拉伸矫直对铝合金厚板平直度的影响

龚海1, 2, 3,吴运新2, 3,陈磊2, 3,李益华2, 3,王晓燕2, 3

(1. 中南大学 材料科学与工程学院,湖南 长沙,410083;

2. 中南大学 高性能复杂制造国家重点实验室,湖南 长沙,410083;

3. 中南大学 机电工程学院,湖南 长沙,410083)

摘要:针对大规格铝合金厚板的变形问题,建立铝厚板的淬火-拉伸矫直有限元模型;运用建立的模型对厚板的非对称淬火工况进行模拟计算,获得厚板的变形分布;进一步对变形厚板进行拉伸矫直,获得拉伸后厚板的变形分布;结合小规格厚板的淬火-拉伸矫直实验,对厚板不同状态下的板形质量进行评估。研究结果表明:非对称淬火会引起厚板极大变形;拉伸矫直能有效提高厚板的平直度,当拉伸量达2.0%时,厚板的平直度能满足生产要求。

关键词:淬火;铝合金;平直度;拉伸矫直

中图分类号:TG146.2;TG156 文献标志码:A 文章编号:1672-7207(2013)12-4827-06

Influence of tension straightening on flatness of aluminum alloy thick-plate

GONG Hai1, 2, 3, WU Yunxin2, 3, CHEN Lei2, 3, LI Yihua2, 3, WANG Xiaoyan2, 3

(1. School of Materials Science and Engineering, Central South University, Changsha 410083, China;

2. State Key Laboratory for High Performance Complex Manufacturing, Central South University, Changsha 410083, China;

3. School of Mechanical and Electrical Engineering, Central South University, Changsha 410083, China)

Abstract: Aiming to solve the deformation problem of large size aluminum alloy thick plate, FEM quenching-tension-straightening model of aluminum thick plate was built, with which asymmetrical quenching of aluminum plate was simulated and deformation distribution of the plate was obtained. Then the deformed plate was straightened, and deformation distribution of the plate after straightening was obtained. With experiments of smaller aluminum plate, plate shape quality of different conditions was evaluated. The results show that the asymmetrical quenching can bring great deformation to aluminum plate, while tension straightening can improve plate flatness effectively. Plate flatness can meet the production requirements at stretching ratio of 2.0%.

Key words: quenching; aluminum alloy; flatness; tension straightening

当前,航空航天领域用铝合金板材不仅对材料的组织、性能有严格要求,而且对铝板平直度的要求非常苛刻,因此,板材的平直度控制与矫直至关重要[1-6]。在板材淬火速冷过程中,工艺条件和内部温度变化非常复杂,是引起板材沿厚度方向的翘曲变形的主要原因之一。长期以来,受工艺条件和大吨位拉伸机的限制,世界上能够生产高性能大规格铝合金板材[7-9]的仅有美国铝业公司、加拿大铝业公司等少数几个工业发达国家的公司。目前,国内对于大规格铝合金板材的生产,由于研究成本高且周期较长,相关工艺参数尚处于摸索和理论研究阶段,我国大规格板材生产过程中的成材率还处于较低水平,成为制约企业发展的重要原因[10-12]。拉伸量是拉伸矫直工艺中最重要的工艺参数,但由于拉伸矫直属于材料非线性、几何非线性问题[13],计算难度大,目前拉伸量更多的是凭借经验来确定。为此,本文作者对不对称喷淋淬火和拉伸矫直过程进行模拟,分析淬火和拉伸对厚板平直度的影响,以优化板材生产工艺参数,加快生产周期,降低生产成本,指导厚板生产。

1 厚板不对称淬火及拉伸矫直模拟

1.1 基本假设

铝合金厚板的变形及矫直对于厚板的制备至关重要,理想的平直度是后期机械加工的重要保证。为了建立理想条件下厚板的淬火-拉伸力学模型,进行如下假设:

(1) 材料连续,内部分布均匀且各向同性;

(2) 在淬火过程中,淬火介质温度恒定;

(3) 在淬火和拉伸矫直过程按小变形弹塑性问题处理;

