DOI:10.19476/j.ysxb.1004.0609.2019.12.14

铜熔池熔炼过程中生物柴油浸没燃烧数值模拟

邓伟鹏1, 2,张小辉1, 3,张广君1,张 汉1,冯立斌1, 2

(1. 昆明理工大学 省部共建复杂有色金属资源清洁利用国家重点实验室,昆明 650093;

2. 昆明理工大学 冶金与能源工程学院,昆明 650093;

3. 昆明理工大学 冶金节能减排教育部工程研究中心,昆明 650093)

摘 要:以生物柴油替代化石柴油进行浸没燃烧熔池熔炼是发展低碳铜冶炼的重要途径,针对该过程建立生物柴油浸没喷吹燃烧计算模型,计算了喷枪在铜熔体中浸没深度为1 cm时不同氧气体积分数条件下生物柴油浸没燃烧过程及烟气气泡和熔体的运动规律,并实验验证了计算模型。结果表明:生物柴油在熔体内的燃烧过程是间歇的,其燃烧主要集中在与喷嘴相连的气泡内完成,脱离喷嘴的气泡内燃烧现象较弱;计算区域内温度变化分为3个阶段:无规律剧烈变化、温度下降较快、温度缓慢下降;气泡上升轨迹为曲线,上升过程中气泡形状变化依次为球形、椭圆形、扁椭圆形;熔体中线处流动速度较大,近壁面处流动速度较小。

关键词:生物柴油;浸没燃烧;熔池熔炼;数值模拟;低碳冶金

文章编号:1004-0609(2019)-12-2809-10 中图分类号:TF811 文献标志码:A

在冶金工业中,冶金炉窑中的高温流体(如金属熔体,燃烧产生的高温烟气等)多相流动过程关系到冶金过程反应的效率和冶金炉窑的安全使用寿命[1]。浸没喷吹铜熔池熔炼过程呈现流体混合、传热传质、动量传递及化学反应等复杂多相流动行为[2]。生物柴油以其可再生性及制造成本低廉等优点越来越多的应用在工业燃烧领域[3-5]。铜熔池熔炼过程为了维持反应的持续进行,需要向炉内补充一定热量[6]。浸没燃烧产生的高温烟气对熔体的搅拌、传热效果直接影响炉内传热传质过程,因此研究生物柴油在铜熔体内浸没燃烧和传热过程十分必要。

关于冷态水模型浸没喷吹气泡运动过程和生物柴油燃烧的研究较多。ABBASSI等[7]研究液体黏度、表面张力、惯性力对气泡上浮过程中形状改变的影响。结果表明:在黏度较低的溶液中,气泡的形状主要受溶液表面张力和惯性力的影响,黏度对气泡上浮过程中形状改变影响很小;在黏度较大溶液中,黏度对气泡的形状改变起主要作用。LIU等[8,9]研究不同黏度液体、不同喷口直径对气泡上浮过程形状变化和运动轨迹的影响,研究结果表明,在黏度较大液体中气泡上浮保持球形或接近球形;喷口直径越大喷吹形成气泡直径越大,运动轨迹越趋向于曲线。LI等[10-11]针对生物柴油的燃烧产物展开分析,得出生物柴油燃烧产生较少的一氧化碳、碳氢化合物和颗粒物。SARAVANAKUMAR等[12]对柴油在不同几何形状的燃烧室内燃烧特性展开研究,发现不同几何形状燃烧室对燃料和空气混合物的湍流强度及燃烧产物有很大的影响。DHAR等[13-14]研究燃料喷射压力对生物柴油燃烧特性的影响,发现提高燃料喷射压力强化雾化作用及油气混合效果,使燃烧最高温度提高。

以上研究均只针对液体燃料在自由区域内燃烧和熔池熔炼浸没喷吹相对应的冷态气泡流动过程。对生物柴油在熔体内浸没燃烧特性研究则未见报道。本课题组在前期通过与某铜冶炼企业合作,以生物柴油为燃料进行了底吹熔池熔炼的工业化实验,取得了较好的节能效果。为进一步探究生物柴油在熔体中的燃烧特性及气泡运动规律,本文建立生物柴油熔池熔炼浸没喷吹过程计算模型,并进行实验验证。研究在不同氧气体积分数时生物柴油的燃烧特性、烟气气泡和熔体的运动规律。

