Al-4.10Cu-1.42Mg-0.57Mn-0.12Zr合金热变形过程中显微组织动态演化的表征

来源期刊:中国有色金属学报(英文版)2014年第11期

论文作者:刘 灿 张 辉 蒋福林

文章页码:3477 - 3485

关键词:铝合金;热变形;流动软化;动态回复;动态析出

Key words:aluminum alloy; hot deformation; flow softening; dynamic recovery; dynamic precipitation

摘 要:在Gleeble-1500热模拟机上对Al-4.10Cu-1.42Mg-0.57Mn-0.12Zr合金在变形温度300 °C和应变速度10 s-1下进行热压缩变形,真应变分别为0.2、0.4、0.6和0.8。通过X射线衍射仪、扫描电镜和透射电镜研究合金变形过程中复杂的动态显微组织演变。结果表明:真应力随着应变的增加而迅速增大至峰值,之后随着应变的增加而趋于稳定,呈现动态软化特征。随着应变的增大,位错缠结成胞状与亚晶结构,表明变形过程中发生动态回复。动态析出相S相、θ相和Al3Zr相在变形过程中粗化速度加快。铝基体中析出连续的S相,并发现有不连续的S相在Al3Zr相附近和亚晶界处形核析出。Al3Zr相相对比较稳定,易于在位错和亚晶界处析出。流动软化机制是由于动态回复和动态析出导致位错密度减少而引起的。

Abstract: The Al-4.10Cu-1.42Mg-0.57Mn-0.12Zr alloy was compressed to different strains at deformation temperature of 300 oC and strain rate of 10 s-1 on Gleeble-1500 system. The dynamic complex microstructures evolutions were investigated by X-ray diffraction, scanning electron microscopy and transmission electron microscopy. The true stress-true strain curves exhibited a peak stress at critical strain, after which the flow stresses decreased monotonically, showing a dynamic flow softening. As the strain increased, the dislocation tangled to cell structure and sub-grain structure, which indicated the occurrence of dynamic recovery during deformation. Dynamic precipitations of S (Al2CuMg), θ (Al2Cu) and Al3Zr phase were accelerated and coarsened by deformation. Continuous S phases precipitated in the Al matrix and discontinuous S phases were found to be nucleated near the Al3Zr phase and at the sub-grain boundary. The flow softening mechanism was resulted from the reduction of dislocation density which attributed to dynamic recovery and precipitates coarsening.

Trans. Nonferrous Met. Soc. China 24(2014) 3477-3485

Can LIU1, Hui ZHANG1,2, Fu-lin JIANG1,3

1. College of Materials Science and Engineering, Hunan University, Changsha 410082, China;

2. Hunan Provincal Key Laboratory of Spray Deposition Technology and Application, Hunan University, Changsha 410082, China;

3. Department of Materials Science and Engineering, McMaster University, Hamiltion, Ontario L8S 4L7, Canada

Received 6 January 2014; accepted 14 May 2014

Abstract: The Al-4.10Cu-1.42Mg-0.57Mn-0.12Zr alloy was compressed to different strains at deformation temperature of 300 °C and strain rate of 10 s-1 on Gleeble-1500 system. The dynamic complex microstructures evolutions were investigated by X-ray diffraction, scanning electron microscopy and transmission electron microscopy. The true stress-true strain curves exhibited a peak stress at critical strain, after which the flow stresses decreased monotonically, showing a dynamic flow softening. As the strain increased, the dislocation tangled to cell structure and sub-grain structure, which indicated the occurrence of dynamic recovery during deformation. Dynamic precipitations of S (Al2CuMg), θ (Al2Cu) and Al3Zr phase were accelerated and coarsened by deformation. Continuous S phases precipitated in the Al matrix and discontinuous S phases were found to be nucleated near the Al3Zr phase and at the sub-grain boundary. The flow softening mechanism was resulted from the reduction of dislocation density which attributed to dynamic recovery and precipitates coarsening.

Key words: aluminum alloy; hot deformation; flow softening; dynamic recovery; dynamic precipitation

1 Introduction

The 2xxx series aluminum-copper alloys, especially those containing magnesium, are often selected for aerospace applications because of their high strength. Based on primary 2024 aluminum alloy, several new 2xxx alloys were developed in recent years by lowering natural impurities, such as iron and silicon, or adding a small amount of zirconium which serves to inhibit recrystallization and favors an un-recrystallized microstructure [1]. During hot deformation of the Al-Cu-Mg-Zr alloys, complex deformation behavior and microstructure evolution have received considerable research interests and optimized processing routes which enable the alloys to be deformed more easily and result in improved mechanical properties.

