DOI: 10.11817/j.issn.1672-7207.2016.06.023

稠油掺稀降黏评价新方法及模拟分析

柯文奇1,赵仁保2,石在虹1,岳湘安2,吴嘉怡2

(1. 中国石油化工股份有限公司 石油勘探开发研究院,北京,100083;

2. 中国石油大学(北京) 油气资源与探测国家重点实验室,北京,100092)

摘要:在分析现有掺稀降黏评价手段的基础上,建立稠油井筒掺稀降黏模拟评价方法,并研究掺稀比、掺稀温度和掺稀稀释剂对掺稀降黏效果的影响。研究结果表明:在黏度为74 mPa·s时,该评价方法的相对误差为5.36%,并具有较好的稳定性和可靠性,能够适用于稠油的黏度测量分析。掺稀过程伴随整个井筒流动逐渐发生。提高掺稀温度、注入合适的稀释剂均有利于提高掺稀效果,为实际生产优化设计提供有力借鉴。

关键词:稠油;掺稀;模拟;降黏

中图分类号:TE355.21 文献标志码:A 文章编号:1672-7207(2016)06-1990-05

A new viscosity evaluation method of heavy oil production assisted with light oil blending and simulation analysis

KE Wenqi1, ZHAO Renbao2, SHI Zaihong1, YUE Xiang’an2, WU Jiayi2

(1. Petroleum Exploration and Production Research Institute, SINOPEC, Beijing 100083, China;

2. State Key Laboratory of Petroleum Resource Prospecting, China University of Petroleum, Beijing 100092, China)

Abstract: Based on the analysis of the existing light oil blending evaluation method, a new viscosity simulation and evaluation method of heavy oil production assisted with light oil blending was established to study the flowing dynamic and viscosity changes of the mixed oil system in wellbore. And the influences of blending ratio, blending temperature and diluents type were evaluated. The results show that the relative error of evaluation method is less than 5.36% when the fluid viscosity is no more than 74 mPa·s, which means this evaluation method has good stability and reliability for heavy oil viscosity measurement and analysis. The mixed and viscosity reduction evolves with the wellbore flowing. And improving the blending temperature and injection diluted thinners are beneficial to improve the effect, which can provide a powerful reference for practical production for optimization design.

Key words: heavy oil; light oil blending; simulation; viscosity reduction

在稠油开采沿井筒举升过程中,伴随温度降低,黏度呈指数上升,流动阻力迅速增大,造成稠油井堵塞、抽油杆断脱、电机烧坏等系列问题[1]。掺稀油、加热[2]、加降黏剂及举升工艺优化[3]等是实现稠油举升的主要方法。由于稠油性质各异,掺稀降黏仍然是稠油举升最有效的方法之一。国内学者通过实验和模型分析,稠油掺稀降黏能降低井筒摩阻,提高举升效率。多采用旋转黏度计/流变仪[4]开展掺稀效果定量评价,以确定合理的掺稀比例,测量在烧杯中稠油和稀油充分混合的黏度[5],但是实际掺稀举升生产过程中效率并不理想。本文作者通过建立合理的稠油黏度动态模拟测量装置,开展掺稀条件下的井筒流动模拟,对比分析模拟评价结果和旋转黏度计中差异性,并分析掺稀温度和稀释剂对降黏效果的影响,为实际掺稀量的确定和掺稀工艺的优化提供一定借鉴。

1 稠油流变性测量原理

考虑一个半径为R长直圆管,假定流体为黏性不可压缩流体,流动是稳定的、充分发展的等温层流,垂直管道轴线方向没有流速。根据哈根-泊肃叶(hagen-poiseuille)定律,流动过程中管两端压差可以表示为[6]

(1)

(1)

其中:v为流过直圆管的流体流速;Δp为直圆管进口端与出口端之间的压差;ρ为流体密度;L为直圆管的长度; 为流体运动黏度。

为流体运动黏度。

因流体运动黏度等于动力黏度与流体密度之比,即

(2)

(2)

而且流过直圆管的流体流速等于流过直圆管的流体流量与直圆管横截面面积之比,即

(3)

(3)

因此,将式(2)和(3)代入式(1),即可得到流量q和直圆管进口端与出口端之间的压差Δp的关系为

(4)

(4)

从而得到混合液的动力黏度为

(5)

(5)

