文章编号:1004-0609(2013)05-1202-06

退火温度对异步轧制铜/铝复合板界面组织及力学性能的影响

李小兵1, 2,祖国胤1,王 平2

(1. 东北大学 材料与冶金学院,沈阳 110819;

2. 东北大学 材料电磁过程教育部重点实验室,沈阳 110819)

摘 要:研究退火温度对异步轧制法制备的铜/铝复合板界面组织及力学性能的影响,采用SEM观察界面组织形貌,结合EDX、XRD分析界面物相成分,采用显微硬度和室温拉伸实验表征复合板的力学性能。结果表明,异步轧制法制备的铜/铝复合板界面形变储能较高,退火温度为400 ℃时界面扩散明显;随着退火温度的升高,复合界面先后生成金属间化合物CuAl2、Cu9Al4、CuAl相,界面撕裂位置位于金属间化合物之间;界面层的显微硬度比基体的高,这是因为受到硬脆性化合物和高温软化的共同影响;退火温度越高,复合板抗拉强度越低,断裂伸长率越大。研究表明,异步轧制法制备的铜/铝复合板最佳退火温度为400 ℃。

关键词:铜/铝复合板;金属间化合物;退火;轧制复合;界面

中图分类号:TG146 文献标志码:A

Effect of annealing temperature on microstructure and mechanical properties of Cu/Al clad sheet fabricated by asymmetrical roll bonding

LI Xiao-bing1, 2, ZU Guo-yin1, WANG Ping2

(1. School of Materials and Metallurgy, Northeastern University, Shenyang 110819, China;

2. Key Laboratory of Electromagnetic Processing of Materials, Ministry of Education, Northeastern University, Shenyang 110819, China)

Abstract: The effects of annealing temperature on the interfacial microstructure and mechanical properties of Cu/Al clad sheet fabricated by asymmetrical roll bonding were investigated according to the microstructure observation by scanning electrical microscope (SEM) and the phase constituent measurement by energy dispersive X-ray detector (EDX) as well as X-ray diffractometer (XRD), in addition with the microhardness of interfacial zone and tensile test of clad sheet. The results indicate that the interfacial layer of Cu/Al clad sheet fabricated by asymmetrical roll bonding grows heavily at 400℃ due to the accumulated deform energy. The intermetallic compounds form in the order of CuAl2, Cu9Al4 and CuAl with increasing the annealing temperature, and peeling occurs between them. The interfacial microhardness is higher than that of the matrix due to the effect of annealing recovery and brittle intermetallic compound. The ultimate tensile strength decreases with rising the annealing temperature, while the elongation increases. According to the experiments, the optimal annealing temperature for Cu/Al clad sheet fabricated by asymmetrical roll bonding is 400 ℃.

Key words: Cu/Al clad sheet; intermetallic compound; annealing; roll bonding; interface

铜/铝复合板既具有铜、铝基体的优良导电、导热及成形性能,又具有外形美观、节约贵金属的优势,可广泛应用于热能、电器等产品中[1-3]。目前,用来制备异种金属复合板的工艺主要为爆炸焊接、轧制复合、铸轧复合及真空扩散焊接等[4-6],它们各自具有一定的应用范围,但在实际工业生产中,这些工艺不同程度地存在着耗能高、污染严重等问题,并且制备的产品性能不稳定。

异步轧制技术制备的铜/铝复合板,在室温易实现复合界面的牢固结合,同时又因剧烈的塑性变形在界面累积了大量热量,因此改善了复合板的最终性能[7-9]。铜/铝复合界面的组织和性能最终决定着复合板的应用[10],但目前关于异步轧制复合技术的研究多局限于宏观的变形因素,较少涉及退火工艺对异步轧制复合产品的显微组织和力学性能的影响。为此,本文作者系统研究退火温度对异步轧制铜/铝复合板界面显微组织及力学性能的影响,以确定最佳的退火热处理制度。

1 实验

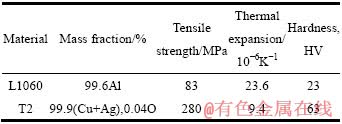

所用实验材料为厚度为1.0 mm的纯铝L1060和厚度为1.5 mm的纯铜T2,初始状态均为完全退火态,化学成分及性能参数如表1所列。组元金属均切割成长度为200 mm、宽度为25 mm的平板,然后用丙酮清洗待复合的表面,再用转速为1 200 r/min的砂轮打磨,最后用细铁丝将叠放整齐的复合金属头尾捆绑。

