田口-灰关联法应用于Inconel 718微放电铣削参数最佳化

来源期刊:中国有色金属学报(英文版)2013年第3期

论文作者:林茂用 曹中丞 许春耀 邱 蕙 黄鹏丞 林裕城

文章页码:661 - 666

关键词:Inconel 718合金;微放电铣削加工;电极消耗;材料去除率;扩口量;田口-灰关联分析

Key words:Inconel 718 alloy; micro milling electrical discharge machining; electrode wear; material removal rate; working gap; Grey-Taguchi method

摘 要:应用田口-灰关联法对Inconel 718微放电铣削多重质量特性如电极消耗率、材料去除率和扩口量进行最佳化,分析放电电流、脉冲时间、休止时间和极间间隙对加工Inconel 718之电极消耗率、材料去除率和扩口量的影响。实验结果表明,以最佳微放电铣削参数进行加工,其电极消耗率由5.6×10-9 mm3/min降低到5.2×10-9 mm3/min,材料去除率由0.47×10-8 mm3/min增加到1.68×10-8 mm3/min,扩口量由1.27 μm降低到1.19 μm。研究结果显示,应用田口-灰关联法,可以改善微放电铣削多重质量特性。

Abstract: The optimization of micro milling electrical discharge machining (EDM) process parameters of Inconel 718 alloy to achieve multiple performance characteristics such as low electrode wear, high material removal rate and low working gap was investigated by the Grey-Taguchi method. The influences of peak current, pulse on-time, pulse off-time and spark gap on electrode wear (EW), material removal rate (MRR) and working gap (WG) in the micro milling electrical discharge machining of Inconel 718 were analyzed. The experimental results show that the electrode wear decreases from 5.6×10-9 to 5.2×10-9 mm3/min, the material removal rate increases from 0.47×10-8 to 1.68×10-8 mm3/min, and the working gap decreases from 1.27 to 1.19 μm under optimal micro milling electrical discharge machining process parameters. Hence, it is clearly shown that multiple performance characteristics can be improved by using the Grey-Taguchi method.

Trans. Nonferrous Met. Soc. China 23(2013) 661-666

Mao-yong LIN 1, Chung-chen TSAO2, Chun-yao HSU3,4, Ai-huei CHIOU3, Peng-cheng HUANG3, Yu-cheng LIN4

1. Department of Mechanical and Electrical Engineering, Fujian Polytechnic of Information Technology, Fuzhou 350003, China;

2. Department of Mechatronic and Electrical Engineering, Tahua University of Science and Technology, Hsinchu 30740;

3. Department of Mechanical Engineering, Lunghwa University of Science and Technology, Taoyuan 33306;

4. Department of Engineering Science, National Cheng Kung University, Tainan 70101

Received 21 May 2012; accepted 22 September 2012

Abstract: The optimization of micro milling electrical discharge machining (EDM) process parameters of Inconel 718 alloy to achieve multiple performance characteristics such as low electrode wear, high material removal rate and low working gap was investigated by the Grey-Taguchi method. The influences of peak current, pulse on-time, pulse off-time and spark gap on electrode wear (EW), material removal rate (MRR) and working gap (WG) in the micro milling electrical discharge machining of Inconel 718 were analyzed. The experimental results show that the electrode wear decreases from 5.6×10-9 to 5.2×10-9 mm3/min, the material removal rate increases from 0.47×10-8 to 1.68×10-8 mm3/min, and the working gap decreases from 1.27 to 1.19 μm under optimal micro milling electrical discharge machining process parameters. Hence, it is clearly shown that multiple performance characteristics can be improved by using the Grey-Taguchi method.

Key words: Inconel 718 alloy; micro milling electrical discharge machining; electrode wear; material removal rate; working gap; Grey-Taguchi method

1 Introduction

With increasing demand for highly technical products, it is easy to recognize the developing trend of the minimum dimension in the design and manufacturing. It can be expected an increase in the selection of high strength materials and the need for higher quality machining using optimized machining parameters and dedicated tools. Inconel 718 has been employed extensively in aerospace, petroleum and nuclear energy applications due to its unique properties, such as high strength, thermal resistance and high corrosion resistance. However, the machining of Inconel 718 causes high cutting temperatures. This has become more problematic in terms of both efficiency and tool wear.

