稳定化热处理对Zn-10Al-2Cu-0.02Ti合金组织及蠕变行为的影响

来源期刊:中国有色金属学报(英文版)2013年第1期

论文作者:林高用 张锐 王莉 雷玉霞 贺家健

文章页码:86 - 91

关键词:Zn-10Al-2Cu-0.02Ti合金;稳定化热处理;显微组织;蠕变行为

Key words:Zn-10Al-2Cu-0.02Ti alloy; stabilizing heat treatment; microstructure; creep behavior

摘 要:采用扫描电子显微镜、透射电镜、电子探针以及X射线衍射物相分析等技术手段,对稳定化热处理前后Zn-10Al-2Cu-0.02Ti合金的显微组织进行观察,通过室温恒载荷拉伸、慢应变速率拉伸实验研究合金组织变化及其对合金室温蠕变行为的影响。结果表明:经过稳定化热处理((350 °C,30 min,水冷)+(100 ℃,12 h, 空冷)),后合金中的α+η层片状组织的减少,胞状和粒状组织增多;与挤压态合金相比,经过稳定化热处理后的Zn-10Al-2Cu-0.02Ti合金的抗蠕变性能显著提高,其稳态蠕变速率降低了96.9%。

Abstract: The microstructures of as-extruded and stabilizing heat-treated Zn-10Al-2Cu-0.02Ti alloys were observed by scanning electron microscopy, transmission electron microscopy, electron probe microanalysis and X-ray diffraction analysis techniques. The change in structure after heat treatment and its effects on room temperature creep behavior were investigated by creep experiments at constant stress and slow strain rate tensile tests. The results show that after stabilizing heat treatment ((350 °C, 30 min, water-cooling)+(100 °C, 12 h, air-cooling)), the amount of α+η lamellar structure decreases, while the amount of cellular and granular structure increases. The heat-treated Zn-10Al-2Cu-0.02Ti alloy exhibits better creep resistance than the as-extruded alloy, and the rate of steady state creep decreases by 96.9% after stabilizing heat treatment.

Trans. Nonferrous Met. Soc. China 23(2013) 86-91

Gao-yong LIN1,2, Rui ZHANG1, Li WANG1, Yu-xia LEI1, Jia-jian HE1

1. School of Materials Science and Engineering, Central South University, Changsha 410083, China;

2. Key Laboratory of Nonferrous Metal Materials Science and Engineering, Ministry of Education, Central South University, Changsha 410083, China

Received 26 December 2011; accepted 12 September 2012

Abstract: The microstructures of as-extruded and stabilizing heat-treated Zn-10Al-2Cu-0.02Ti alloys were observed by scanning electron microscopy, transmission electron microscopy, electron probe microanalysis and X-ray diffraction analysis techniques. The change in structure after heat treatment and its effects on room temperature creep behavior were investigated by creep experiments at constant stress and slow strain rate tensile tests. The results show that after stabilizing heat treatment ((350 °C, 30 min, water-cooling)+(100 °C, 12 h, air-cooling)), the amount of α+η lamellar structure decreases, while the amount of cellular and granular structure increases. The heat-treated Zn-10Al-2Cu-0.02Ti alloy exhibits better creep resistance than the as-extruded alloy, and the rate of steady state creep decreases by 96.9% after stabilizing heat treatment.

Key words: Zn-10Al-2Cu-0.02Ti alloy; stabilizing heat treatment; microstructure; creep behavior

1 Introduction

Over the past few decades, the price of copper goes up continually, and it has occupied the attention of both researchers and industries to develop a material as a substitute for copper and copper alloys [1-4]. Then, zinc-aluminum alloys (ZA alloys) turns out to be a promising alternative material for their attractive physical and mechanical properties combined with good friction and wear resistance properties [5-9]. At this moment, commercially available ZA alloys have become the alternative materials primarily for aluminum cast alloys and bearing bronzes due to good cast ability and unique combination of properties [10,11]. Furthermore, they are relatively cheap and can be processed efficiently with low energy consumption without endangering the environment [12-14].

