DOI: 10.11817/j.ysxb.1004.0609.2020-36394

TiC对W-7Cu复合材料组织与性能的影响

高 银,刘 涛,韩 勇,范景莲,王圆圆,雷 挺

(中南大学 粉末冶金国家重点实验室,长沙 410083)

摘 要:以超细/纳米W-7Cu粉末、TiC粉末为原料,采用机械球磨法制备不同含量TiC(0.3%、0.5%、0.7%、1.0% (质量分数))的W-7Cu复合粉体,经压制、预烧、烧结,获得了W-7Cu-nTiC复合材料。研究了TiC添加量对W-7Cu复合材料的显微组织和力学性能的影响。结果表明:在1300 ℃烧结后,添加不同含量的TiC,使得W-7Cu材料的晶粒大小从5~10 μm细化到2~5 μm;相对密度和抗拉强度也得到提高;在TiC添加量为0.3%时,相对密度从98.22%提高到98.63%,抗拉强度从781 MPa提高到843 MPa;材料的断裂方式从沿晶断裂变为沿晶断裂和穿晶断裂混合的断裂方式。说明TiC的添加,起到良好的细晶强化和弥散强化的作用。

关键词:W-Cu复合材料;TiC;弥散强化;细晶强化

文章编号:1004-0609(2020)-06-1281-08 中图分类号:TG146.1 文献标志码:A

钨铜复合材料是一种由钨和铜组成的既不相互固溶也不形成金属间化合物的一种复合材料,通常称为假合金[1]。钨和铜之间的弱交互作用使它们在复合之后兼具了钨、铜的优点,既具有钨的高熔点、低热膨胀系数、耐电弧腐蚀、抗熔焊性能和抗侵蚀能力,又具有铜的优良导电导热性能[2]。钨铜复合材料利用铜在高温下挥发形成的发汗制冷作用,可降低钨铜表面温度,能够保证其在高温极端条件下使用[3],使得钨铜材料广泛应用于航空航天、国防军工、核工业等尖端领域[4]。然而,由于钨和铜之间互不相溶,常规的制备方法和烧结工艺难以获得高致密度、高强度、组织均匀的W-Cu复合材料,已经不能满足尖端领域的需求[5-6]。

超细/纳米粉体的表面能较高,具有良好的烧结性能,液相烧结过程中,能够降低烧结温度,促进颗粒重排,提高致密化程度[7]。而第二相粒子(稀土氧化物、碳化物等)具有高硬度、高熔点、高弹性模量、化学性质稳定等特性,可以改善钨铜的显微组织,抑制钨颗粒间的合并长大,同时,对W-Cu材料物理性能的影响小于铁、钴等离子,常被用作添加相来提高材料的力学性能[8-11]。国内外科研工作者围绕细化晶粒和弥散强化开展了大量研究。其中,王展等[12]采用水热-共还原法制备了掺杂不同含量La2O3的纳米W-Cu合金,致密度达到 99.32%,抗拉强度达到376 MPa;张明龙等[5]采用EDTA-柠檬酸法制备了含Y2O3 (0~0.8%) 的 Y2O3/W-Cu复合材料烧结体,相对密度高于98%,晶粒尺寸小于1 μm,抗弯强度和维氏硬度可达1040 MPa和312 HV。以上研究表明,添加第二相强化粒子能够细化材料的晶粒,提高材料的强度。由于碳化物相对于稀土氧化物而言,与钨具有更加接近的热膨胀系数、更好的界面结合特性[11],因此本文选用TiC作为添加相,用溶胶-喷雾干燥-热还原法制备的超 细/纳米W-7Cu粉为原料,采用机械球磨法制备不同含量TiC的W-7Cu复合粉体,经压制、预烧、烧结,获得了W-7Cu-TiC复合材料。研究了不同TiC含量对W-7Cu材料显微组织和性能影响的规律。

1 实验

实验以超细/纳米W-7Cu 粉(粒度150 nm,晶粒20 nm,纯度≥99.5%)和TiC粉(粒度50 nm,纯度≥ 99%(质量分数))为原料,采用机械球磨法添加不同含量的TiC(0.3%、0.5%、0.7%、1.0%(质量分数)),制备出W-7Cu-nTiC复合粉体。 然后将W-7Cu-TiC复合粉末压制成“工”字型压坯,将压坯试样在氢气气氛中进行预烧。分别在1210、1240、1270、1300、1330和1360 ℃下,氢气气氛中进行常压烧结,保温120 min。

