文章编号: 1004-0609(2006)02-0197-08

稀土对AZ31B变形镁合金组织和力学性能的影响

郑伟超1, 2, 李双寿2, 汤 彬3, 曾大本1

(1. 清华大学 机械工程系, 北京 100084; 2. 清华大学 基础工业训练中心, 北京 100084;

3. 清华大学 工程力学系, 北京 100084)

摘 要: 研究了稀土(0.1%~1.2%)对AZ31B变形镁合金组织和力学性能的影响。 结果表明: 在AZ31B变形镁合金中添加稀土后, 晶粒显著粗化, 合金的室温力学性能下降。 晶粒粗化一方面是由于RE与Al结合生成了Al11RE3相, 消耗了一部分铝量, 削弱了铝对α-Mg晶粒的细化作用; 另一方面RE与ε-AlMn相反应生成Al-RE-Mn相, 使得合金熔体中的异质形核核心减少; 稀土引起AZ31B变形镁合金晶粒粗化在热分析曲线上表现为初晶形核最低温度从628.8下降到626.3℃, 初晶再辉温差从0.8℃上升到3.2℃。

关键词: AZ31B变形镁合金; 稀土; 晶粒尺寸; 热分析; 力学性能

中图分类号: TG146.2 文献标识码: A

Effects of rare earth on microstructure and

mechanical properties of AZ31B wrought magnesium alloy

ZHENG Wei-chao1, 2, LI Shuang-shou2, TANG Bin3, ZENG Da-ben1

(1. Department of Mechanical Engineering, Tsinghua University, Beijing 100084, China;

2. Fundamental Industry Training Center, Tsinghua University, Beijing 100084, China;

3. Department of Engineering Mechanics, Tsinghua University, Beijing 100084, China )

Abstract: The effects of rare earth on the microstructure and mechanical properties of AZ31B wrought magnesium alloy were investigated. The results show that when adding rare earth into AZ31B wrought magnesium alloy, the grains are coarsened remarkably, as a result the mechanical properties decline. The causes for the grain coarsening are as follows: RE reacts with Al to form Al11RE3 phases, consumes a part of Al atoms, and weakens the grain refinement effect of Al on the α-Mg grains. RE reacts with ε-AlMn phases to form Al-RE-Mn compounds, thus reducing the amounts of heterogeneous nuclei in the melt. As a result of the grain coarsening of AZ31B wrought magnesium alloy by rare earth, the lowest temperature for primary phase nucleation decreases from 628.8℃ to 626.3℃ and the temperature difference of recalescence increases from 0.8℃ to 3.2℃.

Key words: AZ31B wrought magnesium alloy; rare earth; grain size; thermal analysis; mechanical property

近十几年来, 汽车减重节能、 环保的要求推动了镁合金在汽车领域的大规模开发应用[1-4]。 目前, 镁合金零部件主要是通过铸造工艺生产[5]。 与传统的铸造工艺相比, 镁合金热变形后的组织得到细化, 铸造缺陷消除, 产品的综合力学性能大大提高, 比铸造镁合金具有更高的强度和更好的延展性[5, 6]。 因此, 变形镁合金有望成为本世纪新型的高性能结构材料。

AZ31B镁合金是目前应用最广泛的变形镁合金, 具有良好的延展性和中等高强度, 而且价格便宜。 为了实现AZ31B变形镁合金在汽车、 3C产品等领域的大规模、 高成品率生产和应用, 中长期的目标是通过材料改性和变形加工技术的改进等手段使AZ31B变形镁合金的抗拉强度≥300MPa, 延伸率δ>20%[7]。 近年来, 一些研究者在AZ31B变形镁合金材料改性上开展了不少工作, 通过微量元素合金化和复合合金化的方法来提高AZ31B变形镁合金的性能。 稀土在铸造镁合金中的应用已有几十年, 主要用来提高铸造镁合金的高温抗蠕变性能, 如开发的AE系列镁合金(AE21, AE41和AE42合金)[8, 9]。 此外, 稀土还可以净化镁合金熔体、 提高镁合金的高温强度、 流动性、 耐磨性和阻燃性[10-14]。 目前, 稀土在变形镁合金中的作用规律也日益成为研究的焦点, 已有的研究结果表明, 稀土(0.3%~1.0%)可阻碍AZ31B变形镁合金挤压、 轧制时再结晶晶粒的长大, 细化其热变形后的晶粒, 从而提高其力学性能[15, 16], 但稀土对AZ31B变形镁合金铸态晶粒大小与力学性能的影响的报道还较少, 因此本文作者研究了稀土(0.1%~1.2%)对AZ31B变形镁合金热变形前组织和力学性能的影响, 以增进对稀土在变形镁合金中作用规律的认识, 为制定后续的热变形工艺参数提供一定的理论和实验依据。