2 井筒降黏模拟系统建立

2.1 井筒降黏模拟流程

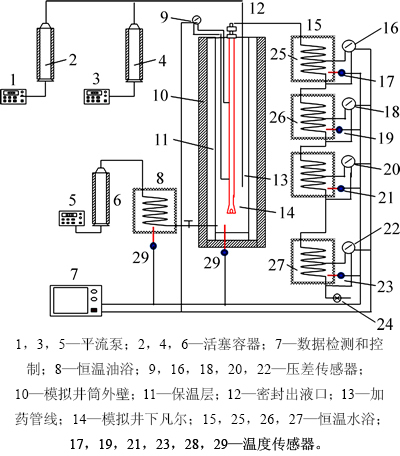

为了模拟稠油掺稀开采过程中,掺入稀油和稠油在井筒中动态混合过程,依据毛细管黏度测量原理,通过建立包括井筒模拟、掺稀注入模拟、供液模拟、恒温模拟和监测控制模拟组成的稠油井筒降黏模拟实验装置[7],如图1所示。该模拟装置通过多个恒温系统(设定不同温度的恒温水浴)模拟井筒沿程过程中温度的变化,并模拟掺稀稀油由环空加注,并和稠油混合流经抽油泵凡尔,进而举升至地面的过程。

考虑稠油体系黏度受温度影响敏感,设计模拟装置需保证每个黏度测量段之前达到恒温,实现40~100 ℃井筒温度区间模拟,且通过热力学计算分析和设计,保证经恒温区间内,原油温度相对误差不超过1%。通过毛细管长度、直径和压力计量系统的组合满足黏度范围为5~4×106 mPa·s流体黏度的测量。

图1 稠油降黏评价物理模拟模型流程图

Fig. 1 Physical simulation model of heavy oil viscosity reduction evaluation

2.2 掺稀降黏模拟测量可靠性

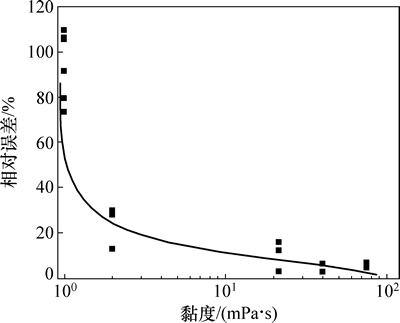

为保证测量的可靠性,实验选取近似牛顿流体液体作为测量系统检验的介质,其黏度受剪切速率和剪切方式影响较小。选取航空煤油和白油作为测量对比介质,采用模拟装置测量结果和旋转黏度计中测量结果进行对比。相对误差随黏度的变化如图2所示。

图2 相对误差随黏度的变化

Fig. 2 Change of error with viscosity

从图2可以看出:模型测量黏度的相对误差随着黏度的增高,相对误差减小,当黏度为74 mPa·s时,相对误差为5.36%。随着黏度的增大,方差σ2减小,可以认为在较高黏度时,黏度测量值具有较好的稳定性和可靠性,适用于稠油的黏度测量分析。

3 井筒掺稀降黏影响因素

3.1 实验仪器及过程

实验仪器为稠油井筒掺稀降黏模拟实验装置(自研)和Brookfield Ⅲ型旋转黏度计。

采用井筒掺稀降黏模拟方法的主要步骤如下。

1) 将中间容器分别装上稠油和掺稀稀油(稀油来自塔河产出稀油,稀油90 ℃时的黏度约为17 mPa·s;40 ℃时其黏度为82 mPa·s),并按照图1所示连接实验装置。

2) 设定井筒模拟温度和可加热中间容器温度为95 ℃,其他恒温水浴温度分别设定为95,90,70,50和40 ℃,恒温3 h以上,以保证稠油和整个系统的温度达到恒定温度,以减小温度对测量的影响。掺稀稀油保持温度为常温,以模拟实际油田掺稀稀油的注入温度。

3) 通过设定2个平流泵的流量来控制稠油流量以及掺稀比,压力计量装置测量并记录各毛细管段压差,记录实验结果。

4) 采用烧杯配置同样掺稀量,充分恒温(70 ℃保鲜膜密封条件)后搅拌均匀,Brookfield Ⅲ型旋转黏度计中定剪切(2.45 s-1)测量原油(95,90,70,50和40 ℃)黏度,取波动后黏度稳定值,与稠油井筒降黏模拟装置测量结果进行对比分析。

