制备方法对ZK60变形镁合金组织与变形能力的影响

来源期刊:中国有色金属学报(英文版)2014年第z1期

论文作者:Ki Ho JUNG Yong Bae KIM Geun An LEE Yuzheng ZHANG Byungmin AHN

文章页码:68 - 74

关键词:镁; 连续铸造; 可加工性; EBSD

Key words:magnesium; continuous casting; workability; electron backscatter diffraction (EBSD)

摘 要:通过微观组织和固有内在缺陷观察,研究了加工方法对ZK60A变形镁合金加工性能的影响。利用半连续铸造、半连续铸造后挤压及模具铸造方法制备了3种合金,并在2种变形速率下进行高温压缩,研究合金的变形能力。利用EBSD和TEM研究了合金的晶粒结构,采用X 射线扫描仪检测了合金的内部缺陷。与传统模具铸造合金相比,半连续铸造合金具有更好的变形能力,且后续的挤压工艺可以提高合金的变形能力。

Abstract: The effects of fabrication processing methods on the workability of Mg-Zn-Zr wrought magnesium alloy (ZK60A) were investigated based on the microstructure and inherent internal defects. Three different billets, semi-continuously cast, semi-continuously cast and subsequently extruded, and die-cast, were fabricated and uniaxially compressed at elevated temperatures and two different strain rates to determine the deformation capabilities. The grain structure of the billets was investigated using electron backscatter diffraction (EBSD) and transmission electron microscopy (TEM). The internal defects were inspected by an X-ray scanner. The enhanced deformability was observed in semi-continuously cast billet compared to the one fabricated by conventional die-casting, and the subsequent extrusion further improved the deformability.

Trans. Nonferrous Met. Soc. China 24(2014) s68-s74

Ki Ho JUNG1, Yong Bae KIM1, Geun An LEE1, Yu-zheng ZHANG2, Byungmin AHN3

1. Metal Forming Technology R&D Group, Korea Institute of Industrial Technology, Incheon 406-840, Korea;

2. Department of Chemical Engineering and Materials Science, University of Southern California, Los Angeles, CA 90089, USA;

3. Department of Energy Systems Research, Ajou University, Suwon 443-749, Korea

Received 18 June 2013; accepted 29 November 2013

Abstract: The effects of fabrication processing methods on the workability of Mg-Zn-Zr wrought magnesium alloy (ZK60A) were investigated based on the microstructure and inherent internal defects. Three different billets, semi-continuously cast, semi-continuously cast and subsequently extruded, and die-cast, were fabricated and uniaxially compressed at elevated temperatures and two different strain rates to determine the deformation capabilities. The grain structure of the billets was investigated using electron backscatter diffraction (EBSD) and transmission electron microscopy (TEM). The internal defects were inspected by an X-ray scanner. The enhanced deformability was observed in semi-continuously cast billet compared to the one fabricated by conventional die-casting, and the subsequent extrusion further improved the deformability.

Key words: magnesium; continuous casting; workability; electron backscatter diffraction (EBSD)

1 Introduction

Magnesium alloys are well known as one of the lightest structural metals with high specific strength and stiffness. Because of the lower density of magnesium alloys, they have recently received great attentions from automobile manufacturers for reducing both weight and fuel consumption [1-2]. Most of the conventional production methods, such as casting and forging, are applicable to the fabrication and processing of magnesium alloys. For example, motor wheels and aerospace parts requiring high mechanical performance are forged with pre-extruded magnesium bars. However, forging of magnesium alloy is not easy due to its limited ductility at room temperature caused by the HCP structure. Magnesium alloy exhibits much higher workability at moderately elevated temperatures than at room temperature, like other alloys with HCP structure, so that warm or hot forming is more favorable rather than cold forming. There have been several studies on the effects of process conditions, such as the aspect ratio of preform, the temperature of workpiece, and the compressing speed, on the formability of various magnesium alloys [3].

