文章编号:1004-0609(2009)10-1840-08

水平连铸-冷轧-退火工艺制备的Cu-Fe-P合金薄带特性

戴姣燕,尹志民,蒋蓉蓉, 宋练鹏,袁 远

(中南大学 材料科学与工程学院,长沙 410083)

摘 要:以水平连铸卷坯-冷轧-退火新工艺制备Cu-0.1Fe-0.03P合金成品薄带,采用拉伸力学性能测试、金相、织构分析和电子显微分析方法研究成品薄带的显微组织结构特征。结果表明,与传统的热轧-冷轧-退火工艺制备的薄带性能相比,水平连铸卷坯-冷轧-退火新工艺没有经过热轧,连铸坯中的缩孔、疏松没有在冷轧过程中实现完全的冶金复合时,产品表面会出现麻点和起皮现象。极图和ODF织构分析表明,水平连铸卷坯-冷轧-退火新工艺制备的Cu-0.1Fe-0.03P合金薄带以{110}〈112〉黄铜织构为主,此外还有较弱的{110}〈100〉高斯织构、{123}〈634〉S织构以及{001}〈100〉立方织构。晶体学织构是薄带出现力学平面各向异性的主要原因。新工艺制备的合金薄带的抗拉强度、电导率和软化温度稍低而伸长率稍高。

关键词:Cu-0.1Fe-0.03P合金;水平连铸卷坯;薄带;麻点;各向异性

中图分类号: TG 146.1 文献标识码: A

Features of Cu-Fe-P alloy strip prepared by process of horizontal continuous casting-cold rolling-annealing

DAI Jiao-yan, YIN Zhi-min, JIANG Rong-rong, SONG Lian-peng, YUAN Yuan

(School of Materials Science and Engineering, Central South University, Changsha 410083, China)

Abstract: Cu-0.1Fe-0.03P alloy strips were prepared by a new process of horizontal continuous casting-cold rolling-annealing. The microstructures of the strips were studied by tensile test, OM, X-ray diffraction and electron microscopy analysis. The results show that compared with the traditional preparation of hot rolling-cold rolling-annealing process, the process of horizontal continuous casting-cold rolling- annealing has no hot rolling. When the shrinkage and osteoporosis in the continuous casting can not complete the metallurgical complex during the cold-rolling process, the spots and peeling appear on the surface of products. The alloy strips prepared by the new process have slight lower tensile strength, electrical conductivity and soften temperature and higher elongation. Mechanical properties anisotropy exists in the strips prepared by the new process, thus causes the 45? direction crack when stamped.

Key words: Cu-0.1Fe-0.03P alloy; horizontal continuous casting volume ingot; strip; spot defect; anisotropy

Cu-0.1Fe-0.03P合金具有优良的导电、导热性能和较低的成本,是一种在国内外应用广泛的低合金化中强高导引线框架材料[1-5]。随着冶金材料制备技术的进步,在低合金化的韧铜合金板带材的生产中,传统的半连续铸锭-热轧-高精冷轧-退火生产方法有逐步被水平连铸卷坯-高精冷轧生产方法取代的趋势[6-7]。水平连铸卷坯-高精冷轧技术其实质是以水平连铸卷坯代替传统的半连铸和热轧工序。与传统工艺相比较,新工艺具有流程短、投资少、成本低、成品率高、建设周期短等显著优点[8-9]。但是,与传统工艺制备的薄带性能相比,新工艺制备的合金薄带表面有时会出现麻点,后续的成型加工过程中会出现45?方向的裂纹,力学性能也还有一定的差距[10-11]。本文作者结合生产现场实际,针对水平连铸卷坯-冷轧-退火新工艺制备的Cu-0.1Fe-0.03P合金薄带特性进行研究,旨在为进一步完善这种新工艺提供实验依据和参考。