1 模型建立

1.1 物理模型

根据实验,计算区域为圆柱体,其直径6 cm、高0.2 m。浸没喷枪为双层套管型,长1 cm,在喷枪出口端设有混合室,长2 mm;内管通生物柴油,内直径为0.6 mm;外管通空气,内直径为2.6 mm,管壁厚度为0.1 mm。计算区域分为上下两部分:上部为烟气区域,高5 cm;下部为熔体区域,高0.15 m。喷枪由计算区域底部几何中心插入,浸没深度为1 cm。如图1所示为计算区域及边界示意图。

图1 计算区域及边界条件

Fig. 1 Simulation domain and boundary conditions

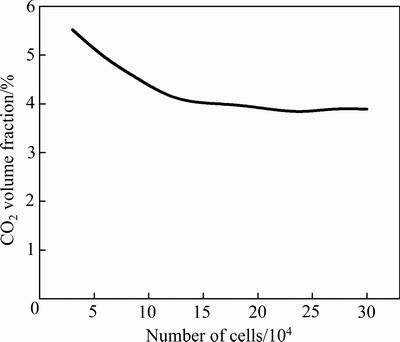

1.2 网格无关性检验

采用四面体结构化网格对计算区域进行离散化,图2所示为不同网格数时计算区域出口CO2体积分数。由图2可知,网格数超过20万个时,计算区域出口处CO2体积分数变化较小,说明此时网格数量对计算精确度的影响可以忽略,因此,结合精确性与计算量的考虑,确定总网格数为20万。

图2 网格无关性检验

Fig. 2 Grid-independent verification

1.3 计算模型

1.3.1 模型的简化与假设

1) 本研究重点关注浸没喷吹铜熔池熔炼过程中熔池内生物柴油的燃烧及多相流动行为,因而暂未考虑加料、放渣及造锍反应等间断性过程,故可假设熔池深度不变;2) 计算区域壁面绝热,与外部环境无任何热交换。

1.3.2 基本方程

将空气、熔体视为互不相溶流体,各计算单元格内两种流体的体积分数 之和为1[15-16],即

之和为1[15-16],即

(1)

(1)

同样,传输方程中密度 和黏度

和黏度 采用体积平均法通过各相的体积分数

采用体积平均法通过各相的体积分数 得到

得到

(2)

(2)

(3)

(3)

注入熔体中生物柴油的体积相对于空气和熔体的体积非常小。因此,忽略生物柴油密度和黏度的影响。

在多相流模型(Volume of fluid model, VOF)[17]中,追踪界面主要是通过求解一相或多相的体积分数的连续性方程来完成的。

连续性方程:

(4)

(4)

(5)

(5)

式中:t为模拟时间,s; 、

、 表示气、液相的体积分数;

表示气、液相的体积分数; 、

、 为气、液相的密度,kg/m3;

为气、液相的密度,kg/m3; 、

、 为气、液相的速度,m/s;

为气、液相的速度,m/s; 是气相到液相的质量输送;

是气相到液相的质量输送; 是液相到气相的质量输送;

是液相到气相的质量输送; 为气相的源项;

为气相的源项; 为液相的源项;

为液相的源项; 为算子符号,表达式为

为算子符号,表达式为 。

。

VOF多相流模型的速度场是由各相共享的,是通过求解整个区域内的单一的动量方程来得到。

动量守恒方程:

(6)

(6)

式中: 为流体密度,kg/m3;p为压强,Pa;g为重力加速度,m/s2;F为作用于控制容积上的体积力[18],N;v为流体速度,m/s;

为流体密度,kg/m3;p为压强,Pa;g为重力加速度,m/s2;F为作用于控制容积上的体积力[18],N;v为流体速度,m/s; 为动力黏度,Pa·s。

为动力黏度,Pa·s。

能量方程:

(7)

(7)

