜磁黄铁矿对As(III)和As(V)有最佳吸附能。刘卓等[15]研究了天然磁黄铁矿对水中低质量浓度As(V)的去除,发现磁黄铁矿对As(V)的去除率达到了99%,并且在其吸附砷之后较长时间内未检测到砷的释放,表明磁黄铁矿作为除砷吸附剂具有广阔的应用前景。然而,有色选冶废水不同于传统的低质量浓度重金属废水,其砷质量浓度往往高达1 g/L以上且酸性较强,传统吸附技术难以解决高质量浓度砷的净化问题且现有的处理方法存在诸多缺点,往往会带来更为严重的环境问题。磁黄铁矿的溶液热力学和动力学研究表明其在强酸性条件下可缓慢分解,并释放S2-,这为As(III)的硫化沉淀创造了条件。因此,磁黄铁矿用于强酸性高质量浓度含砷废水的净化具有一定可行性。本文作者基于磁黄铁矿的溶解行为及其对As(III)的优异吸附性能,研究天然磁黄铁矿净化高质量浓度含As(III)废水的热力学行为和动力学行为;针对其表面钝化行为,通过机械活化增强磁黄铁矿表面活性,提高砷净化效率,以便为高质量浓度含砷废水的高效净化提供参考。

1 实验材料与方法

1.1 实验材料

实验所用磁黄铁矿购自安徽铜陵威特矿产品销售有限公司,块矿经手选后初步破碎至粒径小于0.5 mm,再经过磁选,得到较高纯度的磁黄铁矿粗颗粒。将小块粗颗粒磁黄铁矿经小型颚式破碎机破碎至粒径小于0.2 mm,进瓷球磨磨至粒径小于0.074 mm。实验所用磁黄铁矿粒径均小于0.074 mm。

实验所用亚砷酸钠(NaAsO2)购自湖南省长沙市丰裕化工玻璃仪器有限公司,含少量的Co2+和Cu2+等杂质离子。实验所用含砷溶液均为采用去离子水配制的2 g/L亚砷酸钠溶液。

1.2 实验方法

1.2.1 天然磁黄铁矿对砷的净化实验

以磁黄铁矿为研究对象,对磁黄铁矿去除溶液中As(III)进行单因素实验,探索温度、pH、反应时间等对磁黄铁矿净化As(III)的动力学和热力学过程的影响。

配制一定质量浓度的As(III)溶液,根据实验条件所需质量浓度,量取200 mL As(III)溶液,加入到500 mL的烧杯中,用1 mol/L的H2SO4和NaOH溶液调节pH至设定值,放置于恒温磁力搅拌锅中,加入一定量的磁黄铁矿,用搅拌器以一定的速度搅拌反应,间隔一段时间取样过滤检测。

1.2.2 机械活化的磁黄铁矿对砷的吸附实验

为进一步提高磁黄铁矿的利用效率,采用机械活化对磁黄铁矿进行预处理。利用长沙天创粉末技术有限公司生产的实验搅拌磨对磁黄铁矿进行高速研磨。取研磨后样品加入到三口玻璃烧瓶中,水浴加热至80 ℃进行反应,用搅拌器以500~600 r/min的速度搅拌,待溶液冷却后进行过滤检测。

1.3 表征与分析

采用日本电子公司的JSM-649CLV扫描电子显微镜(SEM)和美国EDAX公司的EDS-WDS能谱波谱仪对反应后的磁黄铁矿颗粒表面形貌进行表征并分析其化学组成。采用美国ThermoFisher Scientific公司的ESCALAB250Xi X线光电子能谱仪(XPS)对反应后的磁黄铁矿表面的元素成分进行分析。使用德国布鲁克公司S4 Pioneer X线荧光光谱仪和德国斯派克分析仪器公司SPECTRO BLUE SOP等离子光谱仪分别分析渣和液中的砷质量分数。采用英国马尔文公司的Mastersizer 2000激光粒度分析仪和美国康塔公司的Quadresorb SI比表面积分析仪分析机械活化后的磁黄铁矿颗粒的粒度和比表面积。

2 结果与讨论

2.1 磁黄铁矿净化除砷热力学研究

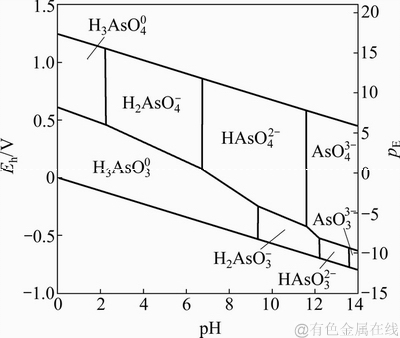

图1所示为温度为25 ℃时As-O2-H2O体系Eh-pH图[16]。氧化还原电位Eh和pH是影响溶液中砷组分类型的重要条件,在氧化环境和低pH下,H2AsO4-占据主导地位,随着pH的增大,HAsO42-和AsO43-在溶液中的质量逐渐增多。在还原环境下,当pH小于9.2时,溶液中的As主要以H3AsO3的形式存在。溶液中的As(III)组分随pH的变化见图1(其中pE=-lg