(4) 拉伸矫直过程中夹钳夹持为理想状态,不存在打滑现象,钳口夹持区域视为绝对刚端,拉伸均匀。

1.2 有限元模型

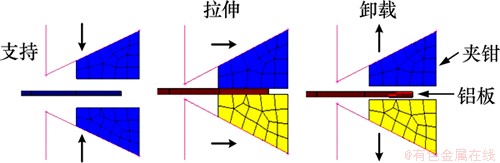

研究的7075板材长为10 m,宽为2 m,高分别为6,10和20 mm。运用有限元软件MSC.MARC,模拟厚板的淬火过程。在淬火过程中,热和力的关系采用耦合求解。以计算得到的铝合金厚板淬火残余应力场和变形场作为拉伸矫直模型的初始条件,模拟拉伸矫直过程。厚板拉伸过程分为夹持、拉伸和卸载3个阶段。模型中对夹钳进行等效简化处理,夹钳与板材之间的接触方式定义为GLUE,不存在打滑现象,通过设定刚性面的位移来控制夹钳的移动和拉伸量的变化。

在简化的理想模型中,厚板变形主要为上下表面不均匀换热引起的翘曲变形,其变形沿长度方向的中心线和宽度方向的中心线均对称分布,根据板材的几何对称性及边界条件的对称性,取长度方向的1/2建立几何模型,建立的拉伸模型如图1所示。

图1 拉伸矫直过程示意图

Fig. 1 Schematic diagram of tension straightening process

模型中板材的几何形状规则,但3个方向上长、宽、高差异较大,尤其是厚度远远小于长度和宽度,模型中网格划分采用八节点六面体单元(HEX43)。在淬火过程中,材料的物热参数随着温度的变化而变化,且呈非线性关系,7075铝合金材料的物热参数见文献[14-15]。

2 计算结果与分析

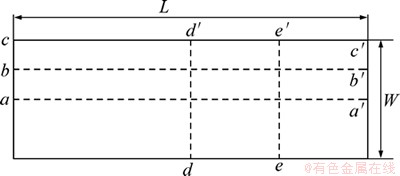

根据板材的几何对称性,选取模型中板材上表面的a-a′线、b-b′线、c-c′线、d-d′线和e-e′线分析淬火和拉伸矫直对板材板形质量的影响。其中:a-a′线、b-b′线和c-c′线平行于板材长度方向,分别对应板宽度中心、宽度的1/4和宽度边缘;d-d′线和e-e′线平行于板材宽度方向,分别对应板长度的中心和长度的1/4且靠近长度的一端,如图2所示。

图2 板材表面示意图

Fig. 2 Schematic diagram of plate surface

2.1 非对称淬火对板材平直度的影响

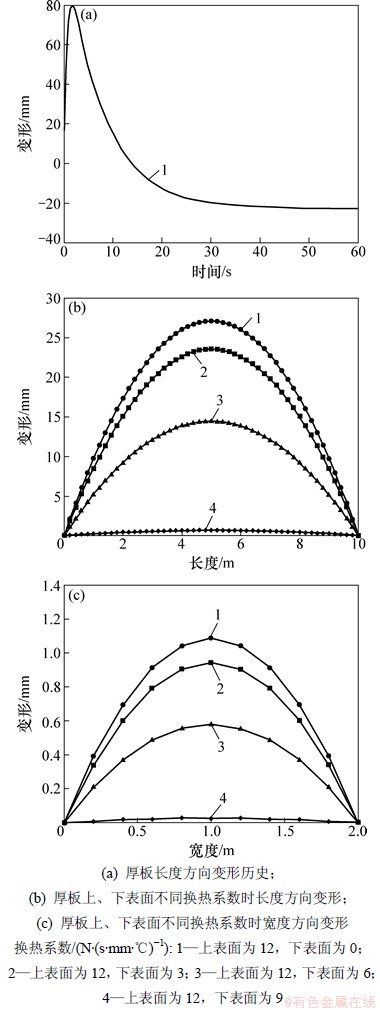

厚度为10 mm的铝板其上表面换热系数为12 N/(s·mm·℃),下表面换热系数为0 N/(s·mm·℃)。淬火后铝板上表面长度端部位置的变形情况如图3(a)所示。从图3(a)可见:由于上、下表面冷却速度不一致,淬火初期厚板即朝上表面方向发生翘曲变形;随着冷却继续,变形逐渐发生反向,最终表现为厚板朝下表面翘曲;对于厚度为10 mm的铝板,上表面换热系数为12 N/(s·mm·℃),下表面换热系数分别为0,3,6和9 N/(s·mm·℃),淬火后厚板变形情况如图3(b)和图3(c)所示。