Generally, dynamic flow softening is presented for such Al-Cu-Mg-Zr alloy during hot deformation and it has been suggested that the softening mechanisms are dynamic recovery (DRV), dynamic recrystallization (DRX) and particles growth [2-8]. During hot deformation of 2014, 2024 and 2618 aluminum alloys, the flow stress-strain curves showed flow softening after reaching the peaks, and particles coarsening was thought to be one of the dominant softening mechanisms [2,8-11]. CAVALIERE [11] suggested that precipitation and subsequent coarsening of precipitates occurred during the hot and warm deformation of 2618 aluminum alloy when testing temperature exceeded 250 °C, which resulted in flow softening. Previous studies also showed that hot deformation could promote dynamic precipitation in aluminum alloys because dislocations could act as nucleation sites for precipitates [12,13]. Precipitation strengthening phases were mainly Al2Cu (θ) and CuMgAl2 (S) and their metastable phases θ" or S" phases in 2xxx alloys, the ratio of Cu and Mg elements mainly determined the corresponding strengthening phase in alloy [14-16].

CABIBBO et al [17] and WANG et al [18] demonstrated that deformation energy could induce or speed up the dissolution and re-precipitation reactions of certain precipitates, and the non-uniform deformation shear bands could act as nucleation sites for the newly precipitates, but such precipitates evolutions in heat treatable aluminum alloys were complex processes coupling with thermo and mechanic interaction during hot deformation [4-6].

Numerous works have been concerned on microstructural evolutions after deformation under a certain strain at different deformation temperatures and strain rates and then deduced the hot deformation behavior and flow softening mechanism. However, the microstructural evolution, especially the complex precipitate processes including the morphology, distribution and compositions of the precipitates at each stage, has seldom been studied for the Al-Cu-Mg-Zr alloys during the whole hot compression deformation process. Consequently, the present work studied on the relationship between the dynamic microstructure and complex precipitates evolution of an Al-4.10Cu-1.42Mg-0.57Mn-0.12Zr alloy during hot compression at deformation temperature of 300 °C and strain rate of 10 s-1. Thus further understanding of the hot deformation behavior and flow softening mechanism can be obtained.

2 Experimental

The experiments were carried out on the Al-4.10Cu-1.42Mg-0.57Mn-0.12Zr alloy. Cylindrical samples with 10 mm in diameter and 15 mm in height were machined from commercially semi-continuous cast ingots with 300 mm in diameter and subsequent homogenized at 500 °C for 24 h, followed by water quenching. Convex depressions of 0.2 mm in deepth were machined on both ends of the specimens to entrap the lubricant of graphite mixed with machine oil so that friction could be minimized during the compression tests. Hot compression tests were performed on a computer servo-controlled Gleeble-1500 system at deformation temperature of 300 °C and strain rate of 10 s-1. The sample was resistance heated to the deformation temperature at a heating rate of 10 °C/s and held for 300 s by thermocoupled-feedback-controlled AC current before compression. After compression to true strains of 0.2, 0.4, 0.6 and 0.8, respectively, the deformed samples were water quenched immediately and then cut parallel to the compression axis along the centerline. The deformed specimens were prepared by the conventional methods for the microstructural observations using the QUANTA200 scanning electron microscope (SEM) and the JEM3010 transmission electron microscope (TEM). And the NETZSCH STA 449C X-ray diffraction (XRD) apparatus was also employed in present work.

