文章编号:1004-0609(2011)06-1220-09

Al-Zn-Mg-Sc-Zr合金的热变形行为及加工图

何振波1, 2,李慧中1,梁霄鹏1,尹志民1

(1. 中南大学 材料科学与工程学院,长沙 410083;

2. 东北轻合金有限责任公司,哈尔滨 150060)

摘 要:在Gleeble-1500热模拟试验机上对Al-5.5Zn-1.5Mg-0.2Sc-0.1Zr铝合金进行高温等温压缩实验,研究该合金在变形温度为300~500 ℃、应变速率为0.01~10 s-1条件下的流变行为,建立合金高温变形的本构方程和加工图,采用电子背散射衍射(EBSD)分析变形过程中合金的组织特征。结果表明:流变应力随变形温度的升高而降低;当应变速率 =10 s-1,变形温度为300~500 ℃时,合金发生了动态再结晶。Al-5.5Zn-1.5Mg-0.2Sc-0.1Zr合金的高温流变行为可用Zener-Hollomon参数描述。在热变形过程中,随着真应变增加,合金的变形失稳区域增大。该合金适宜的变形条件如下:变形温度300~360 ℃、应变速率0.01~0.32 s-1,或变形温度380~500 ℃、应变速率0.56~ 10 s-1。

=10 s-1,变形温度为300~500 ℃时,合金发生了动态再结晶。Al-5.5Zn-1.5Mg-0.2Sc-0.1Zr合金的高温流变行为可用Zener-Hollomon参数描述。在热变形过程中,随着真应变增加,合金的变形失稳区域增大。该合金适宜的变形条件如下:变形温度300~360 ℃、应变速率0.01~0.32 s-1,或变形温度380~500 ℃、应变速率0.56~ 10 s-1。

关键词:Al-Zn-Mg-Sc-Zr合金;热变形;加工图

中图分类号:TG113.26 文献标志码:A

Hot deformation behavior and processing map of

Al-Zn-Mg-Sc-Zr alloy

HE Zhen-bo1, 2, LI Hui-zhong1, LIANG Xiao-peng1, YIN Zhi-min1

(1. School of Materials Science and Engineering, Central South University, Changsha 410083, China;

2. Northeast Light Alloy Co. Ltd, Harbin 150060, China)

Abstract: The flow stress features of Al-5.5Zn-1.5Mg-0.2Sc-0.1Zr aluminum alloy were studied by the isothermal compression of cylindrical specimen in the temperature range of 300-500 ℃ and strain rate range of 0.01-10 s-1 with Gleeble-1500 simulated machine. The high temperature deformation constitutive equations and processing map were established, furthermore, the microstructure characteristics were studied by electron back-scattered diffraction (EBSD) analysis. The results show that the flow stress decreases with increasing deformation temperature. The dynamic recrystallization occurs at the strain rate of 10 s-1 and in the temperature range of 300-500 ℃. The flow stress of Al-5.5Zn-1.5Mg-0.2Sc-0.1Zr alloy during high temperature deformation can be represented by Zener-Hollomon parameter. In the hot deformation process, the flow instability zone increases with increasing the true strain. The feasible deformation temperature and strain rate are 300 ℃<t<360 ℃ and 0.01 s-1< <0.32 s-1 or 380 ℃<t<500 ℃ and 0.56 s-1<

<0.32 s-1 or 380 ℃<t<500 ℃ and 0.56 s-1< <10 s-1.

<10 s-1.