Since conventional cutting or grinding processes have limitations in fabricating reductions in the size and mass of technological devices, micro electrical discharge machining (EDM) is one of the most commonly used non-conventional machining processes in micro injection, stamping and micro die/molds, fuel nozzles, micro probes, photo-masks and micro tools. However, tool wear is the most common defect of this technique. It is caused by the erosive effect occurring during the discharge between the tool and the workpiece, which dramatically deteriorates the machining accuracy in the micro EDM process. Therefore, searching for new machining methods is imperative in order to decrease tool wear in micro EDM processes. Micro milling EDM is an evolution of CNC contouring micro EDM, which eliminates the need for tool wear compensation and customized shaped electrodes required in conventional micro EDM. Micro milling EDM enables the machining of micro cavities, micro grooves or micro curved surfaces under non-contact conditions with simple cylindrical or tubular electrodes. HAN et al [1] proposed the moving electric arc milling method, which has achieved a much higher mean removal rate compared with conventional EDM. Moreover, they pointed out that the wear of tool electrodes is negligible when these moving electric arc milling processes are done in oil dielectric fluid, and this is very favorable in the area of machining accuracy. Since EDM is basically a thermal material removal process, the electrical conditions supplied (such as electrical current, voltage, pulse duration, spark gap) can be very important factors [2]. Adhesion, short-circuiting and cavitations occur frequently during machining processes in micro EDM, making the discharge pulses unstable and machining time excessive [3]. LAUWERS et al [4] claimed that milling EDM is certainly possible in SiC, but the pulse interval times should be selected properly to obtain stable machined surface quality. Several researchers studied the compensation of electrode wear during milling EDM [5-7]. Moreover, SINGH et al [8] studied the effects of varying the pulsed current at reverse polarity with various electrodes on electrode wear (EW), material removal rate (MRR), diametral working gap (WG), and surface roughness in EDM of E-31 tool steel. Their study revealed that various machining parameters influence electrode wear, material removal rate and working gap, and that it is difficult to produce optimum machining quality by setting possible combinations of the parameters. Since EW, MRR and WG determine the cost and accuracy of machining, it is important to optimize the process parameters appropriately, and to maximize MRR, EW and WG. On the other hand, the Taguchi method provides an effective experimental design method for solving the variability in products or processes [9-11]. In addition, grey relational analysis (GRA) can effectively recommend methods for optimizing the complicated inter-relationships among multiple performance characteristics. Hence, the objective of the present study was to optimize the process parameters in micro milling EDM by using the Grey-Taguchi method, which has been used extensively in the past to solve troublesome problems in various industries [12-15].

2 Taguchi method

Generally, in order to satisfy the conditions of micro machining, such as micro EDM, the discharge energy (JP) must be as low as possible during one pulse on-time. The discharge energy of a single pulse can be expressed as follows:

(1)

(1)

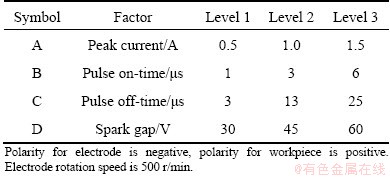

where DP is the spark gap voltage of a single pulse, V; IP is the discharge current of a single pulse, A; ton is the pulse on-time, s. However, spark gap voltage can be uncontrollable depending on the electrode materials and connecting interfaces during a discharge sparking. Furthermore, IP and ton determine the discharge energy level and control the interaction of the machined size and the quality of the tool and workpiece. In order to investigate the influence of control factors (peak current, pulse on-time, pulse off-time and spark gap) on EW, MRR and WG in the micro milling EDM of Inconel 718, four factors were considered at three levels each. Namely, an L9(34) orthogonal array was employed. Table 1 lists the micro milling EDM test parameters and levels.

Table 1 Parameters and levels of micro milling EDM

The experiments were repeated twice and the mean values of each output were subsequently used to analyze the results. The optimization of observed values was determined by analyzing the signal-noise ratio (S/N), based on the Taguchi method. The objective of this study was to determine the machining conditions required to achieve minimum EW, maximum MRR and minimum WG in the micro milling EDM process. Therefore, the quality characteristics of larger-the-better for MRR and smaller-the-better for EW and WG were implemented in this study. The S/N ratio of the smaller-the-better and the larger-the-better characteristics can be expressed as follows:

(2)

(2)

(3)

(3)

where (S/N)S is the S/N ratio of the smaller-the-better characteristic, (S/N)L is the S/N ratio of the larger-the-better characteristic, nK is the number of repetitions of the experiment and yl is the average measured value of experimental data l.