1 实验

研究合金主要成分为Cu-0.1Fe-0.03P。采用水平连铸技术制备出厚度为20 mm、宽度为1 200 mm的水平连铸卷坯,之后对连铸卷坯实施了冷轧和退火(本质上是退火和时效)处理。冷轧-退火工艺为连铸坯双面铣到15 mm→冷轧到5.0 mm→(570 ℃, 1 h)保护性气氛下退火→冷轧到3.0 mm→(560 ℃, 1 h)保护性气氛下退火,之后将3.0 mm冷轧板精轧到1.5 mm,最后在(550 ℃, 1 h)保护性气氛下光亮退火。

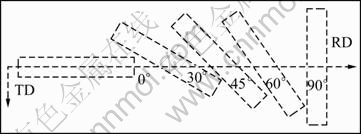

沿与合金薄带轧向分别呈0?(纵向)、30?、45?、60?、90?(横向)的方向上切取拉伸试样(图1),拉伸力学性能测试在INSTRON 8032试验机上进行,拉伸速度为2 mm/min,按文献[12-15]提供的方法计算该合金的平面各向异性指标IPA:

图1 拉伸试样取样方式

Fig.1 Sampling methods of tensile specimen

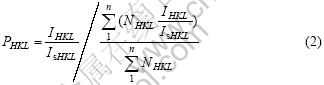

极图测试试样表面采用酸腐蚀减薄以减少试样表面的残余应变和应力的影响。试样宏观极图测定在布鲁克D8型X射线衍射分析仪上进行,采用CuKα辐射,测量了样品的{111}、{200}和{220}极图,其中0≤α≤85?,0≤β≤360?。利用测得的极图计算得到取向分布函数。采用Harris方法(式2)计算出织构轴密度参量PHKL。

制备金相样品时的腐蚀剂是25 mL冰醋酸+55 mL磷酸+20 mL硝酸,将样品在50 ℃的腐蚀剂中腐蚀20 s,然后洗净、干燥,进行金相组织观察。微区成分分析在Sirion 200型扫描电镜上进行。电镜薄膜样在MTP-1双喷电解减薄仪上双喷减薄、穿孔,电解液由硝酸和甲醇按体积比1?3配制,温度为-20~-30 ℃,电流约50 mA。透射电子显微组织结构观察在Tecnai G2 20s分析电镜上进行。

2 结果与分析

2.1 水平连铸卷坯-冷轧-退火新工艺制备的薄带表面缺陷特征

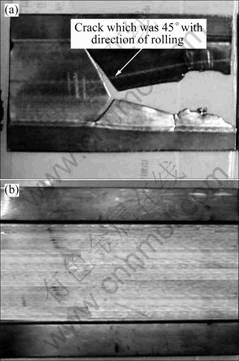

将光亮退火后的薄带加工成型成凹字形的部件,发现部件上容易出现两种缺陷,一种是部件上局部区域有肉眼能观察到的麻点和起皮现象,二是凹字形的部件上存在与轧制方向呈45?的裂纹(见图2(a))。

图2 冷轧退火薄带加工成型部件

Fig.2 Products made of cold roll-annealing strips: (a) Product with crack and spot defect; (b) Product without defect

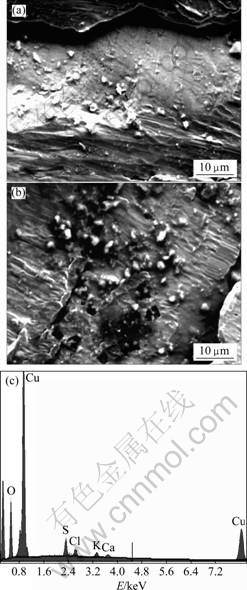

图2(a)中薄带表面麻点和起皮处的形貌如图3所示。由图3可以看出,起皮的地方实际上是分层组织,没有焊合;在裂纹面上还附有一些形状不规则的小颗粒,经能谱微区成分分析(见图3(c)),这些颗粒主要由O、S、Ca等元素组成,可以认为它们是熔炼炉壁碎屑混入所致。