方程式左起前3个分别表示由于传导,物质扩散和黏性耗散引起的能量转移;Sh为源项。

辐射模型采用p-1辐射模型[19]。

(8)

(8)

式中:qr为辐射热流量,w; 为辐射吸收系数;

为辐射吸收系数; 为玻尔兹曼常数,W/(m2·K4);G为入射辐射;

为玻尔兹曼常数,W/(m2·K4);G为入射辐射; 可直接带入能量方程中用解释由于辐射而增加的热源项;n为介质折射率。

可直接带入能量方程中用解释由于辐射而增加的热源项;n为介质折射率。

在非预混燃烧模型[20]中,在所有组分中,燃烧和未燃烧燃料流的元素的局部质量分数f由式(9)表示:

(9)

(9)

式中:Zi是元素的质量分数;下标air表示O2,而下标oil表示生物柴油。

1.4 初始条件、边界条件及计算工况

生物柴油选用小桐子油生物柴油,小桐子油生物柴油是实验室通过酯交换制备的,并对其理化性质进行检测,结果如表1所示。

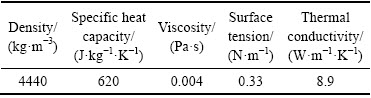

铜熔池熔炼工艺过程为保证熔炼效果最佳,其铜锍温度一般控制在1400 K左右,铜锍物理参数[21-22]如表2所示。

表1 300 K时小桐子油生物柴油理化性能指标

Table 1 Jatropha curcas biodiesel properties and composition at 300 K

表2 铜锍的物理参数

Table 2 Physical parameters of copper-matte

计算区域共一支喷枪,喷枪从计算区域底部几何中心浸没到熔体中,浸没深度为1 cm。空气入口、生物柴油入口均为质量流量入口,熔池出口为压力出口,壁面看作无滑移边界。生物柴油质量流量为1.35× 10-7 kg/s,小桐子油生物柴油完全燃烧理论空燃比为12.3,空气入口质量流量为1.66×10-6 kg/s。初始设定熔体温度为1400 K,熔体上方烟气温度为1400 K,出口温度为1400 K。空气入口温度700 K,生物柴油入口温度为300 K。

在喷入的氧气体积分数分别为21%、24%、27%、30%时,对生物柴油在熔体内燃烧、传热及流动过程展开研究。计算工况如表3所示。

表3 计算工况

Table 3 Calculation condition

2 结果与分析

在浸没深度为1 cm的条件下,分析不同氧气体积分数时生物柴油在铜熔池内燃烧特性、烟气气泡及熔体的运动规律。

2.1 燃烧、排放特性

生物柴油在工业炉窑中燃烧,燃烧室几何形状固定,燃烧室内温度、燃烧产物分布具有较强层次性。生物柴油在熔体中浸没燃烧不同于在常规空间燃烧,燃烧过程中气泡体积、气泡内各组成成分时刻改变。高温气泡上浮将热量传递给熔体,导致熔体中温度分布不同于常规空间燃烧温度分布。

2.1.1 燃烧过程

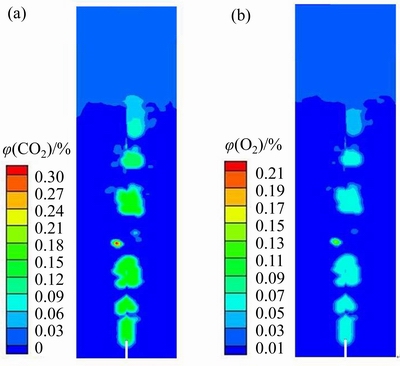

图3所示为熔体内CO2和O2体积分数分布。从图3可观察到,熔体内不同气泡所含有的CO2和O2体积分数变化较小。气泡内CO2体积分数约为15%,O2体积分数约为3%。燃烧过程中产生大量烟气,使气泡体积迅速膨胀。喷吹方向为纵向,因此浸没喷吹初期气泡体积纵向膨胀大于横向,此时气泡为狭长形。继续喷吹,在气泡底部与喷嘴连接处形成很小的缩口,直到后来与喷嘴分离,此时与喷嘴相连的燃烧空间最小,燃烧现象较弱,甚至无燃烧现象。随着油气混合物的持续进入,与喷嘴相连的气泡体积增大,燃烧现象增强,以后将重复此过程。离开喷嘴口后气泡内部烟气成分基本不变,因此,燃烧过程主要集中在与喷嘴相连的气泡内完成。