采用Archimedes排水法测量样品的密度;采用Instron-3369 型力学试验机检测样品的抗拉性能;采用MeF3A 型金相显微镜进行样品显微组织观察;采用NOVA TM Nano SEM230 型超高分辨率场发射扫描电镜观察样品断口形貌,并利用EDX能谱仪进行定点成分分析。

2 结果与分析

2.1 烧结温度对W-Cu材料组织和性能的影响

2.1.1 烧结温度对W-Cu材料性能的影响

图1所示为W-7Cu材料在不同烧结温度下的相对密度和抗拉强度趋势图。由图1可知,W-7Cu材料的相对密度、抗拉性能随着烧结温度的升高先增大后减小,在烧结温度为1300 ℃时,相对密度为98.22%,抗拉强度为781 MPa,均达到最大值。这是因为,随着烧结温度的升高,液相铜的黏度降低,更易实现钨颗粒重排。当烧结温度超过1300 ℃时,液相铜的体积扩散、迁移加剧,由于重力作用,钨颗粒下沉,而铜在烧结坯表面渗出,并且有部分挥发,同时,材料中残留的孔隙也会随着温度的升高发生膨胀,从而造成烧结体密度下降[13]。而抗拉强度与材料自身的致密性有关,因此呈现出了与相对密度类似的变化趋势。

图1 烧结温度对W-7Cu材料相对密度、抗拉强度的影响

Fig. 1 Effects of sintering temperature on density and tensile strength of W-7Cu materials

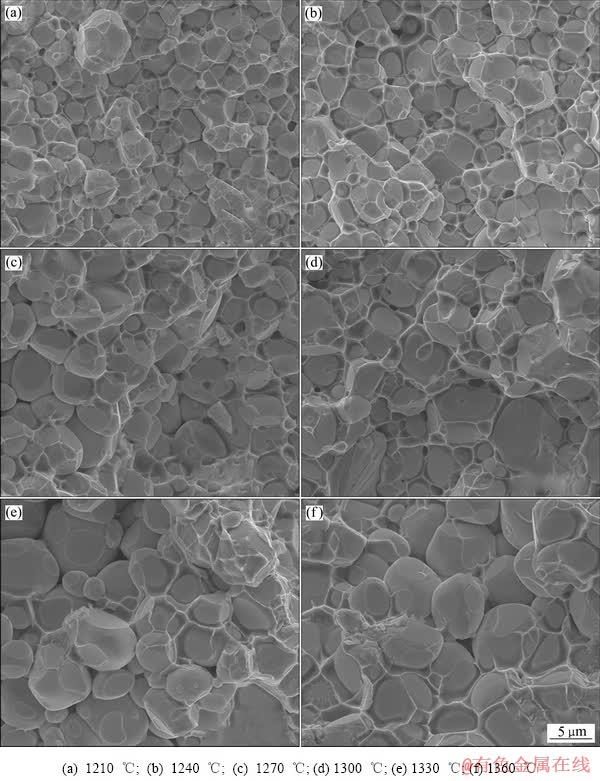

2.1.2 烧结温度对W-Cu材料组织的影响

图2所示为不同烧结温度下W-7Cu材料的断口形貌图。由图2可知,样品断口主要呈冰糖状,断裂方式为沿晶断裂。在1210~1300 ℃烧结温度范围内,随着烧结温度的升高,晶粒明显粗化、圆化,孔隙减少,这是因为随着温度的升高,铜的黏度降低,黏性流动增强,有利于钨颗粒悬浮于液相内受液相表面张力的作用发生位移、重新分布,以达到最紧密的排布。继续升高烧结温度,钨晶粒显著增大,这是由于钨通过液相发生溶解和在析出过程或重结晶过程加快,造成细的钨颗粒溶解,大的钨颗粒更大,高温烧结温度越高,时间越长,钨颗粒则显得越粗大[14-16]。同时,随着烧结温度进一步升高,铜相分布不再均匀,图中部分区域甚至出现无铜现象,这是铜在烧结坯表面渗出、部分挥发引起的,铜相的缺失使材料内部出现大量的孔隙,降低了材料相对密度,这与2.1.1节中致密化分析结论一致。