Regarding the preparation of materials for forging, KANG and OSTROM [4] compared the mechanical behaviors of AM60 alloys, high pressure die-cast by two different manufacturers, and the authors mentioned that the mechanical properties were affected by the different die casting conditions depending on the manufacturers. CHINO et al [5] reported that the critical temperature of the surface cracking for AZ31 alloy in open-die forging was decreased from 573 K to 423 K when the billet was previously extruded causing grain refinement. MATSUMOTO and OSAKADA [6] reported that the ductility of AZ31B alloy can be improved by using a servo press, which is capable to decelerate compressive strain rate to induce relatively uniform temperature distribution. SKUBISZ et al [7] carried out a closed die forging with as-cast AZ31 and as-forged AZ61 alloys at different temperatures and aspect ratios of the specimen. According to their experimental results, a successful forging became feasible when the specimen temperature was at least 200 °C. XIA et al [8] investigated the workability of AZ80 alloy under various combinations of temperature and strain rate by compression, and they observed the effect of the process conditions. They concluded that the critical damage value varied with the given process conditions, and the variation of the critical damage value was more dependent on the strain rate.

High-zinc alloy, ZK60, is a good candidate to fulfill the high strength requirement of the final products [9-11]. Related to workability of ZK60 alloy, CHEN et al [12] compared the mechanical properties of the ZK60 alloy sheets produced by conventional casting and twin roll casting (TRC), and carried out warm rolling with those sheets. According to their investigation, twin roll casting showed beneficial effects on microstructure of ZK60 alloy, such as reducing segregation, improving inclusion size distribution and microstructural homogeneity, and warm rolling of ZK60 alloy, fabricated by TRC, induced high strength and low elongation since no obvious dynamic recrystallization was observed. ORLOV et al [13] reported an improvement in mechanical property of ZK60 alloy by integrating extrusion and ECAP processes. They mentioned that the combination of strength and ductility cannot be fully explained by grain refinement alone, and indicated the contribution of the orientation of the crystallites. OGAWA et al [14] and SITDIKOV and KAIBYSHEV [15] conducted an upsettability test with magnesium alloy ZK60 in a temperature range of 100-400 °C and high compression speed of 300 mm/s as well as backward extrusion at temperatures from 100 °C to 300 °C and compression speed of 200 mm/s without lubrication. They concluded that Cockcroft’s criterion was not adequate to predict the cracking of ZK60 magnesium alloy. However, magnesium alloys are seldom hammer forged or forged in a rapid-action press because they are easy to rupture unless exacting procedures are used [3]. Thus, an investigation on the effect of casting methods and the following processes on the workability of bulk material was rather limited although it is critical for the design of forging processes. In the present study, the ZK60A billets, in conditions of die cast, semi-continuously cast and subsequently forward-extruded with large deformation, are compared in terms of their workability.

2 Experimental

Two different types of ZK60A billets were produced by semi-continuous casting and die casting, respectively. Additionally, one of the semi-continuous cast billets was forward extruded with an extrusion ratio of 10 at about 300 °C, and the lowest extrusion speed of the machine was applied to prevent cracking. Each billet was machined off to be 10 mm in diameter and 15 mm in height for the hot compression tests. To avoid adhesion of the material and reduce friction created at the interface, MoS2 lubricant was sprayed on the surface of the individual specimen before the compression test, and the specimens were placed on the lower platen after the lubricant was completely dried.

For compression tests at elevated temperatures, a heating chamber combined with a universal testing machine (MTS 810 system) was used, and two thermocouples were inserted into the upper and lower platens to measure the temperature of the platens and control the temperature inside the chamber. Each specimen was kept for 15 min to be heated up to the same temperature as the platens, 280, 300, 320, 360, and 400 °C. Then compressive force was applied at engineering strain rates of 0.01 and 0.1 s-1.

For EBSD analysis, both materials were prepared using a precision ion beam cross-section polisher (JEOL CP SM-09010). The grain size and crystalline orientation were characterized using EBSD (Hikari XP, EDAX) in FE-SEM (JEOL JSM-7001F). The step sizes of EBSD map were in the range of 1-2 μm. After the raw orientation maps were collected, standard clean-up procedures were conducted to minimize the incorrectly indexed pixels and background noise. For TEM analysis, samples from bulk material were prepared by electrolytic jet polishing and investigated using FE-TEM (FEI Tecnai G2).