图3 计算区域内CO2、O2体积分数分布

Fig. 3 Volume fraction distribution of CO2(a) and O2(b) in molten slag bath

2.1.2 不同O2体积分数下的温度场

图4所示为不同O2体积分数时计算区域中心线温度分布。提高O2体积分数,生物柴油在熔体中燃烧更充分,燃烧产生的烟气温度升高,向熔体传热量增加,熔体温度提高,但熔体内温度提高幅度逐渐减小。沿中心线熔体温度变化分为3个过程:无规律剧烈变化、温度下降较快、温度缓慢下降。从喷口开始至距熔体底部0.05 m之间熔体温度变化剧烈,此时气泡离开喷枪时间较短,气泡速度较大,气泡温度较高和熔体之间温差最大。在此过程气泡和熔体之间进行强烈对流换热,温度波动较大。距熔池底部0.05 m至0.15 m此时,气泡形状变为较为稳定的椭圆形,气泡向液面运动浮力起主导作用,气泡上浮速度稳定,气泡和熔体之间的对流换热强度较之前降低,熔体内温度下降规律性明显。距熔池底部0.15 m以后,燃烧产物进入 熔体上方气空间,燃烧产物经过前一阶段与熔体传热温度较低,此时以换热方式为辐射换热为主,换热效果较差,温度下降较为缓慢。

图4 不同O2体积分数时的中心线处温度分布

Fig. 4 Temperature distribution along axis with different volume fractions of O2

图5所示为不同O2体积分数计算区域温度分布,图中21%、24%、27%、30%表示不同的O2体积分数。不同O2体积分数下熔体内温度梯度分布一致。O2体积分数提高,生物柴油浸没燃烧传热影响的范围变大,熔体内高温区域面积也变大。图6所示为熔体内不同位置观察线上温度变化。在距喷枪口垂直方向0.05 m、0.10 mm、0.14 m分处别建立3条长度为0.04 m的观察线监测熔体温度变化。不同O2体积分数下相同观察线处熔体温度曲线变化趋势一致。0.05 m处观察线熔体温度分布类似驼峰状,在近喷口处温度变化较为剧烈,燃烧产生的高温横向传递范围较小。0.10 m处观察线熔体温度分布类似梯形,熔体几何中心处温度变化较为平缓,靠近壁面温度下降较快。0.14 m处观察线熔体温度分布类似半椭圆形,熔体内部大部分温度分布均匀,在近壁面处有所下降,温度变化较为平缓。

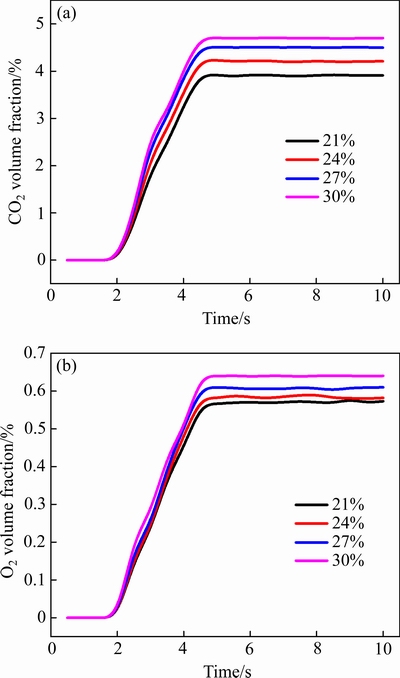

图7所示为出口截面CO2、O2体积分数随时间的变化过程。随着喷枪进口O2体积分数提高,在出口截面处CO2、O2体积分数提高。燃烧产物在喷口产生经过4 s后流到出口截面,4 s后出口截面上CO2、O2体积分数含量稳定,且随O2体积分数的提高,CO2体积分数增加量逐渐减少,出口截面O2体积分数增加量逐渐加大。O2体积分数越高生物柴油燃尽率越高,提高相同体积分数的O2时,出口截面CO2体积分数增加量逐渐减少、O2体积分数增加量逐渐加大。