综上所述,选定1300 ℃作为最佳烧结温度,并开展不同TiC添加量对W-7Cu材料组织和性能影响的探究。

2.2 TiC添加量对W-7Cu材料相对密度和力学性能的影响

2.2.1 TiC添加量对W-7Cu材料相对密度的影响

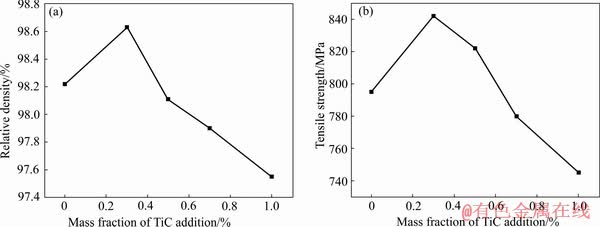

图3(a)所示为不同TiC添加量的W-7Cu材料的烧结相对密度趋势图。从图3(a)中可以看出,随着TiC添加量的增加,材料的相对密度呈现先升高后降低的趋势,在TiC添加量为0.3%时达到最大值,为98.63%,说明适量TiC的添加不仅不会降低材料的相对密度,反而有利于提高其相对密度,合金相对密度的高低与合金内部孔隙的多少直接相关,孔隙越多,合金的相对密度越低。有研究表明[10],坯体中的氧是造成烧结过程中形成孔隙的主要原因。碳化物在800 ℃以上高温烧结时会与坯体内的氧发生反应生成碳氧化合物和CO/CO2气体,在快速致密化前降低了坯体内的氧含量,而反应生成的CO/CO2气体则通过颗粒间连续的孔隙网络排除烧结体外,使得烧结中后期产生的水蒸气减少、闭孔数目减少,烧结体相对密度增大[17]。随着TiC的继续增加,TiC颗粒在烧结过程中容易发生团聚[9],由于共价化合物TiC化学性质稳定,难以发生塑性变形和物质迁移,比钨更难烧结致密。因此,在TiC团聚区域会出现孔洞等缺陷,增大了烧结体孔隙度,导致其相对密度降低。

图2 不同烧结温度下W-7Cu断口形貌图

Fig. 2 Surface diagrams of W-7Cu fracture under different sintering temperatures

2.2.2 TiC添加量对W-7Cu材料抗拉强度的影响

图3(b)所示为添加不同含量TiC后W-7Cu材料的室温抗拉性能趋势图。由图3(b)可知,随着TiC含量的增加,材料的室温抗拉强度呈现先升高后降低的趋势,且TiC添加量为0.3%时,合金强度达到最高值 (843 MPa)。这主要归因于TiC颗粒弥散地分布于钨颗粒的边界上,能够抑制钨颗粒的聚集长大,起到良好的细化晶粒的作用;晶粒内的TiC能够钉扎位错,阻碍位错的运动,也能提高材料强度;同时,TiC能够消耗晶界氧,生成TiO2,净化了晶界,减少孔隙,使得晶界结合强度提高,增强了材料韧性[18]。然而,随着TiC的继续添加,材料的强度开始呈现下降趋势,这是因为TiC添加量过多时,会使得在晶界处分布的脆性相偏多,容易造成沿晶脆断,使得材料的力学性能下降。

2.3 TiC添加量对W-7Cu材料显微组织的影响

2.3.1 金相组织

图4所示为W-7Cu-nTiC(0≤n≤1)材料在光学显微镜下的金相照片。由图4可知,随着TiC添加量的增加,晶粒显著细化,纯W-7Cu材料中钨颗粒的粒径在5~10 μm,添加TiC后的钨颗粒的平均粒径在2~5 μm。这是因为,在高温下烧结时,不同的钨颗粒会发生聚集再结晶,导致钨颗粒长大。当TiC粒子弥散分布在钨基体中,晶界迁移遇到第二相质点时,晶界线将会被钉扎、拉长,不易挣脱质点的障碍向前移动,这就提高了位错运动所需要的能量,同时,晶粒细化增加了晶界面积,当材料承受载荷发生断裂时,裂纹扩展需要穿过更多的晶界、消耗能多的能量,有利于合金强度的提高,这与2.2.2节中抗拉强度分析结论是相符的。

图3 TiC添加量对W-7Cu合金相对密度和抗拉强度的影响

Fig. 3 Effect of TiC addition on relative density(a) and tensile strength(b) of W-7Cu alloy

