文章编号:1004-0609(2009)11-1923-05

铝合金圆环压缩过程中的分流行为

李 峰1,初冠南2,刘晓晶1

(1. 哈尔滨理工大学 材料科学与工程学院,哈尔滨 150040;

2. 哈尔滨工业大学(威海) 船舶工程学院,威海264209)

摘 要:利用有限元方法对不同圆环压缩过程中的分流行为进行模拟研究,揭示铝合金圆环压缩过程中分流行为的产生机理,并利用罗德系数、J2应力偏量不变量等特征量对成形机理进行分析。结果表明:外侧施压时,随着高径比增大,难变形区明显扩大,向内侧流动的金属量逐渐减少,分流面位置明显左移;内侧施压时,随着摩擦因子增大,塑性区内应变类型由均一压缩类变为3种共存,此时向内侧流动的金属量增大,其流动分界面相对右移。

关键词:铝合金;圆环压缩;分流行为;变形分区

中图分类号:TG 306 文献标识码:A

Diffluence behaviour of aluminium alloy during ring compression

LI Feng1, CHU Guan-nan2, LIU Xiao-jing1

(1. College of Materials Science and Engineering, Harbin University of Science and Technology, Harbin 150040, China;

2. School of Naval Architecture, Harbin Institute of Technology at Weihai, Weihai 264209, China)

Abstract: The mechanism of aluminium alloy diffluence behaviour was studied during the ring compression. The FEM simulations of ring compression under different deformation conditions were carried out. The plastic forming mechanism was investigated based on the Lode parameter and J2 invariant of stress deviator. The results show that when the pressure is added on the external side, the metal flowing towards the internal hole decreases with increasing ratio of height to diameter, and the hard deforming zones expand and the diffluence surface shifts towards the left. When the pressure is added on the internal side, the metal flowing towards the internal hole increases with increasing friction factor, the diffluence surface shifts towards the right and the strain in the plastic area changes from the single compression mode into three coexistent modes.

Key words: aluminium alloy; ring compression; diffluence behaviour; deformation division

因变形条件和形状特征的差异,圆环与圆柱压缩变形过程有着本质区别[1]。除个别情况外,圆环受压缩变形时会产生向内外不同方向流动的分界面。控制成形条件可使圆环的压缩变形特征发生相应的改变[2]。

对圆环在平板间压缩变形过程的模拟研究表 明[3-4],在摩擦因子和变形程度相同的条件下,随着高径比的增大,圆环外径呈外凸单鼓形的变形特征,内径的变形特征则分为内外均凸单鼓形、外凸单鼓形和外凸折皱形3种。采用可变积分上限法对圆环压缩过程的研究结果表明,该方法能给出传统方法所忽略的自然边界条件,并能准确地预测圆环压缩过程中分流面位置及坯料形状变化规律[5];材料性能对圆柱压缩行为也有着重要的影响,研究结果表明,常温压缩变形时超声波作用下圆环内径的缩减量显著地大于传统

圆环压缩变形的测试结果,即使与热圆环压缩相比,超声波作用下圆环内径缩减量仍略较大[6]。

圆环压缩方面的报道虽已有不少[7-9],但多是针对具体工艺进行的[10],而对圆环压缩过程中金属分流行为的机理缺乏深入研究。针对以上不足,本文作者通过数值模拟对圆环压缩过程中分流面的位置进行定量分析,并利用罗德系数、J2应力偏张量不变量等应力场特征量[11-13]对圆环压缩过程进行变形分区,为控制金属分流行为的力学本质提供了一定的理论依据。

1 研究方案

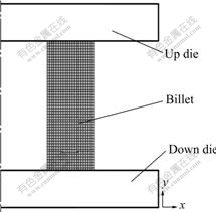

考虑到圆环压缩变形的轴对称性,采用有限元软件DEFORMTM-2D对成形过程进行模拟,同时为了合理地将模型简化又提高计算精度,仅取坯料子午面的一半作为模拟研究对象,有限元模型如图1所示。

图1 有限元模型示意图

Fig.1 Schematic diagram of finite element model

由于影响圆环压缩变形行为的因素较多,通过改变要分析的参数,同时固定其他所有参数值进行模拟。本文作者通过高径比H/(D-d)、摩擦因子m、内外非均匀的侧压力p等工艺条件对圆环压缩分流行为的影响进行研究。为了便于对比分析,固定H=15 mm和D=30 mm,通过改变d值来获得不同的高径比。模拟过程中不考虑上下模板的变形,模具属性为刚性体,坯料选用超硬铝合金7050作为理想刚塑性模型的材料。成形速度为2 mm/s,坯料和模具的温度均为435 ℃。本实验中采用Newton-Raphson迭代法对模拟进行求解,模具与坯料间摩擦边界条件按常剪切因子摩擦模型施加,通过圆环的热压缩试验测得摩擦因子为0.3。