Key words: Al-Zn-Mg-Sc-Zr alloy; hot deformation; processing map

含Sc和Zr的7×××系合金是一种强度高、塑性好、可焊性好、耐腐蚀性能优良的中高强铝合金,被广泛应用于航天航空、核能和舰船等领域[1-2]。目前,对含Sc铝合金的研究主要集中在添加Sc对合金组织,再结晶行为及力学性能的影响方面[3-6]。而合金热变形过程中的流变应力是表征材料塑性变形性能的一个最基本量,在实际塑性变形过程中,合金的流变应力值决定了变形时所需施加的载荷大小和所需消耗能量的多少[7]。热加工图是基于动态材料模型的能量图和失稳图的叠加,能够很好的描述材料高温变形时组织变化同塑性参数间的关系,为合金变形时工艺参数的确定提供了选择范围。对于变形铝合金而言,其热变形行为以及加工图是研究其性能的前提,目前对铝合金的热变形行为和加工图已有较多研究报道,如Cerri对经不同预处理后的7012和7075铝合金的热加工性能进行了对比研究,并建立了相应的本构方程模型[8]。LIN等[9]研究Al-Zn-Mg-Cu-Cr合金的高温热变形行为,建立合金的本构方程模型。JAQAN等[10]建立Al-Li合金的加工图,MENG等[11]建立含Er的Al-5.7Mg合金的热变形加工图。目前,还未见对Al-5.5Zn-1.5Mg- 0.2Sc-0.1Zr合金热变形工艺的参数及加工图的报道。本文作者在热模拟机上对Al-5.5Zn-1.5Mg-0.2Sc-0.1Zr合金进行等温压缩变形,研究该合金的高温热变形行为,建立本构方程模型和加工图,并利用EBSD分析技术对变形过程的组织特征进行研究,可为该合金的热变形工艺的制定提供参考。

1 实验

1.1 材料制备

实验合金化学成分为Al-5.5Zn-1.5Mg-0.2Sc-0.1Zr (质量分数,%)合金。采用工业纯铝、工业纯镁、工业纯锌、Al-5%Zr和Al-2%Sc中间合金,在井式电阻炉中熔炼,熔炼温度为780 ℃,用KCl+NaCl精炼,于740 ℃浇入预热至250 ℃的铁模中,铸锭的尺寸为d 15 mm×150 mm,铸锭经(470 ℃,24 h)均匀化处理,然后加工出尺寸为d 10 mm×15 mm,两端带有d 8 mm×0.2 mm凹槽的热压缩样品。

1.2 实验方法

将加工好的试样在Gleeble-1500热模拟试验机上进行等温压缩实验。压缩温度分别为300、350、400、450、500 ℃,应变速率分别为0.01、0.1、1、10 s-1,变形量为50%,试样两端的凹槽内填充75%石墨+ 20%机油+5%硝酸三甲苯脂(质量分数),以减少摩擦的影响,试样升温速度为2 ℃/s,保温3 min。压缩后的样品迅速水冷到室温以保留热变形时的组织。

电子背散射衍射(Electron back-scattered diffraction, EBSD)数据采集采用装配在Sirion200扫描电镜上型号为XM4-Hikari的装备进行,扫描电镜加速电压选用25 kV,数据分析采用OIM 5.31软件进行,样品经机械减薄至0.2 mm后采用MIT-Ⅱ型双喷减薄仪经行双喷减薄以去除应力层,电解液为30%HNO3+ 70%CH3OH,温度为-25 ℃,电压为15~20 V,电流为80~100 mA,减薄时间为2~3 min,光学显微组织在Leica光学显微镜上观察。

2 结果与分析

2.1 合金的真应力—真应变曲线特征

图1所示为Al-Zn-Mg-Sc-Zr合金在不同变形条件下等温压缩变形时的真应力—真应变曲线。由图1可以看出,合金在整个变形温度和应变速率范围内,合金均存在明显的稳态流变特征。在同一应变速率下,流变应力随着变形温度的升高而降低;在同一变形温度下,流变应力随着应变速率的增大而增大。其中在温度为300~500 ℃、应变速率为0.01~1 s-1的变形条件范围内,当真应变小于一定值时,真应力随着真应变的增大而迅速增大,当应力达到峰值后,真应力保持基本稳定,表明发生了典型的动态回复现象。在应变速率为10 s-1、变形温度为300~500 ℃的变形条件下,合金变形时的应力—应变曲线出现明显的波浪峰,并随着变形温度的升高,该波浪峰表现得越明显,该波浪形的出现是材料发生动态再结晶的表现,说明在该变形范围合金发生了动态再结晶。

2.2 本构方程模型

合金在热加工过程中,其流变行为可以用以下的本构方程表示[12-14]:

(1)

(1)

(2)

(2)

(3)