3 Results and discussion

3.1 True stress-true strain curves

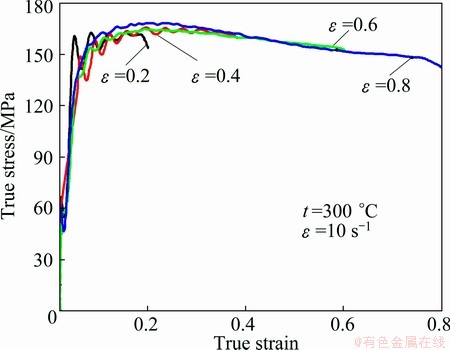

Typical true stress-strain curves of the Al-4.10Cu- 1.42Mg-0.57Mn-0.12Zr alloy deformed under the strains of 0.2, 0.4, 0.6 and 0.8 at temperature of 300 °C and strain rate of 10 s-1 are shown in Fig. 1. It can be found that the curves under different strains agree well at certain strains, and strong uneasy shapes are presented at initial strain stage due to the high strain rate. When deformed at a high strain rate of 10-1, the alloy exhibited unstable flow deformation [19]. The flow stresses exhibit a peak stress at critical strain, after which the flow stresses decrease monotonically until high strains, showing a dynamic flow softening. At the beginning of the deformation, dislocation density increases dramatically; accordingly, the stress increases rapidly. BARDI et al [20] found that the softening can be attributed to the progressive loss of coherence and the coarsening of precipitates in 2618 aluminium alloy. For the flow softening, it is hard to identify the actual mechanism directly from the curves. The precise relationship between the dynamic microstructural evolution and the flow stress of the alloy will be discussed in detail in the following sections by XRD analysis, SEM and TEM observation of the deformed specimens at different strains.

Fig. 1 True stress-true strain curves of Al-4.10Cu-1.42Mg-0.57Mn-0.12Zr alloy during hot compression

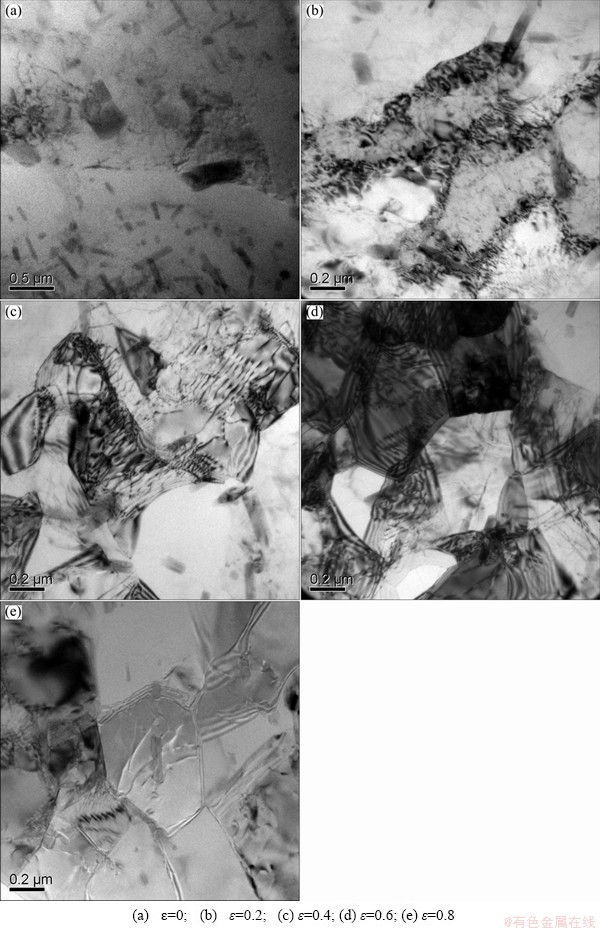

Fig. 2 TEM images of substructure evolution of Al-4.10Cu-1.42Mg- 0.57Mn-0.12Zr alloy deformed at various strains

3.2 Characterization of dynamic microstructure evolution

3.2.1 Substructure evolution

TEM images of the Al-4.10Cu-1.42Mg-0.57Mn- 0.12Zr alloy deformed under various strains are shown in Fig. 2, in which dynamic development of the dislocations and sub-grains can be observed. Dynamic recovery is usually seen in its alloy at the higher strain rate of 10 s-1 and lower deformation temperature [21]. As for preheated specimen (ε=0), part of grain boundaries can be seen and a large number of precipitates are also observed on and inside the grains, as shown in Fig. 2(a). The particles distributed behind grain boundaries are coarser than those within the grains, which lead to formation of clear precipitate-free-zone (PFZ) along the grain boundary while numbers of dislocations or dislocation walls are given at the strain of 0.2 (Fig. 2(b)). When the strain increases to 0.4, dislocations are districted into certain length range and distributed unevenly, which leads to formation of cell substructure. The restricted and dense dislocations tangle through climbing and sliding and interacting with precipitates, as shown in Fig. 2(c). At the strain of 0.6, distinct subgrains can be observed and sub-grain size increases at a certain extent. The microstructure is made up by sub-grains or cellulars with the sizes of 0.2-0.6 μm, which presents an equiaxial tendency. And equiaxed sub-grains appear with a low dislocation density inside. The subgrain boundaries also becoming straight (Fig. 2(d)). In Fig. 2(e), coarser subgrains are presented with higher boundary orientation, and lower dislocation density is given within subgrains at strain of 0.8. To sum up, observation of subgrains formation and growth process is clearly shown in Fig. 2 with increasing the strain during hot deformation process. Such processes indicate typical dynamic recovery and lead to flow softening (Fig. 1).