2 结果与讨论

2.1 金属流动行为研究

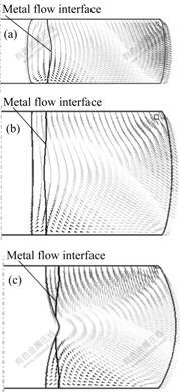

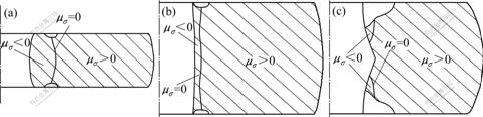

图2所示为不同高径比圆环压缩变形过程中速度场和分流面的分布对比。

图2 不同高径比下速度场和分流面的分布对比

Fig.2 Distribution of velocity field and metal flow interface with different ratios of height to diameter: (a) 0.5; (b) 1.0; (c) 1.5

由图2(a)可以看出,当高径比为0.5时,分流面位于靠近内壁侧约1/5处,此时分流面内侧的金属均沿着径向向内流动;当高径比为1.0时(见图2(b)),流动分界面的位置明显向左移动,圆环内侧向内流动的金属相对减少;当高径比为1.5时(见图2(c)),受压圆环内壁呈现内凸双鼓形的变形趋势,尽管在内壁中部出现了折叠趋势,但位于该处的金属仍均一地沿径向向外流动,分流面分布在靠近内侧壁的角部。

从上述分析可知,随着高径比的增大,圆环压缩变形中外壁鼓形逐渐增大,内壁则由外凸变为内凹的变形趋势,分流面的位置逐渐左移。

图3所示为不同摩擦条件下圆环压缩变形过程中速度场和分流面的分布。由图3(a)可以看出,当摩擦因子较小时,圆环受压变形过程中金属整体均向外发生了显著的变形流动;而摩擦因子为0.3时(见图3(b)),靠近内壁的区域里出现了流动方向相反的分流面;当摩擦因子增大到0.5,分流面的位置则向右发生了偏移(见图3(c)),此时内侧向里流动的金属显著增加,分流面形状呈中部外凸的趋势分布。因受上下端部摩擦力的影响,坯料中部形成了内外壁均呈外凸单鼓的变形特征。

图3 不同摩擦因子时速度场和分流面的分布

Fig.3 Distribution of velocity field and metal flow interface with different fraction factors: (a) 0.1; (b) 0.3; (c) 0.5

由此可知,随着摩擦因子的增大,圆环内壁由内凹逐渐变为外凸单鼓的变形趋势,靠近圆环内侧的部位产生了流动方向相反的分界面,其位置逐渐右移,金属由全部沿径向外流逐渐变为内外分流。

图4所示为非均匀侧压力作用下压缩变形过程中速度场和分流面的分布对比。由图4(a)可以看到,无侧压力作用时分流面位于靠近圆环内壁的一小段距离内。此时除部分金属外,其余金属均向外发生了显著的变形流动;对内壁施加侧压后坯料上没有分流面,金属均沿径向向外流动,此时圆环的内外径均呈增大趋势;而外壁施加侧压后,分流面位置明显内移,且中部向外呈弯曲趋势分布,与无侧压情况相比,圆环压缩时内流的金属量明显增大。

图4 非均匀压力下速度场和分流面的分布

Fig.4 Distribution of velocity field and flow interface under unsymmetrical hydrostatic pressure: (a) Without pressure; (b) Inside pressure, 100 MPa; (c) Outside pressure, 100 MPa

2.2 变形分区对比

为了便于区分,可将Mises屈服准则简写成 因此,可利用应力偏张量第二不变量J2作为发生塑性变形与否的判据。

因此,可利用应力偏张量第二不变量J2作为发生塑性变形与否的判据。

罗德系数μσ能够反映中间主应力的相对大小,其变化范围为-1≤μσ≤1,且和应变类型有一定的对应关系,因此,根据罗德系数的变化可以判断材料的应变类型及变形复杂程度。

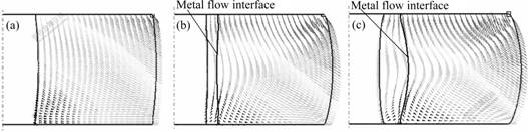

采用J2不变量和罗德系数等应力场特征量对圆柱压缩变形过程进行了定量分区[14-15],进而可对压缩变形过程的分流行为力学机理进行深入分析。图5所示为不同高径比圆环压缩过程的变形分区对比。