However, ZA alloys are easy to generate creep even at stress much less than their yield strength for a period of time. Low creep resistance and serious inter-granular corrosion are the main problems that limit the application of ZA alloys. As the applied range of ZA alloys is enlarged, it is obliged to improve their mechanical properties, and today suitable heat treatment has become an effective way, as is well-known from earlier publications [15-17]. As a kind of ZA alloys that has realized industrialization, Zn-10Al-2Cu-0.02Ti alloy exhibits good comprehensive properties after stabilizing heat treatment, and can be used to replace some copper alloys used as bearings, connectors, hardware, household appliances and other structural parts. The microstructures and property characteristics of a series of ZA alloys have been researched in recent years [18]. However, few relevant reports about Zn-10Al-2Cu-0.02Ti have been published.

In the present work, the complex microstructures and phase transformations of Zn-10Al-2Cu-0.02Ti alloy both in extrusion state and heat treatment condition, and their effects on ambient temperature creep behavior were investigated.

2 Experimental

2.1 Experimental materials

The material for this work was a self-developed Zn-10Al-2Cu-0.02Ti alloy. Its nominal composition is given in Table 1. Some of the alloy specimens were subjected to stabilizing heat treatment by solution treating at 350 °C for 0.5 h, and then quenching in water at ambient temperature. After cooling in the water, the specimens were aged at 100 °C for 12 h.

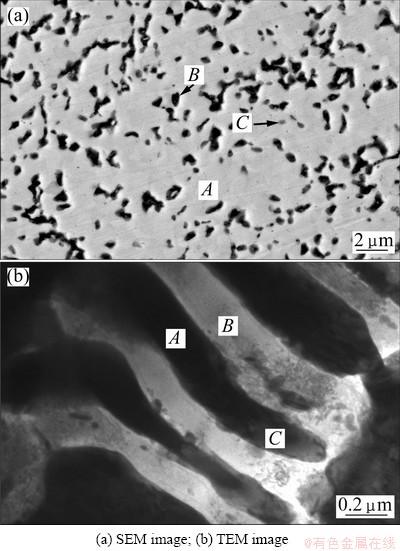

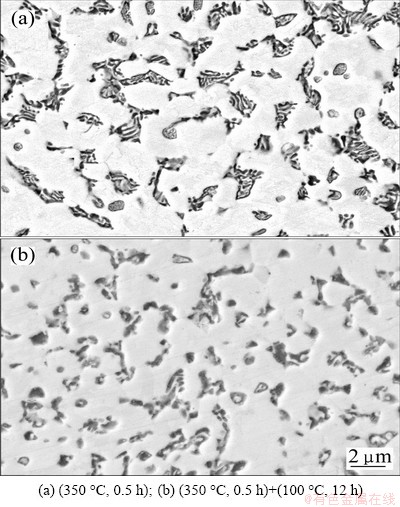

Table 1 Nominal composition of studied alloy (mass fraction, %)

2.2 Measurement of creep properties and microstructures

In order to research the dimensional stability of the Zn-10Al-2Cu-0.02Ti alloy, ambient temperature creep experiments were done both on the as-extruded and stabilizing heat-treated alloys at a constant stress of 130 MPa. In addition, slow strain rate tensile tests (SSRT) were conducted at a strain rate of 5×10-6 s-1 to study the influence of stabilizing heat treatment on creep behavior of the alloy using a universal tensile testing machine, and the initial tensile rate was 0.009 mm/min.

The investigations of microstructures and phase compositions of the alloy were carried out by a Sirion200 field emission scanning electron microscope (SEM), a Tecnai G220 transmission electron microscope (TEM) and a Rigaku D/max 2500 X-ray diffractometer (XRD). The SEM analysis was operated in the mode of backscattered electron (BSE) at 15 kV. The TEM samples with 0.5 mm in thickness were first cut with a saw, and mechanically ground and polished to about 0.06-0.08 mm in thickness, then punched into d3 mm thin flakes and finally electro-polished to 150 μm in thickness using a two-jet Gantan PIPS691 electro- polishing equipment. The XRD analysis was performed on a 2.5 mm-thick sample with a 2θ angle ranging from 36° to 46°, and the scanning speed was 1 (°)/min. After scanning, a software of Jade 6.0 was used to analyze the X-ray diffraction patterns.

