文章编号:1004-0609(2010)01-0125-07

SiC颗粒尺寸对镍基复合镀层耐磨性和耐蚀性的影响

吴俊升,李晓刚,孔 明,董超芳

(北京科技大学 新材料技术研究院 腐蚀与防护中心,北京100083)

摘 要:在正交实验基础上,对比研究微米SiC(平均粒径1.5 μm)和纳米SiC(平均粒径20 nm)增强复合镍基镀层的摩擦磨损行为和耐腐蚀性能。通过TEM、SEM、EDX和XRD等手段研究颗粒分散状态以及复合镀层的表面和截面形貌、成分及相结构。采用球?盘滑动摩擦磨损试验机研究复合镀层的耐磨性。电化学阻抗谱测量在3.5%的NaCl水溶液中进行。结果表明:微米级颗粒增强复合镀层可以获得更高的表面硬度,两种增强复合镀层具有相似的摩擦磨损行为。电化学阻抗谱分析表明:SiC颗粒的加入可以提高镀层的耐腐蚀性,且纳米颗粒复合镀层具有更好的耐蚀性。

关键词:复合镀层;镍;SiC颗粒;耐磨耐蚀性能

中图分类号:TG 153.2 文献标识码:A

Influence of SiC particle size on wear and corrosion resistance of electrodeposited Ni- SiC composite coatings

WU Jun-sheng, LI Xiao-gang, KONG Ming, DONG Chao-fang

(Corrosion and Protection Center, Institute of Advanced Materials,

University of Science and Technology Beijing, Beijing 100083, China)

Abstract: Ni-SiC composite coatings were prepared by the co-electrodeposion of Ni matrix with micron and nano-sized SiC particles (1.5 μm and 20 nm), respectively. The microstructure, hardness, tribological properties and corrosion behaviours of the composite coating on medium carbon steels were investigated. The results indicate that the incorporation of SiC particles in metallic matrix significantly improves the hardness and wear resistance of deposited layer. Moreover, the hardness of the composite coatings is much more improved by the micron-particles than by the nano-sized ones, while there is almost no difference for wear and abrasion resistance between these two sized particles reinforced composite coatings. The corrosion behavior of the composite coatings was evaluated by the electrochemical impedance spectroscopy in 3.5% NaCl solution at room temperature. It is observed that the composite coatings incorporated with SiC particles provide higher corrosion resistance than the pure Ni coating, moreover, the incorporation of the nano SiC particles significantly improves the corrosion resistance than that of the micron-sized ones. The mechanism of improvement of wear resistance and corrosion resistance for the composite coatings was also discussed.

Key words: electrodeposited composite coating; nickel; SiC particle; wear and corrosion resistance

颗粒增强金属基复合镀层技术是近年来表面材料改性和强化研究的热点之一。在金属基镀层体系中复合共沉积金属氧化物、陶瓷、金刚石等第二相颗粒,能够产生显著的弥散强化效应,使镀层的韧性、强度、硬度等性能得到大幅的提高[1]。Ni/SiC镀层是一类研究较早,应用也较为成功的耐磨复合镀层[2?4]。人们往往比较关注Ni/SiC复合镀层的力学和耐磨性能,而就其耐腐蚀方面的研究则很少。通过复合第二相颗粒制备的复合金属镀层在材料表面力学性能得到提高的同时,其耐腐蚀性能却变差。这主要是颗粒的加入使镀层结构中渗透性缺陷增加所致。GARCIA等[5]研究表明,镀层中复合微米级SiC会导致点蚀电位降低,促进基体金属的局部腐蚀。而当复合SiC颗粒尺度小到亚微米级时,镀层的点蚀敏感性显著降低。近年来,为改善颗粒增强镍基复合镀层的耐蚀性,人们把更多的目光都转向了纳米颗粒增强复合镀层方面的研究。研究表明[6?7],复合一定量的纳米SiC颗粒可以使Ni基镀层的耐磨性和耐蚀性都得到提高。但由于纳米颗粒极易团聚,给实际应用带来了很大的困难。KUO 等[8]研究发现,由于纳米颗粒在镀液中很快团聚,导致Ni镀层中颗粒尺度为微米级的二次团聚颗粒,随着镀液中添加纳米颗粒浓度的增加这种团聚越发严重,而且团聚也导致了镀层中纳米颗粒复合量的减少。AAL等[9]研究发现,Ni基镀层中纳米AlN的复合量达到41%才可以得到较高的耐蚀性和耐磨性。同时,也有研究认为[10],相对于微米尺度增强相颗粒,纳米SiC颗粒对镍基复合镀层摩擦磨损性能的影响并不 明显。

