Al-Zn-Mg-Cu-Zr合金加工图的构建及失稳分析

韦莉莉1,潘清林1, 2,周坚1,贾科1,尹志民1

(1. 中南大学 材料科学与工程学院,湖南 长沙,410083;

2. 中南大学 有色金属材料科学与工程教育部重点实验室,湖南 长沙,410083)

摘要:由含Zr的Al-Zn-Mg-Cu合金在不同变形条件下进行热压缩得到的真应力-真应变曲线,计算合金的热变形本构方程。基于动态材料模型构建合金的加工图,并分析功率耗散系数的变化和失稳区的范围。研究结果表明:该合金在热变形时存在2个失稳区,即低温失稳区(温度300~360 ℃、应变速率0.05~1 s-1)和高温失稳区(温度400~460 ℃、应变速率0.005~1 s-1);在温度440~460 ℃,应变速率小于0.002 s-1的区域,最大功率耗散系数为0.52,该区域内的变形软化机制为动态再结晶。

关键词:Al-Zn-Mg-Cu-Zr铝合金;加工图;流变失稳,动态再结晶

中图分类号:TG146.2 文献标志码:A 文章编号:1672-7207(2013)05-1798-08

Processing maps and flow instability analysis of Al-Zn-Mg-Cu-Zr alloy

WEI Lili1, PAN Qinglin1, 2, ZHOU Jian1, JIA Ke1, YIN Zhimin1

(1. School of Materials Science and Engineering, Central South University, Changsha 410083, China;

2. Key Laboratory of Nonferrous Materials Science and Engineering of Ministry of Education, Central South University, Changsha 410083, China)

Abstract: True stress-true strain curves of Al-Zn-Mg-Cu-Zr aluminum alloy were investigated by hot compression thermal simulation test under different deformation conditions and used to calculate its constitutive equations. The processing maps were drawn according to the dynamic material model. Variations of power dissipation figures and scope of instability areas were analyzed. Two instability areas exist, the one is low temperature instability area, with 300-360 ℃ and 0.05-1 s-1 of strain rate; the other is high temperature instability area, with 400-460 ℃ and 0.005-1 s-1 of strain rate. Peak efficiency of power dissipation is 0.52 at 440-460 ℃ with strain rate less than 0.002 s-1 in the high temperature instability area, where dynamic recrystallization is main softening mechanism.

Key words: Al-Zn-Mg-Cu-Zr alloy; processing maps; flow instability; dynamic recrystallization

Al-Zn-Mg-Cu系合金是主要的航空航天结构材料。在该系合金中添加Zr能够提高合金强度、抗应力腐蚀性和断裂韧性,因而,其在航空航天工业建设中得到广泛应用[1-5]。但Zr的添加也加剧了合金化程度,合金成分更为复杂,使得合金在制备和加工过程中容易出现开裂等问题。目前,普遍采用加工图来研究、评定或预测材料在制备或热加工时出现的问题,还可以优化加工温度和应变速率[6-8]。加工图的绘制主要以2类模型为基础:一类是原子模型的加工图,如Raj加工图[9];另一类是基于动态材料模型(DMM) 的加工图。前者在实际应用中存在较大的局限,如只适用于纯金属和简单合金,只在稳态下有效,需要大量材料参数,无法适用于各种变形机制等[10]。后者认为材料在变形过程中能量的转变主要以热和微观组织演化的方式进行耗散,根据变形过程中能量的消耗效率与变形温度及应变速率的变化关系可以建立材料变形的加工图。采用动态材料模型建立的加工图已成功用于分析铝合金、铜合金、不锈钢和钛合金等[11-13]大约200多种合金的高温变形特征。但这些研究多以镁合金、钛合金和钢铁材料为主,针对添加Zr元素的Al-Zn-Mg-Cu合金的研究较少。为此,本文作者对含Zr的高强Al-Zn-Mg-Cu铝合金进行热压缩模拟实验,由不同热变形条件下合金的真应力-真应变曲线求得合金的流变应力本构方程,采用动态材料模型构建热加工图,探索其安全热加工的变形条件和失稳变形条件,以便为制定该合金合理的加工工艺提供指导。

