异种搅拌摩擦焊AA5083-H111和AA6351-T6铝合金的力学和冶金性能

来源期刊:中国有色金属学报(英文版)2014年第1期

论文作者:R. PALANIVEL P. KOSHY MATHEWS I. DINAHARAN N. MURUGAN

文章页码:58 - 65

关键词:铝合金;搅拌摩擦焊;焊接速度;抗拉强度;显微组织

Key words:aluminum alloys; friction stir welding; welding speed; tensile strength; microstructure

摘 要:研究异种搅拌摩擦焊AA5083-H111和AA6351-T6铝合金的微观结构和力学性能。在3种不同的焊接速度(36、63、90 mm/min)下焊接AA5083-H111和AA6351-T6铝合金,分析焊接速度对接头力学和冶金性能的影响。结构表明,与其他焊接速度相比,焊接速度为63 mm/min 时接头的力学性能和冶金性能较好。焊缝区由未混合区、机械混合区和混流区组成。所观察到的断裂模式为韧性纤维断裂。

Abstract: The microstructure and mechanical characterization of dissimilar friction stir welded AA5083-H111 and AA6351-T6 aluminum alloys were studied. Three different welding speeds (36, 63 and 90 mm/min) were used to weld the dissimilar alloys. The effect of welding speed on mechanical and metallurgical properties was analyzed. It is found that the welding speed of 63 mm/min produces better mechanical and metallurgical properties than other welding speeds. The weld zone is composed of three kinds of microstructures, namely unmixed region, mechanically mixed region and mixed flow region. The fracture mode was observed to be a ductile fibrous fracture.

Trans. Nonferrous Met. Soc. China 24(2014) 58-65

R. PALANIVEL1, P. KOSHY MATHEWS2, I. DINAHARAN3, N. MURUGAN4

1. Department of Mechanical Engineering, Roever College of Engineering and Technology, Perambalur, 621212, Tamil Nadu, India;

2. Department of Mechanical Engineering, Kalaivani College of Technology, Coimbatore, 641105, Tamil Nadu, India;

3. Department of Mechanical Engineering, V V College of Engineering, Tisaiyanvilai, 627657, Tamil Nadu, India;

4. Department of Mechanical Engineering, Coimbatore Institute of Technology, Coimbatore, 641014, Tamil Nadu, India

Received 7 April 2013; accepted 12 September 2013

Abstract: The microstructure and mechanical characterization of dissimilar friction stir welded AA5083-H111 and AA6351-T6 aluminum alloys were studied. Three different welding speeds (36, 63 and 90 mm/min) were used to weld the dissimilar alloys. The effect of welding speed on mechanical and metallurgical properties was analyzed. It is found that the welding speed of 63 mm/min produces better mechanical and metallurgical properties than other welding speeds. The weld zone is composed of three kinds of microstructures, namely unmixed region, mechanically mixed region and mixed flow region. The fracture mode was observed to be a ductile fibrous fracture.

Key words: aluminum alloys; friction stir welding; welding speed; tensile strength; microstructure

1 Introduction

Dissimilar welding of aluminum alloys AA6xxx and AA5xxx is often faced in the fabrication of aircraft structures and other structural applications [1]. Numerous welding defects occur in traditional fusion welding of aluminum alloys such as voids, hot cracking, distortion, precipitate dissolution, loss of work hardening, hot cracking and lack of penetration in the joints [2]. Therefore, solid state welding technique is preferred to solve those defects.

Friction stir welding (FSW) is an appropriate solid state welding technique to effectively join any combination of dissimilar aluminum alloys [3]. FSW was invented at The Welding Institute (TWI), UK in 1991. A non-consumable rotating tool harder than the base material is plunged into the abutting edges of the plates to be joined under sufficient axial force and advanced along the line of the joint. The tool consists of two parts, namely shoulder and pin. The material around the tool pin is softened by the frictional heat generated by the tool rotation. Advancement of the tool pushes plastically deformed material from front to back of the tool and forges to complete the joining process [4]. Since FSW is a solid state process, a solidification structure is absent in the weld. Therefore, all the defects related to the presence of brittle inter-dendritic and the eutectic phases are eliminated [5].