3 Results and discussion

3.1 Microstructures of as-extruded and stabilizing heat-treated alloys

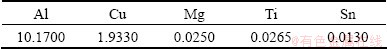

Figure 1 shows the microstructures of as-extruded Zn-10Al-2Cu-0.02Ti alloy. The microstructures of the alloy are equal-fine grains. There are three phases of η, α and β in the alloys. According to the results of the micro-area chemical composition analysis by electron probe microanalysis (EPMA) techniques, the compositions of areas A, B and C in Fig. 1(a) are listed in Table 2. Combining with the phase diagram of Zn-Al alloy [17,20], it can be concluded that area A (matrix) represents η phase, area B (black phase) represents α phase, and area C (gray phase) represents β phase. Figure 1(b) shows the result observed by TEM, where areas A, B and C stand for η, α and β phases, respectively, of which η phase is a Zn-rich phase of HCP crystal structure, α phase is an Al-rich phase of FCC crystal structure, and β phase is an unstable phase of FCC crystal structure based on Al or ZnAl, which will decompose when it is heated to above 275 °C. The decomposition of β phase is determined to be a reaction: β→η+α.

Fig. 1 Microstructures of as-extruded Zn-10Al-2Cu-0.02Ti alloy

Table 2 Chemical compositions of areas A, B and C as shown in Fig. 1(a)

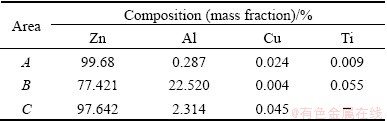

Figure 2 presents the microstructures of stabilizing heat-treated Zn-10Al-2Cu-0.02Ti alloy. There are obvious changes in the microstructure after stabilizing heat treatment. Black α phase declines markedly as compared Fig. 1(a) with Fig. 2(b). The solubility of Zn in Al matrix decreases rapidly with the decrease of temperature, so η phase precipitates from α phase continuously.

There appear lamellar structures, cellular structures and granular structures after the heat treatment. The microstructures of solid solution state (350 °C, 0.5 h, cooling in water) are mainly made up of lamellar structures. However, after aging at 100 °C for 12 h, the lamellar structures diminish accompanied with the emergence of cellular structures and granular structures.

Fig. 2 Microstructures of stabilizing heat-treated Zn-10Al- 2Cu-0.02Ti alloy under different conditions

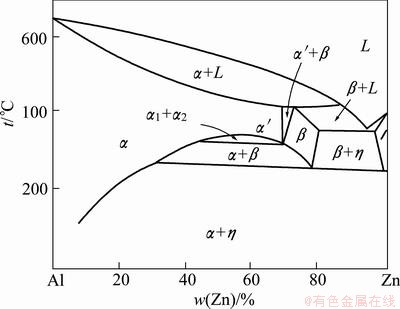

The inter-solubility of Zn-Al alloys is infinite in liquid state, while in solid state their inter-solubility is finite, as shown in Fig. 3. The composition range of Al-rich α phase is very large, and after the heat treatment η phase precipitates from α phase, thus causing the reduction of black α phase, in contrast with specimen in the as-extruded state. In addition, the spinodal decomposition (α→α1+α2) occurring below 353 °C also brings about different contents of Al in black α phase before and after the heat treatment.

Fig. 3 Phase diagram of Zn-Al alloy

When the experimental alloy is heated to 350 °C, α and η phases dissolve into the matrix and supersaturated β solid solution forms. After being quenched in water at room temperature, α+η lamellar structures come into being owing to the phase transformation.

This transformation is supposed to correlate with the eutectoid reaction at 275 °C, β→α+η. During the aging stage of stabilizing heat treatment, the decomposition of supersaturated β solid solution is a very complex process. One or several meta-stable structures turn up before equilibrium phases precipitate. Possible precipitation orders of β solid solution are as follows:

β→GP zone→R →αm→η (1)

α1+α2→α+R→α+η (2)

α1+α2→α+R→α+η (2)

The precipitation of supersaturated β solid solution consists of continuous precipitation and discontinuous precipitation, and discontinuous precipitation is divided into three types: the traditional cellular reaction, autocatalytic cellular reaction and granular precipitation of β phase. And β solid solution is considered to be decomposed into lamellar structures through cellular reaction [19].

