DOI: 10.11817/j.issn.1672-7207.2017.09.031

铜炉渣活性激发实验研究及水化机理分析

吴爱祥1, 2,姜关照1, 2,兰文涛1, 2,刘娟红1, 2,薛杨1, 2

(1. 北京科技大学 金属矿山高效开采与安全教育部重点实验室,北京,100083

2. 北京科技大学 土木与环境工程学院,北京,100083)

摘要:为了实现铜炉渣的回收利用,通过机械活化和碱激发的方式制备铜炉渣胶凝材料,并利用X线衍射(XRD)、扫描电镜(SEM)、能谱仪(EDS)和矿渣玻璃体分相结构模型对铜炉渣水化机理进行分析。研究结果表明:当比表面积为520 m2/kg时,铜炉渣净浆试样的7 d和28 d强度分别达到2.4 MPa和3.3 MPa;当灰砂比为1:1时,铜炉渣全尾砂充填料的7 d和28 d强度分别达到0.7 MPa和1.0 MPa,满足当地矿山充填的要求。水化初期,炉渣玻璃体中的富钙相和高钙石灰共同水化生成了Ca(OH)2,其进一步与富硅相反应生成C-S-H凝胶等水化产物。随着水化反应的继续进行,试样内部的孔隙逐渐被水化产物填充并缩小至孔状,浆体结构更加致密。

关键词:铜炉渣;机械活化;碱激发;充填胶凝剂;水化机理

中图分类号:TD853 文献标志码:A 文章编号:1672-7207(2017)09-2498-08

Experimental study on copper slag activity excitation and hydration mechanism analysis

WU Aixiang1, 2, JIANG Guanzhao1, 2, LAN Wentao1, 2, LIU Juanhong1, 2, XUE Yang1, 2

(1. Key Laboratory of High-Efficient Mining and Safety of Metal Mines, Ministry of Education,University of Science and Technology Beijing, Beijing 100083, China;

2. School of Civil and Environmental Engineering, University of Science and Technology Beijing, Beijing 100083, China)

Abstract: In order to realize the recycling of copper slag, copper slag cementitious material was prepared by the way of mechanical activation and alkali activation, and the hydration mechanism of copper slag was analyzed by XRD, SEM, EDS and slag vitreous phase structure model. The results show that when the specific surface area of slag is 520 m2/kg, 7 d strength and 28 d strength of copper slag paste specimen reach 2.4 MPa and 3.3 MPa, respectively. When cement sand ratio is 1:1, 7 d and 28 d strength of copper slag tailings filling reach 0.7 MPa and 1.0 MPa, respectively, meeting the requirements of local mine filling. In the early stage of hydration, the calcium-rich phase and high calcium lime generates calcium hydroxide, which further forms C-S-H gel and other hydration products with silicon-rich phase. As the hydration reaction continues, the internal pores of sample are filled with hydration products and gradually shrink into hole type, and the structure becomes denser.

Key words: copper slag; mechanical activation; alkali activation; filling gelling agent; hydration mechanism

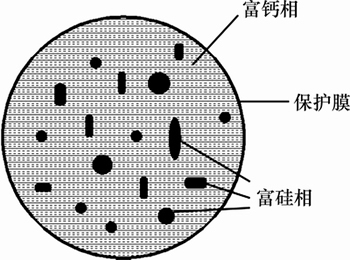

目前,低成本胶凝材料作为水泥替代品的研究在国内外成为热点[1-3]。以矿山充填胶固料为主的新型胶凝材料,从其历史根源、所用原材料和固化原理等方面看,可归为在机械活化下的碱激发或化学激发胶凝材料,其核心技术是活性激发材料或激发剂的选择与组分配比。活性激发材料大多以铝硅酸盐类矿物为主要原材料,如粉煤灰、矿渣等工业废渣。国内外矿山已经做了大量关于粉煤灰作为胶凝材料的实验,掺入粉煤灰的高性能水泥已在井下充填中得到了广泛的应用,同时粉煤灰胶凝材料的水化机理研究也较为成熟[4-5]。大量实验表明[6-10],采用机械活化和碱激发的方式可以激发矿渣的潜在活性,利用矿渣制备新型胶凝材料是可行的。关于矿渣的水化机理,诸培南等[11-12]认为矿渣玻璃体是包含富钙相和富硅相的分相结构,水淬矿渣玻璃体表面有一层较为稳定的“保护膜”—表面硅氧网络结构层。徐彬等[13]进一步给出酸性矿渣的玻璃体结构模型,以上观点的提出为矿渣水化机理的研究进一步指明了方向。虽然利用粉煤灰、高炉矿渣等工业废渣制备胶凝材料的研究已经取得了重大进步,但是目前关于铜炉渣的活性激发实验研究较少,且针对铜炉渣这类酸性矿渣的水化机理的研究尚不成熟。本文作者选取铜炉渣为主要原料,采用机械粉磨和碱激发的方法开展铜炉渣新型胶凝材料的实验研究,并进一步探究铜炉渣的水化机理。

