文章编号:1004-0609(2007)09-1410-07

热压烧结制备近全致密W-Cu梯度热沉材料

刘彬彬,鲁岩娜,谢建新

(北京科技大学 材料科学与工程学院,北京100083)

摘 要:采用粒度配比和热压固相烧结方法制备高致密W-Cu梯度热沉材料,考察烧结温度、压力和保温时间对梯度材料密度和硬度的影响,并对材料的显微组织进行观察。结果表明:采用热压固相烧结和粒度配比法可以制备近全致密的W-Cu梯度热沉材料,各梯度层分界清晰,各层组织致密,成分保持为最初的梯度设计;在烧结温度1 060 ℃、压力85 MPa、保温时间3 h的工艺条件下,所制备的W-Cu三层梯度热沉材料的封接层、中间层、散热层的相对密度分别达到98.6%、99.1%和99.5%,硬度HRB分别为91.6、95.6和74.4。

关键词:钨铜合金;梯度功能材料;热压;粒度配比;相对密度

中图分类号:TB 331 文献标识码:A

Fabrication of tungsten/copper functionally gradient materials with nearly full density by hot press

LIU Bin-bin, LU Yan-na, XIE Jian-xin

(School of Materials Science and Engineering, University of Science and Technology Beijing, Beijing 100083, China)

Abstract: High density W-Cu functionally gradient material was fabricated by particle size distribution method and hot press. The effects of sintering temperature, pressure, holding time on the density, hardness and microstructure of the gradient materials were investigated. The results show that W-Cu functionally gradient materials with full density can be fabricated by this method. The interface between each layer is clear, each layer achieves high density, and the component of initial gradient design can keep stable. Three-layer W-Cu functionally gradient materials with nearly full density are fabricated under the processing conditions of sintering temperature 1 060 ℃, pressure 85 MPa and holding time 3 h. The relative densities of sealing layer, transitional layer and radiating layer are 98.6%, 99.1% and 99.5% respectively, and the hardness are 91.6, 95.6 and 74.4 HRB respectively.

Key words: tungsten/copper alloy; functionally gradient materials; hot press; particle size distribution; relative density

微波功率器件广泛应用于雷达、通信、电子对抗、远程遥控及精密制导等方面。随着功率的大幅度增加(从厘米波到毫米波,再到微米波),使用过程中产生的热量也随之增加。因此,研制高性能散热材料是微波功率器件高性能化的关键[1?3]。对于传统的W-Cu均质热沉材料,由于要考虑到与陶瓷基板的封接问题,要求热沉材料具有低的热膨胀系数,因而在设计成分时不得不采用W含量较高的W-Cu复合材料。因此,在保证与基板封接要求的前提下,进一步提高均质W-Cu复合材料的热导率极为困难。

自日本学者首先提出梯度功能材料这一概念以来,梯度结构热沉材料已成为高性能散热材料的主要研究方向之一[4?5]。梯度功能材料按沿特定方向成分(或组织)连续变化或非连续变化,分为连续或非连续梯度材料两大类[6?7]。由于连续梯度功能材料的预制坯制备难度大、成本高,因此多采用粉末冶金的方法制备非连续梯度复合材料[8?13]。本文作者对采用多坯料挤压法制备三层结构的W-Cu梯度功能材料进行了探讨,证明了该方法制备梯度复合坯料的可行性[14?15]。但研究结果表明,即使采用高能球磨后进行液相烧结的方法,也难以获得近全致密的W-Cu梯度材料;同时,高能球磨容易在W-Cu合金中混入杂质;在液相烧结的条件下,增加烧结时间、提高烧结温度和减小粉末的粒度,均有利于提高W-Cu复合材料的烧结致密性,但这些措施均会促使梯度结构的成分发生均匀化现象,从而改变梯度设计目标。本文作者在采用粒度配比与热压固相烧结制备近全致密W-Cu复合材料研究结果的基础上,研究高致密性W-Cu梯度材料制备的相关问题,并对烧结温度、压力及时间对材料性能的影响规律进行分析,确定可制备满足目标成分设计的近全致密的W-Cu梯度热沉材料的基本工艺参数。