大量的研究表明,采用微米级颗粒作为增强相可以大大提高Ni基复合镀层的力学性能,但对镀层的耐腐蚀性的影响仍然存在较大的争论。超细纳米颗粒可以提高镀层的耐蚀性,但其对复合镀层摩擦磨损性能的影响尚不明确。通常,造成这些分歧的主要原因是所采用的实验体系和条件不同。本文作者在尽可能一致的实验条件下,通过直流电沉积的方法分别制备含微米和纳米SiC增强相颗粒的镍基复合镀层,并对比研究SiC颗粒尺度对镍基复合镀层硬度、耐磨性及其耐腐蚀性的影响。

1 实验

实验选用的基材为普通碳钢O235,试样加工后的尺寸为40 mm×25 mm×2 mm。试样表面预处理过程为:砂纸打磨?丙酮除油?热水洗?冷水洗?除锈?水洗?5%硫酸活化?水洗?吹干。阳极为纯度99.9%的电解镍板,阳阴极表面积比约为2?1。镀液成分为:硫酸镍(NiSO4?6H2O)150~250 g/L,氯化镍(NiCl2?6H2O)40 g/L,氨基乙酸0.05 g/L,硼酸40 g/L,表面活性剂选用十六烷基三甲基溴化铵。实验采用的微米和纳米SiC颗粒的平均粒度分别为1.5 μm和20 nm,使用前要经过超声分散处理。复合镀层通过直流电沉积法制备,采用JPS?3005DG型直流稳压电源,将渡槽置于双显双控恒温磁力搅拌器上施镀。

A

采用H?800型透射电境(TEM)观察颗粒在镀液中的分散情况。采用LEO?1450型扫描电境(SEM)观察镀层表面形貌和截面形貌。采用HVS?1000型显微硬度计测量镀层硬度。

镀层的摩擦磨损性能测量在球?盘滑动UMT摩擦磨损试验机(Universal micro-tribometer)上进行。实验采用的载荷为2 N,回转半径为4 mm,转速为100 r/min,摩擦时间为30 min。实验中可以实时检测摩擦力和摩擦因数的变化。在试样表面磨出一道环形的磨痕后,再用表面形貌仪进行磨痕横截面积的测量,磨痕凹槽的横截面积可以代替磨损体积或磨损质量,直观地反映镀层的耐磨性能。

采用三电极体系在EG&G 2273电化学工作站上测量电化学阻抗谱(EIS),工作电极为镀层试样,参比电极为饱和甘汞电极,辅助电极为铂电极,电解液为3.5%NaCl水溶液,测试温度为室温。扫描频率范围为100 kHz~10 mHz,交流激励信号幅值为5 mV。

2 结果与分析

2.1 表面改性对纳米颗粒分散性的影响

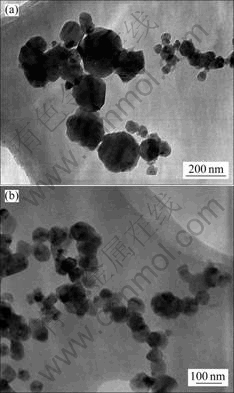

纳米颗粒具有较高的比表面积和大量的化学反应活性位,在镀液中很容易团聚长大。因此,纳米颗粒在镀液中的分散性和稳定性对于制备均匀分布的纳米复合镀层十分关键。为使纳米颗粒在镀液中稳定分散,本研究中采用阳离子表面活性剂十六烷基三甲基溴化铵为分散剂,在施镀前首先将纳米SiC颗粒进行改性,经超声分散均匀后加入镀液中制得稳定的复合镀液。图1所示为镀液中纳米SiC颗粒分散状态的TEM像。由图1可以看出,未添加表面活性剂时,SiC 颗粒在镀液中发生了软团聚,一次纳米颗粒聚集在一起形成了次微米级的二次颗粒;而经过表面活性剂改性后,纳米SiC颗粒的分散状态得到明显的改善,保持了纳米尺度一次颗粒状态。经表面活性剂分散处理制得的纳米复合镀液可以保证纳米颗粒在镀层中均匀分布。