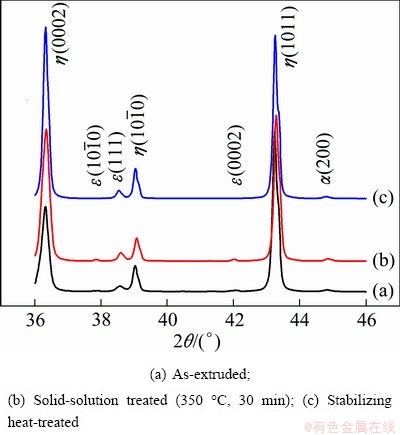

Figure 4 depicts the results of XRD analysis of the as-extruded, solid-solution treated and stabilizing heat-treated Zn-10Al-2Cu-0.02Ti alloys. There are mainly two phases, α and η phases, in the as-extruded experimental alloys. A few diffraction peaks are detected at 2θ value of 42°, which are proved to be ε phase (CuZn4). After solid solution treatment (350 °C, 30 min), new diffraction peaks of ε phase are detected at 2θ values of 38° and 42° simultaneously. After subsequent aging at 100 °C for 12 h, no diffraction peaks of ε phase are detected by XRD, which may be relevant to the four phase transformation as follows:

α+ε→T '+η (3)

For the alloy in the extrusion state, because the content of Cu is only 2% (mass fraction), and majority of Cu dissolves into the matrix, no or little quantity of ε phase precipitates. Nonetheless, in solid solution state, β phase decomposes rapidly, and thus more Cu precipitates in balance as a form of ε phase. During aging at 100 °C, ε phase disappears owing to the transformation of four phases.

Fig. 4 XRD patterns of experimental alloys

3.2 Room temperature creep experiments at constant stress

Figure 5 shows the room temperature creep curves of experimental alloys at 130 MPa, where the creep consists of decelerating, constant rate and accelerating stages. It only takes about 25 h when the creep rupture of the as-extruded alloy occurs. However, after the heat treatment, constant rate stage lasts for 320 h until the specimen fractures. The rate of steady state creep can be obtained from the linear part of creep curves, which is 4.47×10-6 s-1 for the as-extruded alloy and 1.39×10-7 s-1 for the heat-treated alloy. The rate of steady state creep decreases by 96.9% after stabilizing heat treatment. In general, the creep resistance of the experimental alloys is improved observably by stabilizing heat treatment.

Fig. 5 Creep curves at room temperature and 130 MPa

3.3 Slow strain rate tensile tests at ambient temperature

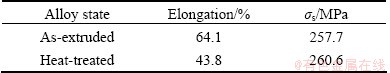

To further determine the influences of heat treatment on the creep behavior, slow strain rate tensile tests were conducted at ambient temperature and a strain rate of 5×10-6 s-1. The mechanical properties of the test materials are listed in Table 3.

Table 3 Mechanical properties of experimental alloys

It can be concluded from Table 3 that the as-extruded sample is more homogeneous in deformation, meanwhile, it has superior elongation with good plasticity. The stabilizing heat-treated sample is inhomogeneous in deformation accompanied with an obvious necking phenomenon. Moreover, compared with the as-extruded sample, its elongation reaches 43.8%, decreasing by 11.3%, but its yield strength is reduced by 1.13%.

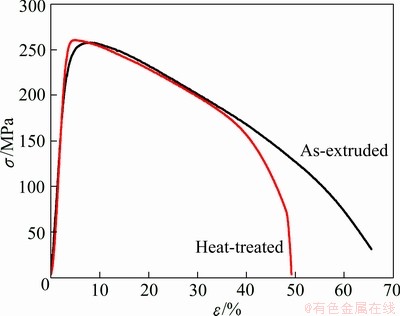

Figure 6 represents the σ—ε curves of experimental alloys after slow strain rate tensile tests. The strain of the as-extruded and the heat-treated samples is approximately equal when the stress is less than 175 MPa, but after arriving to the yield point, the heat-treated sample exhibits less strain than the as-extruded sample at the same stress. That is, the creep resistance of the alloys is improved after stabilizing heat treatment, which coincides well with the analysis of microstructures.

Fig. 6 Stress—strain curves after slow strain rate tensile tests

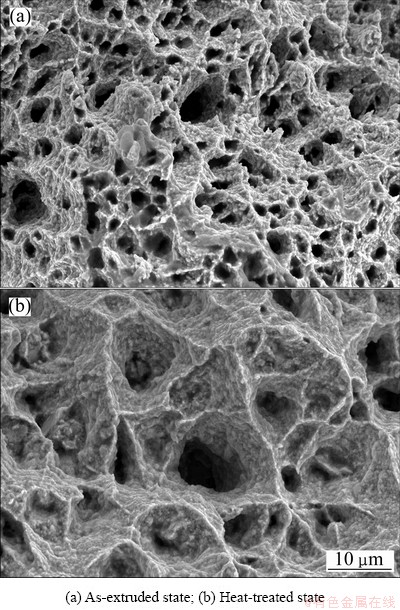

Figure 7 presents the feature of fracture of alloys cross-section after slow strain rate tensile tests. There are a lot of evenly distributed tiny dimples in the fracture morphology of the as-extruded alloy, and the dimples are very deep without evident tear strips, proving good ductility of the as-extruded alloy. Whereas in the heat-treated alloy, the dimples are big and shallow, indicating the alloy’s plasticity becomes worse after the heat treatment, which is in accordance with the results of slow strain rate tensile tests.