1 实验

1.1 原料

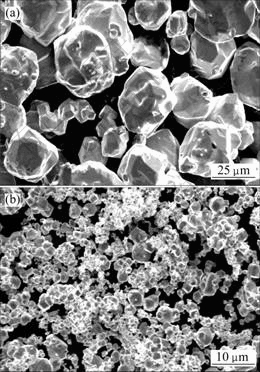

实验采用两种粒度的W粉,其主要粒径范围分别为38.9~76.8 μm(W粉A)和2.2~5.0 μm(W粉B),纯度≥99.9%,W粉的形貌均为近球形,如图1所示。电解Cu粉的平均粒度为8.3 μm,纯度≥99.5%。

图1 实验用W粉的SEM像

Fig.1 SEM images of tungsten powders used by experiment: (a) Tungsten powder A with big particle; (b) Tungsten powder B with small particle

1.2 工艺

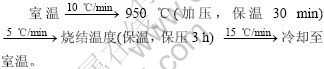

根据前期的研究结果[15],实验制备的三层W-Cu梯度热沉材料的封接层、中间层、散热层的成分分别设计为:W/Cu20(表示混合层中Cu的含量为20%(质量分数))、W/Cu33、W/Cu50;各层的厚度(烧结后)分别为:0.5 mm、0.5 mm、0.5 mm。在固相烧结条件下,采用均一粒度的粉末很难获得近全致密的高W含量的W-Cu复合材料(如W/Cu20),所以对封接层采用粒度配比的方式,即采用W粉的粒度配比为80%A+ 20%B。将W粉与Cu粉混合均匀,所得W/Cu20混合粉末的粒度分布如图2所示。由于其它梯度层Cu相的体积含量较高,较易致密化,因此均采用单一的小粒度W粉与Cu粉配制成W/Cu33和W/Cu50混合粉末。将配制好的混合粉末采用层铺的方法装入石墨热压模具中,石墨模具表面均匀涂覆BN,以防止烧结过程中W与石墨直接接触。将模具放入程控热压炉中进行烧结,通保护气氛N2,烧结工艺如下:

图2 W/Cu20粉末的粒度分布

Fig.2 Particle size distribution of W/Cu20 powders

复合材料密度的测定采用阿基米德法;采用扫描电镜观察粉末和复合材料的显微结构;硬度分析采用TH320全洛氏硬度计进行;粒度分析采用LMS?30粒度分析仪;烧结设备采用程控热压炉HP?1L。

2 结果与分析

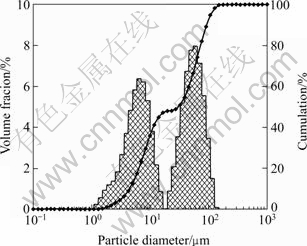

2.1 W-Cu粉末的DSC分析

为了确定Cu粉末的实际熔化温度,以便采用尽可能高的固相烧结温度,对W-Cu混合粉末进行了DSC分析,图3所示为W/Cu20均匀混合粉末的DSC分析结果。从图中可以看出,在850~1 100 ℃之间,除了Cu的一个熔化吸热峰之外,没有发生其它的热反应,Cu粉末的实际开始熔化温度为1 066.5 ℃,低于Cu的理论熔点(1 083.5 ℃)。这是由于粉末具有更多的表面能,这些能量的释放将有助于Cu的熔化。为了获得尽可能高的致密化效果,本文选择在接近于熔点 (1 050 ℃和1 060 ℃)和略高于熔点(1 070 ℃)的温度下进行烧结实验。

图3 W/Cu20粉末的DSC曲线

Fig.3 DSC curve of W/Cu20 powders (20%Cu)

2.2 烧结温度的影响

2.2.1 烧结温度对密度和硬度的影响

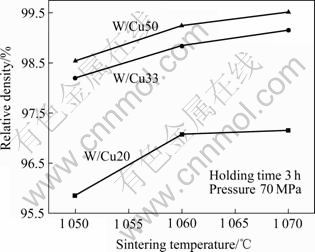

图4所示为保温时间3 h、烧结压力70 MPa工艺条件下,烧结温度对W-Cu梯度材料各梯度层致密性的影响。从图中可以看出,随着烧结温度的增加,各层的致密性是增加的,W/Cu50的相对密度高于W/Cu33的,而W/Cu33的相对密度高于W/Cu20的。当烧结温度为1 050~1 070 ℃时,W/Cu50和W/Cu33的相对密度均在98%以上,W/Cu20的相对密度达到95.8%以上;当烧结温度为1070 ℃时,W/Cu50的相对密度达到99.5%,W/Cu33的相对密度达到99.2%,而W/Cu20达到了97.2%。