(3)

(4)

(4)

(5)

(5)

式中: 为流变应力;

为流变应力; 为应变速率;

为应变速率; 为真应变;T为变形温度;A1、A2、A、n、

为真应变;T为变形温度;A1、A2、A、n、 和

和 (

( )为与温度无关的常数;R为摩尔气体常数;Q为热变形激活能;Z为Zener-Hollomon参数。

)为与温度无关的常数;R为摩尔气体常数;Q为热变形激活能;Z为Zener-Hollomon参数。

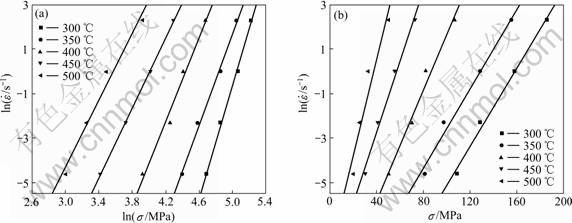

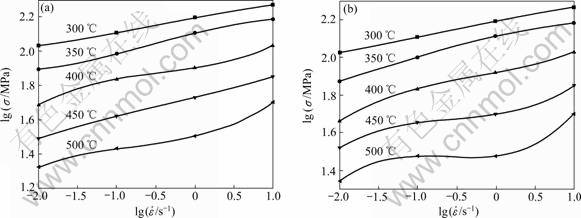

将式(2)和(3)两边取对数可以发现:当温度一定时,n和 分别为

分别为 —

— 曲线(见图2(a))和

曲线(见图2(a))和 —

— 曲线(见图2(b))的斜率,取各直线斜率的平均值可得

曲线(见图2(b))的斜率,取各直线斜率的平均值可得 为0.015 62。

为0.015 62。

由公式(5)可见,式中的第一项代表 —

— 关系曲线的斜率;第二项代表

关系曲线的斜率;第二项代表 —1/T关系曲线的斜率。将压缩变形时各变形条件下的峰值应力和不同温度下求得的

—1/T关系曲线的斜率。将压缩变形时各变形条件下的峰值应力和不同温度下求得的 代入

代入 ,对应相应的应变速率和温度,用线性回归绘制出

,对应相应的应变速率和温度,用线性回归绘制出 —

— 关系曲线如图3所示。

关系曲线如图3所示。 —1/T关系曲线如图4所示。将所得斜率代入式(5),可得不同变形温度下的变形激活能,取其平均值为Q=262.1 kJ/mol。

—1/T关系曲线如图4所示。将所得斜率代入式(5),可得不同变形温度下的变形激活能,取其平均值为Q=262.1 kJ/mol。

图1 不同应变速率下Al-Zn-Mg-Sc-Zr合金的真应力—真应变曲线

Fig.1 True stress—true strain curves of Al-Zn-Mg-Sc-Zr alloy at different stain rates: (a) 0.01 s-1; (b) 0.1 s-1; (c) 1 s-1; (d) 10 s-1

图2 不同温度下Al-Zn-Mg-Sc-Zr合金的应变速率与流变应力的关系

Fig.2 Relationship between strain rate and flow stress for Al-Zn-Mg-Sc-Zr alloy at different temperatures: (a)  —

— ; (b)

; (b)  —

—

图3 不同温度下Al-Zn-Mg-Sc-Zr合金流变应力与应变速率的关系

Fig.3 Relationships between flow stress and strain rate of Al-Zn-Mg-Sc-Zr alloy

图4 Al-Zn-Mg-Sc-Zr合金流变应力与变形温度的关系

Fig.4 Relationships between flow stress and deformation temperature of Al-Zn-Mg-Sc-Zr alloy

对式(1)两边取自然对数可以得到

(6)

(6)

将所计算的变形激活能和不同变形温度下对应的应变速率代入式(1)可以得到不同的Z值,取其自然对数,再与对应的 和峰值应力一起代入式(6),绘制出相应的

和峰值应力一起代入式(6),绘制出相应的 —

— 关系曲线,如图5所示。可见lnA和n分别为

关系曲线,如图5所示。可见lnA和n分别为 —

— 关系曲线中的截距和斜率,可得n=6.109 17,A=8.362×1018 s-1。

关系曲线中的截距和斜率,可得n=6.109 17,A=8.362×1018 s-1。

将求得的Q、n、A、 等材料参数代入式(4),可得合金的高温变形本构方程为

等材料参数代入式(4),可得合金的高温变形本构方程为

(7)

