异步轧制速比对高纯铝箔织构转变的影响

黄 涛1, 2, 曲家惠1, 高 明2, 王 福1, 左 良1

(1. 东北大学 材料与冶金学院, 沈阳 110004;

2. 沈阳师范大学 物理科学与技术学院, 沈阳 110034)

摘 要: 采用不同速比对高纯铝板进行异步冷轧, 并将冷轧样品进行不同温度和时间的再结晶退火, 研究异步轧制速比对高纯铝箔织构转变的影响。 结果表明: 高速比的异步轧制在样品中产生较强的旋转立方织构和{102}〈uvw〉织构, 异步轧制退火后的高纯铝箔样品具有很强的立方织构{001}〈100〉。 立方织构的体积分数与速比和温度有关: 当速比为1.06时, 温度升至300℃开始出现立方织构; 当速比为1.17时, 温度升到200℃就出现立方织构。 立方织构组分的形成存在一个阈值温度, 此温度与异步轧制的速比成反比, 随着速比的增加, 阈值温度逐渐降低, 这与异步轧制提高高纯铝箔的形变储能有关。 异步轧制有利于在低温时形成较强的立方{001}〈100〉织构。

关键词: 异步轧制; 高纯铝箔; 织构; 速比 中图分类号: TG146.2

文献标识码: A

Effect of speed ratio on textures transformation in cross shear rolled high purity aluminum foils

HUANG Tao1, 2, QU Jia-hui1, GAO Ming2, WANG Fu1, ZUO Liang1

(1. School of Materials and Metallurgy, Northeastern University, Shenyang 110004, China;

2. College of Physical Science and Technology, Shenyang Normal University,Shenyang 110034, China)

Abstract: Hot rolled high purity aluminum sheet was cold rolled by cross shear rolling with different roll mismatch speed ratio. Then, the specimens were annealed by different processes. The effects of speed ratio on texture transformation were analyzed. The results show that the strong rotated cube texture components {001}〈110〉 and {102}〈uvw〉 form and develop in high roll mismatch speed ratio cross shear rolling specimen, and there are strong cube textures in the annealed specimen. The volume fraction of the cube texture relates to the speed ratio and the temperature. When the temperature increases to 300℃, the cube texture appears at the speed ratio of 1.06. When the temperature increases to 200℃, it appears at the speed ratio of 1.17. During the annealing of cross shear rolling specimen, there is a temperature threshold value for the formation and development of cube orientated grain, the value is inversely proportional to that of speed ratio. With the increase of the roll mismatch speed ratio, the threshold value decreases. The effects are attributed to an increase of deformation-stored energy. The cross shear rolling speeds up the nucleation and grain-growth of cube orientated grain at lower temperature.

Key words: cross shear rolling; high purity aluminum foil; texture; speed ratio

高纯铝箔主要用作铝电解电容器的阳极材料。 长期以来, 材料科学工作者不断地致力于高纯铝箔微取向流变行为的研究[1- 4], 以期获得较高的立方织构{001}〈100〉。 尤其是近几年, 在这一领域取得了很大的进展[ 5-7] , 我国生产的高纯铝箔在性能上也接近世界先进水平。 但是, 这些工作都是在同步轧制条件下进行的。 迄今, 对异步轧制高纯铝箔的研究报导较少。

东北大学把异步轧制成功应用于结构材料之后, 又开展了功能材料取向硅钢和高纯铝箔异步轧制的研究工作。 吕爱强等[8]在研究了异步轧制下高纯铝箔冷轧织构的基础上, 进一步研究了异步轧制下速比对高纯铝箔织构转变的影响。

异步轧制(cross shear rolling, CSR)是指上、 下工作辊线速度不等的一种轧制方法。 具有轧制压力小, 产品精度高, 经过较少道次进行大压下量轧制等优点, 特别适于轧制薄带和超薄带, 该方法也可用于高纯铝箔的工业生产。 因此, 探讨异步轧制速比对高纯铝箔织构转变的影响, 不仅具有理论意义, 而且具有广阔的应用前景。