,

,

为电子浓度)。由图1可知:在不同的pH条件下,As(III)在溶液中可能以H3AsO3,H2AsO3-和HAsO32-等形式存在。热力学研究表明[17]:还原性和强酸条件有利于As2S3以及其他含砷硫化物的沉淀。磁黄铁矿与溶液中不同形式的As组分在反应速率和反应效率等方面差异巨大,可见pH是磁黄铁矿去除溶液中As的重要影响因素之一。

为电子浓度)。由图1可知:在不同的pH条件下,As(III)在溶液中可能以H3AsO3,H2AsO3-和HAsO32-等形式存在。热力学研究表明[17]:还原性和强酸条件有利于As2S3以及其他含砷硫化物的沉淀。磁黄铁矿与溶液中不同形式的As组分在反应速率和反应效率等方面差异巨大,可见pH是磁黄铁矿去除溶液中As的重要影响因素之一。

图1 25 ℃时As-O2-H2O体系Eh-pH图[16]

Fig. 1 Eh-pH diagram for aqueous As in system of As-O2-H2O at 25 ℃[16]

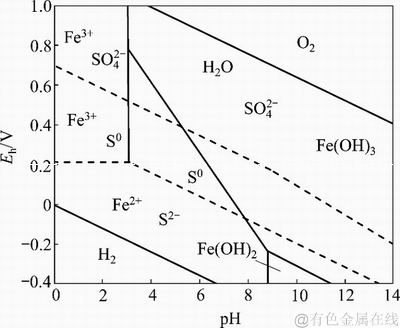

图2所示为磁黄铁矿在水体系中的Eh-pH图[18]。由图2可以看出:在氧化环境下,磁黄铁矿中的S2-容易被氧化为硫单质和硫酸根离子,铁离子则以三价铁的形式存在,随着pH增大,三价铁结合溶液中的OH-形成Fe(OH)3。而在酸性还原性条件下,磁黄铁矿则可分解出二价铁和S2-存在于溶液中,其对于As(III)的去除是有益的。

图2 磁黄铁矿在水体系中的Eh-pH图[18]

Fig. 2 Eh-pH diagram for aqueous pyrrhotite in system of Fe1-xS-H2O at 25 ℃[18]

表1所示为除As(III)时的化学反应及其在温度为25 ℃时的平衡常数。从表1可以看出:在酸性条件下主要是生成As2S3沉淀以达到去除三价砷的目的,随着pH升高,溶液中的离子形态发生改变,此时主要通过磁黄铁矿表面的羟基铁进行吸附来除去砷离子。

表1 除As(III)时的化学反应及其在温度为25 ℃时的平衡常数

Table 1 Equilibrium constants and chemical reactions in process of As(III) removal (25 ℃)

江元汝等[23]根据Eh-pH图,将处理As(III)时的反应过程大致分为3类:

H3AsO3+2FeS+4H+ = HAsS2+2Fe2++3H2O,

pH<3.8 (1)

3FeS +H3AsO3+8H+ = As2S3↓+3Fe2++6H2O,

3.8 pH

pH 6.6 (2)

6.6 (2)

H2AsO3-+2FeS+H2O = AsS2-+2Fe(OH)2,

pH>6.6 (3)

磁黄铁矿的成分与FeS类似,因此,在除砷过程中的主要产物为As2S3,其反应过程大致符合上述的反应过程,但在强酸性溶液中,磁黄铁矿所释放出的部分S2-与溶液中的H+反应,产生少量的H2S,其直接参与溶液中的反应,生成As2S3沉淀,反应方程式如下:

S2-+2H+=H2S↑ (4)

2H3AsO3+3H2S = As2S3↓+6H2O (5)