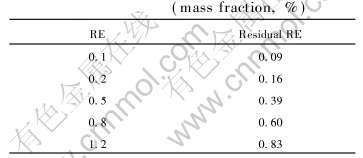

1 实验

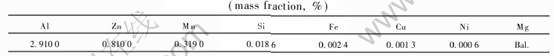

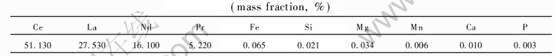

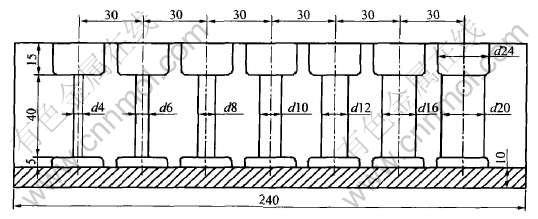

实验采用AZ31B镁合金锭, 其化学成分列于表1。 稀土以富铈混合稀土直接加入, 其化学成分列于表2。 镁合金熔炼实验在电阻炉中进行, 一次装炉量12kg, 熔炼时采用WM5D熔剂保护, 熔炼温度设定为750℃。 当镁合金熔化达到750℃后, 依次添加不同含量的富铈混合稀土(0.1%~1.2%), 待其熔解后搅拌2min, 静置20min, 最后浇注d35mm×52mm砂型、 d30mm×85mm金属型和热裂试样, 浇注前砂型为室温、 金属型和热裂模具温度为300℃, 热裂模具尺寸如图1所示, 浇注砂型时, 采用温度采集系统自动记录凝固曲线, 热电偶采用镍铬—镍硅热电偶。 采用Vista-MPX电感耦合等离子体发射光谱仪分析AZ31B镁合金添加稀土后稀土的残留量, 结果见表3。 分别[CM(22]在距d12mm热裂试样底部20mm和砂型试样底部25mm处截取金相样品, 然后分别进行固溶处理(415℃, 10h)和(415℃, 16h), 最后抛光、 腐蚀, 腐蚀后的热裂试样在Neophot-32金相显微镜上用偏振光和微分干涉相衬法取像, 而砂型试样由于晶粒粗大, 需在低倍下用数码相机取像。 采用ASTM E112-95上的截距法测量热裂和砂型试样的晶粒大小。 采用日本理学D/max-RB型X射线衍射分析仪分析AZ31B镁合金添加富铈混合稀土前后的相组成。 采用CSM-950扫描电镜观察金相样品中Al-RE相的分布情况。 在d30mm×85mm金属型试样上截取矩形拉伸试样(20mm×10mm×1mm), 然后在Gleeble-1500D上进行室温拉伸实验, 拉伸速率为1mm/min。

表1 AZ31B镁合金的化学成分

Table 1 Chemical composition of AZ31B magnesium alloy

表2 富铈混合稀土的化学成分

Table 2 Chemical composition of Ce-rich mischmetal

图1 热裂模具示意图

Fig.1 Schematic diagram of hot tearing mold(Unit: mm)

表3 AZ31B镁合金添加稀土后稀土的残留量

Table 3 Amount of residual rare earth after addition of rare earth into AZ31B magnesium alloy