3.2 实验结果及讨论

3.2.1 掺稀量对降黏效果的影响

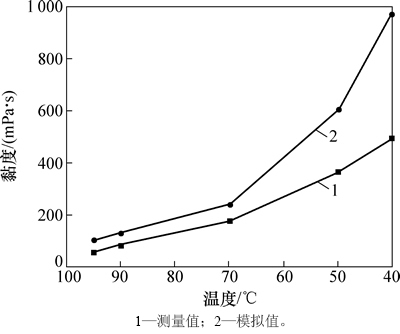

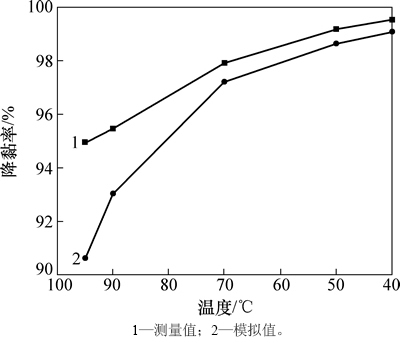

实验采用模拟装置和黏度计方式分别测量不同掺稀量时黏度,分析降黏效率。旋转黏度计和在线测量装置测量得到不同掺稀量下的黏度测量值和降黏率变化。掺稀量50%时混合组分的黏温曲线和降黏度随温度的变化分别如图3和图4所示。

从图3和图4可以看出:当掺稀量为50%时,降黏率模拟值在90.0%(95 ℃)~99.5%(40 ℃)之间;而测定的降黏率在95.0%(95 ℃)~99.7%(40 ℃)之间,即降黏率模拟值比测定的结果低。但在整个温度区间,变化趋势相同,模拟与测量所得降黏率均随温度降低而增大。稠油的黏度主要是胶质沥青质影响。在温度较高时,稠油体系黏度较小,胶质沥青质分子间间距较大,掺稀时轻质组分对胶质沥青质的分散作用相对较弱,降黏效率偏小。

图3 掺稀量50%时混合组分的黏度-温度曲线

Fig. 3 Viscosity-temperature curves of heavy oil blending light oil of 50%

图4 掺稀量50%时的降黏率随温度的变化

Fig. 4 Change of viscosity reduction rate with blending light oil of 50%

掺稀模拟结果小于测量值表明:在实际过程中,掺入稀油并不能达到理想状态下的降黏效率。但沿井筒流动过程中,模拟和测量得到的降黏率逐渐接近,表明流动过程是稀油逐渐分散稠油的过程,并不是在井底就能达到理想混合效果,那么需要在实际设计过程中加以考虑。

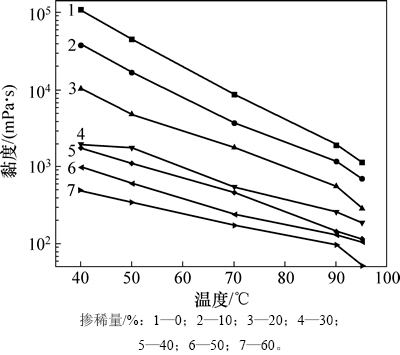

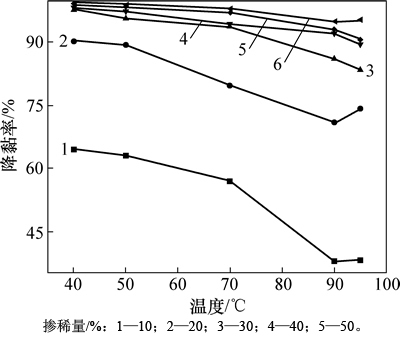

图5和图6所示分别为不同掺稀量时混合体系的黏度和降黏率随温度的变化。由图5和图6可见:随着掺稀量的增加降黏率不断增高,随着温度的升高,降黏率呈降低趋势,但降低幅度随掺稀量的增加而减小。

图5 不同掺稀量下体系黏度-温度曲线

Fig. 5 Viscosity-temperature curves of different blending ratios

图6 不同掺稀量下降黏率变化

Fig. 6 Viscosity reduction rate of different blending ratios

稠油是一种由沥青质和胶质组成的胶体[8]。沥青质、胶质分子间的缔合是稠油高黏的根本原因[9]。稠油黏度随胶质沥青质含量的增加而升高,而随饱和烃和芳烃含量的增加而降低。掺稀量增加,轻质组分对沥青质分散程度增强,原油黏度减小。但随掺稀量的增加,当沥青分子间距达到一定程度时,增加掺稀量降黏效率趋势变小。