1 实验

1.1 实验材料

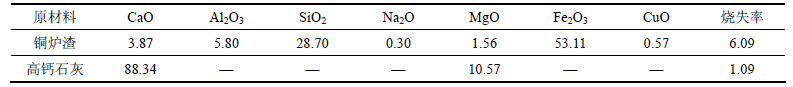

1.1.1 铜炉渣

铜炉渣来自某地区工业废渣地表堆存场,外观形貌为粒径10~15 mm的块体。由于当地选矿水平的限制,铜炉渣中含有的铜金属无法进一步选出。采用普通球磨机将铜炉渣粉磨至75 μm以下,进行X线荧光光谱实验(XRF)分析炉渣中成分,结果如表1所示。

炉渣化学成分组成是影响其活性的主要因素之一,目前仍习惯用各氧化物质量分数之比来衡量炉渣活性[14]。根据表1所示结果,炉渣碱性系数、质量系数、活性系数分别按照式(1)~(3)进行计算。

(1)

(1)

(2)

(2)

(3)

(3)

根据式(1)计算可得铜炉渣的碱性系数M0为0.16,小于1.0,因此,铜炉渣为酸性矿渣。根据我国国家标准GB/T 203—2008“用于水泥中粒化高炉矿渣”的规定,质量系数K不应小于1.2,K越大,矿渣质量越好。由式(2)和(3)计算,炉渣的质量系数K和活性系数Ma分别为0.36和0.13,由此可见,本实验选用的铜炉渣质量较差,活性较低。

1.1.2 激发剂

胶凝材料的水化产物主要为钙矾石和C-S-H凝胶,根据钙矾石和C-S-H凝胶的组成元素和炉渣的化学成分分析可知,水化产物的大量生成需要提高胶凝体系的Ca与Si的物质的量比。经过前期遴选,最终实验选用的化学激发剂为唐山银水窑口生产的高钙石灰[15]、NaOH和早强剂。炉渣活性激发剂为上述3种化学试剂按照一定配比混合而成的混合激发剂。

由表1可知:高钙石灰中CaO和MgO的总质量分数达到98.91%(>90.00%),因此,银水生产的高钙石灰达到优等品。CIHANGIR等[16-17]研究发现,NaOH作为碱激发剂激发粒状高炉矿渣制备的胶凝材料具有水化速度快、早期强度高、强度增加快等优点。早强剂具弱碱性,能够与无机酸或有机酸反应生成盐,提高胶凝材料的流动性和装填密度。NaOH与早强剂均为分析纯。

1.2 实验方法

由于炉渣活性较低,需要采用机械活化与化学活化的方式共同激发铜炉渣的活性。

利用高能球磨机将铜炉渣分别粉磨40,60,80,100和120 min,然后通过激光粒度分析仪及比表面积测定仪对铜炉渣粉末粒度和比表面积进行测定。通过比较不同粉磨时间下炉渣的比表面积,选定碱激发实验铜炉渣的粉磨时间。

将铜炉渣、相应配比下的激发剂和水按照0.4的水胶比进行混合,参考GB177-85“水泥胶砂实验方法”对料浆进行搅拌,然后将料浆注入长×宽×高为7.07 cm×7.07 cm×7.07 cm标准三联试模中,振捣刮平后放入养护箱中,48 h时脱模并继续养护,测定不同龄期试样的单轴抗压强度。为让测试结果更接近实际,养护箱中设定温度为(20±1) ℃、湿度为90%以上。

表1 部分原料化学成分分析(质量分数)