3.2.2 Dynamic precipitates evolution

Figure 3 show the X-ray diffraction (XRD) analysis of the Al-4.10Cu-1.42Mg-0.57Mn-0.12Zr alloy deformed at various strains at temperature of 300 °C and strain rate of 10 s-1. When deformed at the strain of 0.2, diffraction peak positions of S phase change obviously, indicating the happening of re-dissolution and re-precipitate at stain of 0.4; density of S phase increases and diffraction peak broadens. As the strain rises, dislocations will provide channel for diffusion of atom, and re-dissolution will aggravate. But at the last stage of deformation, both S phase and θ phase show a tendency of decrease. At the same time, Al3Zr phase shows less re-dissolution and precipitation during the whole process. In order to confirm the response for these effects, the samples are observed by SEM and TEM.

Figure 4 shows the backscatter SEM images of the Al-4.10Cu-1.42Mg-0.57Mn-0.12Zr alloy deformed at various strains, and general morphology of particle distributions could be seen with increasing the strains. The primary morphology (Fig. 4(a)) shows discontinuous intermetallic particles along grain boundaries and homogeneous fine precipitates within grains while little changes occur for the intermetallic particles distributed at grain boundaries at the initial deformation stage (Figs. 4(b) and (c)). But lower density of precipitates within grains is given due to the dissolution of precipitation during deformation. With further deformation (Figs. 4(d) and (e)), the intermetallic particles seem to coarsen and distribute homogeneously. And little intragranular precipitates are presented.

Fig. 3 XRD analysis of Al-4.10Cu-1.42Mg-0.57Mn-0.12Zr alloy during hot deformation

Fig. 4 Backscattered SEM images of Al-4.10Cu-1.42Mg-0.57Mn-0.12Zr alloy deformed at various strains

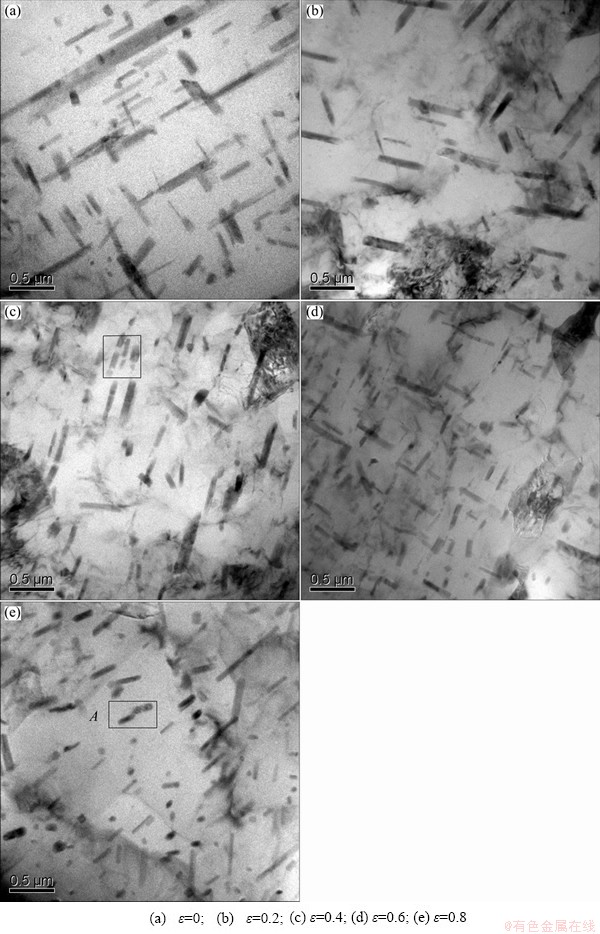

Fig. 5 Dynamic evolution of S phase precipitates of Al-4.10Cu-1.42Mg- 0.57Mn-0.12Zr alloy deformed at various strains