图5 计算区域温度分布

Fig. 5 Temperature distribution in molten slag bath

图6 熔体内不同位置观察线上温度变化

Fig. 6 Temperature change of different monitor lines in molten slag bath

图7 出口处CO2和O2体积分数随时间的变化过程

Fig. 7 Variations of CO2(a) and O2(b) volume fractions with time at outlet

2.2 气泡形成、运动及熔体流动

2.2.1 气泡的形成、运动

生物柴油浸没燃烧产生的烟气在熔体内形成气泡,气泡形成分为3个连续步骤:气泡产生、气泡生长、气泡在喷口分离。图8所示为熔体内烟气气泡形成、运动过程。气泡产生初期熔体表面张力起主导作用,气泡形状类似于球形,随后气泡体积增加,气泡形状变为椭圆形。继续喷吹,气泡体积增加,受到熔体的浮力作用大于表面张力的影响,气泡径向伸长。最后,在继续增大的浮力作用下,气泡和喷口连接部分越来越薄,最终导致气泡与喷口脱离。

第一个气泡离开喷枪,因其体积较大对两侧熔体产生强烈扰动,导致熔体内部形成以气泡为中心沿射流方向向周围熔体卷吸的回流区。回流区的形成使喷枪正上方受到压力减小,在较大空气流速冲击下会在熔体中形成狭长气柱。第二个气泡体积变大,受到熔体的浮力作用起主导作用,喷枪口和气泡的连接部分越来越薄,最后气泡离开喷枪。随着喷吹时间增长,在熔体空间存在气泡数量增加,回流区影响范围越来越大。从第二个气泡开始,回流区对喷枪口的影响逐渐趋于稳定,气泡产生、气泡生长、气泡在喷口分离过程稳定,气泡体积变化较小。

气泡离开喷枪后依靠惯性力和熔体浮力的共同作用使其在熔体内上升。气泡脱离喷枪后先保持直线运动。气泡上升一段距离后,其运动轨迹开始偏离直线, 最终变为曲线上升。同时,气泡形状也由球形变为椭圆形,靠近液面时变为扁椭圆形。从以上分析中可看出,气泡在近喷口是保持直线上升,远离喷口后运动轨迹变为曲线上升。气泡向液面上浮过程中,气泡形状变得更加扁平。

图8 熔体内烟气气泡形成、运动过程

Fig. 8 Formation, motion process of flue gas bubble in molten slag bath

2.2.2 熔体流动

生物柴油浸没燃烧产生的烟气在熔体内形成气泡,气泡向液面运动会对熔体造成一定冲击,导致初始状态为静态的熔体具有一定的速度。本节通过建立的观察线探究气泡上浮过程对熔体流动速度的影响。

图9所示为不同观察线上熔体速度变化曲线。图中21%、24%、27%和30%表示不同的O2体积分数,0.05 m、0.10 m、0.14 m表示所建立的3条观察线。不同O2体积分数下熔体速度曲线变化趋势一致,熔体区域中线处流速较大,近壁面处流速较低。距离喷枪口近的观察线,熔体速度较大;距离喷枪口越远的观察线,熔体的速度越小。气泡向液面运动是减速过程:气泡未脱离喷枪时,气泡内部气流会撞击气泡顶部使气泡径向生长,此时气泡速度较大。气泡离开喷枪后,受惯性力和浮力的共同作用向液面运动,向液面运动过程中惯性力逐渐减小。因此气泡向液面运动是一个减速过程。气泡产生时内部烟气温度较高,向液面运动将部分热量传递给熔体。气泡温度降低,体积减小。但气泡上浮过程中,受到熔体压力降低,体积增大。气泡体积较小以及气泡脱离喷枪直至在液面破碎历经时间较短,在此过程中忽略气泡体积的变化。综上所述可知,熔体流速的变化主要受气泡上浮速度的影响,气泡上浮是减速过程,因此,在距喷枪越远的观察线处,熔体流速越小。