表1 材料的化学成分及性能

Table 1 Chemical compositions and properties of materials

轧制复合实验在d 92 mm×200 mm轧机上进行,工作辊的速度比设定为1.31,轧制过程无润滑,单道次轧制压下率为48%。轧制后的复合板用电火花线切割成热处理试样,在程控热处理炉中进行退火处理,退火温度区间为300~600 ℃,控制精度为±1 ℃,退火时间为20 min。

采用常规金相制备技术研磨、抛光铜/铝复合板的横截面;用SUPERSCAN SSX-550扫描电镜(SEM)观察复合板界面组织形貌,并用SEM配备的能谱仪(EDX)检测界面区域的化学成分;用X’Pert Pro MPD-PW3040/60 X射线衍射仪(XRD)检测铜/铝复合板的剥离面物相成分。

采用402-MVD维氏显微硬度计测量复合板界面区域的硬度值,测试条件为载荷0.25 N,持续时间25 s;在SANSCMT 5000材料实验机上测试复合板的抗拉强度及伸长率,拉伸速度为1 mm/min,拉伸试样的尺寸参照标准GB/T 228—2002制定,标距尺寸为20 mm×10 mm。

2 结果与讨论

2.1 退火温度对界面组织的影响

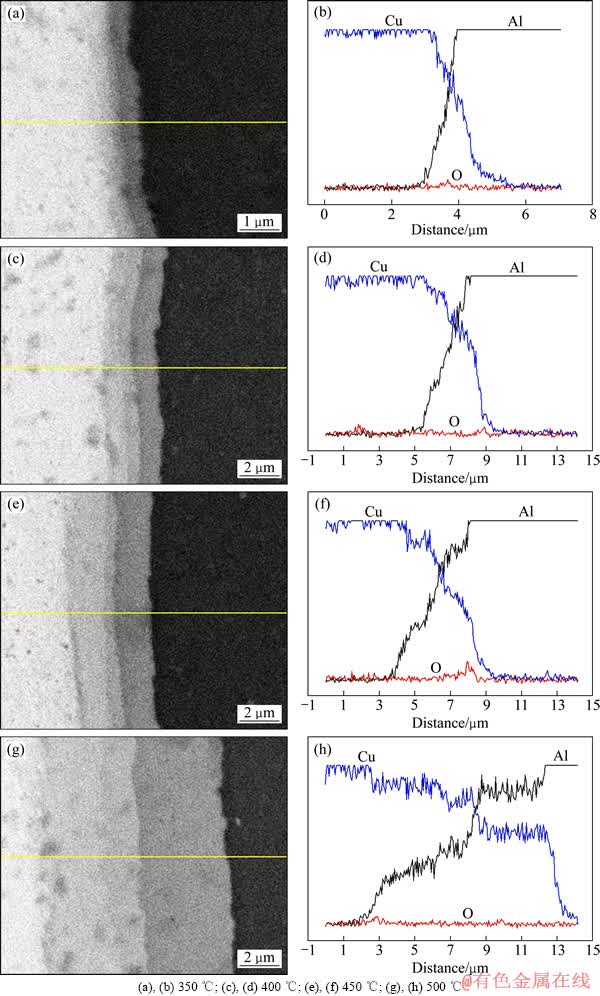

图1(a),(c),(e)和(g)所示分别为不同退火温度下铜/铝复合板界面的SEM像。结合EDX线扫描分析结果(图1(b),(d),(f),(h)),可以清楚反映出退火温度对界面区域显微组织的影响。由图1可知,当退火温度为350 ℃时,铜、铝金属复合界面生成厚度为1 μm左右的扩散层;当退火温度升至400 ℃时,界面生成厚度约为3 μm的过渡层;退火温度继续升高,界面生成的过渡层厚度急剧增大,在450和500 ℃时分别达到了5和10 μm。

低温退火时,绝大部分铜/铝界面原子在表面能的束缚下未能实现跃迁,因此,界面扩散微弱如图1(a)所示。而当退火温度升高时,铜、铝原子获得的热能突破了扩散能量势垒,即可实现大范围自由迁移,扩散层加速生长。由于扩散通量与退火温度呈指数关 系,图1所示的扩散层厚度增长趋势在高温阶段更加显著。