通过以上分析可以看出:在还原环境和酸性条件下利用磁黄铁矿处理溶液中的As(III)在热力学上可行的。

2.2 磁黄铁矿净化除砷动力学研究

2.2.1 pH对磁黄铁矿去除溶液中As(III)去除率的影响

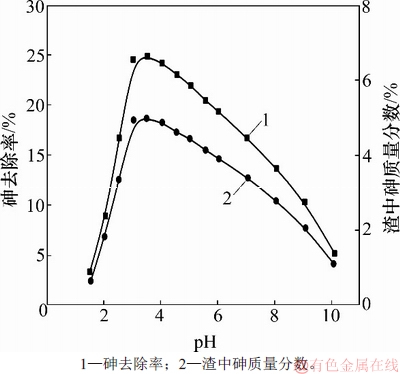

不同pH对磁黄铁矿去除溶液中As(III)去除率的影响如图3所示(初始As(III)质量浓度为2 g/L,磁黄铁矿质量浓度为10 g/L,温度为25 ℃,反应时间为4 h)。由图3可知:pH对磁黄铁矿去除溶液中As(III)具有较大影响,随着pH增大,溶液中As(III)的去除率先增大后减小,当pH为3.0~3.5时,As(III)的去除率达到最大值24.8%,渣中砷质量分数达到4.98%,磁黄铁矿除砷的最佳pH约为3.2。根据式(1)和(3)可知:当溶液pH过低时,溶液中的As(III)主要以H3AsO3的形式存在,这个阶段对砷的去除主要以磁黄铁矿自身吸附形式为主;随着pH增大,磁黄铁矿表面发生反应生成As2S3沉淀,砷去除率明显增大;当pH继续增大时,溶液中OH-离子增多,此条件下砷的净化主要源自与Fe(OH)2和Fe(OH)3沉淀对砷的吸附。因此,当pH较低或较高时,As(III)的去除率都较低。

图3 pH对磁黄铁矿去除溶液中As(III)去除率的影响

Fig. 3 Effect of pH on removal efficiency of As(III) from pyrrhotite

2.2.2 温度对磁黄铁矿去除溶液中As(III)去除率的影响

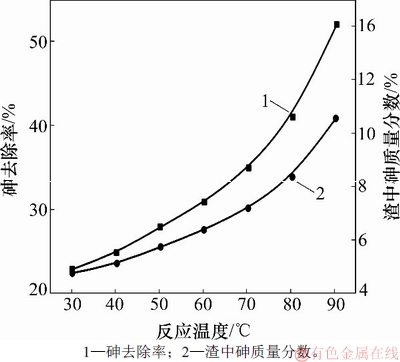

图4所示为温度对磁黄铁矿去除溶液中As(III)去除率的影响(初始As(III)质量浓度为2 g/L,磁黄铁矿质量浓度为10 g/L,pH=3.0,反应时间为4 h)。由图4可以看出:提高温度对磁黄铁矿去除溶液中As(III)去除率有显著的促进作用,随着温度的升高,As(III)去除率从25%提高到53%左右,这是因为磁黄铁矿的分解是吸热反应,升高温度有利于分解使硫离子与砷反应,随着温度的不断升高,溶液中As(III)去除率逐渐升高,即温度升高有利于提高磁黄铁矿的净化效率,本文选择反应温度为80~85 ℃。

图4 温度对磁黄铁矿去除溶液中As(III)去除率的影响

Fig. 4 Effect of temperature on removal efficiency of As(III) from pyrrhotite

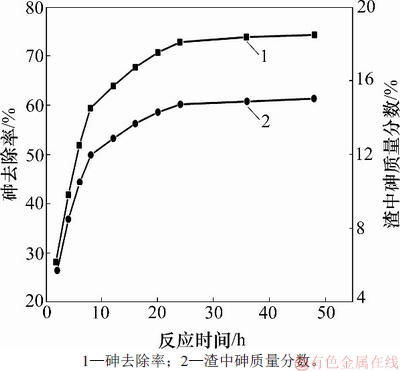

2.2.3 反应时间对磁黄铁矿去除溶液中As(III)去除率的影响

图5所示为反应时间对磁黄铁矿去除溶液中As(III)去除率的影响(初始As(III)质量浓度为2 g/L,磁黄铁矿质量浓度为10 g/L,pH=3.0,温度为80 ℃)。由图5可以看出:随着反应时间的延长,溶液中As(III)去除率逐渐升高,但升高的速率逐渐减小,在反应24 h后,As(III)去除率增加缓慢,逐渐稳定,继续增加反应时间对于As(III)去除率影响不大,因此,实验过程中暂定反应时间为24 h。磁黄铁矿的作用时间也是影响磁黄铁矿去除溶液中As(III)去除率的重要影响因素,必须达到一定时间,才能让磁黄铁矿充分分解,释放出S2-与 As(III)充分反应,提高磁黄铁矿的利用率和As(III)的去除率。