Table 1 Chemical composition of some materials %

2 实验结果

2.1 机械活化

研究表明,炉渣粉只有达到一定细度才能充分水化,细度大于60 μm的颗粒属于惰性粒子对强度无积极作用,起主导作用的是细度30 μm以下的粒子,细度小于10 μm的粒子含量高时对早期强度有利[18-19]。借鉴其他矿渣的粉磨实验[20],选取原状的铜炉渣在高能球磨机上粉磨不同的时间,然后采用激光粒度分析仪和比表面积测定仪对粉磨过后的炉渣粒度及比表面积进行对比分析。

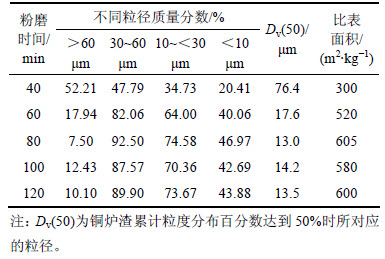

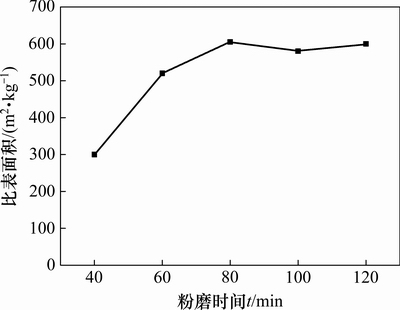

不同粉磨时间下铜炉渣的粒度及比表面积如表2所示,比表面积随着粉磨时间的变化如图1所示。

随着粉磨时间的延长,铜炉渣的比表面积不断增大,粉磨时间达到80 min时,比表面积达到最大,对炉渣活性起作用的非惰性粒子质量分数达到90%以上。粉磨时间超过80 min后,炉渣的比表面积随着粉磨时间的延长出现了先减小后增大的现象,原因是炉渣微粒在研磨过程中细颗粒表面电荷不平衡,导致细微颗粒之间相互聚集出现“团聚”现象[21],细颗粒聚集在一起形成的粒团在随后的粉磨过程中被再次打散,如此往复,炉渣粉末的比表面积不断波动,并达到粉磨极限。粉磨过程中物料在机械力的作用下,比表面积增大,与碱溶液的接触更充分,水化速度加快,有利于提高胶凝材料的早期强度。然而,微粉过于细小也造成了水化反应物过早地在炉渣颗粒表面形成致密的水化产物层,影响后期水化产物的形成,使后期强度增长受到影响,所以,炉渣微粉细度应适宜[16, 22]。

表2 不同粉磨时间下铜炉渣粒度及比表面积

Table 2 Particle size and specific surface area of copper slag at different ground time

图1 粉磨时间对炉渣比表面积的影响

Fig. 1 Effect of grinding time on specific surface area of slag

由于随着粉磨时间的增加,机械活化成本也在不断增加,综合考虑活化成本和炉渣活性激发对比表面积的要求,最终选择采用高能球磨机粉磨60 min的铜炉渣进行碱激发实验。

2.2 化学活化

2.2.1 铜炉渣净浆强度

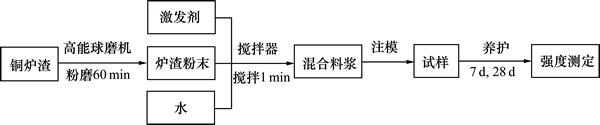

实验采用添加碱激发剂的化学方法实现对炉渣活性的进一步激发,在进行机械活化的基础上对炉渣进行碱激发实验,实验过程如图2所示。

图2 新型胶凝材料制备过程流程图

Fig. 2 Flow diagram of preparation process of new cementitious materials

按照不同激发剂配比制备铜炉渣净浆试样并测定其不同龄期强度,得到试样强度达到最优时的胶凝材料配比,如表3所示。

表3 新型胶凝材料最优配比测定结果

Table 3 Measurement result of new cementitious material under optimal ratio

由表3可知:在机械活化和碱性激发剂的共同作用下,铜炉渣活性得到激发,新型胶凝材料具有一定的强度。因此,用铜炉渣制备胶凝剂部分或者完全替代水泥用于井下采场充填是可行的。