由于界面摩擦剪切作用,异步轧制可产生剧烈塑性变形,因此,在铜/铝复合板界面位置累积了大量的形变能量,降低了原子扩散所需要的外界能量,在一定程度上加速了界面原子的扩散。剧烈塑性变形还可以细化金属晶粒,形成大量晶界或亚晶界,造成大量晶格点阵缺陷,为原子扩散提供通道[11]。根据实验结果,异步轧制复合板经400 ℃保温20 min的退火处理后,获得的界面过渡层厚度与文献[5, 12]中高温长时间退火工艺的相当。

在高温阶段,材料内部因异步轧制复合造成的大量位错发生合并和释放,对铜、铝原子扩散迁移的阻碍作用大大减弱。因此,铜、铝原子在高温退火时扩散系数显著增大,复合界面过渡层急剧增长。

2.2 退火温度对界面化学成分的影响

图1(b),(d),(f)和(h)所示的EDX元素线扫描分析显示,界面过渡层出现元素含量近似恒定的区域,根据Cu-Al二元合金平衡相图推测,在界面位置生成了不同类型的金属间化合物。在不同温度范围内,界面金属发生不同类型的固态相变,Cu-Al二元合金系可能存在的金属间化合物有Cu9Al4、Cu4Al3、Cu3Al2、CuAl和CuAl2。

图1 不同退火温度下铜/铝复合板界面的SEM背散射像及Cu、Al和O元素分布

Fig. 1 BSE-SEM images at interface of Cu/Al clad sheet ((a), (c), (e), (g)) corresponding Cu, Al and O element distribution by EDX ((b), (d), (f), (h)) at different annealing temperatures

由图1(b),(d),(f)和(h)所示元素分布曲线可知,在退火处理时铜原子的扩散程度高于铝原子的扩散程度。由于铝在轧制复合过程中塑性变形比铜剧烈,在热处理过程中铝金属晶粒细化,界面含量较高,利于铜原子扩散。铜原子的晶粒尺寸小于铝原子的晶粒尺寸(晶格常数aCu=0.361 5 nm,aAl=0.408 2 nm),在扩散过程铜原子进入铝晶格点阵的间隙位置较容易[13]。在复合过程中铜金属表面可能形成韧性较好的氧化膜,经复合变形后仍存在于铜表面,阻碍原子扩散。因此,退火后铜向铝基体的扩散高于铝向铜的扩散。

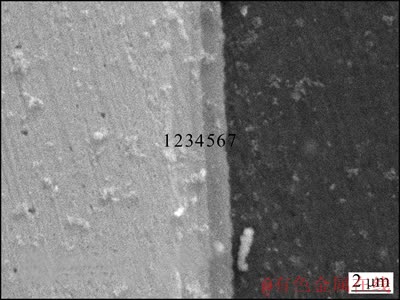

根据图1(b),(d),(f)和(h)所示的EDX线扫描结果,选择400 ℃退火样品检测界面区域局部点的化学成分,检测方法如图2所示,成分结果列于表2。图2显示,在铜/铝复合界面区域元素扩散明显,而且过渡层中的铜、铝原子满足一定的比例关系,结合相图推测可能存在的物相类型于表2所列。

图2 400 ℃退火20 min的铜/铝复合板界面SEM像(二次电子模式)及EDX局部点成分分析

Fig. 2 SEM image and EDX local point analysis in interfacial zone of Cu/Al clad sheet annealed at 400 ℃ for 20 min

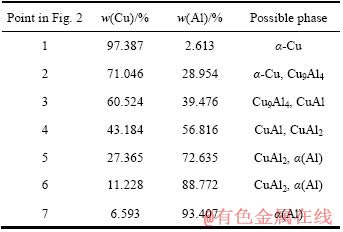

表2 铜/铝复合板界面化学成分及可能存在的物相

Table 2 Chemical compositions and possible phases in interfacial zones of Cu/Al clad sheet