Figure 5 shows the dynamic evolution of S phase of the Al-4.10Cu-1.42Mg-0.57Mn-0.12Zr alloy during hot compression. The EDS analysis of area A is listed in Table 1. After preheating for 300 s at 300 °C, numerous rod-like precipitates, with length of 400-800 nm and diameter of 100 nm, are unevenly distributed and mutually perpendicular. After being deformed to strain of 0.2, some S precipitates initiate a rotation with the matrix during deformation and S precipitates interact with the dislocations due to the introduction of dislocations during plastic deformation. When deformed at the strain of 0.4, several coarse S phases begin to be fragmented into small pieces or shortened precipitates due to the high shear stress during plastic deformation, and the phase/matrix surface energy increases as a result of the fragmentation and the damage of coherency or semi-coherency state between phases and the matrix by the phase rotation [11]. Some of the precipitates seem to re-dissolve with decreasing dimension and increasing density, as marked in Fig. 5. As strain increases further, the rotation and break-up of the pre-existing S precipitates aggravate, and some of the S particles array in vertical direction with length in the range of 100-200 nm and a mean diameter of around 40 nm. The mobile dislocations in combination with the increased surface energy effectively promote the dissolution of small metastable precipitates by shearing through the precipitate particles [2,11]. And the accelerated formation of fine and uniform dispersion of precipitates can be observed at the strain of 0.8.