3.2.2 掺稀温度对降黏效果的影响

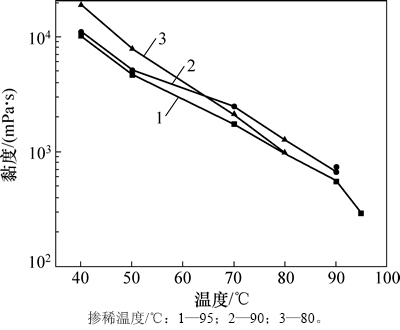

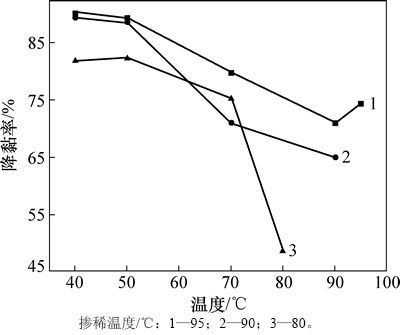

为分析不同的掺稀温度对掺稀稀油和稠油的动态混合,调整模拟井筒温度控制(设定为80,90和95 ℃),来模拟不同掺稀温度,而其他恒温水浴均分别依次设定为80,70,50和40 ℃模拟井筒沿程温降。实验设定掺稀量为20%。不同掺稀温度下黏度和降黏率的变化分别如图7和图8所示。

图7 不同初始掺稀温度下原油黏度-温度曲线

Fig. 7 Oil viscosity-temperature curves at different blending temperatures

图8 不同初始掺稀温度下降黏率变化

Fig. 8 Viscosity reduction ratios at different blending temperatures

由图7和图8可见:随着掺稀温度越高,降黏效果越好。随着掺稀温度的提高,稠油黏度降低,分子热运动加快,在相同流速下,即相同的剪切速率下,稀油中的轻质组分分子更加有效地向稠油中扩散,分散稠油中的胶质沥青质,降低体系黏度。

实际生产过程中提高掺稀温度有3种方法:一是加深掺稀深度,对于产量固定的油井,加深稀油和稠油的混合点,也就是加深泵深/泵入口[10];二是提高产量,产量影响井筒温度场分布,提高产量可降低温度损失;三是提高地面稀油温度。因此,选择合理注入工艺、举升工艺和工作制度均能提高掺稀降黏效果。

3.2.3 不同稀释剂对降黏剂降黏效果的影响

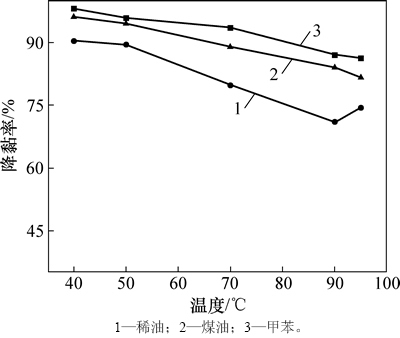

为分析不同组分对掺稀降黏效果的影响,选取稀油、煤油、甲苯作为掺稀溶剂,模拟分析掺稀量为20%时,温度为95,80,70,50和40 ℃,模拟得到不同稀释剂对降黏效果的影响。

采用不同稀释剂作为掺稀介质开展模拟结果如图9所示。模拟结果表明:采用甲苯作为稀释介质时的降黏效果要优于煤油和稀油的降黏效果。稠油中胶质沥青质含量较高,甲苯对稠油降黏效果更优,沥青质在可溶质中对沥青质的胶溶性起主导作用的是芳香族化合物及其含量[11]。芳香族化合物最易被沥青质吸附,对其有很好的胶溶能力。而煤油和稀油以烷烃为主,煤油具有更低的黏度,表现出较好的效果。

图9 不同稀释剂条件下的降黏率

Fig. 9 Viscosity reduction ratio with different diluents

4 结论

1) 井筒掺稀降黏是伴随着井筒中的流动逐渐发生的,井筒掺稀过程是稀油不断分散稀释稠油的过程。

2) 随着掺稀温度的增加,降黏率越大,降黏效果越好,可以通过增加泵深、提高产量和掺稀稀油的温度提高掺稀降黏效果。

3) 稀释剂的降黏效果从大到小依次为甲苯、煤油、稀油。

参考文献:

[1] 曲占庆, 刘宏亭. 深层稠油掺稀油举升方法研究[J]. 油气采收率技术, 2000(3): 26-28.