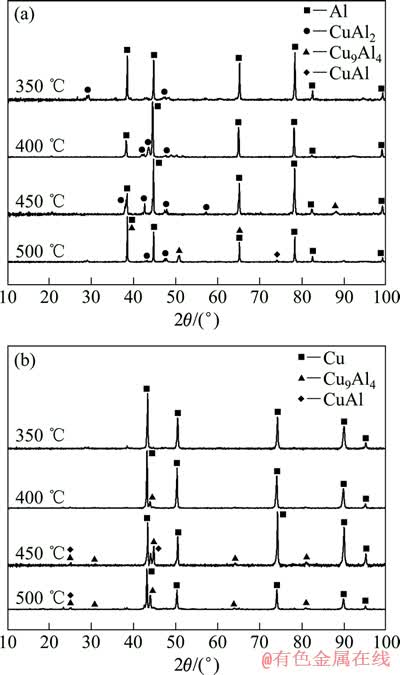

图3 不同退火温度下铜/铝复合板界面的XRD谱

Fig. 3 XRD patterns of Al side (a) and Cu side (b) at interface of Cu/Al clad sheet annealed at different temperatures.

图3所示为铜/铝复合板撕裂界面的XRD物相分析结果。由图3可知,界面区域生成的化合物种类和含量随着退火温度的升高而增多。温度为350 ℃时,只在铝基体上检测到少量CuAl2相;温度增至400 ℃时,铝基体上CuAl2相的含量小幅增加,铜基体表面出现了Cu9Al4相;在450 ℃时,铝基体上CuAl2相含量明显增加,且生成少量Cu9Al4,而铜基体有新相CuAl生成;温度升至500 ℃时,铝基体表面的化合物按含量由高到低的顺序为Cu9Al4、CuAl2、CuAl相,在铜基体上Cu9Al4含量大幅增加,CuAl含量却下降。

根据XRD结果可知,在界面处最先形成的金属间化合物为CuAl2,然后生成Cu9Al4,最后生成CuAl,这取决于化合物的生成热力学条件,同时与铜、铝原子的扩散量有关。如线扫描结果所示,铜原子的扩散量在不同退火温度条件下都明显高于铝原子的扩散量,因此铜扩散至铝基体中先形成铝固溶体,当热力学条件满足时,生成铝含量高的金属间化合物,随着扩散的继续进行,铜基体中生成铝含量低的金属间化合物[14]。铜/铝复合板沿界面的撕裂位置位于各种金属间化合物层之间,证明了这些硬脆性化合物对界面结合的破坏作用。

2.3 退火温度对界面力学性能的影响

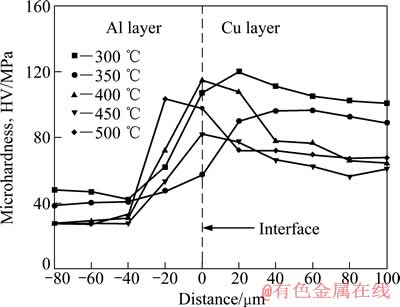

图4所示为铜/铝复合板垂直界面方向上的显微硬度分布。可见,随着退火温度的升高,基体金属的显微硬度逐渐下降,在高温450 ℃之后保持稳定。在300 ℃退火,复合界面尚未得到完全回复软化,硬度较高。温度升至350 ℃,界面金属回复明显,硬度很低。400 ℃时,复合界面的硬度最高,表明此时界面生成了金属间化合物。在450 ℃退火,复合板界面显微硬度较低,这可归因于显著的退火软化作用减弱了硬脆性金属间化合物的破坏作用。在500 ℃退火,界面显微硬度增高,而且铝基体靠近界面的区域显微硬度升高明显,这是大量的CuAl2相生成的缘故。由图4可知,退火温度升高使得复合板界面区域的显微硬度峰值向铝基体侧偏移。根据金属物理和扩散理论[15],铜原子向铝基体的扩散速度较快,在铝基体一侧逐渐生成CuAl2等金属间化合物而导致硬度升高。由以上分析可知,复合界面的显微硬度由退火软化和金属间化合物硬化共同影响,因此,要选择合适的退火温度保证界面性能。