Cylindrical specimens extracted from the billets were scanned by an industrial X-ray inspection system (HWM Rayscan 250EX) with a resolution of 50 μm to observe possible inherent defects inside.

3 Results and discussion

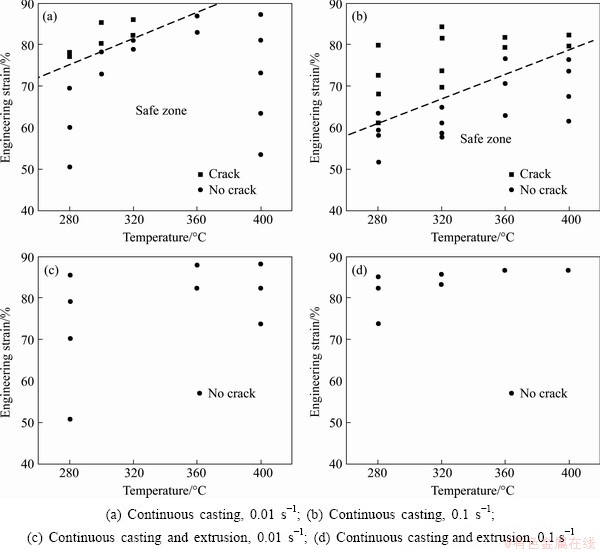

Figure 1 shows the results of compression tests of the semi-continuously cast and subsequently extruded specimens depending on fracture occurrence are depicted. As shown in Fig. 1(a), the workability of the semi-continuously cast material decreased by increasing strain rate. On the other hand, the workability increased as the temperature increased. By comparing Fig. 1(b) with Fig. 1(a), it is obvious that the workability of the subsequently extruded material was remarkably improved after the forward extrusion. The specimens were not fractured up to height reduction more than 85% regardless of the applied strain rates in this work.

Depending on the applied strain rates, the improvement of workability at the relatively higher strain rate of 0.1 s-1 was more outstanding. The workability was not enhanced to the level of the extruded material by increasing temperature at the relatively higher strain rate. Thus, the effect of forging temperature on the workability of the material was rather limited when strain rate was increased at the temperatures applied in this work. On the other hand, it was found that the acceptable degree of deformation of the material increased up to the level of the extruded material when the workpiece temperature was higher than 360 °C under the relatively lower strain rate of 0.01 s-1. This finding is consistent with the evaluated forgeability of semi- continuously cast AZ70 alloy at strain rate of 0.01 s-1 [14].

Based on these findings, the extrusion process to improve the workability can be skipped by an appropriate control of forging temperature when a relatively slow deformation speed is applied unless the strength of the forged product is critical. However, the strength of the forged material should be considered at the stage of process design since the strength is also subjected to forging temperature.

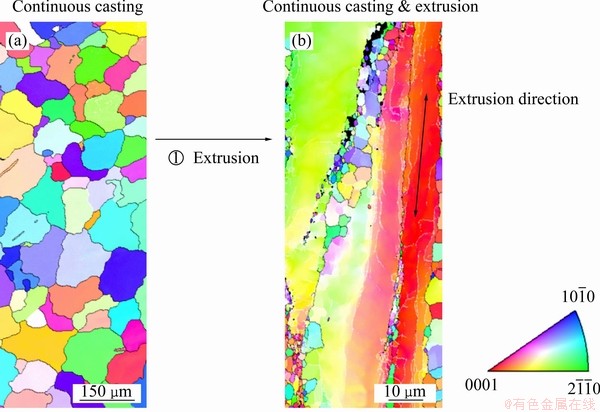

According to the EBSD result in Fig. 2, the subsequent forward extrusion reduced the average grain size up to 96.7%, from 76.6 μm to 2.5 μm. The grain structure of the semi-continuously cast material appeared to have narrow size distribution, random orientation, and equiaxed shape, as shown in Fig. 2(a). However, the material after the forward extrusion has two distinct grain structures; (1) primarily coarse grains elongated along the extrusion direction and (2) equiaxed ultrafine grains, as shown in Fig. 2(b). Preferred textures along the extrusion direction were [0001] or  , as indicated in Fig. 2(b).