图4 W-7Cu-nTiC的金相照片

Fig. 4 Metallographic photos of W-7Cu-nTiC

2.3.2 断口形貌

图5所示为W-7Cu-nTiC(0≤n≤1)材料拉伸样品的断口形貌SEM像。由图5(a)可见,纯W-7Cu的钨晶粒为近等轴状结构,晶界光滑平整,为典型的沿晶脆性断裂特征;而添加TiC粒子后,合金晶粒尺寸变小,同时也出现了明显的穿晶解理断裂,穿晶解理断裂的晶粒呈现明显的河流状解理台阶,说明该材料的晶界结合强度得到了增强,较钨晶粒更难发生断裂,可能的原因是TiC粒子与钨基体形成了共格界面,增强了晶界结合力,强化了晶界,提高了材料韧性;继续添加TiC,由图5(e)可见,TiC颗粒之间发生了明显的团聚,在TiC团聚区域中更容易出现孔洞等缺陷,增大材料的孔隙度,降低其致密度,这与2.2.1节中对材料致密度的分析结论是相符的。

图6所示分别为W-7Cu-TiC材料断口形貌中穿晶区域的进一步放大及第二相粒子的EDX分析。通过EDX分析发现,第二相粒子由钨、钛、碳、氧元素组成,可能是钨原子取代了钛原子在晶格中的位置,进入颗粒当中,形成了(W, Ti)xOyCz复合粒子[19-20],减少了杂质氧在晶界处的富集,同时,由颗粒增强金属基材料拉伸模型可知,第二相粒子承受的应力大于基体,界面强度显著提高,使得钨晶粒优先发生穿晶解理断裂。

图5 W-7Cu-nTiC的断口形貌图

Fig. 5 Fracture topographies of W-7Cu-nTiC

图6 穿晶区域的断口形貌及第二相粒子的EDX图

Fig. 6 Fracture morphology of through-crystal region(a) and EDX figure of the second phase particle(b)

3 结论

1) 不添加TiC的W-7Cu材料,随着烧结温度的升高,其相对密度和抗拉强度先增加后降低,在1300 ℃时两者皆达到最大值,相对密度为98.22%,抗拉强度为781 MPa。

2) 添加TiC后,在1300 ℃烧结温度下,随着TiC含量的增加,W-7Cu材料的相对密度和抗拉强度先增加后降低;当TiC添加量为0.3%时,两者皆达到最大值,相对密度提高到98.63%,抗拉强度提高到843 MPa。

3) 添加TiC后,在1300 ℃烧结温度下,W-7Cu材料的断裂方式由沿晶断裂变为沿晶断裂和穿晶断裂混合的断裂方式,晶粒大小也从不添加TiC时的5~10 μm变为2~5 μm。

REFERENCES

[1] 徐 竹. 钨铜复合材料制备技术的发展与应用[J]. 新技术新工艺, 2016(6): 76-78.

XU Zhu. Development and application of preparation technology of tungsten and copper composites materials[J]. New Technology and New Process, 2016(6): 76-78.

[2] 刘 涛, 范景莲, 田家敏, 成会朝, 高 杨. 超细/纳米W-10%Cu复合粉末制备与烧结工艺[J]. 中南大学学报(自然科学版), 2009, 40(5): 1235-1239.

LIU Tao, FAN Jing-lian, TIAN Jia-min, CHENG Hui-chao. Synthesis and sintering of ultra-fine/nano-W-10%Cu composite powder[J]. Journal of Central South University (Natural Science Edition), 2009, 40(5): 1235-1239.

[3] 黄丽枚, 罗来马, 丁孝禹, 罗广南, 暂 祥, 洪 雨, 吴玉程. 钨铜复合材料的研究进展[J]. 机械工程材料, 2014, 38(4): 1-6.

HUANG Li-mei, LUO Lai-ma, DING Xiao-yu, LUO Guang-nan, ZAN Xiang, HONG Yu, WU Yu-cheng. Research progress of W-Cu composites[J]. Mechanical Engineering Materials, 2014, 38 (4): 1-6.

[4] 范景莲, 朱 松, 刘 涛, 田家敏. 超细/纳米W-20Cu复合粉末的液相烧结机制[J]. 中国有色金属学报, 2011, 21(7): 1587-1593.

FAN Jing-lian, ZHU Song, LIU Tao, TIAN Jia-min. Mechanism of ultrafine/nano W-20Cu composite powder during liquid sintering[J]. The Chinese Journal of Nonferrous Metals, 2011, 21(7): 1587-1593.

[5] 张明龙, 程继贵, 陈会培, 李剑锋, 罗来马, 吴玉程. 超细Y2O3/W-Cu复合粉体的制备及其烧结体的组织性能[J]. 材料热处理学报, 2016, 37(7): 19-24.