图5 反应时间对磁黄铁矿去除溶液中As(III)去除率的影响

Fig. 5 Effect of reacting time on removal efficiency of As(III) from pyrrhotite

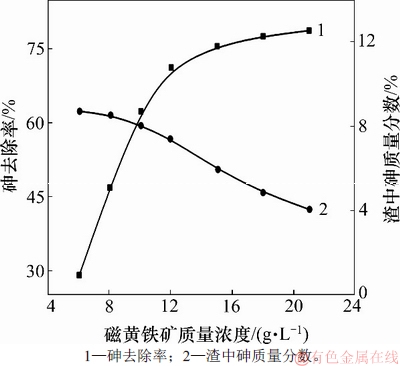

2.2.4 磁黄铁矿质量浓度对去除溶液中As(III)去除率的影响

图6所示为磁黄铁矿质量浓度对去除溶液中As(III)去除率的影响(初始As(III)质量浓度为2 g/L,反应时间为24 h,pH=3.0,温度为80 ℃)。由图6可以看出:随着磁黄铁矿质量浓度的增加,溶液中As(III)去除效果显著增强。当磁黄铁矿质量浓度为6 g/L时,As(III)去除率仅为29.2%,渣中砷质量分数达到8.65%;当磁黄铁矿质量浓度为12 g/L时,As(III)去除率达到71.1%;再增加磁黄铁矿质量浓度,As(III)去除率增长缓慢,且渣中砷质量分数显著降低,说明磁黄铁矿的利用效率明显开始降低,综合考虑选择12 g/L作为磁黄铁矿最佳质量浓度。

图6 磁黄铁矿质量浓度对去除溶液中As(III)去除率的影响

Fig. 6 Effect of pyrrhotite mass concentration on removal efficiency of As(III) in solution

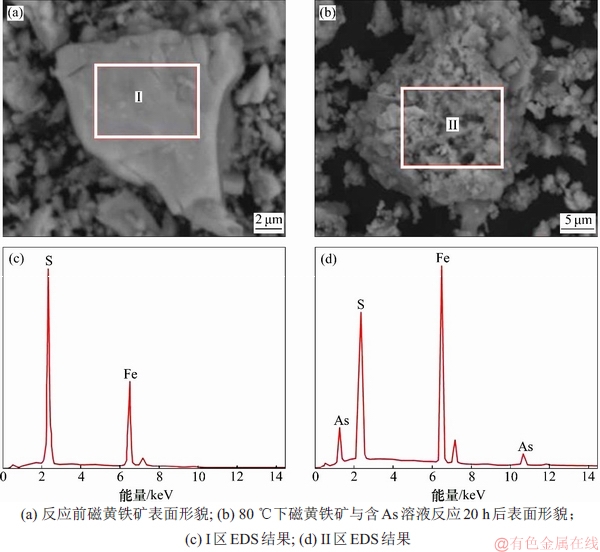

上述研究结果表明:磁黄铁矿净化除砷在热力学上是可行的,pH、温度、反应时间等是影响其动力学过程的主要因素。理论计算表明磁黄铁矿可以实现砷的深度净化,然而实验结果并不理想,表明磁黄铁矿在除砷过程中表面发生了重构,导致其钝化,从而影响了后续反应。为了分析磁黄铁矿与含As(III)溶液受温度和时间影响反应前、后表面形貌的变化,对与含As(III)溶液反应前后的磁黄铁矿进行扫描电镜及EDS分析,观察磁黄铁矿表面的形貌变化,结果如图7所示(As(III)质量浓度为2 g/L,pH=3.5,反应时间为20 h,磁黄铁矿质量浓度为12 g/L)。

图7 磁黄铁矿与含As溶液反应前、后的SEM和EDS能谱图

Fig. 7 SEM and EDS spectra of pyrrhotite before and after reaction with As solution

由图7(a)可知:反应前磁黄铁矿颗粒表面无杂质,比较光滑完整,表面没有物质附着。从图7(b)可以看出:磁黄铁矿在80 ℃条件下与含As(III)溶液反应后,原本光滑的表面在80 ℃条件下有大量生成物,且呈团状和絮状,附着在磁黄铁矿的表面。由图7(c)和(d)可知:磁黄铁矿与含As(III)溶液反应前后,Fe元素和S元素的特征峰和质量分数并没有明显的变化,但反应后表面出现了As元素的特征峰,且80 ℃的条件下出现了2个As元素的特征峰,As元素质量分数为13.31%,可见在80 ℃条件下,磁黄铁矿表面附着的含砷物质较多,磁黄铁矿与溶液中的As(III)反应程度较大。通过SEM和EDS能谱分析,虽无法确定As(III)是以何种物质形式附着在磁黄铁矿表面,但是可以充分说明As(III)与磁黄铁矿表面发生了作用,并且以一种细颗粒物质附着在磁黄铁矿表面。