Some studies on FSW of dissimilar AA5xxx and AA6xxx joints were recently reported in Refs. [6-10]. LEAL et al [6] elaborated the influence of tool shoulder geometry on material flow in 1 mm-thick AA5182-H111 and AA6016-T4 joints. A tool shoulder with a conical cavity was reported to yield an onion ring structure. PARK et al [7] investigated the effect of material locations on the properties of 2 mm-thick AA5052-H32 and AA6061-T6 joints and a proper mixing of dissimilar aluminum alloys was observed when AA5052-H32 was kept in the advancing side. PEEL et al [8] studied the effects of tool rotational speed and traverse speed on the microstructure, hardness and precipitation distribution of 3 mm-thick AA5083 and AA6082 joints. STEUWER et al [9] quantified the effect of tool rotational speed and traverse speed on the residual stresses of 3 mm-thick AA5083 and AA6082 joints. ELANGOVAN and BALASUBRAMANIAN [10] reported that the welding speed has greater influence on the tensile strength. YAN et al [11] studied the dissimilar friction stir welding between AA5052 and AZ31 magnesium alloy and reported that at the top of the stir zone, AA5052 and AZ31 alloys are simply bonded, while onion ring structure which consisted of aluminum bands and magnesium bands is formed at the bottom of the stir zone. The microstructural evolution of dissimilar welds as a function of processing parameters has been widely studied to find the behavior of AA6061-AA2024 materials [12].

In this work, an attempt is made to join 6 mm-thick aluminum alloys AA5083-H111 and AA6351-T6 using FSW and investigate the effect of welding speed on the microstructure and tensile strength of the dissimilar joints.

2 Experimental

A FSW tool made of high carbon and high chromium steel (HCHCr) having straight square (SS) pin profile without draft was used to weld the alloys. The tool had a shoulder diameter of 18 mm, pin diameter of 6 mm and pin length of 5.7 mm. The FSW tool was manufactured using CNC turning center and wire cut EDM (WEDM) machine to get a accurate profile. The tool was oil hardened to 63HRC.

Aluminum alloys AA6351-T6 and AA5083-H111 were used in this work. Their chemical composition is shown in Table 1. Plates with dimensions of 100 mm× 50 mm × 6 mm were prepared from the rolled plates. AA6351-T6 and AA5086-H111 alloys were respectively kept on the advancing side and retreating side of the joint line. The FSW line was parallel to the rolling direction of AA5083-H111 and perpendicular to the rolling direction of AA6351-T6. This joint choice was made to induce the most severe mechanical combination [13]. The dissimilar butt welding was carried out on an indigenously built FSW machine (M/s RV Machine Tools, Coimbatore, INDIA). Three joints were fabricated at three different welding speeds of 36, 63 and 90 mm/min. The rotational speed was kept as 950 r/min. After the welding process, the joints were visually inspected for exterior defects and it was found that the joints were free from any external defects. A specimen was cut from the welded plate perpendicular to the FSW line to carry out the microstructural characterization. The specimen was prepared as per standard metallographic procedure and etched with modified Keller reagent followed by Wecks reagent. The digital image of the macrostructure of the etched specimen was captured using a digital optical scanner. The microstructure was observed using an optical microscope and scanning electron microscope. The tensile specimens were prepared as per ASTM E8 standard. Three such tensile specimens were prepared and the average ultimate tensile strength (UTS) was taken. The UTS was estimated using a computerized universal testing machine. The fractured specimen of the maximum tensile strength was observed using a scanning electron microscope.

Table 1 Chemical composition of AA6351-T6 and AA5083-H111 alloys (mass fraction, %)

3 Results and discussion

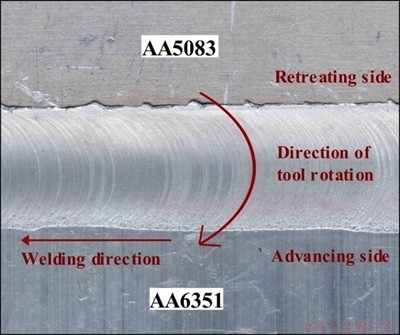

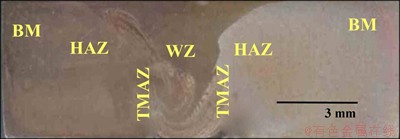

FSW of 6 mm-thick aluminum alloys AA5083- H111 and AA6351-T6 was accomplished. The flow stresses of the two aluminum alloys are different. Aluminum alloy AA5083 offers more resistance to plastic flow compared with AA6351 [14]. The crown appearance of the dissimilar weld is shown in Fig. 1. Semicircular features which are identical to those produced during the conventional milling process can be seen on the crown. The rubbing of the FSW tool shoulder on the plates forms such features which are known as the wake effect [15]. The crown presents the smooth appearance without the presence of voids, cracks, depressions and excessive flashes. The macrostructure of the dissimilar joints is revealed in Fig. 2. It is evident that the joint has no defects such as tunnels, piping or worm hole. The macrostructure suggests that the sufficient frictional heat is formed at the chosen parameters to plasticize both the aluminum alloys which yielded defect free weld. The transportation of plasticized material from advancing side to retreating side is uniform from top to bottom of the joint due to the straight pin profile of the tool employed in this work. The various zones typically present in FSW of aluminum alloys are visible. The macrostructure consists of base metal (BM), heat affected zone (HAZ), thermo- mechanically affected zone (TMAZ) and weld zone (WZ).