ZHANG Ming-long, CHENG Ji-gui, CHEN Hui-pei, LI Jian-feng, LUO Lai-ma, WU Yu-cheng. Synthesis of ultra-fine Y2O3/W-Cu powders and microstructure and properties of sintered materials[J]. Journal of Material Heat Treatment, 2016, 37(7): 19-24.

[6] CHEN Pin-gan, LUO Guo-qiang, LI Mei-juan, SHEN Qiang, ZHANG Lian-meng. Effects of Zn additions on the solid-state sintering of W-Cu composites[J]. Materials & Design, 2012, 36: 108-112.

[7] 桂和仁, 张学斌, 丁 辉, 任 新, 寇思捷, 王松林, 凤 仪. 溶胶-凝胶自蔓延燃烧法制备钨铜复合材料及其性能研究[J]. 稀有金属与硬质合金, 2018, 46(5): 28-33.

GUI He-ren, ZHANG Xue-bin, DING Hui, REN Xin, KOU Si-jie, WANG Song-lin, FENG Yi. Study of preparation and properties of tungsten-copper composites by sol-gel self-propagating combustion[J]. Rare Metals and Cemented Carbide, 2018, 46(5): 28-33.

[8] 杨晓红, 范志康, 梁淑华, 肖 鹏. TiC对CuW触头材料组织与性能的影响[J]. 稀有金属材料与工程, 2007, 36(5): 817-821.

YANG Xiao-hong, FAN Zhi-kang, LIANG Shu-hua, XIAO Peng. Effects of TiC on microstructure and properties of CuW electrical contact materials[J]. Rare Metal Materials and Engineering, 2007, 36(5): 817-821.

[9] 张 顺, 范景莲, 成会朝, 田家敏, 成创功. ZrC对W合金性能与组织结构的影响[J]. 稀有金属材料与工程, 2013, 42(7): 1429-1432.

ZHANG Shun, FAN Jing-lian, CHENG Hui-chao, CHENG Hui-chao, TIAN Jia-min, CEHNG Chuang-gong. Influence of ZrC addition on properties and microstructure of W alloys[J]. Rare Metal Materials and Engineering, 2013, 42(7): 1429-1432.

[10] 成会朝, 范景莲, 钱 昭, 田家敏. 微量ZrC对Mo-Ti-Zr合金显微组织与性能的影响[J]. 中国科技论文, 2013, 8(6): 521-524.

CHENG Hui-chao, FAN Jing-lian, QIAN Zhao, TIAN Jia-min. Effects of trace ZrC on properties and microstructure of Mo-Ti-Zr alloys[J]. Chinese Scientific and Technological Papers, 2013, 8(6): 521-524.

[11] 李鹏飞, 范景莲, 成会朝, 田家敏, 段 涛, 张梓焯. ZrC含量对钨材料组织和性能的影响[J]. 稀有金属材料与工程, 2016, 45(11): 2970-2974.

LI Peng-fei, FAN Jing-lian, CHENG Hui-chao, TIAN Jia-min, DUAN Tao, ZHANG Zi-chao. Effect of ZrC content on microstructure and properties of tungsten materials[J]. Rare Metal Materials and Engineering, 2016, 45(11): 2970-2974.

[12] 王 展, 李继文, 魏世忠, 万 成, 潘昆明, 张国赏. La2O3/Y2O3对水热法制备W-Cu粉体的影响[J]. 稀土, 2017, 38(2): 34-40.

WANG Zhan, LI Ji-wen, WEI Shi-zhong, WAN Cheng, PAN Kun-ming, ZHANG Guo-shang. The influence of rare earth additives on the preparation of W-Cu composite powders by hydrothermal method[J]. Rare Earth, 2017, 38(2): 34-40.

[13] 范景莲, 朱 松, 刘 涛, 田家敏. 溶胶-喷雾干燥W-10Cu和W-20Cu复合粉末烧结与组织性能研究[J]. 粉末冶金技术, 2011, 29(1): 8-12.

FAN Jing-lian, ZHU Song, LIU Tao, TIAN Jia-min. Sintering, microstructure and properties of W-10Cu/W-20Cu composite powders synthesized by sol-spray drying[J]. Powder Metallurgy Technology, 2011, 29(1): 8-12.

[14] 卓海鸥, 刘文胜, 陈树茂. 超细/纳米W-Cu复合粉的制备方法及烧结致密化机制[J]. 中国钨业, 2016, 31(5): 60-65.