图3 水平连铸卷坯-冷轧退火薄带麻点和起皮的SEM像及EDS分析

Fig.3 SEM images and EDS analysis of spot defects and peel of horizontal continuous casting ingot-cold roll-annealing strip: (a) Hierarchical organization without bonding; (b) Irregular shape of small particles in surface of cracks; (c) EDS analysis of small particles

2.2 水平连铸卷坯-冷轧-退火新工艺制备的薄带不同取向条件下的拉伸力学性能

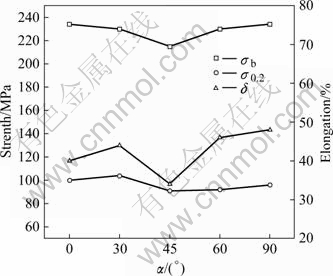

合金薄带不同取向条件下力学性能的测试结果如图4所示。由图4可以看出,在不同取向条件下,合金在0?取向和90?取向的抗拉强度较高,在45?取向的抗拉强度较低;而合金在0?取向和30?取向的屈服强度较高,在45?取向的屈服强度较低;合金在60?取向和90?取向的伸长率最高,在45?取向的伸长率最低。

图4 所研究合金薄带不同取向条件下的力学性能

Fig.4 Mechanical properties of studied alloy strip under different orientation

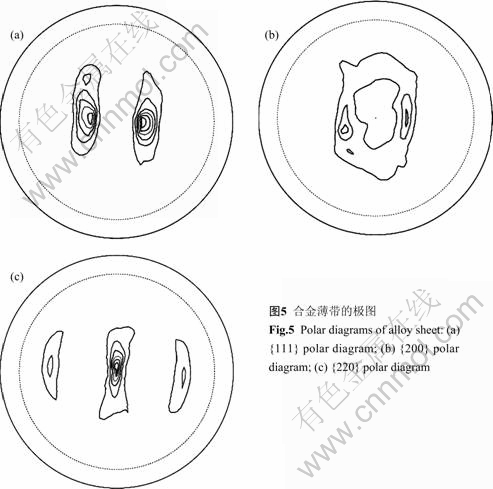

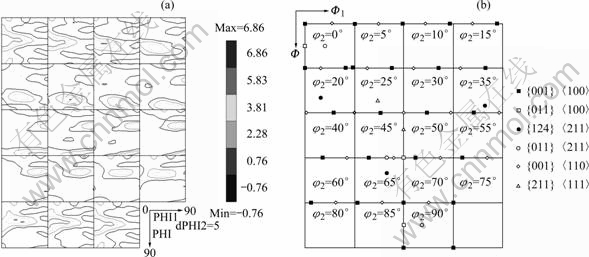

2.3 水平连铸卷坯-冷轧-退火新工艺制备的薄带的织构

合金薄带的极图和取向分布函数(ODF)见图5和6。根据图5和6结果,采用织构组分分析法分析表明,合金薄带的织构以黄铜织构{110}〈112〉为主,此外还有较弱的高斯织构{110}〈100〉、S{123}〈634〉织构和非常微弱的立方织构组分{001}〈00〉。

图6 合金薄带的取向分布函数截面图

Fig.6 ODF diagram of alloy sheet: (a) Measured textures; (b) Position of main orientation