图10所示为不同O2体积分数时观察线上熔体流速变化。不同观察线处熔体速度变化趋势一致:熔体区域中线处流速较大,其速度向四周递减;O2体积分数越大相同观察线处熔体最大流速越大。提高O2体积分数,生物柴油燃尽率越高,烟气产量增加,气泡流速增大。高速气泡对熔体冲击作用增强,相同观察线处O2体积分数越高,熔体流速越大。

3 实验验证

为验证生物柴油浸没燃烧过程计算模型的准确性,搭建生物柴油浸没燃烧实验平台。计算模型尺寸与实验坩埚尺寸一致,对工况1进行实验验证。如图11所示为生物柴油浸没燃烧实验流程示意图:实验系统主要由燃料供给系统、供气系统、管式炉、烟气分析仪等组成。燃油供给系统配备了压力表监测喷油压力。供气系统配备气体流量计监测空气质量流量。烟气出口处配备热电偶测温及烟气分析仪分析烟气成分。

图9 不同观察线上熔体流速变化

Fig. 9 Variation of velocity of melt in different monitor lines

图10 不同O2体积分数时观察线上熔体流速变化

Fig. 10 Variation of melt velocity of monitor lines at different O2 volume fraction

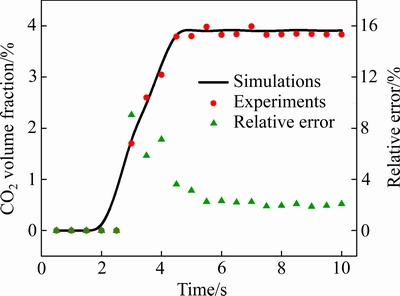

各时刻实验值(7次试验平均值)与计算值及相对误差如下:

相对误差:

(10)

(10)

式中:RE为相对误差;pD,exp和pD,sim分别代表CO2压力的实验值、计算值。

图12所示为烟气出口处CO2的计算值、实验值及相对误差。烟气出口处CO2体积分数的实验平均值小于计算值。主要是烟气管道连接处有外界空气流入,使CO2体积分数降低。生物柴油浸没燃烧开始至10 s时,CO2体积分数在4 s时实验平均值与计算值的相对误差达到最大值9.053%,4 s以后,相对误差稳定在2%,证明了生物柴油浸没喷吹过程计算模型的可靠性。

实验值与计算值有相同的趋势,随时间增加CO2体积分数先升高,后趋于平稳。实验值与计算值的相对误差值变化规律为:先升高后降低,最后趋于平稳。喷枪以底吹方式浸没在熔体中,生物柴油燃烧初期产生的烟气在熔体形成气泡。气泡上浮并在液面破裂放出烟气,烟气继续向上运动到烟气出口,此过程大约需要2.2 s,所以生物柴油浸没燃烧初始至2.2 s时,在烟气出口是监测不到CO2的存在,即0~2.2 s CO2体积分数为0。继续喷吹CO2的体积分数增加,但实验值小于计算值。生物柴油浸没燃烧实验产生的CO2需先经过冷却系统降温在进入烟气分析仪,实验值相对于计算值具有滞后性,此时相对误差较大。继续喷吹燃烧过程稳定,相对误差趋于平稳。

图11 生物柴油浸没燃烧实验流程示意图

Fig. 11 Schematic diagram of biodiesel immersion combustion test system

图12 CO2的计算值、实验值及相对误差

Fig. 12 Experiments, simulations and relative error of CO2 volume fraction

4 结论

1) 计算结果与实验结果的相对误差较小,所建浸没喷吹流动过程计算模型可靠。

2) 生物柴油浸没燃烧过程是间歇的,燃烧主要在与喷嘴相连的气泡内完成,脱离喷嘴的气泡内燃烧现象较弱。

3) 熔体内气泡所在区域为高温区;计算区域内温度变化分为无规律剧烈变化、温度下降较快、温度缓慢下降3个阶段。

4) 气泡上升轨迹为曲线,上升过程中气泡形状变化依次为球形、椭圆形、扁椭圆形。

REFERENCES

[1] SRIDHAR R, TOGURI J M, SIMEONOV S. Copper losses and thermodynamic considerations in copper smelting[J]. Metallurgical and Materials Transactions B, 1997, 28(2): 191-200.