图4 烧结温度对各W-Cu梯度层致密性的影响

Fig.4 Effects of sintering temperature on relative density of different W-Cu gradient layers

图5给出了烧结温度对各W-Cu梯度层硬度的影响。从图中可以看出,在烧结温度1 050~1 070 ℃范围内,随着烧结温度的增加,W/Cu20的硬度随之增加,但从1 060 ℃到1 070 ℃,增加量很小;而W/Cu33和W/Cu50的硬度则呈先增加后降低的趋势,在烧结温度1 060 ℃时获得最大硬度值。这是由于 W/Cu33和W/Cu50中Cu含量高,其烧结主要取决于W与Cu的烧结和Cu与Cu的烧结,又由于W-Cu之间形成的是简单界面,所以硬度最终取决于W的含量与Cu硬度。在1 070 ℃烧结时,温度略高于Cu粉的实际熔化点,烧结时Cu相已部分熔化,在随后的冷却过程中,会经历结晶和晶粒长大的过程,获得粗大的晶粒,因而Cu相的硬度略有降低,导致W/Cu33和W/Cu50层硬度有所降低; W/Cu20中的Cu含量较少,其烧结同时取决于W与W的烧结、W与Cu的烧结和Cu与Cu的烧结,但W颗粒相互接触的数量较多,W与W的烧结对整体的硬度起决定的作用,随着温度的增加,W与W的烧结更加牢固,因此W/Cu20的整体硬度也就随烧结温度的增加和密度的增加而增加。

图5 烧结温度对各钨铜梯度层硬度的影响

Fig.5 Effects of sintering temperature on hardness of different W-Cu gradient layers

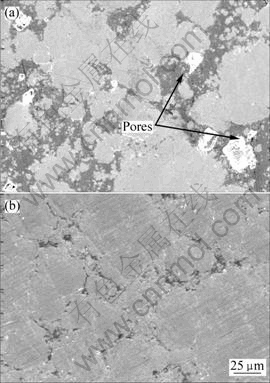

2.2.2 烧结温度对组织的影响

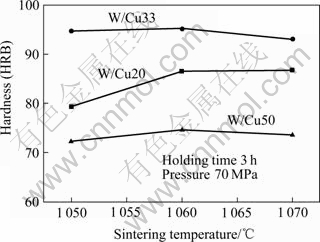

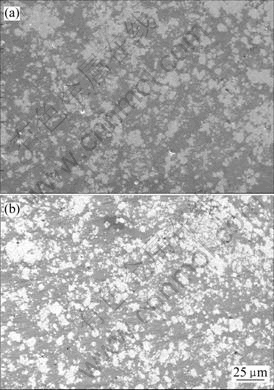

图6所示为烧结压力70 MPa、保温时间3 h、烧结温度为1 050 ℃和1 070 ℃时,W/Cu20(封接层)的显微结构。图中浅色部分为W相,深色部分为Cu相。由于封接层采用了粒度配比的方式,小粒度W粉(B)分布于大颗粒W粉(A)所形成的间隙之间,作为粘结相的Cu粉分布于小颗粒W粉之间,小颗粒W粉(B)与粘结相Cu共同填充大W颗粒所形成的间隙。从图中还可以看出,W颗粒之间已形成了较为明显的烧结颈,烧结温度1 070 ℃时的组织致密性要略高于1 050℃时的。

图6 不同烧结温度条件下W/Cu20的显微结构(压力70 MPa,保温时间3 h)

Fig.6 Microstructures of W/Cu20 under conditions of sintering pressure 70 MPa, holding time 3 h and different sintering temperatures: (a) 1 050 ℃; (b) 1 070 ℃

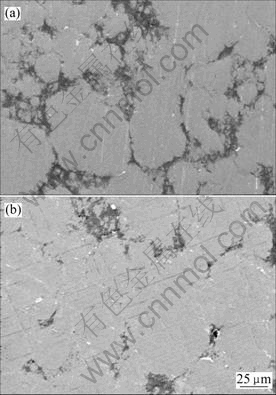

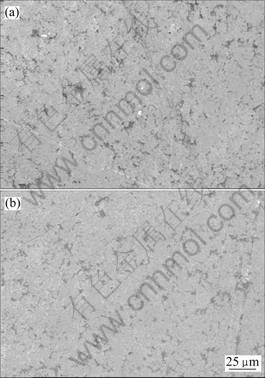

图7和图8分别为相同工艺条件下,W/Cu33和W/Cu50的显微组织形貌,W粉均采用小粒度钨粉。W/Cu33的组织形貌分布比较均匀,而W/Cu50虽然从整体来看分布均匀,但局部出现了W颗粒团聚的现象。这种现象可以通过增加混合时间,提高粉末混合的均匀性来解决。