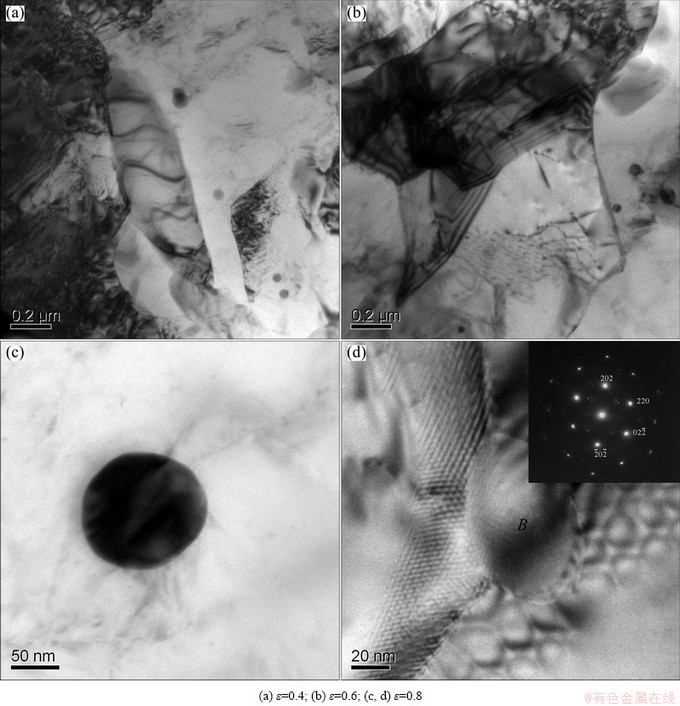

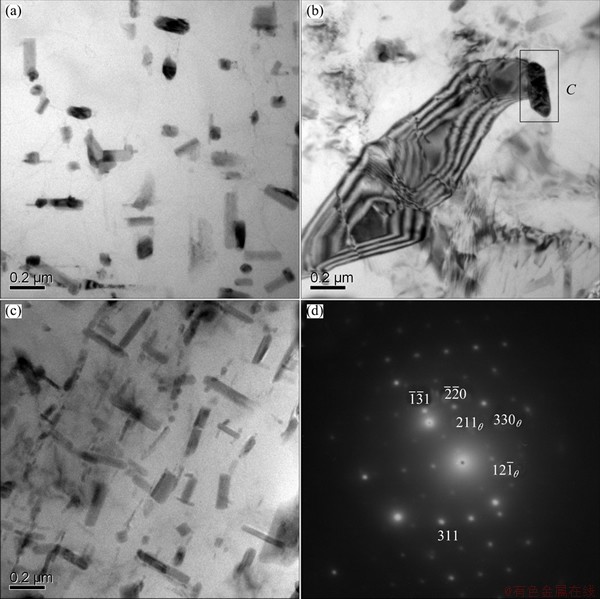

There are not many Al3Zr particles with uneven sizes in the range from 20 to 60 nm, which is consistent with previous XRD analysis (Fig. 3), and some of them are round but others have irregular shape in the presence of other elements, as shown in Fig. 6. As strain increases, round Al3Zr can be observed with the size of about 40 nm. When strain increases to 0.6, fine and dispersive Al3Zr phases precipitating at sub-grain boundary and dislocations are observed, which are round with the diameter about 30 nm. These Al3Zr phases interact with dislocations and pin the sub-grain boundaries and dislocations motion. The stripe-like Al3Zr precipitate clusters have a preferential orientation relationship with the <100>Al directions, which are inferred to be related to θ′-Al2Cu and θ phases [22]. Small Al3Zr dispersoid particles inhibit recrystallization by pinning the grain and subgrain boundaries during hot deformation [17]. Some round granular and coarse Al3Zr phases are also presented in matrix. The selected area diffraction patterns (SADP) and EDS analysis of area B in Table 1 show participates composed of Al-Cu-Mg and Al3Zr participated along the grain boundary at strain of 0.8. It can also be seen from the electron diffraction pattern at the top right corner that the orientation relationship between Al3Zr phase and Al matrix is  .

.

Fig. 6 Dynamic evolution of Al3Zr phase precipitates of Al-4.10Cu-1.42Mg-0.57Mn-0.12Zr alloy deformed at various strains

Dynamic evolution of the θ phase precipitates are shown in Fig. 7. Such Al-Cu binary phases (diameters of 40-200 nm) are mostly disc or short rod shaped in the preheated specimen. At early deformation stage, the dislocation can serve as fast diffusion paths for solute atoms in the matrix, thereby permitting rapid diffusion to the stable precipitates to assist their growth [12], and the particles coalescence or agglomeration may also occur when deformed to the strain of 0.4 [13]. The θ phase (EDS of area C in Table 1) is observed at the grain boundary as well and such precipitates pin the grain boundary and prevent grain from growing. The orientation relationship between the θ phase and Al matrix is  , which can be got from the electron diffraction pattern in Fig. 7. The density of θ phases decreases with increasing the strain, as shown in Fig. 7, which can be explained by two reasons: 1) As strain increases, θ phases assemble together, showing a decrease in number and a wider precipitate spacing; 2) During deformation, S phases nucleate on dislocations ahead of θ phases, consuming more heterogeneous nucleation, while the Cu atoms preferentially gather with Mg atoms to form Mg-Cu atom clusters, thus Cu atoms for θ phases are consumed. But θ phases (diameters of 40-160 nm) begin to coarsen and segregate with increasing the strain (Fig. 7), which will result in flow softening (Fig. 1). The principal effect of deformation on particle coarsening was concluded to be increased diffusion due to the dislocation content. Coarsening rates of particles increase during deformation compared with those during static annealing, and this could be due to accelerated diffusion associated with an increase in vacancy concentration, the formation of extensive substructure and the influence of existing high-angle grain boundaries [23].

, which can be got from the electron diffraction pattern in Fig. 7. The density of θ phases decreases with increasing the strain, as shown in Fig. 7, which can be explained by two reasons: 1) As strain increases, θ phases assemble together, showing a decrease in number and a wider precipitate spacing; 2) During deformation, S phases nucleate on dislocations ahead of θ phases, consuming more heterogeneous nucleation, while the Cu atoms preferentially gather with Mg atoms to form Mg-Cu atom clusters, thus Cu atoms for θ phases are consumed. But θ phases (diameters of 40-160 nm) begin to coarsen and segregate with increasing the strain (Fig. 7), which will result in flow softening (Fig. 1). The principal effect of deformation on particle coarsening was concluded to be increased diffusion due to the dislocation content. Coarsening rates of particles increase during deformation compared with those during static annealing, and this could be due to accelerated diffusion associated with an increase in vacancy concentration, the formation of extensive substructure and the influence of existing high-angle grain boundaries [23].

Fig. 7 Dynamic evolution of θ phase precipitates of Al-4.10Cu-1.42Mg-0.57Mn-0.12Zr alloy deformed at various strains of ε=0 (a), ε=0.4 (b), ε=0.6 (c), and corresponding SAED pattern of area C (d)

Table 1 EDS analysis of Al-Cu-Mg-Zr alloy deformed at various strains at temperature of 300 °C and strain rate of 10 s-1

4 Conclusions

1) True stress-true strain curves exhibited a peak stress at critical strain, after which the flow stresses decreased monotonically, showing a dynamic flow softening. The flow softening mechanism was resulted from the reduction of dislocation density, which was attributed to dynamic recovery and precipitates coarsening.