, as indicated in Fig. 2(b).

Some of the initial grains were refined by large plastic deformation based on an increase in the low angle grain boundary fraction after the forward extrusion. Ultrafine grains were also observed in between the elongated grains and it was noticeable that dynamic recrystallization occurred during the forward extrusion since their orientations were different from the elongated ones and close to random distribution. Thus, it can be explained that the decrease in the average grain size was caused by both grain refinement due to large deformation and dynamic recrystallization during the forward extrusion at elevated temperature. Figure 3 shows a bright field TEM micrograph of refined grains down to several microns with significant amount of dislocations induced by the extrusion. Some high-angle grain boundaries and low-angle sub-grain boundaries with dislocation entanglements can also be seen. The shape and size distribution of grains opposed to the microstructures of as-received and extruded materials in earlier study [8] while a reduction in the average grain size was similarly observed. Therefore, it is obvious that the average grain size is the more important factor affecting the workability rather than the morphology of grains.

Fig. 1 Comparison of workability of semi-continuously cast and subsequently extruded ZK60A under different strain rates

Fig. 2 EBSD inverse pole figure maps of semi-continuously cast (a) and subsequently extruded (b) ZK60A

Fig. 3 Bright field TEM micrograph of semi-continuously cast and subsequently extruded ZK60A

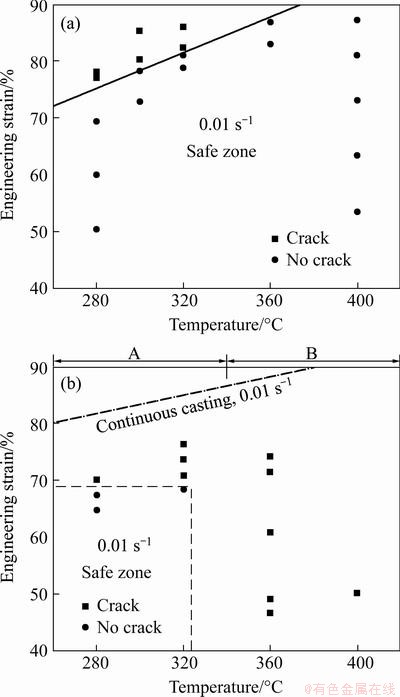

In Fig. 4, the workability of the semi-continuously cast billet and die cast one was compared. It was clearly shown that the workability of the die cast one was relatively inferior to the semi-continuously cast one. Only 50% or so in height reduction was the most acceptable level of deformation. Especially, the effect of temperature on the workability was negligible for the die cast material whereas it was notable for the semi- continuously cast one.

Fig. 4 Determined cracking conditions of semi-continuously cast (a) and die cast (b) ZK60A alloy