2 结果与分析

2.1 稀土对AZ31B镁合金晶粒大小的影响

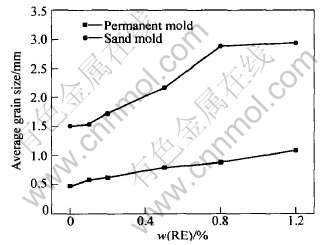

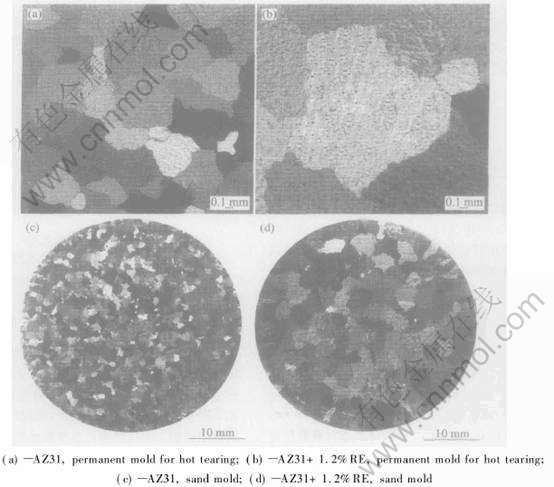

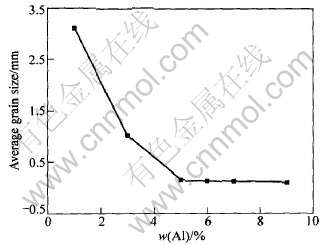

图2所示为不同稀土添加量对AZ31B镁合金平均晶粒大小的影响。 图3所示为AZ31B镁合金添加稀土前后的晶粒度照片。 可以看出, 随着稀土添加量(0.1%~1.2%)的增加, AZ31B镁合金热裂金属型试样的平均晶粒大小从0.476mm长大至1.073mm, 砂型试样的平均晶粒大小从1.500mm长大至2.934mm, 均长大了将近1倍, 这与张世军等[17]的铈细化AZ31镁合金铸态晶粒的实验结果正好相反。 造成实验结果相反的原因可能是由于AZ31镁合金的化学成分不同, 本实验采用的AZ31镁合金含有Mn元素, 而张世军等采用的AZ31镁合金不含有Mn元素, 镁合金熔体凝固时Mn与RE的交互作用导致了合金晶粒的粗化; 另一方面镁合金金相样品的制备和腐蚀工艺的不同, 镁合金金相样品制备和腐蚀工艺选择不当, 晶粒度容易造成假象。

图2 稀土添加量对AZ31B镁合金平均晶粒大小的影响

Fig.2 Effects of RE additions on average grain size of AZ31B magnesium alloy

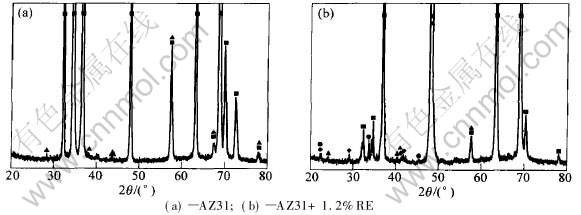

稀土引起AZ31B镁合金晶粒粗化的原因是由于: 首先, 当往AZ31B镁合金中添加稀土时, 由于RE与Al的电负性差值(0.4)大于其与Mg的电负性差值(0.1)[18], RE优先与Al结合生成Al-RE相。 图4所示为AZ31B镁合金添加稀土前后的X射线衍射谱。 可以看出, 添加稀土前, AZ31B镁合金主要由α-Mg固溶体和Al11Mn4相组成; 添加稀土后, RE与Al结合生成Al11RE3相, 但是由于Al11RE3相和Al4RE相的衍射峰相当接近, 因此生成的Al-RE相也可能是Al4RE相, 这还需通过TEM或STEM进一步确认, 如果Al-RE相属于Immm空间群, 则其分子式应为Al11RE [19]3。