2.2.2 充填料强度实验

按照表3制备铜炉渣充填胶凝剂并与铜尾砂混合,测定铜炉渣尾砂充填料强度,实验结果及配比如表4所示。

由表4可知:灰砂质量比达到1:1时,铜炉渣尾砂充填料的强度满足当地井下采场对充填体强度的要求。通过技术经济比较分析得知,在充填体强度满足要求的情况下,采用铜炉渣作为充填胶凝剂的充填成本与水泥相当,但是铜炉渣充填胶凝剂更具生态效益,符合当地政府的环境政策。因此,铜炉渣可以作为胶凝剂用于井下采场充填。

表4 铜炉渣尾砂充填料强度

Table4 Strength of copper slag tailings backfill material

3 分析与讨论

3.1 水化产物SEM分析

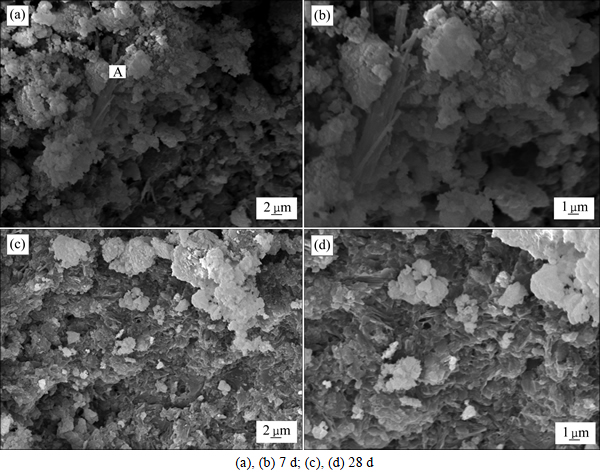

按照表3配比制备铜炉渣胶凝材料净浆试块,养护至相应龄期,将试块用锤子砸开,从中选取形状规则、大小合适的试样,放入无水乙醇中终止其水化过程,然后将其烘干后进行喷金处理,用SEM电镜观察试样微观组织结构,结果如图3所示。

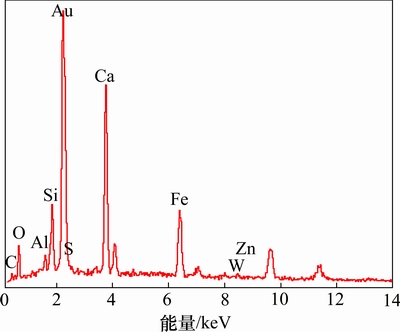

从图3(a)可以看出:试样在水化7 d时出现了无定型的C-S-H凝胶等水化产物,水化产物将炉渣中的部分惰性成分相互粘结在一起,使胶凝材料具有一定的强度。但是,C-S-H凝胶聚团较松散,未能形成良好的絮状结构且相互之间连接不紧密,炉渣颗粒之间存在较多孔隙。在A处出现了少量的针状水化产物,对针状物进行放大(图3(b)),可见针状物晶体直径较大且发育较好,与钙矾石极其相似。对针状物进行EDS分析,结果如图4所示。结合EDS分析结果推测,A处水化产物不是钙矾石,而是形状与其极为相似的碳硫硅钙石[23]。

图3 不同水化龄期铜炉渣胶凝材料的SEM照片

Fig. 3 SEM images of copper slag cementitious material at different hydration times

图4 铜炉渣胶凝材料水化7 d的EDS谱图

Fig. 4 EDS spectra of copper slag cementitious material after hydration for 7 d

从图3(c)可以看出:随着养护龄期增加,水化产物的生成量不断增加并填充在试样内部的孔隙中,使试样内部结构逐渐粘结成为整体。从水化产物的放大图(图3(d))可见,与水化7 d的分析结果相比,无定型的C-S-H凝胶在28 d时已经连成紧密一片,试样内部的孔隙逐渐被水化产物填充并缩小至孔状。但由于铜炉渣中活性成分较少,新生成的水化产物很少,导致胶凝材料后期强度增加缓慢。