(7)

图5 流变应力与Z参数的关系

Fig.5 Relationship between flow stress and Zener-Hollomon parameter

2.3 加工图的构建

材料在热加工过程中单位时间体积内所吸收的功率P转换成塑性变形消耗的功率G和变形过程中组织变化所消耗的功率J,他们之间的关系可用以下关系式来表达[10-11, 15-16]:

(8)

(8)

(9)

(9)

(10)

(10)

其中:m值为应变速率敏感因子。当材料处于理想线性耗散状态时,m=1,J达到最大值,即

(11)

(11)

定义反映材料功率散耗特征的无量纲参数能量散耗效率因子为 ,用应变速率敏感因子(m)表示为

,用应变速率敏感因子(m)表示为

(12)

(12)

失稳图是根据不可逆热力学极值原理,用无量纲参数 来表示塑性变形时的连续失稳判据,Prasad根据最大熵原理材料失稳判据为

来表示塑性变形时的连续失稳判据,Prasad根据最大熵原理材料失稳判据为

(13)

(13)

根据图1求出应变量为0.2和0.5(真应变大于0.5时加工图变化不大,故本研究只讨论真应变为0.2和0.5的加工图),不同变形温度不同变形条件下的真应力 ,采用3次样条插值函数拟合

,采用3次样条插值函数拟合 —

— 关系曲线,拟合函数为

关系曲线,拟合函数为

(14)

(14)

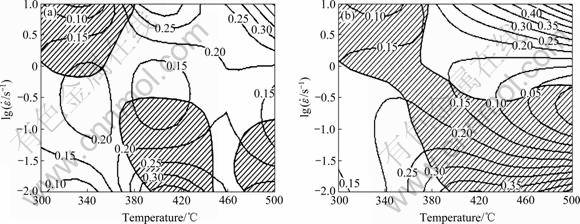

其关系曲线如图6所示,从而可以得到不同温度下拟合函数中的a、b、c和d,由式(8)可得

(15)

(15)

从而求得不同变形条件下的应变速率敏感因子m,然后通过式(12)求出不同变形温度不同应变速率的耗散效率因子 ,在T—

,在T— 平面内绘制能量耗散效率因子

平面内绘制能量耗散效率因子 的等值轮廓线,即为能量耗散图,如图7所示。

的等值轮廓线,即为能量耗散图,如图7所示。

将式(15)带入式(13)得到变量为

(16)

(16)

将不同变形条件下的m值带入式(16),在T— 平面内绘制m的等值轮廓线,可得不同变形温度应变速率条件下的流变失稳图,如图8所示。

平面内绘制m的等值轮廓线,可得不同变形温度应变速率条件下的流变失稳图,如图8所示。

将能量耗散图和流变失稳图叠加可得加工图,如图9所示,其中阴影部分为失稳区(即 区),等值线表示的是能量耗散效率的大小。

区),等值线表示的是能量耗散效率的大小。

合金在非稳定变形区域内对应的工艺参数下进行塑性变形,对微观组织不利,会出现各种缺陷,所以应避免在这个区域内进行热加工。从图9可以看出,该合金热变形时当真应变为0.2时,存在3个失稳区(即图9(a)中3个阴影区域),分别为变形温度为小于380 ℃,应变速率大于0.56 s-1;变形温度为370~450 ℃,应变速率小于0.32 s-1;变形温度大于465 ℃,应变速率小于0.19 s-1。当真应变为0.5时,失稳区较真应变为0.2时有所扩大,并且连成一块,主要为以下两个部分:变形温度小于360 ℃,应变速率大于0.32 s-1;变形温度大于380 ℃,应变速率小于0.56 s-1。所以,合金变形时应避免在失稳区域变形。

图6 三次多项式拟合曲线

Fig.6 Interpolating curves obtained by three order polynomial fitting: (a) ; (b)