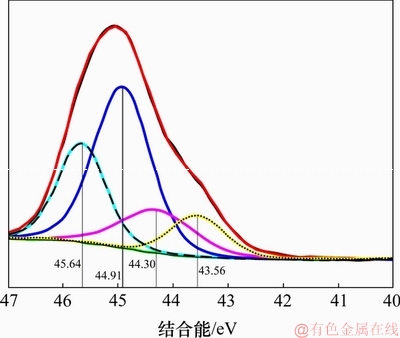

2.3 XPS分析

为了分析磁黄铁矿与含砷溶液反应机理,对反应前磁黄铁矿和反应后过滤渣样进行X线光电子能谱分析。图8所示为磁黄铁矿与含砷溶液反应后As 3d分峰拟合图。图8中出现了结合能分别为43.56,44.30,44.91和45.64 eV的4个不同的峰值,分别代表三价砷硫化物[24]、五价砷硫化物[25],三价砷氧化物[26]以及五价砷氧化物[27]的形成。由此可见,在磁黄铁矿与含三价砷溶液反应的过程中生成了As2S3,另外有一部分三价砷被氧化形成了五价砷,所以,反应后形成了As2S5和As2S3。As2O3和As2O5可能由表面吸附的砷酸根和亚砷酸根,也可能为制样过程中As2S3和As2S5氧化后形成。

图8 磁黄铁矿与含砷溶液反应后As 3d分峰拟合图

Fig. 8 XPS-peak-differentiation-imitating analysis of As 3d after reaction of pyrrhotite with arsenic-containing solution

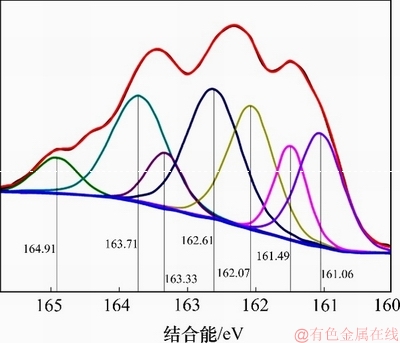

为了分析溶液中As(III)与磁黄铁矿反应后的S元素的物质形态,对磁黄铁矿与含砷溶液反应后 S 2p分峰拟合,如图9所示。图9中出现了7个不同的峰值,对应的结合能分别为161.05,161.49,162.07,162.61,163.33,163.71和164.91 eV。结合能为161.05,161.49,162.07和162.61 eV的峰值分别对应所用天然磁黄铁矿矿物中自有的磁黄铁矿、铁硫化物[28]、闪锌矿[29]和黄铁矿[28];而结合能峰值163.33和164.91 eV的出现,表明磁黄铁矿与含砷溶液过程的反应中产生了三价砷的硫化物As2S3和五价砷的硫化物As2S5[30],结合能峰值163.71 eV的出现,表明在反应过程中出现了单质硫[31],单质硫是S2-的一种氧化产物。

图9 磁黄铁矿与含砷溶液反应后S 2p分峰拟合图

Fig. 9 XPS-peak-differentiation-imitating analysis of S 2p after reaction of pyrrhotite with arsenic-containing solution

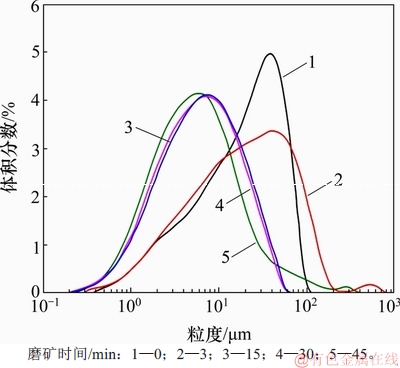

图10 不同磨矿时间下磁黄铁矿粒度分布图

Fig. 10 Particle size distribution of pyrrhotite in different grinding time

XPS的分析结果表明,磁黄铁矿在与含砷溶液反应的过程中,磁黄铁矿的主要成分FeS发生了解离,产生了S2-,因为As2S3的溶度积比FeS的溶度积低几个数量级,所以,一部分S2-与三价砷结合,形成As2S3,还有一部分S2-与五价砷结合形成了As2S5。单质硫形成的来源一方面是由另一部分S2-在溶液中氧化形成,另一方面是由原磁黄铁矿贮存过程中与空气中的氧气氧化生成,其罩盖在磁黄铁矿的表面,在一定程度上阻碍了磁黄铁矿与溶液中砷的进一步反应。

2.4 基于机械活化的磁黄铁矿强化除砷技术研究

上述研究表明:磁黄铁矿净化高质量浓度含砷酸性废水具有一定可行性,但除砷效率受磁黄铁矿本身表面活性及反应过程中的罩盖钝化影响较大。因此,如何提高磁黄铁矿反应活性,同时弱化反应过程中的罩盖行为,成为磁黄铁矿净化除砷的关键。在湿法冶金中一般采用机械活化强化浸出,机械活化即通过外界机械力的作用使矿物颗粒变细,晶格缺陷增加,反应活性增强从而使浸出率有较大的提升[32]。为了进一步增加磁黄铁矿的利用率,提高磁黄铁矿的反应活性,将粒径小于0.074 mm的磁黄铁矿颗粒用搅拌磨进一步湿磨至更小粒度,提高其表面活性,并采用高强度搅拌解决反应过程中的罩盖问题,为高质量浓度砷的净化创造良好的条件。