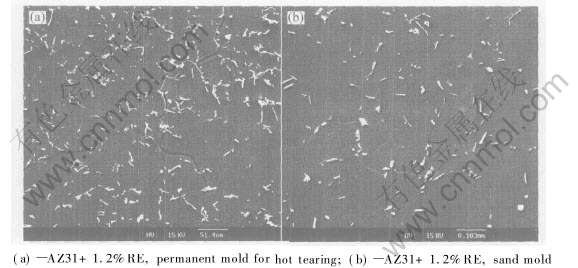

图5所示为AZ31B+1.2%RE镁合金中Al11RE3相的分布。 可以看出, Al11RE3相大部分分布在晶粒内部, 只有一小部分分布在晶界, 因此Al11RE3相对晶粒长大的抑制作用较弱; 而Al11RE3相属于体心四方结构[20], 与α-Mg固溶体的晶体结构不同, 因此在晶粒内部的Al11RE3相亦不能起到异质形核核心的作用。 随着稀土添加量的增加, 由于生成的Al11RE3相越来越多, 消耗的铝量也越来越多。 在低铝含量的Mg-Al镁合金中, 铝含量对α-Mg晶粒大小的影响十分显著。 图6所示为不同铝含量对Mg-Al二元合金平均晶粒大小的影响。 可以看出, 当铝含量低于5%时, 随着铝含量的增加, 晶粒显著细化; 当铝含量超过5%时, 晶粒大小缓慢下降, 这与Lee等[21]的实验结果相一致。 铝细化α-Mg晶粒的原因可归为: 在Mg-Al二元合金凝固的过程中, 由于铝溶质的再分配, 在

图3 AZ31B镁合金添加稀土前后的晶粒度照片

Fig.3 Photographs showing grain size of AZ31B magnesium alloy before and after RE additions

图4 AZ31B镁合金添加稀土前后的X射线衍射谱

Fig.4 XRD patterns of AZ31B magnesium alloy before and after RE additions

图5 AZ31B+1.2%RE镁合金中Al11RE3相的分布

Fig.5 Distributions of Al11RE3 phase in AZ31B magnesium alloy containing 1.2%RE

图6 铝含量对Mg-Al二元合金平均晶粒尺寸的影响

Fig.6 Effect of Al content on average grain size of Mg-Al binary alloys

凝固界面前沿形成了铝溶质富集层, 使得凝固界面前沿熔体的凝固温度下降, 而且α-Mg树枝晶析出也会释放一部分潜热, 造成凝固界面前沿熔体温度上升, 使得过冷降低, 抑制了α-Mg晶粒的生长。 当往低铝含量的AZ31B镁合金中添加稀土时, 由于RE与Al结合消耗了一部分铝量, 削弱了铝对α-Mg晶粒的细化作用, 从而导致了合金晶粒的粗化。

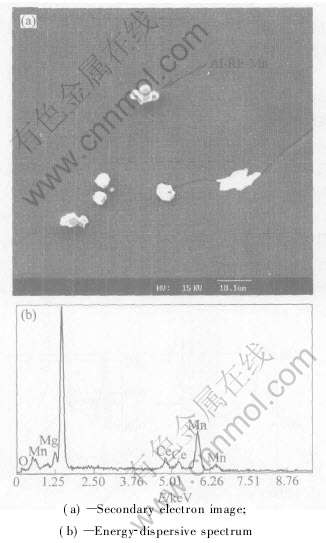

往AZ31B镁合金中添加稀土时, RE除与Al反应生成Al11RE3相外, 还与Al-Mn相反应生成Al-RE-Mn相。 图7所示为AZ31B镁合金添加稀土后生成的Al-RE-Mn相的二次电子形貌像及其能量谱, 箭头所指位置为Al-RE-Mn三元相。 根据文献[20, 22], 该相可能为Al10RE2Mn7相。 Cao等[23]在研究Mn对AZ31镁合金晶粒大小的影响时发现Mn对AZ31镁合金具有明显的晶粒细化效果, 而且随着Mn含量的增加, 合金中ε-AlMn相(可能是Al9Mn11相)所占的比例增加, ε-AlMn相与α-Mg的晶体结构相同, 晶格常数接近, 因此Cao等认为[CM(22]ε-AlMn质点在合金熔体中的含量虽然很少, 但可