; (b)

图7 能量耗散图

Fig.7 Power dissipation map: (a) ; (b)

; (b)

图8 不同变形温度和应变速率下流变失稳图

Fig.8 Flow instability map under different temperatures and strain rates: (a) ; (b)

; (b)

图9 不同真应变下的加工图

Fig.9 Processing map at different true strains: (a) ; (b)

; (b)

真应变为0.2时,是合金开始变形的阶段,在此变形阶段,该合金的适合加工的变形条件范围为变形温度为小于360 ℃、应变速率小于0.56 s-1或变形温度大于380 ℃,应变速率大于0.32 s-1。一般实际加工中变形量较大,确定该合金的变形优化参数应该在真应变较大的条件下确定的,而经研究表明,当真应变大于0.5时,该合金的加工图变化不大,所以以真应变为0.5的加工图来确定该合金的加工优化工艺。根据真应变为0.5 的加工图可知,该Al-Zn-Mg-Sc-Zr合金的适合加工的变形条件范围如下:变形温度小于 360 ℃、应变速率小于0.32 s-1,或变形温度大于380 ℃、应变速率大于0.56 s-1。分析该合金的加工图可以将加工优化工艺分为两个变形条件:低温低速,该变形区适合温变形如挤压等变形方式;高温高速,该变形区域适合高温变形如轧制变形等加工手段。

3 讨论

金属在高温塑性变形时,同时存在着加工硬化和动态软化两个过程。加工硬化是由于在外加应力作用下位错密度增加,并且在运动过程中被晶界、杂质活第二相阻碍而导致许多位错被钉扎住而难以运动。动态软化可使位错密度降低或位错重新排列成低能量状态的组织。在热形变过程中,主要的软化机制为动态回复和动态再结晶。

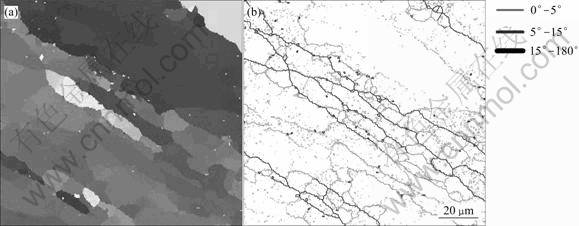

在热变形初期,合金内位错密度陡然增加,而合金中的晶界、杂质、位错缠结及第二相粒子都能阻碍位错运动,位错运动到这些位置就会被阻止,从而产生位错塞积群,使合金产生加工硬化,变形抗力增加,使得流变应力在热变形初期随应变的增加几乎呈直线迅速增大至峰值(见图1)。流变应力达到峰值以后,进入稳态变形阶段,流变应力基本保持不变。此时,合金中位错增值和位错间由于相互作用而引起的相互销毁和重组之间达到动态平衡,合金变形组织中以亚晶组织为主,并且亚晶平均尺寸、亚晶间平均取向差较小,合金中发生“重复多边形化”,表现出强烈的动态回复行为[17-18]。变形温度为300~500 ℃,应变速率为0.01~1 s-1时该合金变形后均呈现出以上特征,典型特征如图10所示,图10表现的是温度为400 ℃,应变速率为1 s-1变形条件下合金的晶粒取向及晶界图。

合金在高温高应变速率下变形时,变形时间短,螺型位错的交滑移和刃型位错的攀移所产生的动态回复有限,亚晶界未能很好的形成,晶内的位错密度依然保持较高水平,从而使得金属内部的储能迅速增加,达到了发生动态再结晶所需的驱动力,最终导致动态再结晶的发生,如图11所示(变形条件为500 ℃、10 s-1时合金的晶粒取向及晶界图),在被拉长晶粒的晶界处形成了细小的再结晶晶粒,并且晶粒间的取向差较大。在应变速率为10 s-1、变形温度为300~500 ℃的变形条件下均表现出这些特征。