3 Grey relational analysis

The data sequences of the higher-the-better performance characteristic for MRR and the lower- the-better performance characteristic for EW and WG were pre-processed as follows [15]:

(4)

(4)

(5)

(5)

where n is the performance characteristic, i is the experimental number,  and

and  are the higher-the-better and lower-the-better values after grey relational generation, respectively,

are the higher-the-better and lower-the-better values after grey relational generation, respectively,  is the smallest value of

is the smallest value of  and

and  is the largest value of

is the largest value of  . The grey relational coefficient

. The grey relational coefficient  can be calculated as follows:

can be calculated as follows:

(6)

(6)

where  is the difference in absolute value between

is the difference in absolute value between  and

and  ,

,

is the smallest value of

is the smallest value of  ,

,  is the largest value of

is the largest value of  .

.  is the reference sequence,

is the reference sequence,  is the comparability sequence, and

is the comparability sequence, and  is the distinguishing coefficient,

is the distinguishing coefficient,  . The value of

. The value of  can be adjusted according to the actual system requirement and

can be adjusted according to the actual system requirement and  is selected in this study.

is selected in this study.

The grey relational grade ( ) is a weighting-sum of the grey relational coefficient. It is defined as follows:

) is a weighting-sum of the grey relational coefficient. It is defined as follows:

(7)

(7)

The experimental data of the multi-response characteristics were evaluated by using this grey relational grade. The evaluated grey relational grade fluctuates from 0 to 1 and equals 1 if these two sequences are identically coincident. The optimum level of the process parameters is the level with the highest grey relational grade.

4 Experimental

The micro milling EDM experiments were conducted on an EDM machine (OCT 200-MA, Ocean Technologies) with an iso-frequent pulse generator, having a maximum operating discharge current of 3 A and capable of setting an open-circuit voltage of 10 V. The maximum travel range of the machine is 200 mm× 150 mm×150 mm with the position resolution of 0.1 μm in X, Y and Z directions and fully closed feed back control ensures sub-micron accuracy. All Inconel 718 specimens were standardized with a size of 25 mm×25 mm×2 mm by using a grinding machine (KGS-520ZT, KENT Industrial Company) with a diamond-grain resin-bond grinding wheel.

The dielectric fluid pressure is closely related to the debris concentration and fluid viscosity, and hence a flushing pressure of 0.1 MPa was maintained. The tool electrode used was a cylinder-type tungsten carbide tool with a diameter of 200 μm. Micro milling EDM depth of 20 μm was evaluated in all experiments. The experimental process variables and settings are summarized in Table 1. Kerosene was selected as a liquid dielectric. The working gap was accurately measured off-line with a video measuring machine (VERTEX 220, Advanced Measurement Machines) with a magnification magnitude of 100. Basically, the smaller the working gap in the micro milling EDM process is, the better the machining performance is. The electrode length becomes shorter and the gap between the electrode tip and the workpiece surface becomes larger due to the electrode wear during machining. Therefore, the electrode wear was calculated using a CCD system with measurement software. Specifically, the length of the micro-electrode was measured both before and after the micro milling EDM process, and the electrode wear was compensated for based on the measured results. A scanning electron microscope (SEM) (JSM-6500F, JEOL) was used to obtain a better picture of surface quality after micro milling EDMed.

5 Results and discussion

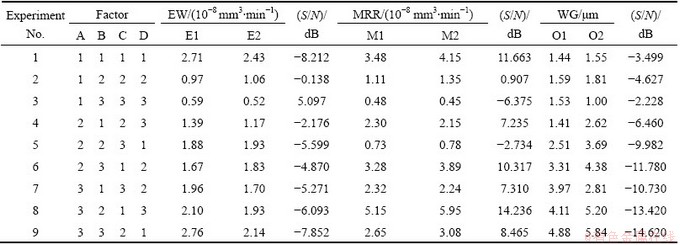

Table 2 shows the experimental results of the EW, MRR and WG, and the corresponding S/N ratios using Eqs. (2) and (3), respectively. The ANOVA results for the EW, MRR and WG are listed in Table 3. For EW, the spark gap (P = 40.62%, P is contribution), peak current (P=30.05%) and pulse off-time (P=21.79%) have a higher effect on the EW; this result agrees quite well with Eq. (1). The best combination for attaining lower EW is A1B3C3D3 (that is, peak current 0.5 A, pulse on-time 6 μs, pulse off-time 25 μs and spark gap 60 V). An increase in pulse off-time and spark gap, and a decrease in peak current can obtain a low EW. Pulse on-time has relatively little effect on the EW. This can be explained by the fact that lower discharge energy input and higher spark gap lead to lower EW generated in micro milling EDM process. Since the moving electric arcs during EDM milling can keep burning in the gap without extinction, the pulse duration can be much longer than that of conventional EDM, resulting in very low EW in EDM milling [1].