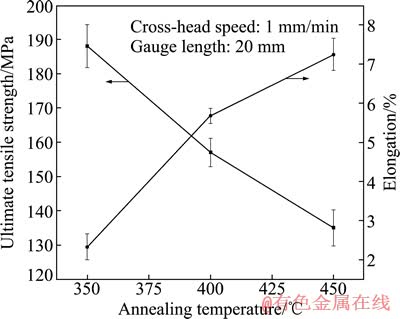

图5所示为退火温度对铜/铝复合板室温拉伸性能的影响。由图5可知,随着退火温度升高,铜/铝复合板抗拉强度逐渐降低,而最大伸长率显著增大。由于高温退火使复合板的加工硬化和残余应力得到有效释放,同时造成金属晶粒长大,因此,复合板的强度降低,塑性提高。根据室温拉伸测试结果,400 ℃退火能保证复合板获得良好的拉伸性能。

图4 不同退火温度时铜/铝复合板界面区的维氏显微硬度

Fig. 4 Vickers microhardness in interfacial zone of Cu/Al clad sheet annealed at different temperatures

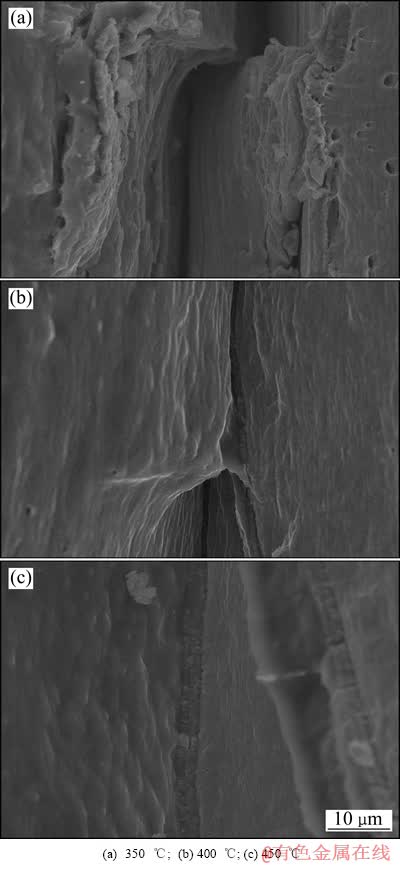

图6所示为室温拉伸试样断口的SEM像。由图6可知,350 ℃退火时,复合界面无过渡层组织存在,且界面撕裂严重。400 ℃退火时,复合界面拉伸断口无明显破坏,并生成厚度1 μm左右的过渡层组织。450 ℃退火时,复合板整体塑性得到提高,因此,复合界面拉伸断口无撕裂现象,但急剧生成了厚度为4 μm的过渡层组织。过渡层厚度与图1中显示厚度存在差别,可能与拉伸变形以及观察角度有关。

图5 铜/铝复合板的室温拉伸断裂强度与伸长率

Fig. 5 Ultimate tensile strength and elongation of Cu/Al clad sheet according to tension tests at ambient temperature

图6 不同退火温度下铜/铝复合板界面区域的拉伸断口SEM像

Fig. 6 SEM images of tensile fracture at interface of Cu/Al clad sheet annealed at different temperatures

在拉伸过程中,复合界面对铜、铝两种基体产生协调变形作用,复合板整体发生拉伸变形。在低温退火时,界面扩散微弱,且铜、铝基体性能差异很大,在拉伸过程中变形不一致,导致复合界面开裂。退火温度越高,界面层越厚,且高温退火使铜、铝基体实现完全回复,因此,复合界面拉伸性能得到改善。

由于金属间化合物在室温条件下表现为硬脆相,对复合界面产生破坏作用,导致复合板的成形加工性能急剧下降[16],因此,在制备过程中需要控制工艺参数,避免在复合界面生成有害的金属间化合物。

3 结论

1) 异步轧制铜/铝复合板经400、450和500 ℃退火20 min后,复合界面扩散层厚度分别约为3、5和10 μm。

2) XRD物相分析表明,经300~500 ℃退火时,在铜/铝复合板界面扩散层中依次形成CuAl2、Cu9Al4和CuAl金属间化合物。400 ℃退火时在复合界面形成少量CuAl2和Cu9Al4相。

3) 显微硬度和室温拉伸实验结果表明,高温退火利于复合板塑性的提高,但界面会生成金属间化合 物。拉伸断口组织显示,合适厚度的界面扩散层能改善界面结合性能。

4) 显微组织和力学测试结果表明,异步轧制铜/铝复合板选择在400 ℃退火20 min能获得最佳的界面组织和力学性能。

REFERENCES

[1] TSENG H C, HUNG C H, HUANG C C. An analysis of the formability of aluminum/copper clad metals with different thicknesses by the finite element method and experiment[J]. International Journal of Advanced Manufacturing Technology, 2010, 49(9/12): 1029-1036.