图12所示为不同变形条件下合金的金相组织。其中图12(a)的变形条件位于加工图的安全加工区,从图中可以看到变形组织未出现裂纹、孔洞和剪切带等失稳现象;图12(b)的变形条件位于加工图的失稳区,从图中可以发现有较多的裂纹,说明该区域已经发生了流变失稳现象。而其他分别位于安全加工区和流变失稳区变形条件下的组织分别类似于图12(a)和12(b),这也证实了加工图的准确性。

图10 400 ℃、1 s-1条件下合金的晶粒取向及晶界图

Fig.10 Grain orientation map and grain boundary map of alloy at 400 ℃, 1 s-1: (a) Grain orientation map; (b) Grain boundary map

图11 500 ℃、10 s-1条件下合金的晶粒取向及晶界图

Fig.11 Grain orientation map and grain boundary map of alloy at 500 ℃, 10 s-1: (a) Grain orientation map; (b) Grain boundary map

图12 不同变形条件下合金的金相组织

Fig.12 Optical microstructures at different conditions: (a) 450 ℃, 10 s-1; (b) 500 ℃, 0.01 s-1

通过加工图得到的两个适合加工的变形条件分别为低温低速和高温高速,对比两个区域发现,高温高速区能耗因子要大得多,其中变形条件为500 ℃、10 s-1时功率耗散效率 值为0.6。在该变形条件下真应力—真应变曲线为动态再结晶型曲线,而该变形条件的组织为典型的动态再结晶组织。一般在选择最优变形工艺时应当遵循安全区内能量耗散效率

值为0.6。在该变形条件下真应力—真应变曲线为动态再结晶型曲线,而该变形条件的组织为典型的动态再结晶组织。一般在选择最优变形工艺时应当遵循安全区内能量耗散效率 值越高越好,如果发生动态再结晶应当首选动态再结晶变形条件,因为动态再结晶组织容易得到控制,从而可以控制合金的性能。综合考虑该合金最优的变形工艺为500 ℃、10 s-1。

值越高越好,如果发生动态再结晶应当首选动态再结晶变形条件,因为动态再结晶组织容易得到控制,从而可以控制合金的性能。综合考虑该合金最优的变形工艺为500 ℃、10 s-1。

4 结论

1) Al-5.5Zn-1.5Mg-0.2Sc-0.1Zr合金高温变形的峰值应力随着变形温度的升高而降低。合金在实验条件下变形时出现稳态流变特征。在温度为300~500 ℃、应变速率为0.01~1 s-1的变形条件下,该合金发生了典型的动态回复,而在应变速率为10 s-1,变形温度为300~500 ℃的变形条件下发生了动态再结晶。

2) Al-5.5Zn-1.5Mg-0.2Sc-0.1Zr合金高温变形时的本构方程为

3) Al-5.5Zn-1.5Mg-0.2Sc-0.1Zr合金在高温压缩变形过程中,随着真应变增加,流变时失稳区增大,该合金适宜的变形条件范围为变形温度300~360 ℃、应变速率0.01~0.32 s-1或变形温度380~500℃,应变速率0.56~10 s-1,在实验条件下最优的变形工艺为 500 ℃、10 s-1。

REFERENCES

[1] 戴晓元, 夏长清, 吴安如, 王杰文, 李杨勇. 含钪超高强铝合金的研究现状及发展趋势[J]. 材料导报, 2006, 20(5): 104-107.

DAI Xiao-yuan, XIA Chang-qing, WU An-ru, WANG Jie-wen, LI Yang-yong. Present research and developing trends of ultra high strength aluminium alloy contained scandium element[J]. Materials Review, 2006, 20(5): 104-107.

[2] DEV S, STUART A A, KUMAAR R C R D, KUMAAR B S, RAO K P. Effect of scandium additions on microstructure and mechanical properties of Al-Zn-Mg alloy welds[J]. Materials Science and Engineering A, 2007, 467(1/2): 132-138.

[3] ZOU Liang, PAN Qing-lin, HE Yun-bing, WANG Chan-zhen, LIANG Wen-jie. Effect of minor Sc and Zr addition on microstructures and mechanical properties of Al-Zn-Mg-Cu alloys[J]. Transactions of Nonferrous Metals Society of China, 2007, 17(2): 340-345.