图1 镀液中纳米SiC颗粒的TEM像

Fig.1 TEM images of SiC particles in electrolyte: (a) Without adding dispersant; (b) After adding dispersant

2.2 复合镀层的显微硬度

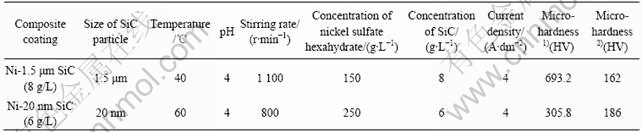

为了对比研究SiC颗粒尺寸对镀层性能的影响,首先通过正交试验考察了温度、电流密度、搅拌速度、主盐浓度、SiC含量、pH值等施镀条件对不同尺寸SiC颗粒增强复合镀层性能的影响,确定添加不同尺寸SiC颗粒时最佳的施镀工艺。镀层的显微硬度通常是反映镀层力学性能的重要指标,为实验方便,在正交实验过程中以镀层的显微硬度作为试验指标。表1所列为在正交实验条件下,以显微硬度为试验指标得出的不同尺寸SiC颗粒增强复合镀层的最佳工艺条件。试验结果显示,镀液中SiC颗粒含量对复合镀层硬度的影响较大,如图2所示。

表1 正交实验得出的最佳施镀条件

Table 1 Optimal operating conditions obtained by orthogonal experiments

1) Composite coating; 2) Pure Ni coating

图2 复合镀层显微硬度与镀液中SiC浓度的关系

Fig.2 Relationship between microhardness of composite coatings and SiC concentration in electrolyte: (a) Ni-1.5 μm SiC; (b) Ni-20 nmSiC2)

由表1可知,相对于纯镍镀层,复合镀层的硬度值都有较大的提高。在本文正交试验所选的施镀条件下,含1.5 μm SiC颗粒的复合镀层硬度值最高可达HV693.2。相对而言,添加纳米级SiC颗粒的复合镀层的硬度值提高较小。从显微硬度的实验结果来看,粒径为1.5 μm左右的SiC颗粒对镀层力学性能的强化作用要优于纳米尺寸SiC颗粒。

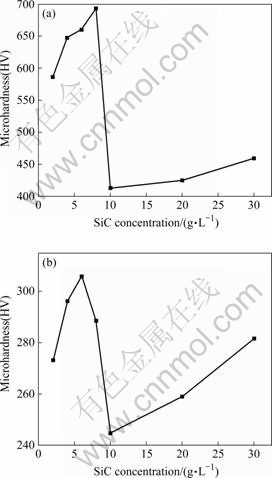

2.3 复合镀层的微观形貌

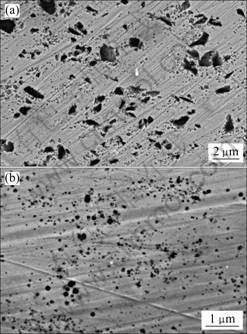

图3所示为镀层表面的微观形貌。由图3(a)可见,纯镍镀层为典型的多面晶粒结构。相对于纯镍镀层,复合镀层的晶粒尺寸变小,且随着复合颗粒尺寸由微米级到纳米级,复合镀层表面晶粒呈无规粒状晶。这种转变可能是由于SiC颗粒在共沉积过程中,镀层晶粒生长择优取向转变所致[11]。由图3(c)可见,复合镀层表面有弥散分布的纳米颗粒,EDX分析证明这些颗粒为SiC颗粒。图4所示为复合镀层截面经抛光处理后的微观形貌。图4(a)中的黑色区域为微米级SiC颗粒在抛光过程中脱落后留下的凹坑,说明微米颗粒在复合镀层中的分布较均匀。而图4(b)中尺寸为100~200 nm的黑色凹坑可能为纳米颗粒团聚体脱落后留下的痕迹,表明二次颗粒数量较少,大部分纳米颗粒在镀

图3 镀层表面的微观形貌

Fig.3 Surface morphologies of electrodeposited coatings: (a) Pure Ni, (b) Ni-1.5 μm SiC (8 g/L), (c) Ni-20 nm SiC (6 g/L)