[2] SASAKI T T, MORRIS R A, THOMPSON G B, SYARIF Y, FOX D. Formation of ultra-fine copper grains in copper-clad aluminum wire[J]. Scripta Materialia, 2010, 63(5): 488-491.

[3] 顾文桂. 铜铝固相轧制复合的界面组成[J]. 中国有色金属学报, 1996, 6(1): 79-83.

GU Wen-gui. Diffusion layer morphology of solid state rolled copper-aluminum composite[J]. The Chinese Journal of Nonferrous Metals, 1996, 6(1): 79-83.

[4] CHEN C Y, CHEN H L, HWANG W S. Influence of interfacial structure development on the fracture mechanism and bond strength of aluminum/copper bimetal plate[J]. Materials Transactions, 2006, 47(4): 1232-1239.

[5] SHENG L Y,YANG F,XI T F,LAI C,YE H Q. Influence of heat treatment on interface of Cu/Al bimetal composite fabricated by cold rolling[J]. Composites B: Engineering, 2011, 42(6): 1468-1473.

[6] GUO Y J, QIAO G J, JIAN W Z, ZHI X H. Microstructure and tensile behavior of Cu-Al multi-layered composites prepared by plasma activated sintering[J]. Materials Science and Engineering A, 2010, 527: 5234-5240.

[7] JAMAATI R, TOROGHINEJAD M R. Cold roll bonding bond strengths: review[J]. Materials Science and Technology, 2011, 27(7): 1101-1108.

[8] LI X B, ZU G Y, DING M M, MU Y L, WANG P. Interfacial microstructure and mechanical properties of Cu/Al clad sheet fabricated by asymmetrical roll bonding and annealing[J]. Materials Science and Engineering A, 2011, 529: 485-491.

[9] PAN D, GAO K, YU J. Cold roll bonding of bimetallic sheets and strips[J]. Materials Science and Technology, 1989, 5(9): 934-939.

[10] ABBASI M, KARIMI T A, SALEHI M T. Growth rate of intermetallic compounds in Al/Cu bimetal produced by cold roll welding process[J]. Journal of Alloys and Compounds, 2001, 319(1/2): 233-241.

[11] ZUO F Q, JIANG J H, SHAN A D, FANG J M, ZHANG X Y. Shear deformation and grain refinement in pure Al by asymmetric rolling[J]. Transactions of Nonferrous Metals Society of China, 2008, 18(4): 774-777.

[12] HENESS G, WUHRER R, YEUNG W Y. Interfacial strength development of roll-bonded aluminium/copper metal laminates[J]. Materials Science and Engineering A, 2008, 483/484(s1): s740-s742.

[13] EIZADJOU M, KAZEMI TALACHI A, DANESH MANESH H, SHAKUR SHAHABI H, JANGHORBAN K. Investigation of structure and mechanical properties of multi-layered Al/Cu composite produced by accumulative roll bonding (ARB) process[J]. Composites Science and Technology, 2008, 68(9): 2003-2009.

[14] GUO Y J, LIU G W, JIN H Y, SHI Z Q, QIAO G J. Intermetallic phase formation in diffusion-bonded Cu/Al laminates[J]. Journal of Materials Science, 2011, 46(8): 2467-2473.

[15] SMALLMAN R E, NGAN A. Physical metallurgy and advanced materials[M]. Oxford: Butterworth-Heinemann, 2007.

[16] 刘洪伟, 郭 成. 铜铝复层板成形极限图研究[J]. 材料科学与工艺, 2010, 18(4): 560-563.

LIU Hong-wei, GUO Cheng. Forming limit diagram of Cu-Al clad[J]. Materials Science and Technology, 2010, 18(4): 560-563.

(编辑 陈卫萍)

基金项目:国家自然科学基金资助项目(50971038,51174058);中央高校基本科研业务费资助项目(100402003)

收稿日期:2012-03-27;修订日期:2012-07-10

通信作者:祖国胤,副教授,博士;电话:024 83686462;E mail:zugy@smm.neu.edu.cn