图7 不同烧结温度条件下W/Cu33的显微结构(压力70 MPa,保温时间3 h)

Fig.7 Microstructures of W/Cu33 under conditions of sintering pressure 70 MPa, holding time 3 h and different sintering temperatures: (a) 1 050 ℃; (b) 1 070 ℃

图8 不同烧结温度条件下W/Cu50的显微结构(压力70 MPa,保温时间3 h)

Fig.8 Microstructures of W/Cu50 under conditions of sintering pressure 70 MPa, holding time 3 h and different sintering temperatures: (a) 1 050 ℃; (b) 1 070 ℃

2.3 烧结压力的影响

2.3.1 烧结压力对密度和硬度的影响

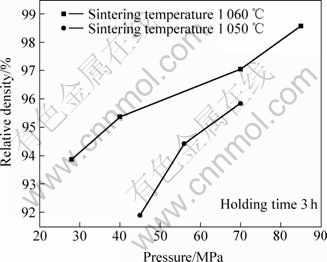

图9所示为保温时间3 h,烧结温度1 050 ℃和 1 060 ℃时,压力对W/Cu20致密性的影响。从图中可以看出,随着压力的增加,W/Cu20的相对密度增加;在相同压力条件下,烧结温度1 060 ℃时获得的样品相对密度高于1 050 ℃时的;在压力28 ~85 MPa的范围内,相对密度呈近似线性增加。在较低的压力条件下,烧结温度1 060 ℃时,就可获得较高的相对密度;在85 MPa压力条件下,W/Cu20的相对密度可达到98.6%。

图9 压力对W/Cu20致密性的影响

Fig.9 Effects of pressure on relative density of W/Cu20

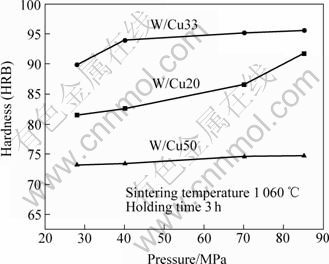

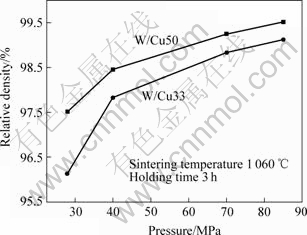

图10所示为烧结温度1 060 ℃,保温时间3 h的工艺条件下,压力对各W-Cu梯度层硬度的影响。从图中可以看出,随着压力的增加,各层的硬度随之增加,且W/Cu33的硬度高于W/Cu20的硬度,而W/Cu20的硬度高于W/Cu50的硬度。这主要是由于W/Cu33的致密性高于W/Cu20(见图9和图11),其W含量高于W/Cu50的结果所致。在压力28~85 MPa的范围内,W/Cu50的硬度变化很小。而在压力40~85 MPa的范围内,W/Cu20的硬度显著增加,这是由于致密性显著提高所导致的。W/Cu33的硬度在压力28~40 MPa范围内增加较快,而在40~85 MPa的范围内,增加很小,这是由于在40~85 MPa范围内烧结样品的相对密度增加较慢所致(如图11所示)。

图10 压力对各W-Cu梯度层硬度的影响

Fig.10 Effects of pressure on hardness of W-Cu gradient layer

图11 压力对W/Cu33和W/Cu50致密性的影响

Fig.11 Effects of pressure on relative density of W/Cu33 and W/Cu50

2.3.2 烧结压力对组织的影响

图12所示为烧结温度1 060 ℃、保温时间3 h、压力28 MPa和70 MPa的工艺条件下,W/Cu20的显微结构。从图12(a)可以看出,在压力28 MPa条件下进行烧结,大W颗粒与大W颗粒之间、小W颗粒与小W颗粒之间均有许多明显的孔隙存在,并在制备金相样品时很容易造成钨颗粒的脱落,表明W与Cu之间的结合较弱。在较高的压力条件下(70 MPa),烧结时很难看到明显的孔隙,且W颗粒之间的烧结颈变得更加粗大,W与Cu结合得更加牢固(图12(b))。