由图5(a)可以看出,当高径比为0.5时罗德系数零值线位于靠近圆环内侧的一小段距离内,位于该线上靠近端面的少部分材料因难以满足塑性条件而未发生塑性变形;该线内侧塑性区内罗德系数为负值分布,可知该区内材料所处应变类型为伸长类,即沿径向伸长而轴向和环向呈缩短趋势;该线外侧大部分区域内材料的应变类型为压缩类,即沿轴向呈缩短而沿着环向和径向呈伸长趋势。

图5 不同高径比时的变形分区对比

Fig.5 Comparison of deformation division under different ratios of height to diameter: (a) 0.5; (b) 1.0; (c) 1.5

随着高径比的增大,处于伸长类材料的范围相对减小而处于压缩类材料的范围则明显扩大(见图5(b)),罗德系数零值线和难变形区的位置向内发生了偏移。由图5(c)可以看出,难变形区的范围显著扩大,并集中在靠近内壁的角部。由于整个圆环中部的材料均处于压缩类,因此,罗德系数零值线沿轴向呈间断分布,处于罗德系数零值线以内的小块区域里材料的应变为伸长类。

由此可知,随着高径比的增加,难变形区的范围明显扩大,处于伸长类变形的区域范围逐渐缩小而压缩类变形的区域则相对扩大。

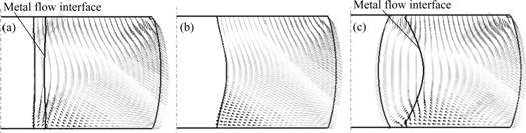

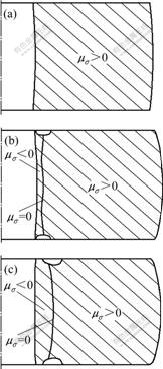

图6所示为不同摩擦条件下圆环压缩过程的变形分区对比,其中阴影部分为塑性区。

图6 不同摩擦条件下的变形分区对比

Fig.6 Comparison of deformation division under different friction conditions

由图6(a)可以看到,当摩擦因子较小时变形体内的材料均能满足塑性屈服条件而发生变形,各处材料的应变类型为均一的压缩类,即沿轴向呈缩短而沿环向和径向呈伸长趋势;随着摩擦因子的增大,内壁角部出现小部分难变形的区域(见图6(b)),靠近圆环内侧的小段距离内罗德系数为负值分布,由此可知,该区内材料所处应变类型为伸长类,即沿径向呈伸长而沿轴向和环向呈缩短趋势;当摩擦因子继续增大时(见图6(b)),罗德系数零值线及难变形区的位置均向外发生了偏移,即处于伸长类材料的范围相对扩大而处于压缩类变形的区域则相对缩小。

随着摩擦因子的增大,变形体与模具接触的端部逐渐出现了难变形区,塑性区内的应变类型由均一的压缩类变为三种共存。

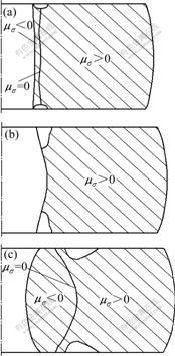

图7所示为非均匀侧压力作用下圆环压缩过程的变形分区对比,其中阴影部分为塑性区。

图7 非均匀压力下的变形分区对比

Fig.7 Comparison of deformation division under unsymmetrical hydrostatic pressure: (a) Without pressure; (b) Inside, 100 MPa; (c) Outside, 100 MPa

由图7(a)可以看出,无侧压作用下难变形区位于与上下模板接触的内孔端部,罗德系数零值线处的材料为平面应变类变化。内侧区内罗德系数为负值,其应变类型为伸长类,即沿径向呈伸长而沿轴向和环向呈缩短趋势;对内侧施压后,难变形区向内侧发生偏移而完全集中在内孔角部,其范围显著扩大(见图7(b))。塑性区内材料应变类型为均一的压缩类,即沿轴向呈缩短而沿环向和径向呈伸长趋势变化,受压圆环的内壁呈内凹而外壁呈外凸单鼓的变形趋势;对外壁施加侧压力时,难变形区显著地向坯料中部发生右移,塑性区内处于压缩类变形材料的范围则明显扩大(见图7(c)),而右侧处于伸长类变形的区域则相对缩小,因此,圆环内外壁均呈外凸单鼓的变形特征。

3 结论

1) 随着高径比的增加,圆环压缩变形中外壁鼓形逐渐增大,分流面逐渐左移;随着摩擦因子的增大,金属由全部沿径向外流逐渐变为内外分流的形式。

2) 随着高径比和摩擦因子的增加,圆环压缩变形中难变形区的范围扩大。且随着高径比的增加,难变形区显著左移;随着摩擦因子增大,塑性区内应变类型由均一压缩类变为3种共存。

3) 当内壁加侧压时,金属均沿径向外流,难变形区集中在内壁角部,塑性区内为均一的压缩类变化;而外壁加侧压时,圆环呈内外均鼓的变形趋势,难变形区沿端部向外偏移,塑性区内应变类型为3种共存。

REFERENCES

[1] ROBINSON T, OU H, ARMSTRONG C G. Study on ring compression test using physical modeling and FE simulation[J]. J Mater Process Technol, 2004, 153/154: 54-59.