[4] KIM J H, KIM J H, YEOM J T, LEE D G, LIM S G, PARK N K. Effect of scandium content on the hot extrusion of Al-Zn-Mg-(Sc) alloy[J]. Journal of Materials Processing Technology, 2007, 187/188(12): 635-639.

[5] WU L M, WANG W H, HSU Y F, TRONG S. Effects of homogenization treatment on recrystallization behavior and dispersoid distribution in an Al-Zn-Mg-Sc-Zr alloy[J]. Journal of Alloys and Compounds, 2008, 456(1/2): 163-169.

[6] SENKOV O N, BHAT R B SENKOVA S V, SCHLOZ D. Microstructure and properties of cast ingots of Al-Zn-Mg-Cu alloys modified with Sc and Zr[J]. Metallurgical and Materials Transactions A, 2005, 36(8): 2115-2126.

[7] 李慧中, 张新明, 陈明安, 周卓平. 2519铝合金热变形行为[J]. 中国有色金属学报, 2005, 15(4): 621-625.

LI Hui-zhong, ZHANG Xin-ming, CHEN Ming-an, ZHOU Zhuo-ping. Hot deformation behavior of 2519 aluminum alloy[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(4): 621-625.

[8] CERRI E, EVANGELISTA E, FORCELESS A, MCQUEEN H J. Comparative hot workability of 7012 and 7075 alloys after different pretreatments[J]. Materials Science and Engineering A, 1995, 197(1/2): 181-198.

[9] LIN Gao-yong, ZHANG Zhen-feng, ZHANG Hui, PENG Da-shu, ZHOU Jia. Study on the hot deformation behaviors of Al-Zn-Mg-Cu-Cr aluminum alloy[J]. Acta Metallurgica Sinica, 2008, 21(2): 109-115.

[10] JAQAN R G, SRINIVASAN N, GOKHALE A A, KASHYAP B P. Processing map for hot working of spray formed and hot isostatically pressed Al-Li alloy (UL40)[J]. Journal of Materials Processing Technology, 2009, 209(18/19): 5964-5972.

[11] MENG Gang, LI Bo-long, LI Hong-mei, HUANG Hui, NIE Zuo-ren. Hot deformation and processing maps of an Al-5.7wt.% Mg alloy with erbium[J]. Materials Science and Engineering A, 2009, 517(1/2): 132-137.

[12] WANG Yu, LIU Dong-liang, LAY C C. A correlation between tensile flow stress and Zenner-Hollomon factor in TiAl alloys at high temperatures[J]. Journal of Materials Science Letters, 2000, 19(13): 1185-1188.

[13] SPIGARELLI S, EVANGELISTA E, MCQUEEN H J. Study of hot workability of a heat treated AA6082 aluminum alloy[J]. Scripta Materialia, 2003, 49(2): 179-183.

[14] MCQUEEN H J, RYAN N D. Constitutive analysis in hot working[J]. Materials Science and Engineering A, 2002, 322(1/2): 43-63.

[15] LUO Jiao, LI Miao-quan, YU Wei-xin, LI Hong. Effect of the strain on processing maps of titanium alloys in isothermal compression[J]. Materials Science and Engineering A, 2009, 504(1/2): 90-98.

[16] SRINIVASAN N, PRASAD Y V R K, RAO P R. Hot deformation behavior of Mg-3Al alloy—A study using processing map[J]. Materials Science and Engineering A, 2008, 476(1/2): 146-156.

[17] MCQUEEN H J, YUE S, RYAN N D, FRY E. Hot working characteristics of steels in austenitic state[J]. Journal of Materials Processing Technology, 1995, 53(1/2): 293-310.

[18] MCQUEEN H J, FRY E, BELLING J. Comparative constitutive constants for hot working of Al-4.4Mg-0.7Mn (AA5083)[J]. Journal of Materials Engineering and Performance, 2001, 10(2): 164-172.

(编辑 李艳红)

基金项目:国家民口配套项目(JPPT-115-2-948)

收稿日期:2010-05-24;修订日期:2010-12-30

通信作者:李慧中,副教授,博士;电话:0731-88830377;E-mail: lhz606@mail.csu.edu.cn