1 材料及实验方法

试验材料采用工业化铸造扁锭,化学成分为Al-6.22Zn-1.9Mg-2.54Cu-0.08Zr。铸锭经465 ℃均匀化处理24 h后加工成直径×高为10 mm×15 mm的圆柱形试样,两端各加工出深度为0.2 mm的凹槽,槽内均匀填充润滑剂(75%石墨+20%机油+5%硝酸三甲苯脂(质量分数))以减少试样与压头之间的摩擦。热压缩试验在Gleeble-1500模拟机上进行。试样压缩前升温速率为10 ℃/s,在加热到预定变形温度后保温3 min。应变速率分别选取0.001,0.01,0.1和1.0 s-1,变形温度分别选取300,340,380,420和460 ℃,总压缩变形量为60%。压缩变形结束后立即对试样进行水淬以保留高温变形组织。用POLYVER-MET金相显微镜对不同变形条件压缩后合金纵剖面的显微组织进行观察,用Sirion200场发射扫描电镜观察发生失稳后合金的微观组织。

2 实验结果与分析

2.1 真应力-真应变曲线

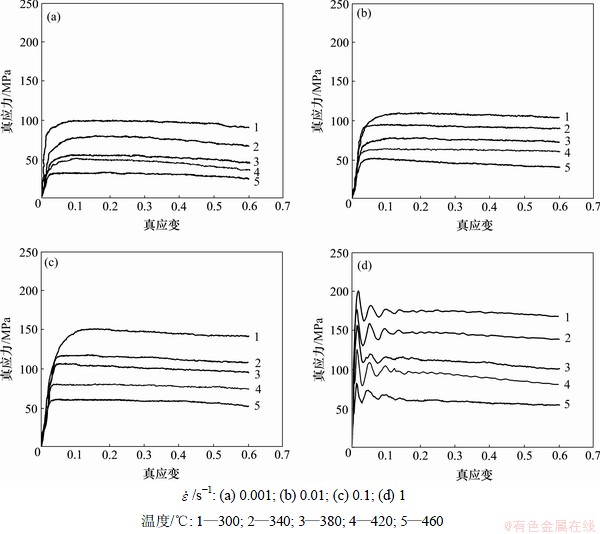

图1所示为Al-Zn-Mg-Cu-Zr合金在不同条件压缩变形时的真应力-真应变曲线。由图1可见:热变形初期,流变应力随应变的增加而急剧升高,达到某一峰值后不随应变量的继续增加而发生明显的变化,呈现稳态流变特征。因为变形前期产生大量位错,位错的交互作用使其运动受阻,合金的变形抗力急剧增大,加工硬化的作用占主导。随压缩变形的继续进行,晶内的储存能逐渐增大,合金发生动态回复和动态再结晶,加工硬化、回复和再结晶软化的相互抵消和趋于平衡使得合金的流变应力处于稳态变化。相比不同变形条件,在同一应变速率下,随着变形温度的升高,流变应力明显降低;在同一变形温度下,随着应变速率的增加,流变应力升高。因为当变形温度升高时,原子的热激活作用加剧,位错的活动能力增强,变形过程中可以有更多的位错进行滑移和攀移,从而使软化过程更加突出,流变应力降低。当应变速率增加时,变形时间缩短,发生动态回复或再结晶程度不够充分,软化程度降低,流变应力升高。但是应变速率为1 s-1变形时合金的应力应变曲线出现明显的波浪峰。这主要是由于高应变速率下,位错的急剧增加导致合金发生不连续动态再结晶,软化和硬化的主导作用交替进行,应力呈现周期性变化。

2.2 流变应力本构方程

用流变应力σ、应变速率 和变形温度T之间的关系来描述合金在热变形过程中的流变行为[14-17]:

和变形温度T之间的关系来描述合金在热变形过程中的流变行为[14-17]:

(1)

(1)

其中:A为与温度无关的常数;Q为变形激活能;R为摩尔气体常数;T为变形温度。f(σ)与应力水平有关:

低应力水平( <0.8)时,

<0.8)时,

(2)

(2)

高应力水平( >1.2)时,

>1.2)时,

(3)

(3)

在整个应力范围内,

(4)

(4)

其中:n,α和β均为与温度无关的常数,且α=β/n。

Zener等[18]提出并验证应变速率和温度关系可用参数Z表示:

(5)

(5)