3.2 水化产物XRD分析

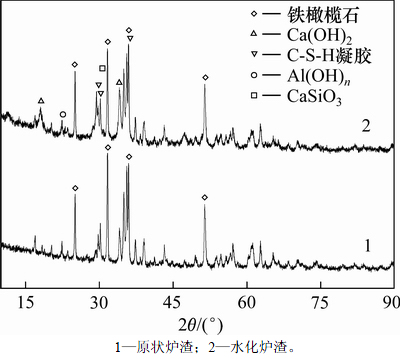

对铜炉渣净浆试样的28 d水化产物继续进行X线衍射(XRD)分析,并与原状磨细铜炉渣XRD分析结果进行对比,结果如图5所示。

由图5可知:原状炉渣中含有一定量的玻璃体,结晶相物质晶粒较大。因此,实验选用的铜炉渣是玻璃体与结晶相相间分布,硅(铝)氧四面体或以玻璃网状结构相连接或以晶体格子状质点结构相连接,或以晶界过度状结构相连接的物质[20]。随着炉渣中活性物质不断水化,水化产物不断增加,在28 d时炉渣胶凝体系中出现了C-S-H凝胶、Ca(OH)2和Al(OH)n等水化产物。另外,在碱性激发剂的作用下,炉渣中的铁橄榄石等结晶相的衍射强度出现下降,说明在机械粉磨和碱性激发剂的共同作用下,铜炉渣中部分结晶相溶解并参与了水化反应。

图5 试样28d水化产物XRD图谱

Fig. 5 XRD patterns of sample hydration products at 28 d

综上所述,铜炉渣胶凝材料的水化产物以无定型的C-S-H凝胶为主,其次为Ca(OH)2和Al(OH)n等,无钙矾石生成。在水化初期水化产物较少,相互之间连接不够紧密。随着固化时间不断增加,C-S-H凝胶等水化产物不断生长并逐渐填充胶凝材料的内部孔隙,使胶结材料的强度增加。

3.3 水化机理

3.3.1 高能球磨

铜矿石经过冶炼后得到的炉渣主要包括结晶相和玻璃体,对炉渣活性起决定性作用的为玻璃体,玻璃体含量越高炉渣活性越强。由图5可知:铜炉渣具有玻璃体和结晶相相间分布的内部结构。本实验铜炉渣机械活化的本质为:在高强度的机械力下使玻璃体结构解聚、结晶相的Si和Fe分离,提高炉渣的潜在活性,为碱激发下铜炉渣活性的完全释放奠定基础。

一方面,在高能球磨的过程中,强烈的机械冲击、剪切、磨削作用和颗粒之间的相互挤压、碰撞作用,可以促使炉渣玻璃体发生部分解聚,颗粒内部出现微裂缝,同时会使结构内部四面体和连续四面体的形成体发生扭曲,导致构成链的连续结构和多面体之间的角度发生变化,加剧网络结构的不规则化程度。在碱激发剂的作用下,不规则的网格结构更容易断裂,使炉渣玻璃体产生解离。另一方面,炉渣粉细度的增加会提高颗粒的比表面积,增加其与高钙石灰等激发剂反应的接触面积,加快化学反应速度,促进炉渣的解聚溶解。

3.3.2 碱激发

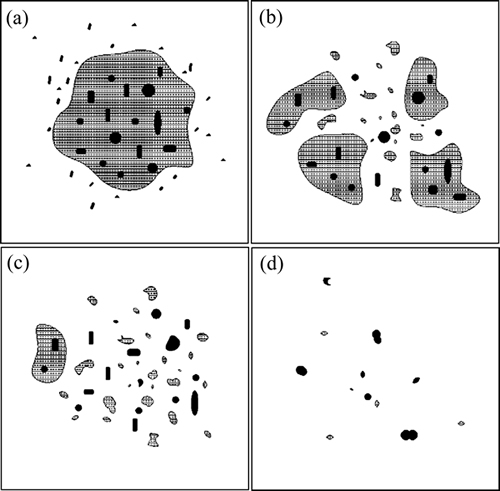

根据ZACHARIASEN[24]提出的网络理论,矿渣玻璃体的成分元素可以分为3类:网络形成体、网络改变体和中间体。矿渣中Si是典型的网络形成体,主要作用为与O形成Si—O键,进而聚合成SiO44-四面体、SiO7[6-]团、链以及其他聚合产物的硅酸络阴离子,最后形成玻璃体的三维空间网络。Ca是矿渣玻璃体中典型的网络改变体,其一部分平衡了Al取代Si而形成的负电荷,另一部分作为激发剂可以解聚多面体的形成体,使连结链断裂,加速矿渣粉的溶解。中间体是指既能成为网络形成体又能成为网络改变体的元素,其中Al和Mg是典型的中间体。因此,结合矿渣玻璃体的网络结构和玻璃体结构模型(图6)探讨铜炉渣在碱性环境下的水化机理。