层金属基体中呈均匀的弥散分布状态。

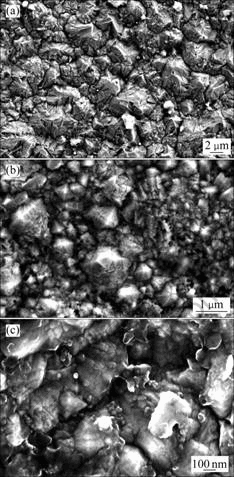

图4 复合镀层截面的微观形貌

Fig.4 Cross-section morphologies of composite coatings: (a) Ni-1.5 μm SiC (8 g/L); (b) Ni-20 nm SiC (6 g/L)

2.4 复合镀层的摩擦磨损行为

如前所述,镀液中SiC颗粒含量是影响复合镀层硬度的主要因素,为对比研究了不同SiC颗粒添加量下制得的复合镀层的耐磨性,选取典型样品在UMT摩擦磨损试验机上测试了复合镀层的摩擦因数变化规律,并采用形貌仪分析了磨损凹槽的截面积,结果如图5和6所示。由图5可以看出,两种尺度SiC颗粒复合镀层的摩擦因数都小于纯镍镀层的,而且随着镀液中SiC颗粒添加量的增加,摩擦因数先降低,达到最小值后又逐渐增加,当镀液中SiC颗粒浓度为4~8 g/L时复合镀层的摩擦因数较小。由图6可以看出,复合镀层磨损凹槽截面积与镀液中SiC颗粒浓度的关系也呈现出相同的变化趋势。

图5 不同SiC浓度复合镀层的摩擦因数变化曲线

Fig.5 Typical friction coefficient curves of composite coatings with different SiC concentrations: (a) Ni-1.5 μm SiC; (b) Ni-20 nm SiC

图6 复合镀层磨损量与镀液中SiC浓度的关系

Fig.6 Relationship between wear-out area of composite coatings and SiC concentration in electrolyte: (a) Ni-1.5 μm SiC; (b) Ni-20 nm SiC

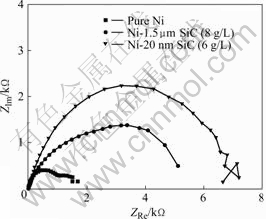

2.5 电化学阻抗谱

图7所示为纯镍镀层和添加微米和纳米SiC颗粒复合镀层在3.5%NaCl水溶液中的电化学阻抗谱。根据Nyquist 图求高频端容抗弧的直径,即为电化学反应电阻Rp(腐蚀电阻)的值,腐蚀电阻越大,表明耐蚀性越强。由图7可以看出,在NaCl水溶液中,复合镀层的容抗弧半径呈 Ni-20 nm SiC(6 g/L)>Ni-1.5 μm SiC(8 g/L)>纯Ni的变化趋势。这表明纳米和微米复合镀层的耐蚀性比纯镍镀层的好,且添加纳米颗粒复合镀层的耐蚀性要优于添加微米颗粒复合镀层的。

图7 复合镀层在3.5%NaCl水溶液中的电化学阻抗谱(Nyquist 图)

Fig.7 Electrochemical impedance spectra (Nyquist diagram) of composite coatings in 3.5%NaCl solution at room temperature