[2] SERGEI A D, ARTHUR D P. A thermodynamic database for copper smelting and converting[J]. Metallurgical and Materials Transactions B, 1999, 30(4): 661-669.

[3] LIU H L, MA X, LI B W, CHEN L C, WANG Z, WANG J X. Combustion and emission characteristics of a direct injection diesel engine fueled with biodiesel and PODE/biodiesel fuel blends[J]. Fuel, 2017, 209: 62-68.

[4] GRAHAM S. The viability of biodiesel and hydrogen as complementary fuel vectors in a hybrid platform[J]. International Journal of Hydrogen Energy, 2017, 42: 19331-19336.

[5] NAIJAF G. Diesel engine combustion characteristics using nano-particles in biodiesel blends[J]. Fuel, 2018, 212: 668-678.

[6] 王仕博. 艾萨炉顶吹熔池流动与传热过程数值模拟研究[D]. 昆明: 昆明理工大学, 2013: 6-7.

WANG Shi-bo. Numerical simulation research of flow and heat transfer on top-blown bath in ISA furnace[D]. Kunming: Kunming University of Science and Technology, 2013: 6-7.

[7] ABBASSI W, BESBES S, HAJEM M E, AISSIA H B, CHAMPAGNE J Y, JAY J. Influence of operating conditions and liquid phase viscosity with volume of fluid method on bubble formation process[J]. European Journal of Mechanics B, 2017, 65: 284-298.

[8] LIU L, YAN H J, ZHAO G J, ZHUANG J C. Experimental studies on the terminal velocity of air bubbles in water and glycerol aqueous solution[J]. Experimental Thermal and Fluid Science, 2016, 78: 254-265.

[9] LIU L, YAN H J, ZHAO G J. Experimental studies on the shape and motion of air bubbles in viscous liquids[J]. Experimental Thermal and Fluid Science, 2015, 62: 109-121.

[10] LIU H Y, MA X, LI B W, CHEN L F, WANG Z, WANG J X. Combustion and emission characteristics of a direct injection diesel engine fueled with biodiesel and PODE/biodiesel fuel blends[J]. Fuel, 2017, 209: 62-68.

[11] LI B W, LI Y F, LIU H Y, LIU F, WANG Z, WANG J X. Combustion and emission characteristics of diesel engine fueled with biodiesel/PODE blends[J]. Applied Energy, 2017, 206: 425-431.

[12] BAPU B R R, SARAVANAKUMAR L, PRASA B D. Effects of combustion chamber geometry on combustion characteristics of a DI diesel engine fueled with calophyllum inophyllum methyl ester[J]. Journal of the Energy Institute, 2017, 90(1): 82-100.

[13] AGARWAL A K, DHAR A, GUPTA J G, KIM W I, CHOI K, LEE C S, PARK S W. Effect of fuel injection pressure and injection timing of Karanja biodiesel blends on fuel spray, engine performance, emissions and combustion characteristics[J]. Energy Conversion and Management, 2015, 91: 302-314.

[14] AGARWAL A K, DHAR A, GUPTA J G, KIM W I, LEE C S, PARK S W. Effect of fuel injection pressure and injection timing on spray characteristics and particulate size-number distribution in a biodiesel fuelled common rail direct injection diesel engine[J]. Applied Energy, 2014, 130(5): 212-221.

[15] JRIDER W J, KOTHE D B. Reconstructing volume tracking[J]. Journal of Computational Physics, 1998, 141: 112-152.

[16] 邓伟鹏, 张小辉, 冯立斌, 王 华. 生物柴油浸没喷吹的雾化特性[J]. 化工进展, 2018, 37(6): 2166-2174.