Fig. 1 Crown appearance of dissimilar weld

Fig. 2 Macrostructure of dissimilar weld at welding speed of 63 mm/min

Fig. 3 Microstructures of various regions in weld zone using SS tool pin profile at welding speed of 63 mm/min

Fig. 4 Microstructures of various regions in weld zone using SS tool pin profile at welding speed of 36 mm/min

Fig. 5 Microstructures of various regions in weld zone using SS tool pin profile at welding speed of 90 mm/min

Fig. 6 Microstructures of various zones of FS welded dissimilar aluminum alloy at welding speed of 63 mm/min

The weld zones are revealed in Figs. 3-5. It is evident from the figures that the microstructure of the dissimilar joint is dependent to a large extent on the position within the weld zone. Different microstructures are observed while moving across the breadth and depth of the weld zone. All the observed microstructures can be categorized into three different regions, namely unmixed region, mechanically mixed region and mixed flow region. The formation of three kinds of regions within the weld zone agrees to the reports on the dissimilar friction stir welded aluminum alloys [3,12,16]. The formation and characterization of the three regions are detailed as follows. The unmixed regions (Figs. 3(b), 4(b), 5(b)) contain the recrystallized microstructure of either AA5083 or AA6351 alloy. This region is observed at the top of the joints closer to shoulder region. The fine grain structure indicates that this unmixed region experienced dynamic recrystallization during welding. The mechanically mixed regions (Figs. 3(f), 4(c, d) and 5(c-e)) contain the microstructure of both the aluminum alloys. The etchant reveals that AA5083 is darker and AA6351 is lighter in color. The plasticized dissimilar alloys are mechanically coupled to each other. The penetration of one aluminum alloy into the other is not fully accomplished. But dynamic recrystallization of grains is evident. The mixed flow regions (Figs. 3(d, e)) contain a alternative lamellae structure of both the aluminum alloys. A complex vortex like flow pattern is visible. The mixed flow region presents extreme super plastic flow of plasticized material which creates chaotic intercalation patterns. The stirring action of the tool causes intense plastic deformation and in situ extrusion of aluminum alloys AA6351 and AA5083. The plasticized material is transported layer by layer, which forms such a lamellae structure. The penetration and mixing of both the aluminum alloys in this region is intense. In general, FSW at higher welding speeds results in a short exposure time in the weld area with insufficient heat and poor plastic flow of the metal and causes some voids like defects in the joints. The reduced plasticity and rates of diffusion in the material may result in a weak interface. Higher welding speeds are associated with low heat inputs, which results in faster cooling rates of the welded joint. Hence, mixed flow region was not formed (Figs. 4 and 5) at the highest (90 mm/min) or lowest (36 mm/min) welding speed.

Figures 6(a) and (b) show the microstructures of base material of AA6351 and AA 5083 respectively. Different grain sizes of the TMAZ and WZ zones are also observed in Figs. 6(c)-(e). Figure 6(e) shows the WZ composed of fine-equiaxed recrystallized grains and precipitates dispersed in a finer matrix. The fine recrystallized structure at the weld nugget is due to heavy plastic deformation followed by dynamic recrystallization occurring during thermo-mechanical processing. TMAZ adjacent to the weld nugget is plastically deformed and thermally affected. TMAZ exhibits highly elongated grains of aluminum alloy as shown in Figs. 6(c) and (d) due to stirring but it does not have crystallized microstructure.

The welding speed has a strong impact on productivity in streamlined production of FSW of aluminum alloy sections. A significant increase in welding speed is achieved with high weld quality and excellent joint properties. The effects of welding speed on tensile strength of the dissimilar joints are shown in Fig. 7. At the lowest (36 mm/min) and the highest (90 mm/min) welding speeds, a lower tensile strength was observed. The increase in welding speed leads to the increase in the tensile strength up to the maximum value, while further increase in welding speed results in the decrease in the tensile strength of FS welded joints.