2.6 讨论

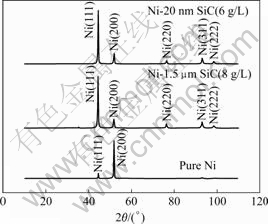

通常认为颗粒增强复合镀层的强化机制包括:细晶强化、颗粒强化、弥散强化等[12]。在本文所述的实验条件下,无论是添加微米SiC颗粒还是纳米SiC颗粒,都起到了晶粒细化的作用。图8所示为纯镍镀层和复合镀层的XRD谱,利用Scherrer公式通过衍射峰半峰宽估算的晶粒尺寸表明,纯镍镀层中Ni的平均晶粒尺寸为63 nm,添加微米SiC颗粒(平均粒径1.5 μm)制备的复合镀层中Ni的平均晶粒尺寸为39 nm,而添加纳米SiC颗粒制备的复合镀层中Ni的平均晶粒尺寸最小,约为24 nm。研究表明[13],由于SiC颗粒增大了电沉积过程的阴极极化和电荷转移电阻,从而增大了阴极表面Ni微晶的成核数目,同时夹杂或吸附在镀层表面的惰性颗粒所起到的空间位阻效应抑制了Ni晶粒的长大,二者的共同作用导致了复合镀层的晶粒细化。SiC颗粒在共沉积过程中起到细化晶粒的同时也改变了镀层Ni晶粒的择优取向。由图8可以看出,纯镍镀层具有明显的(200)晶面择优取向。而添加SiC颗粒后,无论添加的是微米级还是纳米级颗粒,都使Ni晶粒的择优取向变为(111),与纯镍镀层相比,削弱了(200)晶面择优取向,而在(220)、(311)、(222)等晶面上的金属电沉积得到加强。这样就使原来主要集中在这些晶面上的晶格空位缺陷等得到改善,从而提高了金属原子及晶格缺陷在晶体结构中分布的均匀性,这也在一定程度上改善了镀层的微观力学性能[6]。本研究中制备的两种尺度颗粒复合镀层都表现了一定的晶粒细化作用,而且复合纳米SiC效果似乎更加明显。但从前面的实验结果看,微米级颗粒对提高镀层硬度的作用更加明显,这可能与其他两种强化机制有关。

图8 复合镀层的XRD谱

Fig.8 XRD patterns of composite coatings

对于纳米颗粒而言,其在沉积过程中的机理与微米颗粒的不同。在复合镀层中纳米颗粒不仅可以在晶界镶嵌,而且也可以进入镍晶粒内部[10],使复合镀层中位错、孪晶以及各类缺陷等的数量大大提高。因此,纳米颗粒在复合镀层中表现为弥散强化效应。通常认为复合较细小的颗粒(直径<1 μm)才具有较明显的弥散强化效应,但实际上尺寸较大的微米级颗粒在镀层中表现出更加明显的颗粒强化效应。在这种情况下,基质和硬质颗粒同时承受载荷,由于粒径较大的微米级颗粒可以更好地抑制基质的变形而使镀层得到强化,且这种强化作用对镀层硬度的增强作用更加有效。在本文实验条件下制备的复合镀层中,微米复合镀层所获得的高硬度值可能更多地来自于微米级SiC颗粒的硬质颗粒强化效应。

摩擦磨损实验结果显示,两种复合镀层都表现出了较好的耐磨性。对比图5、6和图2可知,复合镀层的耐磨性与镀层表面显微硬度变化具有完全一致的趋势,镀层硬度越高,其耐磨性就越好。对于添加两种不同尺寸SiC颗粒的镀层,微米SiC复合镀层的显微硬度值远大于纳米SiC复合镀层的,但两者的耐磨损性能却呈现了基本相同的特点。这可能要归因于两种尺寸颗粒对复合镀层的强化机制不同,导致复合镀层的摩擦磨损机制具有较大的区别,具体机理还有待于进一步研究。

通过电化学交流阻抗谱测量可知,在3.5%NaCl水溶液中,添加SiC颗粒制得的复合镀层比纯镍镀层具有更高的反应电阻,且纳米复合镀层表现出更好的耐蚀性。复合镀层耐蚀性的提高可以归因于以下几方面[5, 14]:首先,大量惰性SiC颗粒存在于镀层表面,在一定程度上屏蔽或减小了金属基体与腐蚀介质的接触面积;其次,SiC颗粒的晶粒细化效应使复合镀层晶粒变小,加之惰性颗粒在镀层晶界缺陷处的填充镶嵌作用,使复合镀层结构更加均匀和致密,这种作用在纳米复合镀层中更加明显;再次,SiC颗粒在复合电沉积过程中改变了镍晶粒的结晶取向,使复合镀层表面的电位分布趋于均匀化,化学稳定性得到提高。在与镀层表面耐蚀性相关的质量改善方面,纳米复合镀层比微米复合镀层具有先天的优势。

3 结论

1) 在镀液中添加微米级SiC颗粒(平均粒径1.5 μm)对镍基复合镀层硬度的强化效应比在镀液中添加粒度更细的纳米SiC颗粒(平均粒径20 nm)好,但由此制备的两种尺寸颗粒复合镀层的耐磨性基本相当。