2.4.1 磁黄铁矿的粒度与比表面积和磨矿时间的关系

图10所示为不同磨矿时间下磁黄铁矿颗粒粒度分布图。由图10可知:当搅拌磨磨矿3 min时,15~80 μm粒级的磁黄铁矿体积分数有所减少,2~10 μm粒级磁黄铁矿体积分数略增大;当搅拌磨磨矿15 min后,磁黄铁矿粒度分布更接近正态分布N(μ,σ2),且正态分布的均值μ比磨矿3 min时的μ大幅度减小;磨矿30 min和45 min,磁黄铁矿粒度分布并未发生显著变化。可以看出磨矿15 min后,增加磨矿的时间,磁黄铁矿颗粒粒径不会发生明显变化,这可能是由于磁黄铁矿颗粒粒径减小至一定程度后便开始发生团聚。

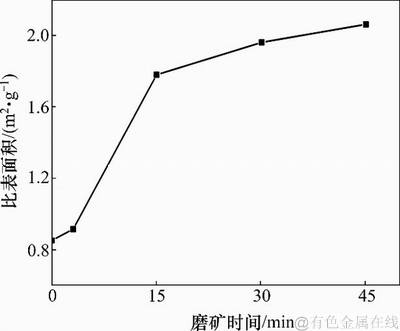

由于磨矿对磁黄铁矿颗粒粒度产生较大影响,必然也对磁黄铁矿颗粒比表面积产生较大的影响。图11所示为磁黄铁矿颗粒比表面积与磨矿时间的关系。由图11可以看出:当磨矿3 min时,磁黄铁矿颗粒比表面积从0.867 m2/g增加到0.919 m2/g,只有小幅度增加;当磨矿15 min后,比表面积增加到1.780 m2/g,磁黄铁矿比表面积增加了近1倍;当磨矿30 min和45 min后,磁黄铁矿比表面积相比磨矿15 min时只有小幅度增加,由此可见磨矿15 min以后,即使磨矿时间大幅度增加,磁黄铁矿比表面积也不会显著增加。

图11 磨矿时间对磁黄铁矿颗粒比表面积的影响

Fig. 11 Effect of grinding time on specific surface area of pyrrhotite particles

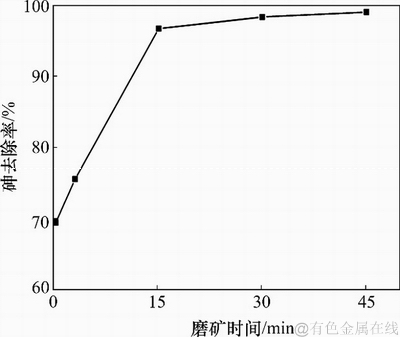

2.4.2 机械活化磁黄铁矿对去除溶液中As(III)去除率的影响

图12所示为不同磨矿时间对磁黄铁矿去除溶液中As(III)去除率的影响(As(III)质量浓度为2 g/L,pH=3.0,反应时间为24 h,磁黄铁矿质量浓度为12 g/L,反应温度为80 ℃)。由图12可见:随着磁黄铁矿磨矿时间增加,溶液中As(III)的去除率逐渐增加;当磨矿3 min时,随着磨矿时间的增加,As(III)的去除率从未磨矿时的69%增加至75%;当磨矿15 min时,随着磨矿时间的增加,As(III)的去除率急剧上升,As(III)的去除率从75%增加到97%;当磨矿30 min和45 min时,As(III)的去除率相比磨矿15 min时分别增加1.4%和2.2%。由此可见,磨矿15 min以内,随着磨矿时间增加,As(III)的去除率显著增加;磨矿15 min以后,增加磁黄铁矿磨矿时间对As(III)的去除率影响不大。

图12 磨矿时间对机械活化的磁黄铁矿去除溶液中As(III)的效率的影响

Fig. 12 Effect of grinding time on As(III) removal efficiency in mechanically activated pyrrhotite solution

由实验结果可知:在未经搅拌磨磨矿之前,磁黄铁矿表面与空气中的氧作用,发生氧化反应,生成了S的氧化产物,罩盖在磁黄铁矿颗粒表面,阻碍了磁黄铁矿与溶液中As(III)的反应;机械活化使得磁黄铁矿表面氧化层遭到破坏,暴露了颗粒内部新鲜表面,增强了磁黄铁矿与溶液中As(III)的作用面积,砷的去除率得到较大提高。

3 结论

1) 磁黄铁矿除砷最佳条件如下:pH为3.0~3.5,温度为85 ℃,反应时间为24 h。

2) As(III)吸附在磁黄铁矿表面,并与表面S2-发生作用生成As2S3,表面含砷组分及单质硫的存在在一定程度上阻碍了磁黄铁矿与溶液中砷的进一步反应。

3) 基于机械活化原理,在使用搅拌磨磨矿后,显著提高了磁黄铁矿比表面积,暴露出新鲜表面,从而优化了磁黄铁矿的除砷效率。当磨矿时间为15 min时,砷的去除率大于97%。

参考文献:

[1] 汤洁, 卞建民, 李昭阳, 等. 中国饮水型砷中毒区的水化学环境与砷中毒关系[J]. 生态毒理学报, 2013, 8(2): 222-229.