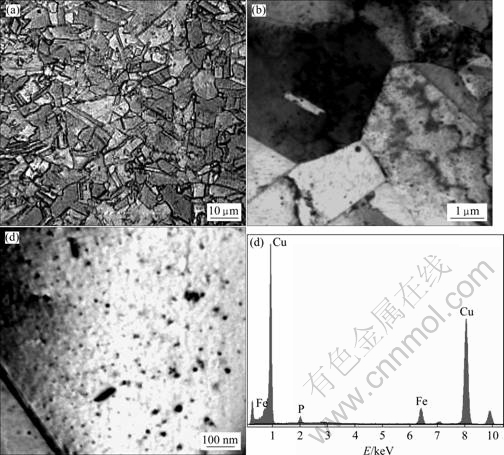

2.4 水平连铸卷坯-冷轧-退火新工艺制备的薄带的显微组织

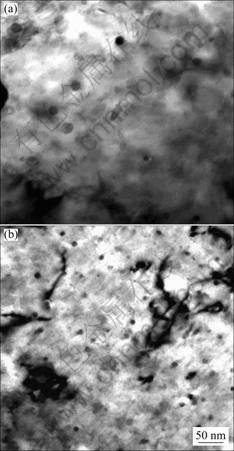

合金薄带的金相和电子显微组织见图7。由7可以看出,薄带加工成型部件是明显的再结晶组织(图7(a)~(b)),高倍下透射电子显微组织可以见到微细质点,微区成分分析表明这些质点是富Fe及富Fe和P。

图7 研究合金薄带的OM和TEM像以及EDS分析

Fig.7 OM and TEM images and EDS analysis of studied alloy strip: (a) OM; (b) TEM, small magnification; (c) TEM, large magnification; (d) EDS analysis of precipitation

3 讨论

3.1 水平连铸卷坯-冷轧-退火新工艺制备的薄带表面缺陷形成原因

由图3中薄带表面麻点和起皮处的微观形貌可以看出,起皮的地方实际上是分层组织,没有焊合;还可以看到,有些裂纹面上还附有一些形状不规则的细小的炉壁夹渣。炉壁夹渣的问题相对来说容易解决,只需要在炉壁有缺陷时及时修补就能解决。分层组织与铸锭内存在的缩孔、疏松有关。在传统的热轧工艺条件下,缩孔、疏松可以在热轧过程中热轧冶金复合,而新工艺没有经过热轧,铸锭过程中的疏松缩孔在前面几道冷轧过程中没有实现冶金复合,冷轧到一定程度后,疏松缩孔处会移动到薄带表面产生麻点和起皮。解决这些缺陷的办法有两个:一是在铸锭过程中添加磁场以提高水平连铸卷坯的质量,不仅可以细化晶粒,而且可以清除铸锭中的疏松和缩孔;二是设计优化冷轧道次和道次变形量,加大前几个道次的道次变形量,强制疏松缩孔在冷轧过程中实现冶金复合。根据上面的分析,通过添加磁场及对冷轧道次和道次变形量进行重新设计,合金薄板表面麻点和起皮的问题得到解决,薄板冲压后的表面见图2(b)。

3.2 合金薄带晶体学各向异性对力学性能各向异性的影响

从极图的分析可知,研究合金薄带主要织构组分为{110}〈112〉织构(见图5)。为了便于分析织构对Cu-0.1Fe-0.03P合金板材力学性能各向异性的影响,作为一级近似,可将薄带视为金属单晶体材料,单晶的轧面为{110},单晶的轧向为〈112〉。铜合金为面心立方结构,主要滑移系为{111}〈110〉,4个可能的{111}滑移面与织构(110)[ ]的空间关系如图8所示。