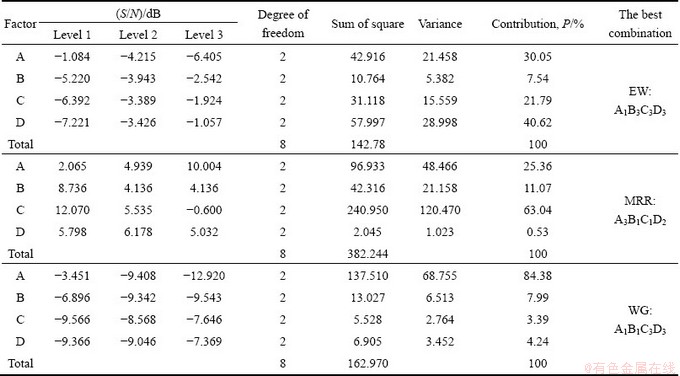

For MRR, pulse off-time (P=63.04%), peak current (P=25.36%) and pulse on-time (P=11.07%) all have a significant effect on the micro milling EDM process. In the case of a shorter pulse on-time, the MRR is greater than in the case of a longer one [2]. With the increase in peak current and the decrease in pulse on-time and pulse off-time, large amount of energy dissipated during a certain period of time. This produced higher discharge energy input into the discharge channel, resulting in high MRR. Spark gap did not contribute significantly to the increase of MRR in the micro milling EDM process. The best combination to attain higher MRR is A3B1C1D2 (that is, peak current 1.5 A, pulse on-time 1 μs, pulse off-time 3 μs and spark gap 45 V). However, decreasing the input peak current caused the machining time to be increased from the decrease of the removal rate. This led to slightly intense tool wear [2]. For working gap, peak current (P=84.38%) has a significant effect on the micro milling EDM process. Generally, working gap is associated with the development of high thermal stress exceeding the ultimate tensile strength of the material, as well as with plastic deformation. Working gap sizes increase with the increase of the pulse energy. The best combination for lower working gap is A1B1C3D3 (that is, peak current 0.5 A, pulse on-time 1 μs, pulse off-time 25 μs and spark gap 60 V). An increase in pulse off-time and spark gap, and a decrease in peak current and pulse on-time can obtain a low working gap in the micro milling EDM process, which is due to less input discharge energy. When the peak current and pulse on-time increase, sparking or electron bombardment from the side-wall of the tool electrode of the affected area increases, leading to more working gap [16]. However, the results of the optimum combination, which was obtained using the Taguchi method, were unable to select suitable process parameters with a single performance characteristic in the micro milling EDM of Inconel 718. In order to acquire and optimize micro milling EDM process parameters for EW, MRR and WG, the analysis of multiple performance characteristics is required. Table 4 shows the grey relational grade and its ranking for each experiment. The higher grey relational grades represent that the corresponding experimental result is closer to the ideal normalized value. In other words, the larger the grey relational grade is, the better the multiple performance characteristics are. Since A1B3C3D3 has the highest grey relational grade, as in Experiment 3, it has the best multiple performance characteristics among all experiments.

Table 2 Experimental results and S/N ratios for EW, MRR and WG in micro milling EDM of Inconel 718