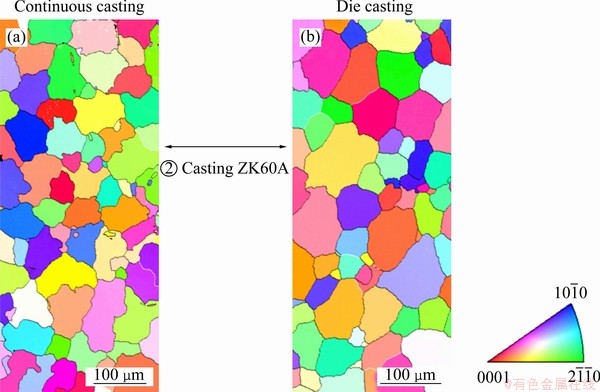

Figure 5 shows the microstructural comparison of continuously cast and die cast materials. The shapes of grains in both materials were primarily randomly oriented equiaxed grains without a preferred texture. The fractions of the high-angle grain boundary were larger than 95% for both materials. The average grain sizes were 80.4 μm and 55.2 μm for the semi-continuously cast and die cast alloys, respectively. In general, smaller grain size tends to improve the workability at elevated temperature because of the superplastic behavior of magnesium alloy. However, the die cast material with smaller grains exhibited poorer workability than the semi-continuously cast one. Therefore, a different approach to explain the inferior workability of the die cast material must be considered. Since the critical strain in cracking occurrence of the die cast billet was insensitive to the temperature variation, an approach to understand the reduction in workability in the viewpoint of internal defects was chosen. To investigate the inherent defects of the as-received billets, those materials were inspected by X-ray, and the less dense area than the surrounding appeared darker in the X-ray inspection results. As shown in Fig. 6, relatively less dense area was locally observed at the central region of the semi-continuously cast billet. On the other hand, an inherent defect of 1.7 mm in length and 1.1 mm in height was clearly observed in the die cast one. The defect was deduced to be a void since the brightness of the defect was relatively lower than the neighbors and to be originated from shrinkage cavities due to insufficient metal feeding during solidification.

It is obvious that the void deteriorated the workability at 280 and 320 °C within the temperature range A in Fig. 4(b). The cross-sections of selected areas from both semi-continuously cast and die cast materials were investigated as shown in FE-SEM micrographs at the lower part of Fig. 6. The amount of voids in the semi-continuous cast material was negligible, however, an amount of void clusters were observed in the die cast material. It is obvious that air was entrapped during feeding the molten alloy, meaning that the open surface in voids contained magnesium oxide. The workability must be deteriorated because of embrittlement due to the magnesium oxide.

According to Ref. [3], the forgeablity of magnesium alloys depends on three factors, including solidus temperature of the alloy, the deformation rate, and the grain size. Magnesium alloys are often forged within 55 °C of the solidus temperature. An exception is the high-zinc alloy ZK60A, which sometimes contains small amounts of the low melting eutectic that forms during ingot solidification. Forging of this alloy above about 315 °C, the melting point of eutectic, can cause severe rupturing due to micro-voids. When zinc is present, a divorced eutectic is observed with particles of the phase dispersed in the matrix. If little or no precipitate is formed in the immediate vicinity of the voids, the voids are definitely attributable to micro-porosity. This problem can be minimized by holding the cast ingot for extended periods at elevated temperature to re-dissolve the eutectic and to restore the solidus temperature. However, a further investigation is needed to verify the effect of low melting eutectic on the workability above 320 °C for semi-continuously cast magnesium alloy.

Fig. 5 EBSD inverse pole figure maps of semi-continuously cast (a) and die cast (b) ZK60A alloy

Fig. 6 X-ray tomography and cross-sectional FE-SEM micrographs of two billets fabricated by semi-continuous casting (a) and die casting (b) [16]

4 Conclusions

The deformability of the semi-continuously cast and subsequently extruded ZK60A alloy is remarkably improved after the forward extrusion due to the dynamic recrystallization and relatively smaller grains refined by extrusion. It is also obviously concluded that the average grain size is a dominant factor affecting the workability rather than the grain morphology, such as elongated or equiaxed grain shapes. The workability of the die-cast material is relatively inferior to the semi-continuously cast one. Since the critical strain in cracking occurrence of the die-cast billet was insensitive to the temperature variation, it is reasonable to conclude that the internal defects, void and magnesium oxide formation cause a decrease in the workability of the die-cast billet.

References

[1] MORDIKE B L, EBERT T. Magnesium properties-applications- potential [J]. Materials Science and Engineering A, 2001, 302(1): 37-45.

[2] LUO A A. Magnesium: Current and potential automotive applications [J]. Journal of the Minerals and Materials Society, 2002, 54(2): 42-48.

[3] AVEDESIAN M M, BAKER H. ASM specialty handbook: Magnesium and magnesium alloys [M]. Ohio: ASM International, 1999: 85-89.

[4] KANG H T, OSTROM T. Mechanical behavior of cast and forged magnesium alloys and their microstructures [J]. Materials Science and Engineering A, 2008, 490(1/2): 52-56.

[5] CHINO Y, MABUCHI M, SHIMOJIMA K, YAMADA Y, WEN C, MIWA M, NAKAMURA M, ASAHINA T, HIGASHI K, AIZAWA T. Forging characteristics of AZ31 Mg alloy [J]. Materials Transactions, 2001, 42(3): 414-417.