]的空间关系如图8所示。

由图8可知,其中两个{111}面与轧制面垂直,另外两个{111}面与轧制面成35.27?的夹角。图7同时给出

图8 {111}滑移面与(110)[ ]织构的空间关系

]织构的空间关系

Fig.8 Space relationship between {111} slip surfaces and (110)[ ] texture

] texture

了合金板材取向宏观坐标系(轧向、横向和法向)和晶

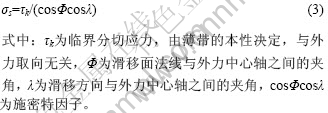

体取向坐标系((110)[ ])之间的关系。依据金属单晶体拉伸变形机制和变形临界分切应力定律,屈服强度

])之间的关系。依据金属单晶体拉伸变形机制和变形临界分切应力定律,屈服强度

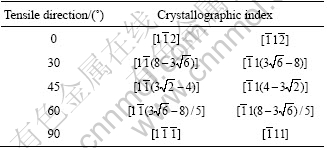

试样拉伸取向的晶体学指数见表1。

表1 试样拉伸取向的晶体学指数

Table 1 Tensile-oriented crystallography indexes of specimens

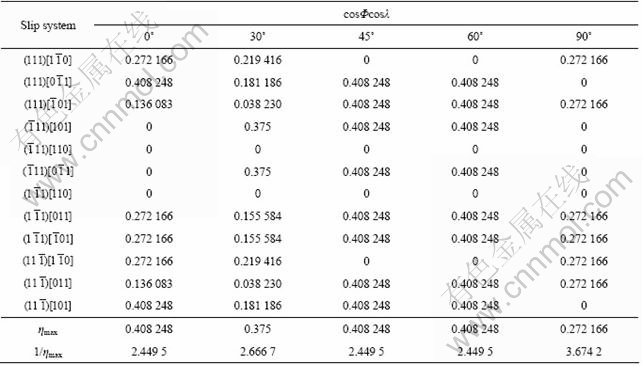

依据立方系晶向之间的关系,运用矢量运算法则算出不同拉伸轴晶体学取向在每个滑移系上的施密特因子和每个取向的施密特因子最大值的倒数,结果如表2所列。结果表明:沿与板材成30?和90?取向的试样拉伸时,施密特因子最大值的倒数值比较大,合金板材的强度会较高:而沿与板材成45?和60?取向的试样拉伸时,施密特因子最大值的倒数值比较小,合金板材的强度会较低。通过对比可以发现,理论分析结果和试验结果基本一致,这说明晶体学织构各向异性是造成Cu-0.1Fe-0.03P合金板材平面各向异性的主要原因,也是导致合金薄带冲压过程中容易产生45?方向开裂的主要原因。要消除45?方向开裂,需要进一步调整冷轧-退火工艺,抑制{110}〈112〉织构的形成。

表2 不同拉伸轴方向的施密特因子和每个取向施密特因子最大值的倒数

Table 2 Different stretch axis of Schmidt and countdown of maximum-Schmidt of each orientation (ηmax=max(cosΦcosλ))

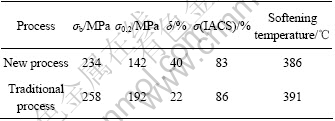

3.3 新工艺与传统工艺制备的薄带性能比较及其产生差距的原因探讨

水平连铸卷坯-高精冷轧新工艺与传统的半连续铸锭-热轧-高精冷轧工艺制备的薄带力学性能和电学性能测试结果如表3所列。由表3可以看出,新工艺制备的冷轧-退火薄带的合金强度、电导率和软化温度稍低,伸长率则较高。

表3 新工艺制备的冷轧-退火薄带的力学性能、电学性能和软化温度

Table 3 Mechanical properties, electrical properties and soften temperatures of cold roll-annealing strips prepared by new and traditional process