图12 不同压力条件下W/Cu20的显微结构(烧结温度1 060 ℃,时间3 h)

Fig.12 Microstructures of W/Cu20 under conditions of sintering temperature 1 060 ℃, holding time 3 h and different pressures: (a) 28 MPa; (b) 70 MPa

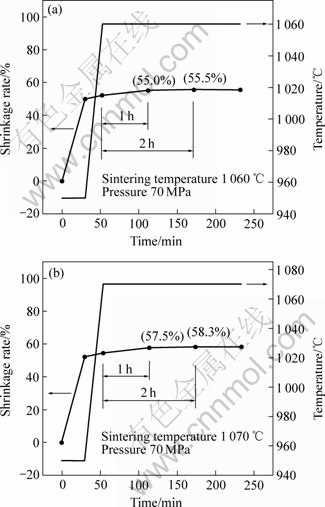

2.4 烧结时间对烧结体收缩率的影响

在烧结过程中,烧结体收缩率越大,其致密性越好。图13所示为压力70 MPa,不同烧结温度条件下,烧结时间对材料收缩率的影响。从图中可以看出,从950 ℃开始加压,起初体积收缩率很大,到达烧结温度时,体积收缩率已达到50%以上;随着保温时间的延长,烧结体继续收缩,但收缩的速度变得非常缓慢,保温2 h后,收缩率几乎没有变化。一般而言,长时间烧结有利于样品组织性能的进一步提高,但根据本文获得的收缩率曲线,可以确定合适的烧结时间为2~3 h。

图13 不同温度条件下烧结时间对样品收缩率的影响

Fig.13 Effects of holding time on shrinkage rate under different sintering temperatures

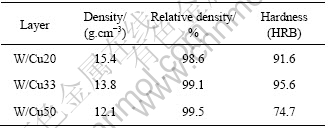

2.5 近全致密W-Cu梯度材料合适的热压烧结工艺的确定

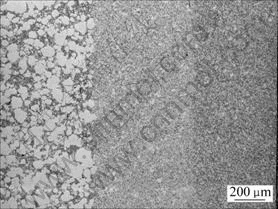

综合分析上述结果,确定近全致密W-Cu梯度材料合适的热压固相烧结工艺为:烧结温度1 060 ℃、压力85 MPa、保温时间3 h 。在所确定的工艺条件下,所制备的三层W-Cu梯度材料的密度和硬度如表1所示。从表1中可以看出,三层梯度材料各梯度层的密度均大于98%,中间层的硬度略高于封接层的硬度。图14为W-Cu三层梯度材料的形貌,从图中可以看出,三层W-Cu梯度材料层厚均匀,各层界面清晰可见,没有发生成分均匀化的现象,保持了最初的目标设计成分。

表1 W-Cu梯度材料各梯度层材料的密度和硬度

Table 1 Density and hardness of each gradient layer in W-Cu FGMs

图14 W-Cu三层梯度材料形貌

Fig.14 Morphology of three-layer W-Cu gradient material (Sintering temperature 1 060 ℃, pressure 85 MPa, holding time 3 h)

3 结论

1) 随着烧结温度的增加,W-Cu梯度材料各层的密度随之增加,W/Cu20烧结样品的硬度随着烧结温度的增加而先增加后保持不变,W/Cu33和W/Cu50的硬度呈现先增加后减小的趋势。

2) 随着烧结压力的增加,W-Cu梯度材料各层的致密性增加;烧结压力对W/Cu20的影响较为显著,而对W/Cu33、W/Cu50的影响较小。

3) 随着保温时间的增加,烧结体的收缩率增加,合理的保温时间为2~3 h。

4) 在烧结温度1 060 ℃、压力85 MPa、保温时间3 h的工艺条件下,采用粒度配比和热压固相烧结法可以制备近全致密的W-Cu梯度热沉材料,各梯度层分界清晰,成分保持最初的梯度设计目标,封接层、中间层和散热层的相对密度分别为98.6%、99.1%和99.5%,硬度分别为91.6、95.6和74.4 HRB。

REFERENCES

[1] Kim Y D, Oh N L, Oh S T, Moon I H. Thermal conductivity of W-Cu composites at various temperatures[J]. Materials Letters, 2001, 51: 420?424.