2) 电化学阻抗谱测量说明添加SiC颗粒可以提高镀层的耐腐蚀性,且纳米级颗粒增强复合镀层的耐蚀性优于微米级颗粒复合镀层的,但阻抗谱分析并不能对镀层局部腐蚀行为给出准确、全面的反应。

3) SiC颗粒在复合电沉积过程中改变了镍晶粒的结晶取向,使复合镀层表面的电位分布趋于均匀化,化学稳定性得到提高。

REFERENCES

[1] STEINHAUSER S, WIELAGE B. Composite coatings: Manufacture, properties, and applications[J]. Surface Engineering, 1997, 13(4): 289?294.

[2] METZGER W, OTT R, LAUX G. Electrodeposition of dispersion hard end nickel[J]. Galvanotechnic, 1970, 61(12): 998?1005.

[3] TAKEUCHI N, NAGAI T, MIURA T. The adhesive wear resistance of Ni-SiC electrodeposited composite coatings[J]. Journal of the Metal Finishing Society of Japan, 1986, 37(2): 73?77.

[4] AAL A A, IBRAHIM K M, HAMID Z A. Enhancement of wear resistance of ductile cast iron by Ni-SiC composite coating[J]. Wear, 2006, 260(9/10): 1070?1075.

[5] GARCIA I, CONDE A, LANGELAAN G, FRANSAER J, CELIS J P. Improved corrosion resistance through microstructural modifications induced by codepositing SiC-particles with electrolytic nickel[J]. Corrosion Science 2003, 45: 1173?1189.

[6] VAEZI M R, SADRNEZHAAD S K, NIKZAD L. Electrodeposition of Ni–SiC nano-composite coatings and evaluation of wear and corrosion resistance and electroplating characteristics[J]. Colloids and Surfaces A: Physicochem Eng Aspects, 2008, 315: 176?182.

[7] BENEA L, BONORA P L, BORELLO A, MARTELLI S. Effect of SiC size dimensions on the corrosion wear resistance of the electrodeposited composite coating[J]. Materials and Corrosion, 2002, 53(1): 23?29.

[8] KUO S L, CHEN Y C, GER M D, HWU W H. Nano-particles dispersion effect on Ni/Al2O3 composite coatings[J]. Materials Chemistry and Physics, 2004, 86(1): 5?10.

[9] AAL A A, BAHGAT M, RADWAN M. Nanostructured Ni-AlN composite coatings[J]. Surface and Coatings Technology, 2006, 201(6): 2910?2918.

[10] GYFTOU P, STROUMBOULI M, PAVLATOU E A, ASIMIDIS P, SPYRELLIS N. Tribological study of Ni matrix composite coatings containing nano and micro SiC particles[J]. Electrochimica Acta, 2005, 50: 4544?4550.

[11] ZHOU Y, ZHANG H, QIAN B. Friction and wear properties of the co-deposited Ni–SiC nanocomposite coating[J]. Applied Surface Science, 2007, 253: 8335?8339.

[12] ROBIN A, FRATARI R Q. Deposition and characterization of nickel-niobium composite electrocoatings[J]. Journal of Applied Electrochemistry, 2007, 37(7): 805?812.

[13] NIU Z X, CAO F H, WANG W, ZHANG Z, ZHANG J Q, CAO C N. Electrodeposition of Ni-SiC nanocomposite film[J]. Trans Nonferrous Met Soc China, 2007, 17: 9?15.

[14] 张文峰, 朱 荻. Ni-ZrO2 纳米复合电镀层的制备及其耐蚀性研究[J]. 腐蚀科学与防护技术, 2006, 18(5): 325?328.

ZHANG Wen-feng, ZHU Di. Preparation of Ni-ZrO2 nano-composite electrodeposits and its corrosion resistance[J]. Corrosion Science and Protection Technology, 2006, 18(5): 325?328.

基金项目:国家自然科学基金资助项目(50701006);北京市科技计划资助项目(D09030303790901)

收稿日期:2009-02-03;修订日期:2009-07-15

通信作者:吴俊升,副教授,博士;电话:010-62333975;传真:010-62334005;E-mail: wujs76@163.com

(编辑 李向群)