图6 矿渣玻璃体分相结构模型

Fig. 6 Phase structure model of slag vitreum

由图6可知:炉渣玻璃体结构表面存在着防止环境离子与玻璃体内离子互换的硅氧结构层,在机械活化和OH-的强烈作用下玻璃体表面的“保护膜”开始解离(图7(a)),为富钙相和富硅相的解聚提供了必要条件。炉渣富钙相是一种逆性玻璃,主要化学成分为CaO和MgO,其形成网络中的Ca—O和Mg—O键比Si—O和Al—O键弱得多,所以在OH-的强作用下富钙相会先于富硅相溶解(图7(b))。在碱性环境中,OH-使Ca—O和Mg—O键断裂,Ca2+和Mg2+溶出并与OH-结合生成水化产物,反应过程为

(=Si—O—Ca—O—Si—)+NaOH→2(—Si—O—Na)+Ca(OH)2 (4)

由于富钙相是连续相,富硅相呈类似球状分布于富钙相中,故在炉渣玻璃体中,富钙相相当于胶结物维持着整个矿渣玻璃体结构的稳定。当富钙相在碱性介质中与OH-迅速反应并溶解后,炉渣玻璃体解体,富硅相大量暴露于碱性介质中(图7(c)),其Si—O—Si键能与NaOH发生如下反应:

图7 铜炉渣玻璃体溶解示意图

Fig. 7 Schematic diagram of copper slag vitreum dissolving

(=Si—O—Si=)+H·OH→2(=Si—OH) (5)

(=Si—OH)+NaOH→(=Si—ONa)+H·OH (6)

碱性激发剂对Al—O—Al键也具有同样的作用,Si—OH、Al—OH键可以进一步形成Si(OH)4和Al(OH)4-等单体。最后,CaO和富钙相在碱性环境中生成的Ca(OH)2会与Si(OH)4和Al(OH)4-反应形成C-S-H凝胶、C-A-H等水化产物。从化学键和分散结构的特点可以判断,在碱性溶液中,富钙相的反应较为剧烈和迅速,而富硅相的反应则较为缓慢和持久(图7(d)),富硅相的存在保证了铜炉渣胶凝材料后期强度持续增大。

4 结论

1) 高能球磨80 min时,铜炉渣比表面积达到最大为605 m2/kg,粉磨至80 min之后,铜炉渣颗粒之间出现了“团聚”现象。综合考虑粉磨成本和炉渣活性激发对比表面积的要求,选用粉磨60 min,表面积为520 m2/kg的铜炉渣进行碱激发实验。

2) 高钙石灰、NaOH、早强剂与炉渣的质量比分别为28%,2%,0.1%时,铜炉渣胶凝材料的强度达到最优。采用灰砂质量比为1:1,质量分数为75%的充填体料浆进行室内实验验证,结果表明充填料的28 d强度达到1.0 MPa,铜炉渣胶凝材料可以用于井下充填。

3) 铜炉渣玻璃体中的SiO2和Al2O3等氧化物分别与富钙相、高钙石灰中的CaO发生水化反应后生成C-S-H凝胶和C-A-H等水化物。其中,C-S-H凝胶为主导水化产物并使铜炉渣胶凝材料具有良好的结构强度,水化产物中无钙矾石生成。

4) 目前硅氧网络“保护膜”的观点和对不同组分矿渣分相结构模型都缺乏进一步的实验验证,且尚不能从熔体结构变化的角度来分析这些结构的形成过程,所以,铜炉渣这类活性较低矿渣的水化机理还需要进一步研究。

参考文献:

[1] 李克庆, 冯琳, 高术杰. 镍渣基矿井充填用胶凝材料的制备[J]. 北京科技大学学报, 2015, 37(1): 1-6.

LI Keqing, FENG Lin, GAO Shujie. Preparation of cementitious materials for backfilling by using nickel slag[J]. Journal of University Science and Technology Beijing, 2015, 37(1): 1-6.

[2] 于霖. 碱激发矿渣胶凝材料的制备及其性能研究[D]. 郑州: 郑州大学材料科学与工程学院, 2010: 12-25.