ZHUO Hai-ou, LIU Wen-sheng, CHEN Shu-mao. Preparation methods and sintering densifying mechanism of ultrafine and nano-sized W-Cu composite powders[J]. Tungsten Industry of China, 2016, 31(5): 60-65.

[15] 郭垚峰, 范景莲, 刘 涛. W-30Cu纳米复合粉末液相烧结致密化与晶粒长大机制[J]. 稀有金属材料与工程, 2014, 43(1): 125-129.

GUO Yao-feng, FAN Jing-lian, LIU Tao. Mechanism of densification and grain growth of W-30Cu nano-composite powder by liquid phase sintering[J]. Rare Metal Materials and Engineering, 2014, 43(1): 125-129.

[16] 李鹏飞, 范景莲, 章 曼, 陈卓华, 田家敏, 段 涛. 烧结温度对ZrC-Y2O3复合增强细晶钨组织与性能的影响[J]. 中国有色金属学报, 2016, 26(9): 1952-1958.

LI Peng-fei, FAN Jing-lian, ZHANG Man, CHEN Zhuo-hua, TIAN Jia-min, DUAN Tao. Effect of sintering temperature on microstructure and properties of tungsten composites reinforced by ZrC-Y2O3 particles[J]. The Chinese Journal of Nonferrous Metals, 2016, 26(9): 1952-1958.

[17] 范景莲, 钱 昭, 成会朝, 田家敏, 成创功. 微量TiC/ZrC对TZM合金室温及高温性能与组织的影响[J]. 稀有金属材料与工程, 2013, 42(4): 853-856.

FAN Jing-lian, QIAN Zhao, CHENG Hui-chao, TIAN Jia-min, CHENG Chuang-gong. Effect of trace TiC/ZrC on properties and microstructure of TZM alloy at room temperature and high temperature[J]. Rare Metal Materials and Engineering, 2013, 42(4): 853-856.

[18] LI Peng-fei, FAN Jing-lian, HAN Yong, ZHANG Man, CHENG Hui-chao, TIAN Jia-min. Microstructure evolution and properties of tungsten reinforced by additions of ZrC[J]. Rare Metal Materials and Engineering, 2018, 47(6): 1695-1699.

[19] ROOSTA M, BAHARVANDI H. The change occurred in W/ZrC composite properties by using nano reactants[J]. International Journal of Refractory Metals and Hard Materials, 2013, 37(2): 29-32.

[20] LIPKE D W, ZHANG Yun-shu, LIU Ya-jun, CHURCH B, SANDHAGE K H. Near net-shape/net-dimension ZrC/W-based composites with complex geometries via rapid prototyping and displacive compensation of porosity[J]. Journal of the European Ceramic Society, 2010, 30(11): 2265-2277.

Effects of TiC on microstructure and properties of W-Cu composites

GAO Yin, LIU Tao, HAN Yong, FAN Jing-lian, WANG Yuan-yuan, LEI Ting

(State Key Laboratory of Powder Metallurgy, Central South University, Changsha 410083, China)

Abstract: Ultra-fine/ nano-W-7Cu powders and TiC powders were used as reactors to synthesize W-7Cu composite powder containing TiC (0.3%, 0.5%, 0.7%, 1.0% (mass fraction)) by mechanical milling. Then the productions were pressed, pre-sintered, sintered to synthesize W-7Cu-TiC composites to find the effects of TiC on the microstructure and properties of W-7Cu composites. The results show that the fracture mode of W-7Cu material changes from along the crystal fracture to the mixed fracture mode. And the addition of TiC can refine the grain from 5-10 μm to 2-5 μm after sintered at 1300 ℃. The relative density and tensile strength of W-7Cu materials are increased by the addition of TiC. The tensile strength is promoted from 781 MPa to 843 MPa and the relative density is from 98.22% to 98.63% when the content of TiC is 0.3% after sintered at 1300 ℃. In summary, the addition of TiC can play a good role in grain refinement and dispersion strengthening.

Key words: W-Cu composites; TiC; dispersion strengthening; fine grain strengthening

Foundation item: Project(2017YFBO306002) supported by the National Basic Research Development Program of China

Received date: 2019-06-10; Accepted date: 2020-03-12

Corresponding author: LIU Tao; Tel: +86-731-88836652; E-mail: 2816799@qq.com

(编辑 王 超)

基金项目:国家重点研发计划项目(2017YFBO306002)

收稿日期:2019-06-10;修订日期:2020-03-12

通信作者:刘 涛,副教授,博士;电话:0731-88836652;E-mail:2816799@qq.com