图7 AZ31B镁合金添加稀土后生成的Al-RE-Mn相

Fig.7 Al-RE-Mn phase in AZ31B magnesium alloy after addition of rare earth

作为AZ系列镁合金有效的异质形核核心。 当往AZ31B镁合金中添加稀土时, 由于RE与ε-AlMn相反应生成Al-RE-Mn相, 使得合金熔体中的异质形核核心减少, 从而加剧了合金晶粒的粗化, 这也是稀土引起AZ31B镁合金晶粒粗化的主要原因。 若AZ31镁合金中不含有Mn元素, 则不存在RE减少ε-AlMn异质形核质点的问题, 这可能是造成本实验结果与张世军等[17]Ce细化AZ31镁合金铸态晶粒实验结果相反的原因之一。

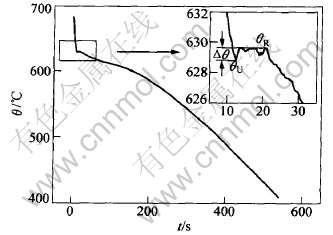

2.2 稀土对AZ31B镁合金凝固过程的影响

图8所示为AZ31B镁合金凝固时的热分析曲线。 由于AZ31B镁合金中的铝含量较低, 非平衡凝固时共晶反应释放的热量不足以产生共晶平台, 因此热分析曲线上只有α-Mg初晶析出阶段。 为考察稀土对AZ31B镁合金凝固过程的影响, 将α-Mg初晶析出阶段局部放大, 研究稀土对AZ31B镁合金初晶形核最低温度θU、 初晶再辉温度θR和初晶再辉温差Δθ(Δθ=θR-θU)的影响。

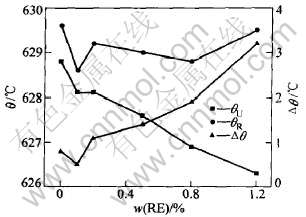

图9所示为稀土对AZ31B镁合金凝固过程的影响。 可以看出, 随着稀土添加量的增加, 初晶形核最低温度从628.8降到626.3℃, 初晶再辉温差从0.8升到3.2℃。 往AZ31B镁合金中添加稀土后, 由于合金熔体中的异质形核核心减少, 形核变得困难, 使得α-Mg初晶析出所需的过冷度增大, 从而降低了初晶形核最低温度 [24]。 不管α-Mg晶核是以连续长大方式还是以侧面长大方式生长, 过冷度越大, α-Mg晶核的长大速度越快, 单位时间内释放的结晶潜热越多, 从而使得初晶再辉温差越大[25]。

图8 AZ31B镁合金凝固时的热分析曲线

Fig.8 Thermal analysis curve of AZ31B magnesium alloy

图9 稀土对AZ31B镁合金凝固过程的影响

Fig.9 Effects of RE on solidification process of AZ31B magnesium alloy

2.3 稀土对AZ31B镁合金力学性能的影响

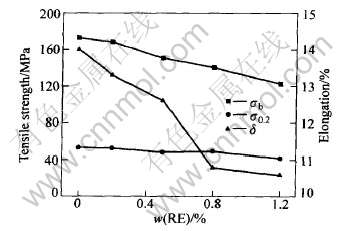

图10所示为稀土对AZ31B镁合金室温力学性能的影响。 随着稀土添加量的增加, AZ31B镁合金的抗拉强度从172.7降到122.7MPa, 屈服强度从53.2降到41.8MPa, 延伸率从14%降到10.6%。 AZ31B镁合金添加稀土后室温力学性能下降主要与晶粒粗化有关。 根据Hall-Petch公式[26]:

σy=σ0+kd-1/2

式中 σy为多晶体的屈服强度; σ0为相当于单晶体的屈服强度; k为常数; d为晶粒尺寸。

上式反映了材料晶粒大小对屈服强度影响的一般规律。 Nussbaum等[27]研究发现对于六方结构的镁合金来说, 晶粒大小对强度产生的影响远比立方结构的材料大得多。 因此, 当往AZ31B镁合金添加稀土时, 由于晶粒显著粗化, 导致其室温力学性能下降。