当变形温度T或应变速率 不变时,流变应力σ及其对数与应变速率

不变时,流变应力σ及其对数与应变速率 的对数(

的对数( -

- ,σ-

,σ- ,

, -

- ),流变应力σ的对数与温度T的倒数(

),流变应力σ的对数与温度T的倒数( -1/T),流变应力σ的对数与参数Z的对数(

-1/T),流变应力σ的对数与参数Z的对数( -

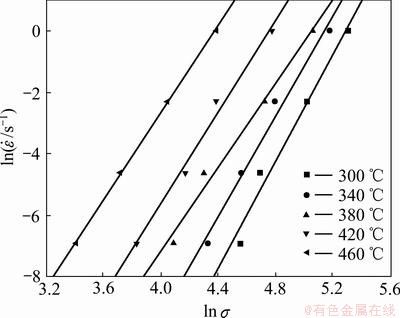

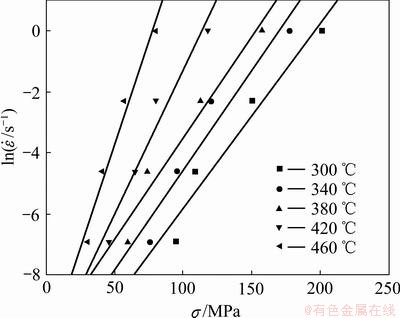

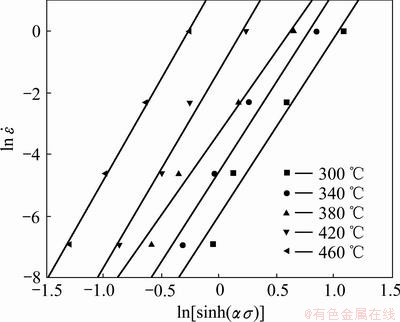

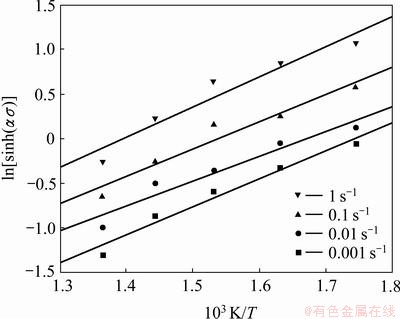

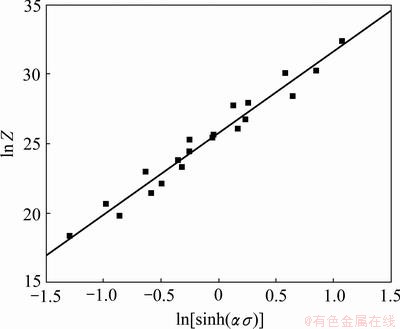

- )之间均满足线性关系。图2~6所示为实验合金在不同变形条件下各关系的线性回归图,由各图中直线斜率的平均值可求得本构方程所需常数,计算得到A=1.604 3×1011 s-1,

)之间均满足线性关系。图2~6所示为实验合金在不同变形条件下各关系的线性回归图,由各图中直线斜率的平均值可求得本构方程所需常数,计算得到A=1.604 3×1011 s-1, =0.008 9 MPa-1,n=5.830 3,Q=154.024 kJ/mol。

=0.008 9 MPa-1,n=5.830 3,Q=154.024 kJ/mol。

图1 不同应变速率变形 Al-Zn-Mg-Cu-Zr合金真应力-真应变曲线

Al-Zn-Mg-Cu-Zr合金真应力-真应变曲线

Fig.1 True stress-strain curves of Al-Zn-Mg-Cu-Zr alloy at different strain rates

图2 不同变形温度下 -

- 关系

关系

Fig.2 Relationship between  and

and

图3 不同变形温度下σ- 关系

关系

Fig.3 Relationship between σ and

图4 不同变形温度下 -

- 关系

关系

Fig.4 Relationship between  and

and

图5 不同变形温度下 -1/T关系

-1/T关系

Fig.5 Relationship between  and 1/T

and 1/T

图6 Z参数与流变应力的关系

Fig.6 Relationship between Z parameter and flow stress

将上述数据代入式(3),即可得到该合金热压缩变形的流变应力本构方程:

(6)

(6)