YU Lin. A study on the preparation and properties of alkali-aetivated slag cementitious material[D]. Zhengzhou: Zhengzhou University. School of Materials Science and Engineering, 2010: 12-25.

[3] AL-JABRI K, TAHA R, AL-HARTHY A, et al. Use of cement by-pass dust in flowable fill mixtures[J]. Cement Concrete & Aggregates, 2002, 24(2): 53-57.

[4] ZHANG Yaojun, YANG Mengyang, KANG Le, et al. Research progresses of new type alkali-activated cementitious material catalyst[J]. Journal of Inorganic Materials, 2016, 31(3): 225-233.

[5] 李茂辉, 杨志强, 王有团, 等. 粉煤灰复合胶凝材料充填体强度与水化机理研究[J]. 中国矿业大学学报, 2015, 44(4): 650-655.

LI Maohui, YANG Zhiqiang, WANG Youtuan, et al. Experiment study of compressive strength and mechanical property of filling body for fly ash composite cementitious materials[J]. Journal of China University of Mining & Technology, 2015, 44(4): 650-655.

[6] 王强, 黎梦圆, 石梦晓. 水泥—钢渣—矿渣复合胶凝材料的水化特性[J]. 硅酸盐学报, 2014, 42(5): 629-634.

WANG Qiang, LI Mengyuan, SHI Mengxiao. Hydration properties of cement-steel slag-ground granulated blast furnace slag complex binder[J]. Journal of the Chinese Ceramic Society, 2014, 42(5): 629-634.

[7] 王有团, 杨志强, 李茂辉, 等. 全尾砂-棒磨砂新型胶凝充填材料的制备[J]. 材料研究学报, 2015, 29(4): 291-298.

WANG Youtuan, YANG Zhiqiang, LI Maohui, et al. Preparation of new backfill cementitious materials with unclassified tailings-rod milling sands[J]. Chinese Journal of Materials Research, 2015, 29(4): 291-298.

[8] 闫国斌, 许立顺, 赵建文. 利用脱硫灰烧结渣制备新型充填胶凝材料的试验[J]. 矿业研究与开发, 2015, 35(12): 22-26.

YAN Guobin, XU Lishun, ZHAO Jianwen. Test study on a new filling cementing material for iron tailings using sintering desulfurization ash[J]. Mining Research and Development, 2015, 35(12): 22-26.

[9] 孙小巍, 吴陶俊. 碱激发矿渣胶凝材料的实验研究[J]. 硅酸盐通报, 2014, 33(11): 3036-3040.

SUN Xiaowei, WU Taojun. Experimental research of alkali-activated slag cementitious material[J]. Bulletin of the Chinese Ceramic Society, 2014, 33(11): 3036-3040.

[10] 高术杰, 倪文, 祝丽萍, 等. 脱硫石膏对赤泥-矿渣胶结充填料强度性能的影响[J]. 中南大学学报(自然科学版), 2013, 44(6): 2259-2266.

GAO Shujie, NI Wen, ZHU Liping, et al. Effect of gypsum on strength performance of cemented backfilling materials of red mud-slag system[J]. Journal of Central South University (Science and Technology), 2013, 44(6): 2259-2266.

[11] 诸培南. 粒化高炉矿渣与活性关系的探讨[J]. 硅酸盐学报, 1983, 11(3): 290-296.

ZHU Peinan. Preliminary study on the relationship between structure and activity of blast furnace slag[J]. Journal of the Chinese Ceramic Society, 1983, 11(3): 290-296.

[12] 孙家瑛, 诸培南, 吴初航. 矿渣在碱性溶液激发下的水化机理探讨[J]. 硅酸盐通报, 1988(6): 16-25.

SUN Jiaying, ZHU Peinan, WU Chuhang. Study on the hydration mechanism of slag in excitation alkaline solution[J]. Bulletin of the Chinese Ceramic Society, 1988(6): 16-25.

[13] 徐彬, 蒲心诚. 矿渣玻璃体分相结构与矿渣潜在水硬活性本质的关系探讨[J]. 硅酸盐学报, 1997, 25(6): 105-109.

XU Bin, PU Xincheng. Study on the relationship between the phase separation of slag glass and the latent hydraulic activity of bfs[J]. Journal of the Chinese Ceramic Society, 1997, 25(6): 105-109.