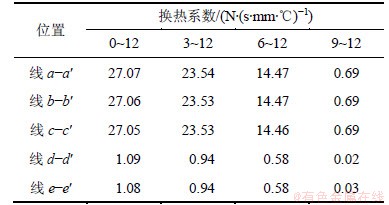

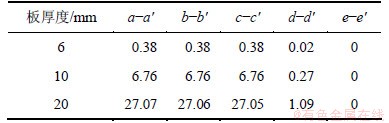

各板上表面位置的最大挠度δ如表1所示。

从图3和表1可以看到:在上下表面不均匀淬火时,板材呈中间向上凸的“拱形”变化,不平直度主要表现为纵向的翘曲变形;随着下表面换热系数的减小即淬火强度的减弱,板材沿长度和宽度方向的不平度都会增大,长度方向的不平度远大于宽度方向的不平度,且不平度的增大量与换热系数的降低量呈非线性关系。

对于长×宽为10 m×2 m,厚度分别为6,10和20 mm的铝板,上、下表面换热系数分别为12和0N/(s·mm·℃)。淬火后板材长度方向线a-a′的挠度如表2所示。从表2可以看出:对于长×宽相同的板材,厚度越大,板材的平直度越低。这主要是由于在淬火过程中,板材表面温度急剧降低,厚度越大,板材内外温度梯度越大,导致板材内部的残余应力越大,相应的变形也越大。

图3 不对称淬火后板材的平直度

Fig. 3 Flatness of asymmetric quenched plates

表1 不对称淬火板最大挠度δ

Table 1 The maximum deflection of asymmetric quenched plates mm

表2 不同厚度的不对称淬火板最大挠度δ

Table 2 The maximum deflection of asymmetric quenched plates of different thicknesses mm

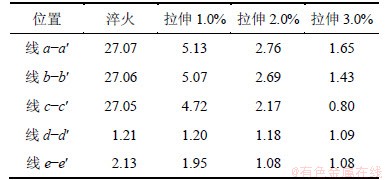

2.2 拉伸量对板材平直度的影响

对长×宽为10 m×2 m、厚度为20 mm的铝板,上、下表面的换热系数分别取12和0 N/(s·mm·℃),淬火后进行拉伸,在不同拉伸量下,厚板表面各条路径的挠度如表3所示。从表3可以看出:非对称淬火引起板材发生很大的翘曲变形,长度方向的的平直度

表3 不同状态时厚板的最大挠度δ

Table 3 The maximum deflection of aluminum plates under different conditions mm

严重降低,最大挠度发生在板材宽度中心(线a-a′)处,达到27.07 mm;当拉伸量为1.0%时,线a-a′的挠度降至5.13 mm;当拉伸量增大至2.0%时,线a-a′的挠度降至2.76 mm;当拉伸量增大到3.0%时,线a-a′的挠度降至1.65 mm时,板形质量改善的幅度逐渐降低;随着拉伸量的增加,宽度方向的平直度均略有提高,且离线d-d′越远的位置宽度方向平直度越低,即板材长度两端位置宽度方向的平直度较低;当拉伸量达到2.0%时,板材的最大挠度能达到英国标准(3L100)平直度指标(见表4)的要求[16-17]。对于厚度为6 mm和10 mm的铝板,当拉伸量为2.0%时,其平直度同样达到标准要求。

表4 3L100拉伸板平直度

Table 4 Flatness of 3L100 stretched aluminum plates mm/m

3 厚板淬火与拉伸实验

3.1 实验设计

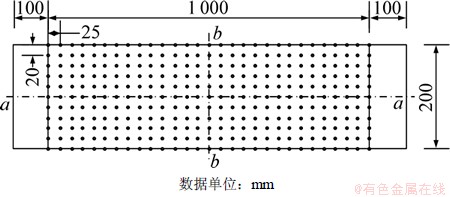

对小件试样进行实验研究,验证仿真模型的可靠性和正确性。实验材料为某铝厂生产的7075T6铝合金板,试样长×宽×高为1.2 m×200 mm×6 mm。

试样固溶加热至475 ℃并保温1 h,快速转移至淬火池中,淬火池分左、右两排喷头,将左侧一排喷头用铝板挡住,模拟单边淬火。右侧喷头喷水压力约为0.40 MPa,水流量约为160 L/min,冷却用水约为20 ℃。板材从加热炉到淬火池的转移时间控制在3~5 s,淬火喷水时间为60 s。淬火完成后,在5MN液压拉伸机上进行矫直,试样长度两端夹持区域长度均为100 mm左右。