TANG Jie, BIAN Jianming, LI Zhaoyang, et al. Relationship between hydrochemical environment and arsenism in areas with arsenic poisoning drinking water in China[J]. Asian Journal of Ecotoxicology, 2013, 8(2): 222-229.

[2] VAISHYA R C, GUPTA S K. Modelling arsenic(III) adsorption from water by sulfate-modified iron oxide-coated sand (SMIOCS)[J]. Journal of Chemical Technology and Biotechnology, 2003, 78(1): 73-80.

[3] KIM E J, BATCHELOR B. Macroscopic and X-ray photoelectron spectroscopic investigation of interactions of arsenic with synthesized pyrite[J]. Environmental Science & Technology, 2009, 43(8): 2899-2904.

[4] MAMINDY-PAJANY Y, HUREL C, MARMIER N, et al. Arsenic(V) adsorption from aqueous solution onto goethite, hematite, magnetite and zero-valent iron: Effects of pH, concentration and reversibility[J]. Desalination, 2011, 281: 93-99.

[5] LI Yiran, WANG Jun, ZHAO Ying, et al. Research on magnetic seeding flocculation for arsenic removal by superconducting magnetic separation[J]. Separation and Purification Technology, 2010, 73(2): 264-270.

[6] TAVARES D S, LOPES C B, COELHO J P, et al. Removal of arsenic from aqueous solutions by sorption onto sewage sludge-based sorbent[J]. Water, Air, & Soil Pollution, 2012, 223(5): 2311-2321.

[7] KATSOYIANNIS I A, ZOUBOULIS A I. Removal of arsenic from contaminated water sources by sorption onto iron-oxide-coated polymeric materials[J]. Water Research, 2002, 36(20): 5141-5155.

[8] HAN Jingtai, FYFE W S. Arsenic removal from water by iron-sulphide minerals[J]. Chinese Science Bulletin, 2000, 45(15): 1430-1434.

[9] FARQUHAR M L, CHARNOCK J M, LIVENS F R, et al. Mechanisms of arsenic uptake from aqueous solution by interaction with goethite, lepidocrocite, mackinawite, and pyrite: an X-ray absorption spectroscopy study[J]. Environmental Science & Technology, 2002, 36(8): 1757-1762.

[10] BOSTICK B C, FENDORF S. Arsenite sorption on troilite (FeS) and pyrite (FeS2)[J]. Geochimica et Cosmochimica Acta, 2003, 67(5): 909-921.

[11] BLANCHARD M, ALFREDSSON M, BRODHOLT J, et al. Arsenic incorporation into FeS2 pyrite and its influence on dissolution: a DFT study[J]. Geochimica et Cosmochimica Acta, 2007, 71(3): 624-630.

[12] KATSOYIANNIS I A, ZOUBOULIS A I. Removal of arsenic from contaminated water sources by sorption onto iron-oxide-coated polymeric materials[J]. Water Research, 2002, 36(20): 5141-5155.

[13] 史亚丹. 煅烧黄铁矿结构演化及其净化水中砷的作用和机理[D]. 合肥: 合肥工业大学资源与环境工程学院, 2015: 65-71.

SHI Yadan. The structure evolution of heat-treated pyrite and its performance and mechanism for arsenic removal from groundwater[D]. Hefei: Hefei University of Technology. School of Resources and Environment Engineering, 2015: 65-71.

[14] 刘卓, 张小梅, 肖才林, 等. 利用天然磁黄铁矿去除水中As(V)的研究[J]. 环境科学学报, 2016, 36(10): 3701-3708.

LIU Zhuo, ZHANG Xiaomei, XIAO Cailin, et al. As(V) Removal from water with natural pyrrhotite[J]. Acta Scientiae Circumstantiae, 2016, 36(10): 3701-3708.

[15] SMEDLEY P L, KINNIBURGH D G. A review of the source, behaviour and distribution of arsenic in natural waters[J]. Applied Geochemistry, 2002, 17(5): 517-568.

[16] CULLEN W R, REIMER K J. Arsenic speciation in the environment[J]. Chemical Reviews, 1989, 89(4): 713-764.

[17] 洪秋阳. 磁黄铁矿晶体化学和可浮性研究[D]. 长沙: 中南大学资源加工与生物工程学院, 2011: 47-52.