图10 稀土对AZ31B镁合金室温力学性能的影响

Fig.10 Effects of RE on mechanical properties of AZ31B magnesium alloy

综上所述, AZ31B变形镁合金添加稀土后, 铸态晶粒显著粗化, 这将对后续的挤压、 轧制过程产生不利影响, 如何复合添加其他合金元素来消除稀土的粗化作用、 发挥稀土在AZ31B变形镁合金热变形后的有利作用还有待进一步深入的研究。

3 结论

1) 往AZ31B镁合金中添加0.1%~1.2%RE后, 晶粒显著粗化, 热裂金属型试样的平均晶粒大小从0.476长大至1.073mm, 砂型试样的平均晶粒大小从1.500长大至2.934mm, 均长大了将近1倍。

2) 稀土引起AZ31B镁合金晶粒粗化的原因: 一方面是由于RE与Al结合生成Al11RE3相, 消耗了一部分铝量, 削弱了铝对α-Mg晶粒的细化作用; 另一方面是由于RE与ε-AlMn相反应生成Al-RE-Mn相, 使得合金熔体中的异质形核核心减少, 加剧了合金晶粒的粗化。

3) 随着稀土添加量的增加, AZ31B镁合金的初晶形核最低温度从628.8降到626.3℃, 初晶再辉温差从0.8升到3.2℃。

4) 在AZ31B镁合金中添加稀土后, 合金的室温力学性能下降, 抗拉强度从172.7降到122.7MPa, 屈服强度从53.2降到41.8MPa, 延伸率从14%降到10.6%, 这主要与添加稀土后晶粒粗化有关。

REFERENCES

[1]Mordike B L, Ebert T. Magnesium properties-applications-potential[J]. Mater Sci Eng A, 2001, A302: 37-45.

[2]Friedrich H, Schumann S. Research for a new age of magnesium in the automotive industry[J]. Journal of Materials Processing Technology, 2001, 117: 276-281.

[3]Schumann S, Friedrich H. Current and future use of magnesium in the automobile industry[J]. Materials Science Forum, 2003, 419-422: 51-56.

[4]Kaneko T, Suzuki M. Automotive applications of magnesium alloys[J]. Materials Science Forum, 2003, 419-422: 67-72.

[5]Aghion E, Bronfin B. Magnesium alloys development towards the 21st century[J]. Materials Science Forum, 2000, 350-351: 19-28.

[6]余琨, 黎文献, 王日初, 等. 变形镁合金的研究、 开发及应用[J]. 中国有色金属学报, 2003, 13 (2): 277-288.

YU Kun, LI Wen-xian, WANG Ri-chu, et al. Research, development and application of wrought magnesium alloys[J]. The Chinese Journal of Nonferrous Metals, 2003, 13 (2): 277-288.

[7]李忠盛, 潘复生, 张静. AZ31镁合金的研究现状和发展前景[J]. 金属成形工艺, 2004, 22 (1): 54-57.

LI Zhong-sheng, PAN Fu-sheng, ZHANG Jing. Present research status and development prospect of AZ31 magnesium alloy[J]. Metal Forming Technology, 2004, 22 (1): 54-57.

[8]Luo A A. Recent magnesium alloy development for automotive powertrain applications[J]. Materials Science Forum, 2003, 419-422: 57-66.

[9]Moreno I P, Nandy T K, Jones J W, et al. Microstructural stability and creep of rare-earth containing magnesium alloys[J]. Scripta Materialia, 2003, 48: 1029-1034.

[10]郭旭涛, 李培杰, 曾大本, 等. 混合稀土去除再生镁合金中的夹杂[J]. 中国有色金属学报, 2004, 14(8): 1295-1300.

GUO Xu-tao, LI Pei-jie, ZENG Da-ben, et al. Inclusions decrease in recycling magnesium alloy with rare earths[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(8): 1295-1300.

[11]Lu Y Z, Wang Q D, Zeng X Q, et al. Effects of rare earths on the microstructure, properties and fracture behavior of Mg-Al alloys[J]. Mater Sci Eng A, 2000, A278: 66-76.

[12]Wang Q D, Lu Y Z, Zeng X Q, et al. Study on the fluidity of AZ91+xRE magnesium alloy[J]. Mater Sci Eng A, 1999, A271: 109-115.