采用美国Brwon & Sharpe公司生产的GLOBAL STATUS575型三坐标测量仪测量厚板初始状态、淬火后和拉伸后的板形状况,测点布局如图4所示(长度方向步长为25 mm,宽度步长为20 mm)。

图4 板形测量测点布置图

Fig. 4 Schematic diagram of shape test points

3.2 结果与讨论

为了对比板材表面形状的变化,对三坐标测量仪测量数据进行三点归零处理。

图5所示为铝板不同状态下的尺寸形状。从图5可以看出:初始状态板材较平整,板材中间略向上翘曲;固溶-不对称淬火后,板材的长度中部向上翘曲,考虑到加热过程中厚板底部保持水平,认为加热过程引起的变形较小,变形主要是淬火造成的;板材拉伸1.0%后,板形得到大幅度改善;继续增大拉伸量至2.0%,板形质量改善幅度不大。

图5 铝板不同状态时上表面尺寸形状

Fig. 5 Shapes of plate surface under different conditions

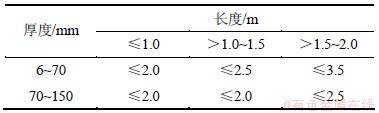

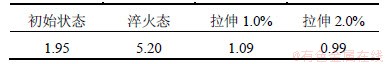

用2个平行的包络平面之间的最小距离d来描述厚板的表面形状,3块铝板在不同状态时包络平面间的最小距离如表5所示。从表5可以看出:拉伸1.0%后,铝板包络面间最小距离大幅度下降,基本满足标准规定的要求;继续增大拉伸量,最小距离d减小幅度较小。

表5 铝板包络平面间的最小距离d

Table 5 Minimum distance between two envelope surfaces of aluminum plate mm

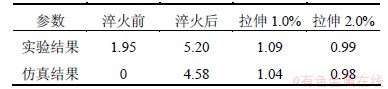

3.3 计算结果与实验结果对比

建立长×宽×高为1.2 m×2 00 mm×6 mm板材的淬火-拉伸矫直计算模型,对比计算铝板实验结果验证模型的可靠性。实验结果和仿真结果如表6所示。从表6可以看出:实验结果和仿真计算较吻合,验证了所建立模型的准确性;仿真结果能够有效反映板材的平直度变化。

表6 拉伸实验结果与仿真结果变形值对比

Table 6 Comparison of deformation of straightening experiment and simulation mm

4 结论

(1) 不均匀淬火是引起厚板变形的一个重要原因,厚板上下表面换热对称性越差,变形越大,板厚度越大。在相同冷却条件下,厚板变形越大。

(2) 不均匀淬火主要引起厚板长度方向的变形,宽度方向变形较小。在淬火过程中,厚板经历一个变形历程,即先朝冷却速度快的一面收缩,然后变形反向,表现为朝冷却速度快的一面凸起。

(3) 拉伸能有效改善厚板的板形质量,拉伸量达到2.0%时可使厚板的平直度符合板形标准。

参考文献:

[1] 王祝堂. 铝合金中厚板的生产、市场与应用[J]. 轻合金加工技术, 2005, 33(1): 1-18.

WANG Zhutang. Production, market and application of aluminum alloy plate[J]. Light Alloy Fabrication Technology, 2005, 33(1): 1-18.

[2] Park K C, Hwang S M. Development of a finite element analysis program for roller levelling and application for removing blanking bow defects of thin steel sheet[J]. ISIJ International, 2002, 42(9): 900-999.

[3] LIU Zhifang, WANG Yongqin, YAN Xingchun. A new model for the plate levelling process based on curvature integration method[J]. International Journal of Mechanical Sciences, 2012, 54(1): 213-224.

[4] ZHANG Shuming, SUN Yanming. ASC-II automatic shaft straightener[J]. Test Technology and Testing Machine, 2006, 2(1): 60-64.

[5] 吕正风, 曲大保. 铝合金热连轧板形控制策略[J]. 有色金属加工, 2011, 40(5): 21-24.

L Zhengfeng, QU Dabao. Profile control strategy in aluminum alloy hot strip tandem rolling[J]. Nonferrous Metals Processing, 2011, 40(5): 21-24.