关于两种工艺制备的薄带性能差异,本文作者有如下的认识。在传统工艺的情况下,锭坯半连续铸造后要进行热轧及在线固溶处理。这种工艺耗能耗时,但是如前所述,一方面连铸坯中的缩孔和疏松可以在热轧过程中实现冶金复合,成品薄带表面缺陷少;另一方面,热轧坯进行了在线固溶,凝固过程和热轧过程中产生的平衡相可以通过固溶进入过饱和固溶体,然后再通过冷轧-退火(时效)这种形变热处理可以获得亚结构强化和时效析出强化,所以合金强度和电导率相对比较高,塑性则比较低。在水平连铸板坯-冷轧-退火(时效)新工艺的情况下,虽然锭坯连铸后不进行热轧也没有在线固溶处理,但是连铸时的一次水冷和二次水冷就相当于固溶处理,之后的冷轧-退火(时效)也属于形变热处理,也一样有亚结构强化和时效析出强化。新工艺省去了铸锭的切头去尾和热轧工艺,节能、省时、效率高。但是一方面,如前所述,连铸坯中的缩孔、疏松很难在冷轧过程中实现完全的冶金复合,产品表面有时会出现麻点和起皮的现象;另一方面,凝固过程中产生的平衡相无法再溶入固溶体而一直会传承到成品薄带中,退火过程(时效过程)中析出相的数量不如传统工艺条件下的多(见图9)。这两点应当是新工艺与传统工艺制备的薄带性能产生差距的主要原因。

图9 新工艺和传统工艺制备的合金薄带的TEM像

Fig.9 TEM images of alloy strips prepared by new process (a) and traditional process (b)

4 结论

1) 水平连铸卷坯-冷轧-退火新工艺没有经过热轧,连铸坯中的缩孔、疏松很难在冷轧过程中实现完全的冶金复合,产品表面有时会出现麻点和起皮的现象,解决的办法是提高铸坯的质量, 消除铸锭中的疏松和缩孔。

2) 极图和ODF织构分析表明水平连铸卷坯-冷轧-退火新工艺制备的Cu-0.1Fe-0.03P合金薄带以{110}〈112〉黄铜织构为主,此外还有较弱的{110}〈100〉高斯织构、{123}〈634〉 S织构以及{001}〈100〉立方织构,晶体学织构是薄带出现力学平面各向异性的主要原因。水平连铸卷坯-冷轧-退火新工艺制备的薄带存在力学性能平面各向异性,是导致合金薄带冲压过程中容易产生45?方向开裂的主要 原因。

3) 与传统工艺制备的薄带性能相比,新工艺制备的合金薄带抗拉强度、电导率和软化温度稍低而伸长率稍高。

REFERENCES

[1] 曹兴民, 向朝建, 杨春秀, 慕思国, 郭富安. 一种新型Cu-Fe-P系合金材料的组织性能分析[J]. 稀有金属材料与工程, 2007, 36(9): 527-529.

CAO Xing-min, XIANG Chao-jian, YANG Chun-xiu, MU Si-guo, GUO Fu-an. The Microstructure and properties of a new type of Cu-Fe-P alloy[J]. Rare Metal Materials and Engineering, 2007, 36(9): 527-529.

[2] 李银华, 刘 平, 田保红, 贾淑果, 任凤章, 张 毅. 集成电路用铜基引线框架材料的发展与展望[J]. 材料导报, 2007, 21(7): 24-27.

LI Yin-hua, LIU Ping, TIAN Bao-hong, JIA Shu-guo, REN Feng-zhang, ZHANG Yi. Development and expectation of copper-based lead frame material used in intergrated circuit[J]. Materials Review, 2007, 21(7): 24-27.

[3] 苏娟华, 许莹莹, 董企铭, 刘 平, 李贺军. Cu-Fe-P合金引线框架材料残余应力的有限元分析[J]. 热加工工艺, 2006, 35(12): 7-10.

SU Juan-hua, XU Ying-ying, DONG Qi-ming, LIU Ping, LI He-jun. Finite element analysis on residual stress of Cu-Fe-P alloy for lead frame[J]. Hot Working Technology, 2006, 35(12): 7-10.

[4] 陆德平, 王 俊, 陆 磊, 刘 勇, 谢仕芳, 孙宝德. 硼和铈对Cu-Fe-P合金显微组织和性能的影响[J]. 中国稀土学报, 2006, 24(4): 475-479.

LU De-ping, WANG Jun, LU Lei, LIU Yong, XIE Shi-fang, SUN Bao-de. Effect of B and Ce on microstructures and properties of Cu-Fe-P alloy[J]. Journal of the Chinese Rare Earth Society, 2006, 24(4): 475-479.