[2] 李 峰. 盘类件模锻过程金属变形模式及流动规律研究[D]. 哈尔滨: 哈尔滨工业大学, 2007.

LI Feng. Deformation modes and flow behaviour of metal in die forging process of disk components[D]. Harbin: Harbin Institute of Technology, 2007.

[3] YEH Wei-ching, WU Ming-Chang. A variational upper- bound method for analysis of upset forging of rings[J]. J Mater Process Technol, 2005, 170(1/2): 392-402

[4] HAMZAH S, STAHLBERG U. A study of pore closure in the manu-facturing of heavy rings[J]. J Mater Process Technol, 1998, 84(1/3): 25-37.

[5] 俞彦勤, 黄早文, 夏巨谌, 余明俊, 徐智勇. 管料镦锻变形规律的物理模拟[J]. 锻压技术, 2000, 25(2): 10-12.

YU Yan-qin, HUANG Zao-wen, XIA Ju-chen, YU Ming-jun, XU Zhi-yong. Physical modeling on deformation law of tube upsetting[J].Forging & Stamping, 2000, 25(2): 10-12

[6] HUNG J C, TSAI Y C, HUNG C H. Frictional effect of ultrasonic-vibration on upsetting[J]. Ultrasonics, 2007, 46(3): 277-284.

[7] 刘 钢, 刘志奇, 王礼良, 王仲仁. 静液压力下7075铝合金圆环压缩试验研究[J]. 哈尔滨工业大学学报, 2006, 38(1): 81-84.

LIU Gang, LIU Zhi-qi, WAND Li-liang, WANG Zhong-ren. Experimental research on compressing 7075 Al alloy ring under hydrostatic pressure[J]. Journal of Harbin Institute of Technology, 2006, 38(1): 81-84.

[8] LIU Gang, WANG Li-liang, LIU Zhi-qi, WANG Zhong-ren. Numerical simulation and experimental research on compressing 7075 aluminum alloy rings under hydro-static pressure[J]. Trans Nonferrous Met Soc China, 2006, 16(5): 1103-1109

[9] RUDKINS N T, HARTLEY P, PILINGER I, PETTY D. Friction modeling and experimental observations in hot ring compression tests[J]. J Mater Process Technol, 1996, 60(1): 349-353.

[10] HASAN S, JAHAN R. On the measurement of friction coefficient utilizing the ring compression test[J]. Tribology International, 1999, 32(6): 327-335.

[11] HU W L, HE Z B, FANG Y. Uniform principle on stress, strain and yield locus for analyzing metal forming processes: The contribution of Prof. Z.R. Wang[J]. J Mater Process Technol, 2004, 151(1/3): 27-32.

[12] WANG Z R, HE Z B, TENG B G. Three-dimensional representation of normal stress magnitude with applications to hydrobulge forming[J]. J Stra Ana Eng Des, 2004, 39(2): 205-211.

[13] WANG Z R. A consistent relationship between the stress- and strain-components and its application for analyzing the plane-stress forming process[J]. J Mater Process Technol, 1995, 55(1): 1-4.

[14] 苑世剑, 李 峰, 刘 钢. 不同摩擦挤压过程中金属流动行为的变形分区研究[J]. 金属学报, 2007, 43(2): 199-204.

YUAN Shi-jian, LI Feng, LIU Gang. Research of metal flow during extrusion process under different friction conditions by deforming area division[J]. Acta Metallurgica Sinica, 2007, 43(2): 199-204.

[15] LI F, YUAN S J, LIU G, HE Z B. Effect of friction on metal flow behavior during extrusion process[J]. J Mater Eng Per, 2008, 17(1): 7-1.

基金项目:黑龙江省教育厅科研资助项目(11541042);哈尔滨市青年科技创新人才基金资助项目(RC2010QN017008)

收稿日期:2008-09-16;修订日期:2009-06-10

通信作者:李 峰,副教授,博士;电话:0451-86392510;E-mail: hitlif@126.com

(编辑 李向群)