2.3 基于DMM模型的加工图原理

DMM模型的基础是大塑性流变连续介质力学、物理系统模型和不可逆热力学等理论。用其来研究材料的变形行为的基本原理是:将材料的热加工看作是一个能量耗散系统,能量的消耗取决于合金的流变行为。在塑性变形过程中,加工件会将外界输入的总能量P以2种方式消耗:一是加工件发生塑性变形所需要的能量,用G表示;二是加工件变形过程中微观组织演化所消耗的能量,用耗散协量J表示。总能量P可表示为

(7)

(7)

这2种能量的比例由材料在一定应力条件下的应变速率敏感指数m决定:

(8)

(8)

假定材料满足 本构关系,则

本构关系,则

(9)

(9)

其中: 0<m≤1。当m=1时,材料处于理想耗散状态,J达到最大值,即 。对于非线性耗散,可用功率耗散效率

。对于非线性耗散,可用功率耗散效率 来反映材料的功率耗散特征:

来反映材料的功率耗散特征:

(10)

(10)

在由应变速率 的对数和变形温度T构成的平面区域上绘制出功率耗散效率因子η的等值线图,即为功率耗散图。由功率耗散图可分析不同区域的变形机制,进而找出加工安全区。一般来说,η越高的区域,材料在此条件下的加工性能就越好。但是,在变形失稳区η也可能很高,所以,还要确定材料的变形失稳区。

的对数和变形温度T构成的平面区域上绘制出功率耗散效率因子η的等值线图,即为功率耗散图。由功率耗散图可分析不同区域的变形机制,进而找出加工安全区。一般来说,η越高的区域,材料在此条件下的加工性能就越好。但是,在变形失稳区η也可能很高,所以,还要确定材料的变形失稳区。

采用PRASAD[19-20]建立的失稳判据,该判据是将不可逆热力学的极值原理应用于大应变塑性变形中,若

(11)

(11)

则材料会出现变形失稳。式(11)中D为耗散函数。按照动态材料模型原理,D等于协变量J,由此推导出材料发生变形失稳的判据为

(12)

(12)

在由应变速率 的对数和变形温度T构成的平面区域内绘制出

的对数和变形温度T构成的平面区域内绘制出 的区域,即为失稳区,合金在该区域内进行热加工可能会出现流变失稳。将不同应变条件下的功率耗散图和失稳区进行叠加,就构成该应变条件下的DMM加工图。

的区域,即为失稳区,合金在该区域内进行热加工可能会出现流变失稳。将不同应变条件下的功率耗散图和失稳区进行叠加,就构成该应变条件下的DMM加工图。

2.4 构建Al-Zn-Mg-Cu-Zr合金的加工图

由于在轧制、挤压等加工过程中,合金所受的应变量均较大,而应变量达0.5以后,合金基本为稳态变形,因此,本文作者构建应变量为0.5时的加工图进行分析。

为保证m的精度,采用三次多项式拟合 与

与 的函数关系:

的函数关系:

(13)

(13)

其中:a1,a2,a3和a4均为常数。在一定变形温度下,由式(8)可得:

(14)

(14)

将不同应变速率的 代入式(14)即可获得相应的m,再将m代入式(10)就可以计算出合金在不同变形温度和应变速率下热变形时的η。在由T和

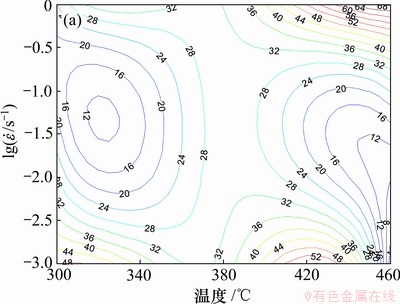

代入式(14)即可获得相应的m,再将m代入式(10)就可以计算出合金在不同变形温度和应变速率下热变形时的η。在由T和 所构成的平面内绘制出功率耗散图,见图7。

所构成的平面内绘制出功率耗散图,见图7。

将式(14)代入式(12),可得:

(15)

(15)