Table 3 ANOVA results for EW, MRR and WG in micro milling EDM of Inconel 718

Table 4 Grey relational grades and their orders

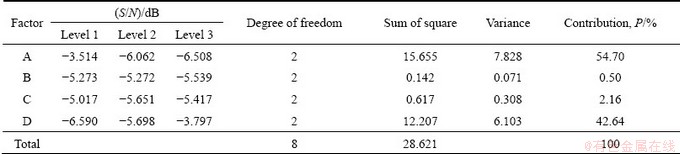

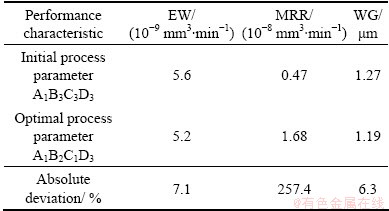

Table 5 illustrates the results of the ANOVA for multiple performance characteristics in the micro milling EDM of Inconel 718. As shown in Table 5, peak current (P=54.70%) and spark gap (P=42.64%) strongly affect the multiple performance characteristics of the micro milling EDM of Inconel 718, while the pulse on-time and the pulse off-time are not significant. From Table 5, the optimum conditions to obtain good multiple performance characteristics in micro milling EDM of Inconel 718 are A1B2C1D3 (that is, 0.5 A peak current, 3 μs pulse on-time, 3 μs pulse off-time and 60 V spark gap). By combining the use of lower peak current and higher spark gap, the multiple performance characteristics can be improved due to lower discharge of energy input. The comparisons of experimental results using the initial (A1B3C3D3) and optimal (A1B2C1D3) micro milling EDM parameters are shown in Table 6. As shown in Table 6, the EW decreases from 5.6×10-9 to 5.2×10-9 mm3/min, the MRR increases from 0.47×10-8 to 1.68×10-8 mm3/min, and the WG decreases from 1.27 to 1.19 μm.

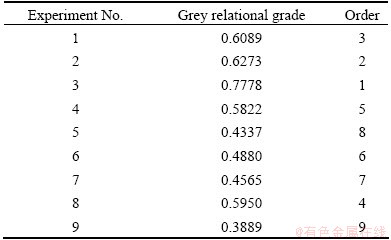

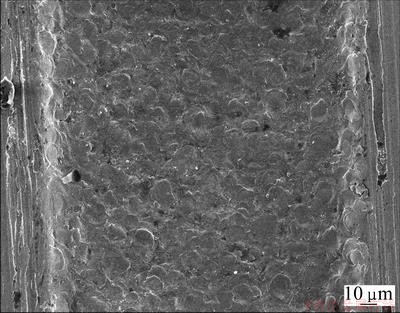

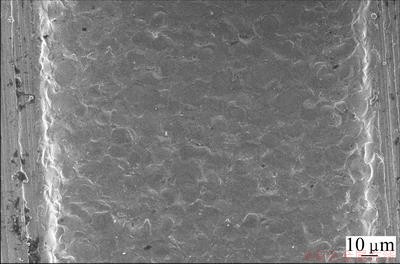

It is revealed from Table 6 that the EW, MRR and WG in the micro milling EDM process can be improved by 7.1%, 257.4% and 6.3%, respectively, with the selection of optimum conditions. Figures 1 and 2 show SEM micrographs under the conditions of the initial and optimal micro milling EDM parameters, respectively. The initial and optimal micro milling EDMed surfaces are uniformly dotted with circular discharge craters obtained from micro milling EDM with moving electric arcs. However, under optimal micro milling EDM parameters, the machined surface is smoother than with the initial micro milling EDM parameters. This result indicates that the multiple performance characteristics of micro milling EDM can be greatly improved by using the Grey-Taguchi method.

Fig. 1 SEM micrograph on A1B3C3D3

Fig. 2 SEM micrograph on A1B2C1D3

Table 5 Results of ANOVA for grey relational grades in micro milling EDM of Inconel 718

Table 6 Confirmation test results for multiple performance characteristics with initial and optimal process parameters

6 Conclusions

1) The optimization of micro milling EDM parameters with multiple performance characteristics (low electrode wear, high material removal rate and small working gap) for the machining of Inconel 718 was carried out.

2) The optimum conditions for obtaining higher multiple performance characteristics, such as A1B2C1D3, (peak current 0.5 A, pulse on-time 3 μs, pulse off-time 3 μs, and spark gap 60 V) were obtained.

3) Peak current and spark gap were the two important factors to achieve optimum results.

4) A confirmation experiment was carried out with the optimal levels of micro milling EDM process parameters in order to demonstrate the effectiveness of the Grey-Taguchi method. It seems that Grey-Taguchi method is very suitable for solving the quality problem of machining in the micro milling EDM of Inconel 718.

References

[1] HAN F Z, WANG Y X, ZHOU M. High-speed EDM milling with moving electric arcs [J]. International Journal of Machine Tools & Manufacture, 2009, 49: 20-24.

[2] SON S M, LIM H S, KUMAR A S, RAHMAN M. Influences of pulsed power condition on the machining properties in micro EDM [J]. Journal of Materials Processing Technology, 2007, 190: 73-76.