Fig. 7 Effect of welding speed on ultimate tensile strength

The welding speed prompts the translation of tool, which in turn pushes the stirred material from front to the back of the tool pin and completes the welding. The rubbing of tool shoulder and pin with the work piece generates frictional heat. The welding speed determines the exposure time of this frictional heat per unit length of weld and subsequently affects the grain growth and precipitates. Optimum exposure time and translation of stirred material will lead to good consolidation of material with finer grains. Since joint which experiences such condition at welding speed of 63 mm/min during welding exhibited the highest UTS. Decrease in frictional heat generation with increase in welding speed was observed. Higher heat conditions prevail at lower welding speeds with slower cooling rate, which leads to coarsening of grains and dissolution of precipitates [10,17]. Lower welding speeds cause improper consolidation of material, which leads to the reduction in UTS owing to the defect. The stirring becomes insufficient at higher welding speeds. The material present in the advancing side of the tool does not travel enough to the retreating side, which causes a defect. Lower heat generation with faster cooling rate occurs at higher welding speeds. The tendency of the tool to drag at higher welding speeds also contributes to the lower UTS. The welding speed influences the plastic flow of material, change in grain size and precipitates and formation of defects.

The factors that determine the tensile strength of dissimilar aluminum alloy joints are the presence of macroscopic defects in weld zone and the degree of plastic flow and amount of mixing of both the materials. The welding speeds of 36 mm/min and 90 mm/min induced the defect while the dissimilar alloy welded at 63 mm/min had no defect. The failure location of the dissimilar joints is shown in Fig. 8. Due to macroscopic defects, failure takes place in TMAZ sides of AA5083 at welding speed of 36 mm/min and in TMAZ side of AA6351 at welding speed of 90 mm/min. But failure takes place in the weld zone at welding speed of 63 mm/min.

Fig. 8 Failure regions of dissimilar FS welded aluminum alloy at welding speed of 36 mm/min (a), 90 mm/min (b) and 63 mm/min (c)

Fig. 9 SEM images of fracture surface of dissimilar welded alloy at welding speed 63 mm/min at lower magnification (a) and higher magnification (b)

The fracture surface of the tensile tested dissimilar weld specimen is shown in Fig. 9. The fracture surface is covered with a large population of microscopic voids which vary in size and shape. The failure of the dissimilar joint is dictated by the coalescence of those microscopic voids. The observed failure mode is ductile fibrous fracture.

4 Conclusions

1) The dissimilar joint shows the presence of various zones such as weld zone (WZ), thermo- mechanically affected zone (TMAZ) and heat affected zone (HAZ).

2) The weld zone is composed of three kinds of microstructures, namely unmixed region, mechanically mixed region and mixed flow region.

3) The welding speed influences the formation of plastic flow region. The joints fabricated at the lowest or highest welding speeds show the absence of mixed flow region.

4) The joints produced at a welding speed of 63 mm/min show better tensile properties.

5) The observed failure mode is a ductile fibrous fracture.

Acknowledgements

The authors are grateful to the Management and Department of Mechanical Engineering, Coimbatore Institute of Technology, Coimbatore, India. The authors also acknowledge the financial support rendered by the Naval Research Board, Govt. of India. One of the authors, Dr. I. DINAHARAN acknowledges the Department of Science and Technology, Govt. of India for providing INSPIRE fellowship.

References

[1] HEINZ A, HASZLER A, KEIDEL C, MOLDENHAUER S, BENEDICTUS R, MILLER W S. Recent development in aluminium alloys for aerospace applications [J]. Materials Science and Engineering A, 2000, 280(1): 102-107.

[2] LUIJENDIJK T. Welding of dissimilar aluminium alloys [J]. Journal of Material Processing Technology, 2000, 103: 29-35.

[3] MURR L E. A review of FSW research on dissimilar metal and alloy systems [J]. Journal of Material Engineering Performance, 2010, 19(8): 1071-1089.

[4] MISHRA R S, MA Z Y. Friction stir welding and processing [J]. Materials Science and Engineering R, 2005, 50(1-2): 1-78.

[5] THREADGILL P L, LEONARD A J, SHERCLIFF H R, WITHERS P J. Friction stir welding of aluminium alloys [J]. International Journal of Material Review, 2009, 54(2): 49-93.

[6] LEAL R M, LEITAO C, LOUREIRO A, RODRIGUES D M, VILACA P. Material flow in heterogeneous friction stir welding of thin aluminium sheets: Effect of shoulder geometry [J]. Materials Science and Engineering A, 2008, 498(1-2): 384-391.