QU Zhanqing, LIU Hongting. Deep heavy oil mixing thin oil lifting method research[J]. Petroleum Geology and Recovery Efficiency, 2000(3): 26-28.

[2] 刘明辉, 张庚祥. 井筒电加热技术在稠油试油试采中的应用[J]. 石油钻采工艺, 1998(3): 95-98.

LIU Minghui, ZHANG Gengxiang. Wellbore electric heating technology application in the test of heavy oil well[J]. Oil Drilling & Production Technology, 1998(3): 95-98.

[3] 袁波, 杜林辉, 梁志艳, 等. 稠油掺稀液压反馈式抽稠泵杆柱设计优化[J]. 西南石油大学学报(自然科学版), 2013, 35(5): 157-164.

YUAN Bo, DU Linhui, LIANG Zhiyan, et al. Rod design optimization of the hydraulic feedback pump of heavy oil mixed with light oil[J]. Journal of Southwest Petroleum University (Science & Technology Edition), 2013, 35(5): 157-164.

[4] 顾琳婕, 黄启玉, 马桂霞, 等. 掺稀质量对油井产出液降粘效果的影响[J]. 辽宁石油化工大学学报, 2011, 31(1): 1-4.

GU Linjie, HUANG Qiyu, MA Guixia, et al. Effects of light oil on rheology behavior of produced mixture[J]. Journal of Liaoning Shihua University, 2011, 31(1): 1-4.

[5] 张素青, 张祖国, 柯文奇, 等. 新疆深层稠油井筒掺稀降黏举升摩阻分析[J]. 石油钻采工艺, 2013(6): 91-94.

ZHANG Suqing, ZHANG Zuguo, KE Wenqi, et al. Xinjiang deep heavy oil wellbore blending diluting lift friction drag analysis[J]. Oil Drilling & Production Technology, 2013(6): 91-94.

[6] 李传宪, 罗哲鸣. 原油流变性及测量[M]. 东营: 石油大学出版社, 1994: 58-74.

LI Chuanxian, LUO Zheming. Crude oil trheology and measurement[M]. Dongying: Petroleum University Press, 1994: 58-74.

[7] 赵仁保, 柯文奇, 岳湘安, 等. 稠油井筒举升降粘模拟装置及方法: CN102852498A[P]. 2013-04-02.

ZHAO Renbao, KE Wenqi, YUE Xiangan, et al. Wellbore viscosity reduction simulation device and method of heavy oil production: CN102852498A[P]. 2013-04-02.

[8] 王子军. 石油沥青质的化学和物理IV: 石油沥青质溶液的胶体化学[J]. 石油沥青, 1996, 10(3): 36-48.

WANG Zijun. Petroleum asphaltene IV: the chemical and physical solution of petroleum asphaltene colloid chemistry[J]. Petroleum Asphalt, 1996, 10(3): 36-48.

[9] 李晓辉. 沥青质相分离行为与抑制基础研究[D]. 东营: 中国石油大学(华东)化学工程学院, 2008: 51-54.

LI Xiaohui. The asphalt phase separation behavior and inhibit research[D]. Dongying: China University of Petroleum (East China). School of Chemical Engineering, 2008: 51-54.

[10] 杜林辉, 梁志艳, 蒋磊, 等. 稠油机采井泵深与掺稀混配点分离设计及应用[J]. 特种油气藏, 2014(3): 145-147.

DU Linhui, LIANG Zhiyan, JIANG Lei, et al. Deep well pump separated from mixed rare mixed point design and application in heavy oil well[J]. Journal of Special Reservoirs, 2014(3): 145-147.

[11] 柴静, 彭雅娟, 洪金庆, 等. 采用掺稀降粘法探索新疆超稠油的应用[J]. 石油化工应用, 2009(1): 41-45.

CHAI Jing, PENG Yajuan, HONG Jinqing, et al. Exploring the use of the super heavy oil from Xinjiang by blending diluting solvents technology[J]. Petrochemical Industry Application, 2009(1): 41-45.

(编辑 赵俊)

收稿日期:2015-06-13;修回日期:2015-09-20

基金项目(Foundation item):国家科技重大专项(2011ZX05031-003-004)(Project(2011ZX05031-003-004) supported by the National Science and Technology Major Program of China)

通信作者:赵仁保,副教授,从事采油气工艺研究;E-mail:zhaorenbao@vip.sina.com