[14] 李兵, 杨仕教, 王洪武, 等. 某冶炼厂炼铅炉渣制备胶凝材料的实验研究[J]. 硅酸盐通报, 2014, 33(3): 583-588.

LI Bing, YANG Shijiao, WANG Hongwu, et al. Experimental research on producing cementing material using Smelter’s lead refinery slag[J]. Bulletin of the Chinese Ceramic Society, 2014, 33(3): 583-588.

[15] 董璐, 高谦, 南世卿, 等. 超细全尾砂新型胶结充填料水化机理与性能[J]. 中南大学学报(自然科学版), 2013, 44(4): 1571-1576.

DONG Lu, GAO Qian, NAN Shiqing, et al. Performance and hydration mechanism of new super fine cemented whole-tailings backfilling materials[J]. Journal of Central South University (Science and Technology), 2013, 44(4): 1571-1576.

[16] CIHANGIR F, ERCIKDI B, KESIMAL A, et al. Paste backfill of high-sulphide mill tailings using alkali-activated blast furnace slag: effect of activator nature, concentration and slag properties[J]. Minerals Engineering, 2015, 83: 117-127.

[17] 王峰, 张耀君, 宋强, 等. NaOH碱激发矿渣地质聚合物的研究[J]. 非金属矿, 2008, 31(3): 9-11.

WANG Feng, ZHAGN Yaojun, SONG Qiang, et al. Study on synthesis of geopolymer by naoh alkali-activated slag powder[J]. Non-Metallic Mines, 2008, 31(3): 9-11.

[18] 陈益民, 张洪滔, 郭随华, 等. 磨细钢渣粉作水泥高活性混合材料的研究[J]. 水泥, 2001(5): 1-4.

CHEN Yimin, ZHANG Hongtao, GUO Suihua, et al. Study on the finely ground steel slag as high reactivity blending materials of cement[J]. Cement, 2001(5): 1-4.

[19] 何娟, 程从密, 李烈军. 细度对电炉钢渣活性指数的影响[J]. 混凝土, 2011(7): 77-78.

HE Juan, CHENG Congmi, LI Liejun. Influence of fineness on electric arc furnace slag activity index[J]. Concrete, 2011(7): 77-78.

[20] 杨志强, 高谦, 王永前, 等. 利用金川水淬镍渣尾砂开发新型充填胶凝剂试验研究[J]. 岩土工程学报, 2014, 36(8): 1498-1506.

YANG Zhiqiang, GAO Qian, WANG Yongqian, et al. Experimental study on new filling cementing material using water-hardening nickel slag tailings of Jinchuan Mine[J]. Chinese Journal of Geotechnical Engineering, 2014, 36(8): 1498-1506.

[21] ZHAO Ruichao, HAN Yuexin, YANG Guang, et al. Mechanism of adsorption and aggregation of fine siderite, quartz and hematite[J]. Journal of Northeastern University, 2015, 36(4): 596-600.

[22] KRIVENKO P, PETROPAVLOVSKY O, PETRANEK V, et al. High strength alkali activated slag cements with controlled setting times and early strength gain[J]. Advanced Materials Research, 2015, 1100: 44-49.

[23] 内维尔A M. 混凝土性能[M]. 刘数华, 冷发光, 李新宇, 等译. 北京: 中国建筑工业出版社, 2011: 369-372.

NEVILLE A M. Properties of concrete[M]. LIU Shuhua, LENG Faguang, LI Xinyu, et al trans. Beijing: China Architecture & Building Press, 2011: 369-372.

[24] ZACHARIASEN W H. The atomic arrangement in glass[J]. Journal of the American Chemical Society, 1932, 44(10): 3841-3851.

(编辑 赵俊)

收稿日期:2016-09-06;修回日期:2016-11-27

基金项目(Foundation item):国家自然科学基金资助项目(51374034,51304011,51374035);国家“十二五”科技支撑计划项目(2012BAB08B02) (Projects(51374034, 51304011, 51374035) supported by the National Natural Science Foundation of China; Project(2012BAB08B02) supported by the National 12th “Five-Year” Plan for Science & Technology of China)

通信作者:吴爱祥,博士,教授,从事膏体充填采矿、矿山岩石力学、溶浸采矿等方面的研究;E-mail: wuaixiang@126.com