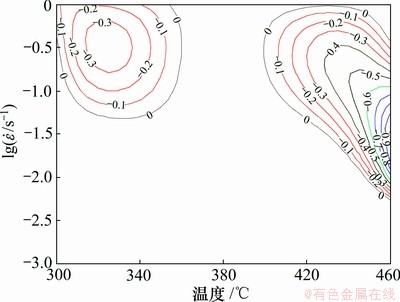

在由T和 所构成的平面内绘制出

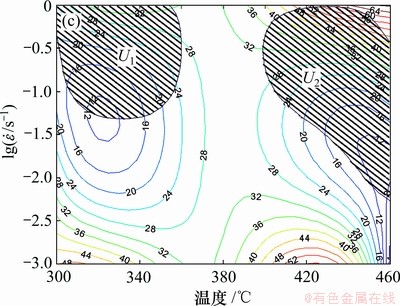

所构成的平面内绘制出 的区域,即合金的流变失稳区(图8)。将功率耗散图和失稳图叠加得到合金应变量为0.5的热加工图,如图9所示。图9中阴影区为流变失稳区,等值线上的数字表示功率耗散系数。

的区域,即合金的流变失稳区(图8)。将功率耗散图和失稳图叠加得到合金应变量为0.5的热加工图,如图9所示。图9中阴影区为流变失稳区,等值线上的数字表示功率耗散系数。

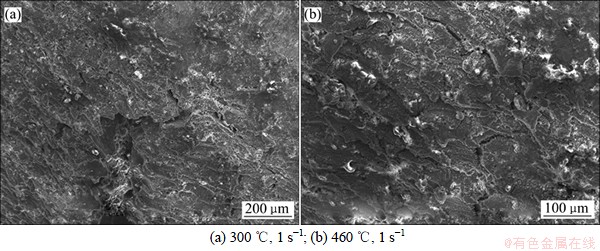

2.5 组织观察与失稳分析

从图9可见:该合金加工图上有2个失稳区U1和U2,U1区温度为300~360℃,应变速率0.05~1 s-1;U2区温度为400~460 ℃,应变速率0.005~1 s-1。由此可见:合金的失稳较多发生于高应变速率条件,即在高应变速率下该合金的加工区域较窄。这是由于在高应变速率下,大量塑性功转变成的热量以及界面滑移产生的应力集中没有足够的时间通过扩散等途径释放,容易引起局部流动或者开裂。U2区面积比U1区面积大,表明该合金高温加工更容易发生失稳。因为变形温度较高时,合金相界和晶界更容易发生滑移,从而引起界面开裂。为验证加工图的判断,观察不同加工条件下的压缩试样的微观组织。图10所示为变形条件在失稳区的合金SEM照片。从图10可见:在加工图失稳区的变形条件下进行热压缩,合金出现微裂纹,由此判断加工图中失稳区的绘制是正确的,在实际加工过程中应尽量避免采用这些区域的变形条件。

图7 T和 所构成平面内的功率耗散图

所构成平面内的功率耗散图

Fig.7 Power dissipation map in plane of T and

图8 合金流变失稳区

Fig.8 Flow instability areas for alloy

图9 真应变0.5时合金的热加工图

Fig.9 Processing map at 0.5 true strain

加工图中不同区域的功率耗散效率有明显变化,这表明温度和应变速率对于合金动态能量消耗行为的影响非常显著。合金加工图中可安全加工的区域存在2个能量耗散值较高的峰区:一个区的温度范围为440~460 ℃,应变速率0.5~1 s-1,最大功率耗散系数不低于0.64,该区与失稳区较接近,安全区面积小;另一个区温度为385~445 ℃,应变速率小于0.002 s-1,最大功率耗散系数不低于0.52,该区面积较大。

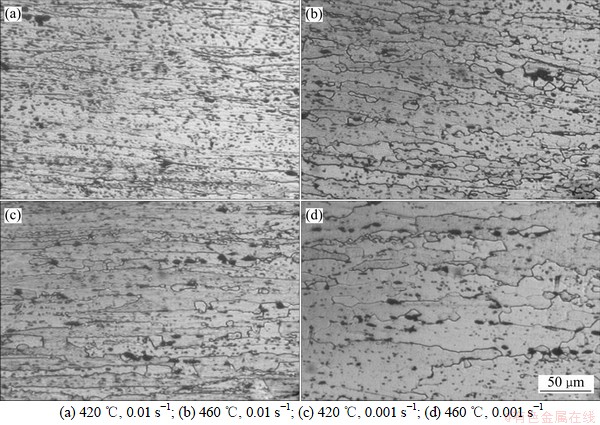

图11所示为不同变形条件下合金的金相显微组织。变形温度420 ℃下,采用0.01 s-1应变速率变形,合金的晶粒沿垂直压缩方向变长,并未观察到再结晶晶粒;在同一应变速率下,提高变形温度至460 ℃,合金中出现较多的再结晶晶粒。由此表明:在高温条件下变形,合金更容易发生动态再结晶。这是因为当变形温度较低时,位错难以通过运动而实现重组,因而动态再结晶不易发生;当变形温度升高时,合金中原子热振动和扩散速率增加,比低温时更容易发生位错的滑移、攀移或者交滑移,使得动态再结晶的形核率增大。