[7] PARK S K, HONG S T, PARK J H, PARK K Y, KWON Y J, SON H J. Effect of material locations on properties of friction stir welding joints of dissimilar aluminium alloys [J]. Science and Technology of Welding and Joining, 2010, 15(4): 331-336.

[8] PEEL M J, STEUWER A, WITHERS P J, DICKERSON T, SHI Q, SHERCLIFF H. Dissimilar friction stir welds in AA5083-AA6082. Part I: Process parameter effects on thermal history and weld properties [J]. Metallurgical and Materials Transactions A, 2006, 37(7): 2183-2193.

[9] STEUWER A, PEEL M J, WITHERS P J. Dissimilar friction stir welds in AA5083–AA6082: The effect of process parameters on residual stress [J]. Materials Science and Engineering A, 2006, 441(1-2): 187-196.

[10] ELANGOVAN K, BALASUBRAMANIAN V. Influences of tool pin profile and welding speed on the formation of friction stir processing zone in AA2219 aluminium alloy [J]. Journal of Material Processing Technology, 2008, 200(1-3): 163-175.

[11] YAN Yong, ZHANG Da-tong, QIU Cheng, ZHANG Wen. Dissimilar friction stir welding between 5052 aluminum alloy and AZ31 magnesium alloy [J]. Transaction of Nonferrous Material Society China, 2010, 20(S2): s619-s623.

[12] OUYANG J H, KOVACEVIC R. Material flow and microstructure in the friction stir butt welds of the same and dissimilar aluminum alloys [J]. Journal of Material Engineering Performance, 2002, 11(1): 51-63.

[13] CAVALIERE P, NOBILE R, PANELLA F W, SQUILLACE A. Mechanical and microstructural behaviour of 2024-7075 aluminium alloy sheets joined by friction stir welding [J]. International Journal of Machine Tools & Manufacture, 2006, 46(6): 588-594.

[14] LEITAO C,  B, CHAPARRO B M, RODRIGUES D M. Formability of similar and dissimilar friction stir welded AA 5182-H111 and AA 6016-T4 tailored blanks [J]. Material and Design, 2009, 30(8): 3235-3242.

B, CHAPARRO B M, RODRIGUES D M. Formability of similar and dissimilar friction stir welded AA 5182-H111 and AA 6016-T4 tailored blanks [J]. Material and Design, 2009, 30(8): 3235-3242.

[15] CESCHINI L, BOROMEI I, MINAK G, MORRI A, TARTERINI F. Effect of friction stir welding on microstructure, tensile and fatigue properties of the AA7005/10vol.%Al2O3p composite [J]. Composite Science and Technology 2007, 67(4): 605-615.

[16] AVAL H J, SERAJZADEH S, KOKABI A H, LOUREIRO A. Effect of tool geometry on mechanical and microstructural behaviours in dissimilar friction stir welding of AA 5086-AA 6061 [J]. Science and Technology of Welding and Joining, 2011, 16(7): 597-604.

[17] PALANIVEL R, KOSHYMATHEWS P. Prediction and optimization of process parameter of friction stir welded AA5083- H111 aluminum alloy using response surface methodology [J]. Journal of Central South University of Technology, 2012, 19(1): 1-8.

R. PALANIVEL1, P. KOSHY MATHEWS2, I. DINAHARAN3, N. MURUGAN4

1. Department of Mechanical Engineering, Roever College of Engineering and Technology, Perambalur, 621212, Tamil Nadu, India;

2. Department of Mechanical Engineering, Kalaivani College of Technology, Coimbatore, 641105, Tamil Nadu, India;

3. Department of Mechanical Engineering, V V College of Engineering, Tisaiyanvilai, 627657, Tamil Nadu, India;

4. Department of Mechanical Engineering, Coimbatore Institute of Technology, Coimbatore, 641014, Tamil Nadu, India

摘 要:研究异种搅拌摩擦焊AA5083-H111和AA6351-T6铝合金的微观结构和力学性能。在3种不同的焊接速度(36、63、90 mm/min)下焊接AA5083-H111和AA6351-T6铝合金,分析焊接速度对接头力学和冶金性能的影响。结构表明,与其他焊接速度相比,焊接速度为63 mm/min 时接头的力学性能和冶金性能较好。焊缝区由未混合区、机械混合区和混流区组成。所观察到的断裂模式为韧性纤维断裂。

关键词:铝合金;搅拌摩擦焊;焊接速度;抗拉强度;显微组织

(Edited by Xiang-qun LI)

Corresponding author: R. PALANIVEL; Tel: +91-9943707552; E-mail: rpelmech@yahoo.co.in

DOI: 10.1016/S1003-6326(14)63028-4