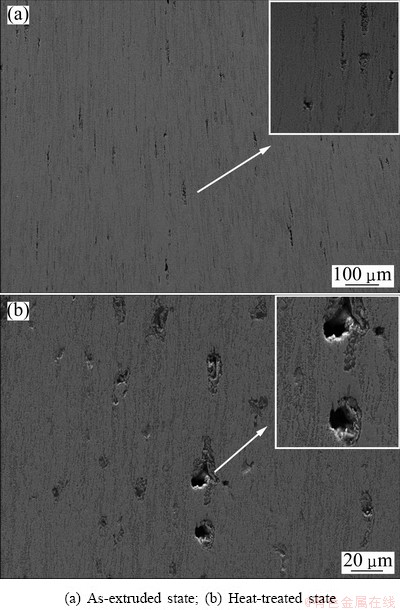

The fracture morphologies of longitudinal section were observed by SEM. The specimens were first cut form the fractured alloys, and then polished with abrasive paper from 600# up to 1400#. Figure 8 represents the fracture morphologies of experimental alloys, and the insert diagrams in Figs. 8 (a) and (b) reflect the amplified mapping of the corresponding zones, both of them are magnified in the same multiple. Obvious cavities close to the location of fracture are found. It can be seen that the cavities in the as-extruded alloy are much less than that in heat-treated alloy, and the size is smaller. Combining with the feature of cavities in the cross-section and the distribution in the longitudinal section, it can be inferred that the creep fracture mechanism of the heat-treated alloy mainly fits the cavity aggregating and linking theory.

Fig. 7 Fracture morphologies after slow strain rate tensile tests (Cross-section)

Fig. 8 Fracture morphologies after slow strain rate tensile tests (Longitudinal section)

It is known that certain stress will lead to the grain boundary sliding of Zn-10Al-2Cu-0.02Ti alloys, and cavities will emerge when grain boundary sliding and trans-granular slip bands deliver at the grains boundary. Even under low stress, these cavities will grow up, link and shape flaw. Hence, the grain boundary sliding, vacancy diffusion and cavity connection followed by the flaw result in the final fracture of samples.

But as for the alloy under the as-extruded condition, few cavities are observed, which suggests that the fracture occurs before these cavities aggregate and grow up, so the creep fracture mechanism of the as-extruded alloy is inferred to be the grain boundary sliding theory.

4 Conclusions

1) Phase transformations of the as-extruded Zn-10Al-2Cu-0.02Ti alloy during the heat treatment are the resultant process of the decomposition of several supersaturated phases. In particular, the decomposition of un-equilibrium β phase into equilibrium η phase and α phase (β→η+α) leads to the change of microstructures. After stabilizing heat treatment, cellular and granular structures increase, followed by the reduction of α+η lamellar structure.

2) Stabilizing heat treatment ((350 °C, 30 min, water-cooling)+(100 °C, 12 h, air-cooling)) can improve the creep resistance of Zn-10Al-2Cu-0.02Ti alloy dramatically, and the rate of steady state creep decreases by 96.9% after stabilizing heat treatment.

References

[1] ABOU EL-KHAIR M T, DAOUD A, ISMAIL A. Effect of different Al contents on the microstructure, tensile and wear properties of Zn-based alloy [J]. Materials Letters, 2004, 58(11): 1754-1760.

[2] HOUGHTON M E, MURRAY M T. An introduction to zinc alloys [J]. Metals Forum, 1983, 6(4): 211-225.

[3] ZHU Y H, TO S, LIU X M, LEE W B. Micro-structural changes inside the lamellar structures of alloy ZA27 [J]. Materials Characterization, 2006, 57(4-5): 326-332.

[4] ZHU Y H, LEE W B, TO S. Ageing characteristics of cast Zn-Al based alloy (ZnAl7Cu3) [J]. Journal of Materials Science, 2003, 38(9): 1945-1952.