HONG Qiuyang. Study on the crystal chemistry and floatability of pyrrhotite[D].Changsha: Central South University. School of Minerals Processing and Bioengineering, 2011: 47-52.

[18] HELZ G R, TOSSELL J A. Thermodynamic model for arsenic speciation in sulfidic waters: a novel use of ab initio computations[J]. Geochimica et Cosmochimica Acta, 2008, 72(18): 4457-4468.

[19] VLASSOPOULOS D, BESSINGER B, O'DAY P A. Aqueous solubility of As2S3 and thermodynamic stability of thioarsenites[C]//Proceedings of the 13th International Conference on Water-Rock Interaction. London, UK: Taylor & Francis Group, 2010: 823-826.

[20] CORNELIS G, POPPE S, VAN GERVEN T, et al. Geochemical modelling of arsenic and selenium leaching in alkaline water treatment sludge from the production of non-ferrous metals[J]. Journal of Hazardous Materials, 2008, 159(2/3): 271-279.

[21] 白猛, 郑雅杰, 刘万宇, 等. 硫化砷渣的碱性浸出及浸出动力学[J]. 中南大学学报(自然科学版), 2008, 39(2): 268-272.

BAI Meng, ZHENG Yajie, LIU Wanyu, et al. Alkaline leaching and leaching kinetics of arsenic sulfide residue[J]. Journal of Central South University(Science and Technology), 2008, 39(2): 268-272.

[22] 江元汝, 黄琼玉. 硫化亚铁处理含砷废水中砷的形态变化[J]. 环境化学, 1996, 15(2): 118-126.

JIANG Yuanru, HUANG Qiongyu. The change of arsenic forms in the treatment for arsenic wastewater by ferrous sulfide[J]. Environmental Chemistry, 1996, 15(2): 118-126.

[23] BAHL M K, WOODALL R O, WATSON R L, et al. Relaxation during photoemission and LMM Auger decay in arsenic and some of its compounds[J]. The Journal of Chemical Physics, 1976, 64(3): 1210-1218.

[24] STEC W J, MORGAN W E, ALBRIDGE R G, et al. Measured binding energy shifts of “3p” and “3d” electrons in arsenic compounds[J]. Inorganic Chemistry, 1972, 11(2): 219-225.

[25] TAYLOR J A. An XPS study of the oxidation of AlAs thin films grown by MBE[J]. Journal of Vacuum Science and Technology, 1982, 20(3): 751-755.

[26] EPP J M, DILLARD J G. Effect of ion bombardment on the chemical reactivity of gallium arsenide(100)[J]. Chemistry of Materials, 1989, 1(3): 325-330.

[27] LEGRAND D L. Oxidation/alteration of pentlandite and pyrrhotite surfaces at pH 9.3: Part 1. Assignment of XPS spectra and chemical trends[J]. American Mineralogist, 2005, 90(7): 1042-1054.

[28] AGOSTINELLI E, BATTISTONI C, FIORANI D, et al. An XPS study of the electronic structure of the ZnxCd1–xCr2(x = S, Se) spinel system[J]. Journal of Physics and Chemistry of Solids, 1989, 50(3): 269-272.

[29] PETKOV K, KRASTEV V, MARINOVA T. XPS study of amorphous As2S3 films deposited onto chromium layers[J]. Surface and Interface Analysis, 1994, 22: 202-205.

[30] PEISERT H, CHASS T, STREUBEL P, et al. Relaxation energies in XPS and XAES of solid sulfur compounds[J]. Journal of Electron Spectroscopy and Related Phenomena, 1994, 68: 321-328.

T, STREUBEL P, et al. Relaxation energies in XPS and XAES of solid sulfur compounds[J]. Journal of Electron Spectroscopy and Related Phenomena, 1994, 68: 321-328.

[31] 张有新, 何利华, 刘旭恒. 机械活化对磁黄铁矿浸出动力学的影响[J]. 中南大学学报(自然科学版), 2010, 41(6): 2085-2090.

ZHANG Youxin, HE Lihua, LIU Xuheng. Effect of mechanical activation on leaching kinetics of pyrrhotite[J]. Journal of Central South University(Science and Technology), 2010, 41(6): 2085-2090.

(编辑 伍锦花)

收稿日期: 2019 -01 -26; 修回日期: 2019 -03 -26

基金项目(Foundation item):中南大学中央高校基本科研业务费专项资金资助项目(2019zzts702);国家自然科学基金资助项目(51634009, 51804340)(Project(2019zzts702) supported by the Fundamental Research Funds for the Central Universities of Central South University; Projects(51634009, 51804340) supported by the National Natural Science Foundation of China)

通信作者:韩海生,博士,副教授,从事湿法冶金及二次资源回收利用研究; E-mail: hanhaishengjingji@126.com