图10 变形条件在失稳区的合金SEM照片

Fig.10 SEM images of alloy with deformation conditions at flow instability areas

图11 不同变形条件热压缩后合金的金相显微组织

Fig.11 Optical microstructures of alloy under different deformation conditions

同样地,当420 ℃变形,应变速率减小至0.001 s-1时,合金晶界呈波浪状,在晶界附近出现一些粒度为5~10 μm的小晶粒,这表明在该变形条件下发生部分动态再结晶,这与Ravichandran等[21]的研究相符。即对于高层错能金属,动态再结晶主要受晶界的迁移率控制,其动态再结晶能量耗散效率高;随着应变速率的减小,位错有足够的时间进行攀移或者滑移,发生相互抵消或重组,进而发生动态再结晶。这也说明加工图中功率耗散系数较高的区域的变形软化机制为动态再结晶。但当变形温度较高时,应变速率太小也会出现再结晶晶粒长大的现象。如图11(d)所示,当变形温度460 ℃、应变速率为0.001 s-1时,变形后,合金中再结晶晶粒粒度比0.01 s-1变形后合金中的再结晶晶粒粒度大。因此,在加工图安全区域适当降低变形温度或提高变形速率,可以获得更加细小的再结晶晶粒。

3 结论

(1) 由不同变形条件下Al-Zn-Mg-Cu-Zr合金的热压缩变形真应力-真应变曲线得到该合金流变应力本构方程为:

。

。

(2) 合金加工图上在低温区(温度为300~360 ℃、应变速率为0.05~1 s-1)和高温区(温度为400~460 ℃、应变速率为0.005~1 s-1)存在2个失稳区。

(3) 在温度440~460 ℃、应变速率0.001~0.002 s-1范围内热加工,合金能量耗散值达到峰值,对应的变形后组织发生动态再结晶。

参考文献:

[1] Williams J C, Starke Jr. E A. Progress in structural materials for aerospace systems[J]. Acta Materialia, 2003, 51(19): 5775-5799.

[2] LI Wenbing, PAN Qinglin, XIAO Yanping, et al. Microstructure and mechanical properties of Al-Zn-Cu-Mg-Sc-Zr alloy after retrogression and re-aging treatments[J]. Journal of Central South University of Technology, 2011, 18(2): 279-284.

[3] WANG Shaohua, MENG Linggang, YANG Shoujie, et al. Microstructure of Al-Zn-Mg-Cu-Zr-0.5Er alloy under as-cast and homogenization conditions[J]. Transactions of Nonferrous Metals Society of China, 2011, 21(7): 1449-1454.

[4] Seyed S H, Emamy M, Pourkia N, et al. The microstructure, hardness and tensile properties of a new super high strength aluminum alloy with Zr addition[J]. Materials Design, 2010, 31(9): 4450-4456.

[5] 曾渝, 尹志民, 潘青林, 等. 超高强铝合金的研究现状及发展趋势[J]. 中南大学学报: 自然科学版, 2002, 33(6): 592-596.

ZENG Yu, YIN Zhimin, PAN Qinglin, et al. Present research and developing trends of ultrahigh strength aluminum alloys[J]. Journal of Central South University: Science and Technology, 2002, 33(6): 592-596.

[6] 何振波, 李慧中, 梁霄鹏, 等. Al-Zn-Mg-Sc-Zr合金的热变形行为及加工图[J]. 中国有色金属学报, 2011, 21(6): 1220-1228.

HE Zhenbo, LI Huizhong, LIANG Xiaopeng, et al. Hot deformation behavior and processing map of Al-Zn-Mg-Sc-Zr alloy[J]. The Chinese Journal of Nonferrous Metals, 2011, 21(6): 1220-1228.