[2] Johnson J L, German R M. Factors affecting the thermal conductivity of W-Cu composites[J]. Adv Powder Metall Part Mater, 1993, 4: 201?213.

[3] 任淑彬, 叶 斌, 曲选辉, 何新波. 复杂形状SiCP/Al复合材料零件的制备与性能[J]. 中国有色金属学报, 2005, 15(11): 1722?1726.

REN Shu-bin, YE Bin, QU Xuan-hui, HE Xin-bo. Preparation and properties of SiCP/Al composite parts with complex-shape[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(11): 1722?1726.

[4] Jedamzik R, Neubrand A, Rodel J. Functionally graded materials by electrochemical processing and infiltration: application to tungsten/copper composites[J]. Journal of Materials Science, 2000, 35: 477?482.

[5] 凌云汉, 周张健, 李江涛, 杨大正, 葛昌纯. 超高压梯度烧结法制备W/Cu梯度功能材料[J]. 中国有色金属学报, 2001, 11(4): 576?581.

LING Yun-han, ZHOU Zhang-jian, LI Jiang-tao, YANG Da-zheng, GE Chang-chun. Fabrication of W/Cu functionally gradient material by graded sintering under ultra-high pressure [J]. The Chinese Journal of Nonferrous Metals, 2001, 11(4): 576?581.

[6] Suresh S, Mortensen A. 功能梯度材料基础——制备及热机械行为[M]. 北京: 国防工业出版社, 2000.

Suresh S, Mortensen A. Fundamentals of functionally graded materials—fabrication and thermal mechanical property[M]. Beijing: National Defence Industry Press, 2000.

[7] Ma J, Tan G B. Processing and characteriazation of metal-ceramics functionally gradient materials[J]. Materials Processing Technology, 2001, 113: 446?449.

[8] 谢建新, 李世波, 曲选辉. 一种钨铜梯度热沉材料及其制备方法[P]. 中国专利: ZL031426786, 2004?12?22.

XIE Jian-xin, LI Shi-bo, QU Xuan-hui. One tungsten/copper gradient heat-sink material[P]. CN: ZL031426786, 2004?12?22.

[9] Zhang W Q, Xie J X, Wang C Z. Fabrication of multiplayer 316/PSZ gradient composite pipes by means of multi-billet extrusion[J]. Materials Science and Engineering A, 2004, 382: 371?377.

[10] 周张健, 葛昌纯, 李江涛. 热压法制备钨/铜梯度功能材料[J]. 材料科学与工艺, 2000, 8(1): 52?54.

ZHOU Zhang-jian, GE Chang-chun, LI Jiang-tao. Fabrication of W/Cu FGM by hot pressing[J]. Material Science and Technology, 2000, 8(1): 52?54.

[11] 陈 姝. W/Cu梯度功能材料的优化设计与制备[D]. 北京: 北京科技大学, 2004.

CHEN Shu. Design and fabrication of W/Cu FGM as heat sink materials for microwave[D]. Beijing: University of Science and Technology Beijing, 2004.

[12] Feng H B, Meng Q H, Zhou Y, Jia D C. Spark plasma sintering of functionally graded material in the Ti-TiB2-B system[J]. Materials Science and Engineering A, 2005, 397: 92?97.

[13] Zhang W Q, Xie J X, Wang C Z. Properties of 316L/PSZ composites fabricated by means of extrusion forming and gas-pressure sintering[J]. Materials Science and Engineering A, 2004, 382: 387?394.

[14] Li S B, Xie J X. Processing and microstructure of functionally graded W/Cu composites fabricated by multi-billet extrusion using mechanically alloyed powders[J]. Composites Science and Technology, 2006, 66: 2329?2336.

[15] 刘彬彬, 谢建新. W-Cu梯度热沉材料的成分与结构设计[J]. 稀有金属, 2005, 29(5): 757?761.

LIU Bin-bin, XIE Jian-xin. Design of component and structure for tungsten/copper heat-sink gradient materials[J]. Chinese Journal of Rare Metals, 2005, 29(5): 757?761.

基金项目:国家杰出青年科学基金资助项目(50125415)

收稿日期:2006-11-06;修订日期:2007-06-18

通讯作者:谢建新,教授,博士;电话:010-62332309;传真:010-62327283;E-mail: jxxie@mater.ustb.edu.cn

(编辑 袁赛前)