[5] BABIC M, NINKOVIC R. Zn-Al alloys as tribomaterials [J]. Tribology in Industry, 2004, 26(1-2): 3-7.

[6] BARNHURST R J. Designing zinc alloy bearings [J]. Journal of Materials Engineering, 1990, 12(4): 279-285.

[7] BABIC M, MITROVIC S, JEREMIC B. The influence of heat treatment on the sliding wear behavior of a ZA-27 alloy [J]. Tribology International, 2010, 43(1-2): 16-21.

[8] LEHUY H, L'ESPERANCE G. Ageing characteristics of dendritic and non-dendritic (stir-cast) Zn-Al alloy (ZA-27) [J]. Journal of Materials Science, 1991, 26(2): 559-568.

[9] PANDEY J P, PRASAD B K. Sliding wear response of a zinc-based alloy compared to a copper-based alloy [J]. Metallurgical and Materials Transactions, 1989, 29(4): 1245-1255.

[10] SHARMA S C, GIRISH B M, KAMATH R, SATISH B M. Graphite particles reinforced ZA-27 alloy composite materials for journal bearing application [J]. Wear, 1998, 219(2): 162-168.

[11] CHOUDHURY P, DAS S, DATTA B K. Effect of Ni on the wear behavior of a zinc-aluminum alloy [J]. Journal of Materials Science, 2002, 37(10): 2103-2107.

[12] GEVAIS E, BARNHURST R J, LOONG C A. An analysis of selected properties of ZA alloys [J]. Journal of Metals, 1985, 37(11): 43-47.

[13] ZHU Y H, BIAO Y, WEI H. Bearing wear resistance of monotectoid Zn-Al based alloy (ZA-35) [J]. Journal of Material Science and Technology, 1995, 11: 109-113.

[14] LYON R. High strength zinc alloys for reengineering applications in the motor car [J]. Metals and Materials, 1985, 1: 55-57.

[15] CAI Qiang. Zinc alloy [M]. Changsha: Central South University of Technology Press, 1987: 102-170. (in Chinese)

[16] REN Chun-yan. The research on the process and properties of bar-shaped ZA alloy squeeze casting [D]. Shenyang: Shenyang University of Technology, 2006: 45-49. (in Chinese)

[17] SI Jia-yong. Study on phase transformation and thermophysical properties of high aluminum Zn-based alloys [D]. Nanning: Guangxi University, 2005: 43-51. (in Chinese)

[18] LIN Gao-yong, SUN Li-ping, ZENG Ju-hua, WANG Li. Microstructure and properties of free-cutting deformation Zn-Al alloy containing Bi [J]. Journal of Central South University: Science and Technology, 2010, 42(11): 3296-3302. (in Chinese)

[19] SUN Lian-chao, TIAN Rong-zhang. Physical metallurgy of zinc and Zn-alloy [M]. Changsha: Central South University of Technology Press, 1994: 12-20. (in Chinese).

林高用1, 2,张 锐1,王 莉1,雷玉霞1,贺家健1

1. 中南大学 材料科学与工程学院,长沙 410083;

2. 中南大学 有色金属材料科学与工程教育部重点实验室,长沙 410083

摘 要:采用扫描电子显微镜、透射电镜、电子探针以及X射线衍射物相分析等技术手段,对稳定化热处理前后Zn-10Al-2Cu-0.02Ti合金的显微组织进行观察,通过室温恒载荷拉伸、慢应变速率拉伸实验研究合金组织变化及其对合金室温蠕变行为的影响。结果表明:经过稳定化热处理((350 °C,30 min,水冷)+(100 ℃,12 h, 空冷)),后合金中的α+η层片状组织的减少,胞状和粒状组织增多;与挤压态合金相比,经过稳定化热处理后的Zn-10Al-2Cu-0.02Ti合金的抗蠕变性能显著提高,其稳态蠕变速率降低了96.9%。

关键词:Zn-10Al-2Cu-0.02Ti合金;稳定化热处理;显微组织;蠕变行为

(Edited by Wei-ping CHEN)

Foundation item: Project (2009BAE71B00) supported by the National Key Technology R&D Program during the Eleventh Five-Year Plan Period

Corresponding author: Gao-yong LIN; Tel: +86-13507422779; E-mail: mater218@163.com

DOI: 10.1016/S1003-6326(13)62433-4