[7] Jaqan R G, Srinivasan N, Gokhale A A, Kashyap B P. Processing map for hot working of spray formed and hot isostatically pressed Al-Li alloy (UL40)[J]. Journal of Materials Processing Technology, 2009, 209(18/19): 5964-5972.

[8] 孔凡涛, 张树志, 陈玉勇. Ti-46Al-2Cr-4Nb-Y合金的高温变形及加工图[J]. 中国有色金属学报, 2010, 20(1): 233-236.

KONG Fantao, ZHANG Shuzhi, CHEN Yuyong. Hot deformation and processing map of Ti-46Al-2Cr-4Nb-Y alloy[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(1): 233-236.

[9] Rishi R. Development of a processing map for use in warm- forming and hot forming processes[J]. Metallurgical and Materials Transactions A-Physical Metallurgy and Materials Science, 1981, 12(6): 1089-1097.

[10] 曾卫东, 周义刚, 周军, 等. 加工图理论研究进展[J]. 稀有金属材料与工程, 2006, 35(5): 673-677.

ZENG Weidong, ZHOU Yigang, ZHOU Jun, et al. Recent development of processing map theory[J]. Rare Metal Materials and Engineering, 2006, 35(5): 673-677.

[11] Luo J, Li M Q, Ma D W. The deformation behavior and processing maps in the isothermal compression of 7A09 aluminum alloy[J]. Materials Science and Engineering A, 2012, 532(15): 548-557.

[12] Sun Y, Zeng W D, Zhao Y Q, et al. Research on the hot deformation behavior of Ti40 alloy using processing map[J]. Materials Science and Engineering: A. 2011, 528(3): 1205-1211.

[13] LI Li, ZHANG Xinming. Hot compression deformation behavior and processing parameters of a cast Mg-Gd-Y-Zr alloy[J]. Materials Science and Engineering A, 2011, 528(3): 1396-1401.

[14] Poirier J P. High temperature plastic deformation of crystals[M]. 关得林, 译. 大连: 大连理工大学出版社, 1989: 1-100.

Poirier J P. High Temperature Plastic Deformation of Crystals[M]. GUAN De-lin, trans. Dalian: University of Science and Technology Press, 1989: 1-100.

[15] QIN Yinjiang, PAN Qinglin, HE Yunbin, et al. Modeling of flow stress for magnesium alloy during hot deformation[J]. Materials Science and Engineering A, 2010, 527(10/11): 2790-2797.

[16] LIU Juan, CUI Zhenshan, LI Congxing. Modelling of flow stress characterizing dynamic recrystallization for magnesium alloy AZ31B[J]. Computational Materials Science, 2008, 41(3): 375-382.

[17] 蹇海根, 姜锋, 郑秀媛, 等. 高强高韧B93铝合金的热变形行为[J]. 中南大学学报: 自然科学版, 2011, 42(8): 2291-2296.

JIAN Haigen, JIANG Feng, ZHENG Xiuyuan, et al. Hot deformation behavior of high strength and toughness B93 aluminum alloy[J]. Journal of Central South University: Science and Technology, 2011, 42(8): 2291-2296.

[18] Zener C, Hollomon J H. Effect of strain-rate upon the plastic flow of steel[J]. Journal of Applied Physics, 1944, 15(1): 22-27.

[19] Prasad Y V R K, Rao K P. Processing maps and rate controlling mechanisms of hot deformation of electrolytic tough pitch copper in the temperature range 300-950°C[J]. Materials Science and Engineering A, 2005, 391(1/2): 141-150.

[20] Prasad Y V R K, Rao K P. Processing maps for hot deformation of rolled AZ31 magnesium alloy plate: Anisotropy of hot workability[J]. Materials Science and Engineering A, 2008, 487(1/2): 316-327.

[21] Ravichandran N, Prasad Y V R K. Influence of oxygen on dynamic recrystallization during hot working of polycrystalline copper[J]. Materials Science and Engineering A, 1992, 156(2): 195-204.

(编辑 邓履翔)

收稿日期:2012-05-11;修回日期:2012-07-10

基金项目:国家重点基础研究发展计划(“973”计划)项目(2012CB619503)

通信作者:潘清林(1964-),男,湖北孝感人,教授,从事高性能有色合金的研究;电话:0731-88830933,E-mail: pql@csu.edu.cn