2) The dislocations tangled to cells and sub-grain, and the subgrains grew through the migration of dislocations and sub-grain boundaries with further deformation. The finer precipitates delayed the sub-grain coarsening by impeding grain boundary mobility.

3) Dynamic precipitations of S (Al2CuMg), θ (Al2Cu) and Al3Zr phase were accelerated and they coarsened by deformation. Continuous S phases precipitated in the Al matrix and discontinuous S phases were found to be nucleated near the Al3Zr phase and at the sub-grain boundary. Al3Zr phases were relatively stable and easy to be precipitated on dislocations and at sub-grain boundaries.

References

[1] LAM D F, MENZEMERA C C, SRIVATSANB T S. A study to evaluate and understand the response of aluminum alloy 2026 subjected to tensile deformation [J]. Mater Des, 2010, 31: 166-175.

[2] WOUTERS P, VERLINDEN B, McQUEEN H J, AERNOUDT E, DELAEY L, CAUWENBERG S. Effect of homogenization and precipitation treatments on the hot workability of an aluminium alloy AA2024 [J]. Mater Sci Eng A, 1990, 123: 239-245.

[3] LIU Xiao-yan, PAN Qing-lin, HE Yun-bin, LI Wen-bin, WEN Jie-liang, YIN Zhi-min. Flow behavior and microstructural evolution of Al-Cu-Mg-Ag alloy during hot compression deformation [J]. Mater Sci Eng A, 2009, 500: 150-154.

[4] LI H Z, WANG H J, LIANG X P, LIU H T, LIU Y, ZHANG X M. Hot deformation and processing map of 2519A aluminum alloy [J]. Mater Sci Eng A, 2011, 528: 1548-1552.

[5] MCQUEEN H J. Development of dynamic recrystallization theory [J]. Mater Sci Eng A, 2004, 387-389: 203-208.

[6] HUANG Xu-dong, ZHANG Hui, HAN Yi, WU Wen-xiang, CHEN Jiang-hua. Hot deformation behavior of 2026 aluminum alloy during compression at elevated temperature [J]. Mater Sci Eng A, 2010, 527: 485-490.

[7] ZHANG Hui, CHEN Rong, HUANG Xu-dong, CHEN Jiang-hua. Microstructural evolution of 2026 aluminum alloy during hot compression and subsequent heat treatment [J]. Transactions of Nonferrous Metals Society of China, 2011, 21: 955-961.

[8] VERLINDEN B, WOUTERS P, McQUEEN H J, AERNOUDT E, DELAEY L, CAUWENBERG S. Effect of different homogenization treatments on the hot workability of aluminium alloy AA2024 [J]. Mater Sci Eng A, 1990, 123: 229-237.

[9] EBRAHIMI G R, ZAREI-HANZAKI A, HAGHSHENAS M, ARABSHAHI H. The effect of heat treatment on hot deformation behaviour of Al 2024 [J]. J Mater Process Technol, 2008, 206: 25-29.

[10] GAVGALI M, AKSAKAL B. Effects of various homogenisation treatments on the hot workability of ingot aluminium alloy AA2014 [J]. Mater Sci Eng A, 1998, 254: 189-199.

[11] CAVALIERE P. Hot and warm forming of 2618 aluminium alloy [J]. J Light Met, 2002, 2: 247-252.

[12] GUBICZA J, SCHILLER I, CHINH N Q, ILLY J, HORITA Z, LANGDON T G. The effect of severe plastic deformation on precipitation in supersaturated Al-Zn-Mg alloys [J]. Mater Sci Eng A, 2007, 460-461: 77-85.

[13] ROVEN H J, LIU M P, WERENSKIOLD J C. Dynamic precipitation during severe plastic deformation of an Al-Mg-Si aluminium alloy [J]. Mater Sci Eng A, 2008, 483-484: 54-58.

[14] WANG S C, STARINK M J, GAO N. Precipitation hardening in Al-Cu-Mg alloys revisited [J]. Scripta Mater, 2006, 54: 287-291.

[15] GOREGE W S. Precipitation kinetics in solutionized aluminum alloy 2l24: Determination by scanning and isothermal calorimetry [J]. Thermochimi Acta, 1998, 317: 7-23.

[16] WANG S C, STARINK M J. Precipitates and intermetallic phases in precipitation hardening Al-Cu-Mg- (Li) based alloys [J]. Int Mater Rev, 2005, 50(4): 193-215.