DENG Wei-peng, ZHANG Xiao-hui, FENG Li-bin, WANG Hua. Atomization characteristics of biodiesel immersion blown[J]. Chemical Industry and Engineering Progress, 2018, 37(6): 2166-2174.

[17] HIRT C W, NICHOLS B D. Volume of fluid (VOF) method for the dynamics of free boundaries[J]. Journal of Computational Physics, 1981, 39(1): 201-225.

[18] ALAMOS L, INTRODUECTION I. A continuum method for modeling surface tension[J]. Journal of Computational Physics, 1992, 100(2): 335-354.

[19] SIEGEL R, HOWELL J R. Thermal radiation heat transfer[M]. Washington, DC: Hemisphere Publishing Corporation, 1992: 93.

[20] SIVATHANU Y R, FAETH G M. Generalized state relationships for scalar properties in non-premixed hydrocarbon/air flames[J]. Combustion and Flame, 1990, 82(2): 211-230.

[21] 张振扬, 闫红杰, 刘方侃, 王计敏. 富氧底吹熔炼炉内氧枪结构参数的优化分析[J]. 中国有色金属学报, 2013, 23(5): 1471-1478.

ZHANG Zhen-yang, YAN Hong-jie, LIU Fang-kan, WANG Ji-min. Optimization analysis of lance structure parameters in oxygen enriched bottom-blown furnace[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(5): 1471-1478.

[22] 张振扬, 陈 卓, 闫红杰, 刘方侃, 刘 柳, 崔志祥, 申殿邦. 氧气底吹熔炼炉内气液两相流动的数值模拟[J]. 中国有色金属学报, 2012, 22(6): 1826-1834.

ZHANG Zhen-yang, CHEN Zhuo, YAN Hong-jie, LIU Fang- kan, LIU Liu. CUI Zhi- xiang, SHEN Dian- bang. Numerical simulation of gas-liquid multi-phase flows in oxygen enriched bottom-blown furnace[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(6): 1826-1834.

Numerical simulation of biodiesel submerged combustion in copper bath smelting process

DENG Wei-peng1, 2, ZHANG Xiao-hui1, 3, ZHANG Guang-jun1, ZHANG Han1, FENG Li-bin1, 2

(1. State Key Laboratory of Complex Nonferrous Metal Resources Clean Utilization, Kunming University of Science and Technology, Kunming 650093, China;

2. Faculty of Metallurgical and Energy Engineering, Kunming University of Science and Technology, Kunming 650093, China;

3. Engineering Research Center of Metallurgical Energy Conservation and Emission Reduction, Ministry of Education, Kunming University of Science and Technology, Kunming 650093, China)

Abstract: It is an important way to develop the low-carbon metallurgy with biodiesel instead of fossil diesel in copper bath smelting process. A simulation model of biodiesel submerged blowing process was established. The biodiesel submerged combustion process, the motion of gas bubble and copper-matte were simulated under different O2 volume fractions when the submerged depth of the spray nozzle is 1 cm. The simulation model was verified by experiment. The results show that the submerged combustion process of biodiesel is intermittent, this process is mainly done within bubble which is connected to the nozzle, the combustion is weaker after the bubble depart from the nozzle. The temperature changed in the bath is divided into three stages, first irregular drastic stage, then rapid decrease stage, and finally gradually decrease stage. The rising trajectory of the bubble is a curve, and the shape of the bubble changes from spherical to elliptical and finally oblate. The liquid velocity is larger in the axis area and lesser in the near wall area.

Key words: biodiesel; submerged combustion; bath smelting; numerical simulation; low-carbon metallurgy

Foundation item: Project(U1602272) supported by the National Natural Science Foundation of China Joint Fund

Received date: 2018-12-07; Accepted date: 2019-06-24

Corresponding author: ZHANG Xiao-hui; Tel: +86-18487319560; E-mail: xiaohui.zhang@kust.edu.cn

(编辑 李艳红)

基金项目:国家自然科学基金联合基金项目(U1602272)

收稿日期:2018-12-07;修订日期:2019-06-24

通信作者:张小辉,副教授,博士;电话:18487319560;E-mail:xiaohui.zhang@kust.edu.cn