Zhengfeng, QU Dabao. Profile control strategy in aluminum alloy hot strip tandem rolling[J]. Nonferrous Metals Processing, 2011, 40(5): 21-24.

[6] 叶陶勇. 热轧铝合金大规格板不良板形的成因及对策[J]. 铝加工, 2008(6): 33-36.

YE Taoyong. Cause and countermeasures of flatness failures of large-scale aluminum hot-rolled plates[J]. Aluminum Fabrication, 2008(6): 33-36.

[7] 江志邦, 宋殿臣, 关云华. 世界先进的航空用铝合金厚板生产技术[J]. 轻合金加工技术, 2006, 33(4): 1-7.

JIANG Zhibang, SONG Dianchen, GUAN Yunhua. Global advanced process technology of aluminum alloy plates for aircraft and aerospace[J]. Light Alloy Fabrication Technology, 2006, 33(4): 1-7.

[8] Zadpoor A A, Sinke J, Benedictus R. Formability prediction of high strength aluminum sheets[J]. International Journal of Plasticity, 2009, 25(12): 2269-2297.

[9] Tu J F, Paleocrassas A G. Fatigue crack fusion in thin-sheet aluminum alloys AA7075-T6 using low-speed fiber laser welding[J]. Journal of Materials Processing Technology, 2011, 211(1): 95-102.

[10] 王小红, 张丁非, 彭建, 等. 拉伸矫直数学模型及试验验证[J]. 机械工程学报, 2011, 47(8): 66-70.

WANG Xiaohong, ZHANG Dingfei, PENG Jian, et al. Mathematical model of tension straightening process and its experiment validation[J]. Journal of Mechanical Engineering, 2011, 47(8): 66-70.

[11] 张君, 韩炳涛, 杨合, 等. 基于有限元的大型铝型材拉伸矫直设备设计方法研究[J]. 重型机械, 2006(1): 22-25.

ZHANG Jun, HAN Bingtao, YANG He, et al. Design method research of large-size aluminum stretcher by means of FEM[J]. Heavy Machinery, 2006(1): 22-25.

[12] 崔甫. 矫直原理与矫直机械[M]. 北京: 冶金工业出版社, 2007: 2-10.

CUI Fu. Straightening theory and straightening machine[M]. Beijing: Metallurgical Industry Press, 2007: 2-10.

[13] Clausen A H, Hopperstad O S, Magnus L. Sensitivity of model parameters in stretch bending of aluminum extrusions[J]. Mechanical Sciences, 2001, 43(2): 427-453.

[14] 姚灿阳. 7050铝合金厚板淬火温度场及内应力场的数值模拟研究[D]. 长沙: 中南大学机电工程学院, 2007: 14-28.

YAO Canyang. Numerical simulation of quench temperature field and internal stress field of aluminum alloy 7050 thick plate[D]. Changsha: Central South University. School of Mechanical and Electrical Engineering, 2007: 14-28.

[15] 龚海. 铝合金厚板内应力演变规律及残余应力场评估模型研究[D]. 长沙: 中南大学机电工程学院, 2011: 18-27.

GONG Hai. Research on evolution and evaluation model of residual stress in aluminum alloy thick plate[D]. Changsha: Central South University. School of Mechanical and Electrical Engineering, 2011: 18-27.

[16] 陈磊. 大规格铝合金板材拉伸矫直仿真与实验研究[D]. 长沙: 中南大学机电工程学院, 2012: 36-41.

CHEN Lei. Simulation and experiment research of tension straightening for large size aluminum alloy plate[D]. Changsha: Central South University. School of Mechanical and Electrical Engineering, 2012: 36-41.

[17] 王瑞梓, 王韬, 陈原. 铝合金厚板控制拉伸的基本数据[J]. 铝加工, 2001, 24(6): 19-22.

WANG Ruizi, WANG Tao, CHEN Yuan. Basic data on restrained stretching heavy plate of aluminum alloy[J]. Aluminum Fabrication, 2001, 24(6): 19-22.

(编辑 陈灿华)

收稿日期:2012-12-12;修回日期:2013-02-20

基金项目:国家重点基础研究发展规划(“973”计划)项目(2010CB731703,2012CB619505);中南大学博士后基金资助项目(2012年)

通信作者:龚海(1982-),男,湖南新化人,博士后,从事铝合金厚板残余应力调控的研究;电话:0731-88877840;E-mail;gonghai88@163.com