[17] CABIBBO M, EVANGELISTA E, SPIGARELLI S. Microstructural characterization of secondary-phase particles in a hot-deformed Al-Cu-Mg-Zr alloy [J]. Mater Trans A, 2004, 35: 293-300.

[18] WANG Y, SHAO W Z, ZHEN L, ZHANG B Y. Hot deformation behavior of delta-processed superalloy 718 [J]. Mater Sci Eng A, 2011, 528: 3218-3227.

[19] ZHANG Jing, CHEN Bo-quan, ZHANG Bao-xiang. Effect of initial microstructure on the hot compression deformation behavior of a 2219 aluminum alloy [J]. Mater Des, 2012, 34: 15-21.

[20] BARDI F, CABIBBO M, SPRGARELLI S. An analysis of thermo-mechanical treatments of a 2618 aluminium alloy: Study of optimum conditions for warm forging [J]. Mater Sci Eng A, 2002, 334: 87-95.

[21] CHEN Yong-lai, LI Jin-feng,  Hong-jun, LI Shi-chen, ZHENG Zi-qiao, ZHANG Yu-wei, ZHANG Xu-hu. Hot deformation behavior of Al-Cu-Li-Mg-Zr alloy containing Zn and Mn [J]. Transactions of Nonferrous Metals Society of China, 2007, 17: 271-275.

Hong-jun, LI Shi-chen, ZHENG Zi-qiao, ZHANG Yu-wei, ZHANG Xu-hu. Hot deformation behavior of Al-Cu-Li-Mg-Zr alloy containing Zn and Mn [J]. Transactions of Nonferrous Metals Society of China, 2007, 17: 271-275.

[22] JIA Zhi-hong,  J P, CHERDOUDI N, GUILLOT I, ARNBERG L,

J P, CHERDOUDI N, GUILLOT I, ARNBERG L,  SHOLT P, BRUSETHAUG S, BARLAS B, MASSINON D. Precipitation behaviour of Al3Zr precipitate in Al-Cu-Zr and Al-Cu-Zr-Ti-V alloys [J]. Transactions of Nonferrous Metals Society of China, 2012, 22: 1860-1865.

SHOLT P, BRUSETHAUG S, BARLAS B, MASSINON D. Precipitation behaviour of Al3Zr precipitate in Al-Cu-Zr and Al-Cu-Zr-Ti-V alloys [J]. Transactions of Nonferrous Metals Society of China, 2012, 22: 1860-1865.

[23] ROFMAN O V, BATE P S. Dynamic grain growth and particle coarsening in Al-3.5Cu [J]. Acta Mater, 2010, 58: 2527-2534.

刘 灿1, 张 辉1,2, 蒋福林1,3

1. 湖南大学 材料科学与工程学院,长沙 410082;

2. 湖南大学 湖南省喷射沉积技术及应用重点实验室,长沙 410082;

3. Department of Materials Science and Engineering, McMaster University, Hamiltion, Ontario L8S 4L7, Canada

摘 要:在Gleeble-1500热模拟机上对Al-4.10Cu-1.42Mg-0.57Mn-0.12Zr合金在变形温度300 °C和应变速度10 s-1下进行热压缩变形,真应变分别为0.2、0.4、0.6和0.8。通过X射线衍射仪、扫描电镜和透射电镜研究合金变形过程中复杂的动态显微组织演变。结果表明:真应力随着应变的增加而迅速增大至峰值,之后随着应变的增加而趋于稳定,呈现动态软化特征。随着应变的增大,位错缠结成胞状与亚晶结构,表明变形过程中发生动态回复。动态析出相S相、θ相和Al3Zr相在变形过程中粗化速度加快。铝基体中析出连续的S相,并发现有不连续的S相在Al3Zr相附近和亚晶界处形核析出。Al3Zr相相对比较稳定,易于在位错和亚晶界处析出。流动软化机制是由于动态回复和动态析出导致位错密度减少而引起的。

关键词:铝合金;热变形;流动软化;动态回复;动态析出

(Edited by Chao WANG)

Foundation item: Project (2009CB623704) supported by the National Basic Research (973) Program of China; Project (20130161110007) supported by the Doctoral Program of the Ministry of Education, China; Project (CX2013B128) supported by Hunan Provincial Innovation Foundation for Postgraduate, China

Corresponding author: Hui ZHANG; Tel: +86-731-88664086; Fax: +86-731-88821483; E-mail: zhanghui63hunu@163.com

DOI: 10.1016/S1003-6326(14)63491-9