[13]Qi Q J, Liu Y B, Yang X H, et al. Friction and wear characteristics of Mg-Al alloy containing rare earths[J]. Journal of Rare Earths, 2003, 21: 157-162.

[14]Huang X F, Zhou H, He Z M. Structure analysis of oxidation film of ignition-inhibition AZ91D magnesium alloy added with cerium[J]. Journal of Rare Earths, 2003, 21: 73-76.

[15]Liu Y, Chen W P, Zhang W W, et al. Effects of RE on microstructures and mechanical properties of hot-extruded AZ31 magnesium alloy[J]. Journal of Rare Earths, 2004, 22: 527-532.

[16]余琨, 黎文献. 细晶粒AZ31(Ce)镁合金板材的组织与性能[J]. 金属热处理, 2005, 30 (4): 34-37.

YU Kun, LI Wen-xian. Microstructure and properties of refine-grain AZ31(Ce) magnesium alloys plate[J]. Heat Treatment of Metals, 2005, 30 (4): 34-37.

[17]张世军, 黎文献, 余琨. 铈对镁合金AZ31晶粒大小及铸态力学性能的影响[J]. 铸造, 2002, 51(12): 767-771.

ZHANG Shi-jun, LI Wen-xian, YU Kun. The effect of Ce on the grain size and as-cast mechanical properties of magnesium alloy AZ31[J]. Foundry, 2002, 51(12): 767-771.

[18]Zhang S C, Wei B K, Cai Q Z, et al. Effect of mischmetal and yttrium on microstructures and mechanical properties of Mg-Al alloy[J]. Trans Nonferrous Met Soc China, 2003, 13(1): 83-87.

[19]Wei L Y, Dunlop G L, Westengen H. Development of microstructure in cast Mg-Al-rare earth alloys[J]. Mater Sci Technol, 1996, 12: 741-750.

[20]Pettersen G, Westengen H, Hoier R, et al. Microstructure of a pressure die cast magnesium-4% aluminium alloy modified with rare earths additions[J]. Mater Sci Eng A, 1996, A207: 115-120.

[21]Lee Y C, Dahle A K, StJohn D H. The role of solute in grain refinement of magnesium[J]. Metall Mater Trans A, 2000, 31A (11): 2895-2906.

[22]He S M, Peng L M, Zeng X Q, et al. Effects of var-[CM(23]iable La/Ce ratio on microstructure and mechanical[CM)] properties of Mg-5Al-0.3Mn-1RE alloys[J]. Mater-ials Science Forum, 2005, 488-489: 231-234.

[23]Cao P, StJohn D H, Qian M. The effects of manganese on the grain size of commercial AZ31 alloy[J]. Materials Science Forum, 2005, 488-489: 139-142.

[24]Tuttle B L. Principles of thermal analysis for molten metal process control[A]. Proceedings of the Conference on Thermal Analysis of Molten Aluminum[C]. USA: Cast Metals Institute, 1985. 1-36.

[25]胡汉起. 金属凝固原理[M]. 北京: 机械工业出版社, 2000. 98-106.

HU Han-qi. Principles of Metal Solidification[M]. Beijing: China Machine Press, 2000. 98-106.

[26]哈宽富. 金属力学性质的微观理论[M]. 北京: 科学出版社, 1983. 429-431.

HA Kuan-fu. Micro-theory of Metal Mechanical Properties[M]. Beijing: Science Press, 1983. 429-431.

[27]Nussbaum G, Sainfort P, Regazzoni G, et al. Strengthening mechanisms in the rapidly solidified AZ91 magnesium alloy[J]. Scripta Metallurgica, 1989, 23: 1079-1084.

(编辑陈爱华)

基金项目: 北京市科技计划资助项目(Y0405004040211)

收稿日期: 2005-08-25; 修订日期: 2005-11-09

作者简介: 郑伟超(1979-), 男, 博士研究生

通讯作者: 李双寿, 副教授; 电话: 010-62773633; 传真: 010-62773633; E-mail: lss@mail.tsinghua.edu.cn