[6] MATSUMOTO R, OSAKADA K. Ductility of a magnesium alloy in warm forging with controlled forming speed using a CNC servo press [J]. Journal of Materials Processing Technology, 2010, 210: 2029-2035.

[7] SKUBISZ P, SINCZAK J, BENDNAREK S. Forgeability of Mg-Al-Zn magnesium alloys in hot and warm closed die forging [J]. Journal of Materials Processing Technology, 2006, 177: 210-213.

[8] XIA Yu-feng, QUAN Guo-zheng, ZHOU Jie. Effects of temperature and strain rate on critical damage value of AZ80 magnesium alloy [J]. Transactions of Nonferrous Metals Society of China, 2010, 20: 580-583.

[9] ZHANG Z, COUTURE A. An investigation on the properties of Mg-Zn-Al alloy [J]. Scripta Materialia, 1998, 39(1): 45-53.

[10] HONO K, MENDIS C L, SASAKI T T, OH-ISHI K. Towards the development of heat-treatable high-strength wrought Mg alloys [J]. Scripta Materialia, 2010, 63(4): 710-715.

[11] WANG C Y, WANG X J, CHANG H, WU K, ZHENG M Y. Processing maps for hot working of ZK60 magnesium alloy [J]. Materials Science and Engineering A, 2007, 464(1/2): 52-58.

[12] CHEN H, YU H, KANG S B, MING G, JIN Y. Effect of forming process on microstructure and mechanical properties of ZK60 alloy sheet [J]. Rare Metal Materials and Engineering, 2011, 40(10): 1708-1712.

[13] ORLOV D, RAAB G, LAMARK T T, POPOV M, ESTRIN Y. Improvement of mechanical properties of magnesium alloy ZK60 by integrated extrusion and equal channel angular pressing [J]. Acta Materialia, 2011, 59: 375-385.

[14] OGAWA N, SHIOMI M, OSAKADA K. Forming limit of magnesium alloy at elevated temperatures for precision forging [J]. International Journal of Machine Tools & Manufacture, 2002, 42: 607-614.

[15] SITDIKOV O, KAIBYSHEV R. Dynamic recrystallization in pure magnesium [J]. Materials Transactions, 2001, 42(9): 1928-1937.

[16] JUNG K H, LEE S, KIM Y B, AHN B, KIM E Z, LEE G A. Assessment of ZK60A magnesium billets for forging depending on casting methods by upsetting and tomography [J]. Journal of Mechanical Science and Technology, 2013, 27(10): 3149-3153.

Ki Ho JUNG1, Yong Bae KIM1, Geun An LEE1, Yuzheng ZHANG2, Byungmin AHN3

1. Metal Forming Technology R&D Group, Korea Institute of Industrial Technology, Incheon 406-840, Korea;

2. Department of Chemical Engineering and Materials Science, University of Southern California, Los Angeles, CA 90089, USA;

3. Department of Energy Systems Research, Ajou University, Suwon 443-749, Korea

摘 要:通过微观组织和固有内在缺陷观察,研究了加工方法对ZK60A变形镁合金加工性能的影响。利用半连续铸造、半连续铸造后挤压及模具铸造方法制备了3种合金,并在2种变形速率下进行高温压缩,研究合金的变形能力。利用EBSD和TEM研究了合金的晶粒结构,采用X 射线扫描仪检测了合金的内部缺陷。与传统模具铸造合金相比,半连续铸造合金具有更好的变形能力,且后续的挤压工艺可以提高合金的变形能力。

关键词:镁; 连续铸造; 可加工性; EBSD

(Edited by Yun-bin HE)

Foundation item: Project (B551179-11-02-00) supported by a Grant from the Co-operative Research Project Funded by the Ministry of Trade, Industry & Energy, Korea

Corresponding author: Byungmin AHN, Tel: +82-31-219-3531; Fax: +82-31-219-1613; E-mail: byungmin@ajou.ac.kr

DOI: 10.1016/S1003-6326(14)63290-8