[3] MAHARDIKA M, MITSUI K. A new method for monitoring micro-electric discharge machining processes [J]. International Journal of Machine Tools & Manufacture, 2008, 48: 446-458.

[4] LAUWERS B, KRUTH J P, BRANS K. Development of technology and strategies for the machining of ceramic components by sinking and milling EDM [J]. Annals of the CIRP, 2007, 56(1): 225-228.

[5] BLEYS P, KRUTH J P, LAUWERS B, ZRYD A, DELPRETTI R, TRICARICO C. Real-time wear compensation in milling EDM [J]. Annals of the CIRP, 2002, 51(1): 157-160.

[6] YU Z Y, MASUZAWA T, FUJINO M. Micro-EDM for three-dimensional cavities-development of uniform wear method [J]. Annals of the CIRP, 1998, 47(1): 169-172.

[7] BLEYS P, KRUTH J P, LAUWERS B. Sensing and compensation of tool wear in milling EDM [J]. Journal of Materials Processing Technology, 2004, 149: 139-146.

[8] SINGH S, MAHESHWARI S, PANDEY P C. Some investigations into the electric discharge machining of hardened tool steel using different electrode materials [J]. Journal of Materials Processing Technology, 2004, 149: 272-277.

[9] TAGUCHI G, ELSAYED E A, HSAING T. Quality engineering in production systems [M]. New York: McGraw-Hill Publisher, 1989.

[10] ROSS P J. Taguchi techniques for quality engineering: loss function, orthogonal experiments, parameter and tolerance design [M]. New York: McGraw-Hill Publisher, 1996.

[11] PARK S H. Robust design and analysis for quality engineering [M]. New Jersey: Chapman & Hall Publisher, 1996.

[12] NARENDER SINGH P, RAGHUKANDAN K, PAI B C. Optimization by grey relational analysis of EDM parameters on machining Al-10% SiCp composites [J]. Journal of Materials Processing Technology, 2004, 155-156: 1658-1661.

[13] CHIANG K T, CHANG F P. Optimization of the WEDM process of particle-reinforced material with multiple performance characteristics using grey relational analysis [J]. Journal of Material Processing Technology, 2006, 180: 96-101.

[14] CHAN W K, TONG K L. Multi-criteria material selections and end-of-life product strategy: Grey relational analysis approach [J]. Material and Design, 2007, 28: 1539-1546.

[15] GOPALSAMY B M, MONDAL B, GHOSH S. Optimisation of machining parameters for hard machining: Grey relational theory approach and ANOVA [J]. International Journal of Advanced Manufacturing Technology, 2009, 45: 1068-1086.

[16] KHANRA A K, SARKAR B R, BHATTACHARYA B, PATHAK L C, GODKHINDI M M. Performance of ZrB2-Cu composite as an EDM electrode [J]. Journal of Materials Processing Technology, 2007, 183(1): 122-126.

林茂用1,曹中丞2,许春耀3,4,邱 蕙3,黄鹏丞3,林裕城4

蕙3,黄鹏丞3,林裕城4

1. 福建信息职业技术学院 机电工程系,福州 350003;2. 大华科技大学 机电工程系,新竹 30741;

3. 龙华科技大学 机械工程系,桃园 33306;4. 成功大学 工程科学系,台南 701

摘 要:应用田口-灰关联法对Inconel 718微放电铣削多重质量特性如电极消耗率、材料去除率和扩口量进行最佳化,分析放电电流、脉冲时间、休止时间和极间间隙对加工Inconel 718之电极消耗率、材料去除率和扩口量的影响。实验结果表明,以最佳微放电铣削参数进行加工,其电极消耗率由5.6×10-9 mm3/min降低到5.2×10-9 mm3/min,材料去除率由0.47×10-8 mm3/min增加到1.68×10-8 mm3/min,扩口量由1.27 μm降低到1.19 μm。研究结果显示,应用田口-灰关联法,可以改善微放电铣削多重质量特性。

关键词:Inconel 718合金;微放电铣削加工;电极消耗;材料去除率;扩口量;田口-灰关联分析

(Edited by Wei-ping CHEN)

Corresponding author: Yu-cheng LIN; Tel: +886-6-2762329; E-mail: yuclin@mail.ncku.edu.tw

DOI: 10.1016/S1003-6326(13)62513-3