[5] SAKAMOTO T. The tendency toward higher integration of I.C. and problems for copper based lead frame materials[J]. Journal of Functional Materials, 1993, 24: 100-105.

[6] 雷鹏飞, 胡 锐, 王一川, 寇宏超, 尹云飞, 李金山, 傅恒志. Cu-1.0Cr 自生复合材料的水平连铸过程及组织[J]. 特种铸造及有色合金, 2005, 25(9): 562-566.

LEI Peng-fei, HU Rui, WANG Yi-chuan, KOU Hong-chao, YIN Yun-fei, LI Jin-shan, FU Heng-zhi. The horizontal continuous casting process and organization composites Cu-1.0Cr[J]. Special Casting and Nonferrous Alloys, 2005, 25(9): 562-566.

[7] 黄国杰, 谢水生, 程镇康, 闫晓东, 涂思京. KFC铜合金带材的生产工艺研究[J]. 稀有金属, 2005, 29(2): 228-231.

HUANG Guo-jie, XIE Shui-sheng, CHENG Zhen-kang, YAN Xiao-dong, TU Si-jing. Production of KFC copper alloy strip[J]. Chinese Journal of Rare Metals, 2005, 29(2): 228-231.

[8] 杨后川, 王东峰, 孔立堵, 肖启敏. 引线框架Cu-Fe-P合金的加工工艺研究[J]. 热加工工艺, 2005, 34(1): 23-26.

YANG Hou-chuan, WANG Dong-feng, KONG Li-du, XIAO Qi-min. Research on processing technique of Cu-Fe-P alloy used in lead frame[J]. Hot Working Technology, 2005, 34(1): 23-26.

[9] LU De-ping, WANG Jun, ZENG Wei-jun, LIU Yong, LU Lei, SUN Bao-de. Study on high-strength and high-conductivity Cu-Fe-P alloys[J]. Mater Sci Eng A, 2006, 421: 254-259.

[10] CAO H, MIN J Y, WU S D, XIAN A P, SHANG J K. Pinning of grain boundaries by second phase particles in equal-channel angularly pressed Cu-Fe-P alloy[J]. Mater Sci Eng A, 2006, 431: 86–91.

[11] 龚寿鹏. 铜系合金引线框架材料的生产、发展和国产化[J]. 上海有色金属, 1998, 19(2): 49-52.

GONG Shou-peng. Production development and nationalization of lead frame materials of copper alloys[J]. Shanghai Nonferrous Metals, 1998, 19(2): 49-52.

[12] JATA K V, HOPKINS A K, RIOJA R J. Anisotropy and texture of Al-Li alloys[J]. Mat Sci Forum, 1996, 217/222: 647-652.

[13] SINGH R K, SINGH A K, PRASAD N E. Texture and mechanical property anisotropy in an Al-Mg-Si-Cu alloy[J]. Mater Sci Eng A, 2000, 277: 114-122.

[14] SAKUMA T, KOMATSUBARA T, KOMATSU S Y. Effects of texture and arrangements of dislocation cell walls on yield stress anisotropy in cold rolled and recovery annealed Al-Mg alloy sheets[J]. Mat Sci Forum, 2002, 396/402: 1055-1060.

[15] VASUDEVAN A K, PRZYSTUPA M A, FRICKE W G Jr. Texture-microstructure effects in yield strength anisotropy of 2090 sheet alloy[J]. Scripta Metallurgica et Materialia, 1990, 24: 1429-1434.

基金项目:国家自然科学基金资助项目(50371106);中南大学博士生创新基金资助项目

收稿日期:2008-11-26;修订日期:2009-05-27

通信作者:尹志民,教授,博士;电话:0731-88830262;E-mail: yin-grp@csu.edu.cn

(编辑 何学锋)