1 实验

采用西南铝加工厂提供的99.99%的高纯铝热轧板, 厚度为7.5mm, 化学成分为Fe 0.0012, Si 0.0008, Cu 0.0033, 其余为铝(质量分数, %)。 将铝板分别按1.06、 1.17和1.28的速比经4个道次异步轧制成形变量为98.7%, 厚度为100μm的样品。 道次形变量依次为60%、 66.7%、 70%和66.7%。 从与慢速辊侧接触的表面开始, 沿慢速辊侧以20μm为单位依次磨去各层, 得厚度(d)为20、 40、 60、 80和100μm的各面。 退火样品分两组, 一组试样从室温(约20℃)以10℃/min 的升温速度, 随炉加热到 400和500℃, 分别保温2h, 随后出炉空冷; 另一组试样仍随炉加热, 当温度升到100、 200、 300、 400和500℃时, 立刻在冷水中淬火, 将样品的高温组织保存下来, 用于测量。

对冷轧及退火样品分别进行织构测定, 织构测定在东北大学测试中心D/max-ⅢA型X射线衍射仪及B-7半自动织构测角台上扫测完成, 并按Schulz反射法进行。 采用CuKα辐射, 管电压为35kV, 管电流为20mA, 发散狭缝DS 2°+2mm限高光阑, 防散射狭缝SS为5mm, 接受狭缝RS为5mm。 测量样品的{111}、 {200}、 {220}的3张不完整极图, 扫测按同心圆步进方式进行, α从0°到70°, β从0°到360°扫测, 测量步长为 5°, 由计算机采集数据。 ODF分析采用东北大学材料研究所的“二步法”定量织构分析软件系统[9]进行, 结果用恒ψ-ODF截面图表示。

在R.J.Roe提出的取向分布函数里, 一组(ψ, θ, φ)表达晶粒的一种取向。 ψ、 θ、 φ为晶轴坐标系相对于外观坐标系(轧向、 横向、 轧面法向)的Euler角。 对立方系来说, 一组(ψ, θ, φ)值和相对应的(hkl)[uvw]之间有如下关系:

据此可以求得截面图上极点密度最强区的相应织构组分。

2 结果及讨论

2.1 异步冷轧织构

图1所示为速比为1.28、 形变量为98.7%的冷轧样品慢、 快辊侧的恒ψ-ODF截面图。 由图1可知, 样品中除了常见的S{123}〈634〉织构和C{112}〈111〉织构外, 还出现了旋转立方织构

图1 速比为1.28时慢、快辊侧的恒ψ-ODF截面图

Fig.1 ODFs constant ψ sections of slow(a) and fast(b) roller side with speed ratio of 1.28

{001}〈110〉和{102}〈uvw〉, 且快、 慢辊侧的织构类型和数量明显不同, 尤其在旋转立方织构的含量上存在更大的差异。 慢辊侧强区则集中在S织构、 C织构和旋转立方织构上, 而快辊侧强区则集中在S织构和{102}〈uvw〉织构上。 速比为1.06和1.17的样品亦有类似结果, 且随着速比的增加, 旋转立方织构的体积分数有所增加。

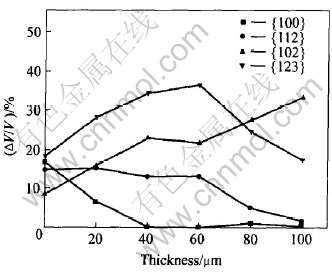

图2所示为速比为1.28时, 主要丝织构体积分数随厚度(d)的变化。 由图2可以看出, 4种织构组分含量呈现规律性的变化, 且随着厚度的增加, {100}和{112}丝织构含量逐渐递减, {102}丝织构含量逐渐递增, 而{123}丝织构以d=60μm面为拐点先增后减。

图2 速比为1.28时{100}、 {112}、 {102}和{123}丝织构体积分数与厚度的关系

Fig.2 Relationship between volume fraction and thickness of {100}, {112}, {102} and{123} fiber with speed ratio of 1.28

异步轧制时, 由于轧辊速度不同, 快速辊侧首先流动, 且存在着很大的剪切变形, 摩擦阻力指向出口; 而慢速辊侧则相反, 与慢速辊侧相接触的金属表面不产生剪切变形, 摩擦阻力指向入口, 这样, 变形区内就形成了所谓的搓轧区。 由于搓轧区的存在, 使变形区内产生不对称形变, 这种不对称的金属流变行为在织构类型和强度上呈现出一种特殊的变化, 且与速比和形变量的大小有关, 不同的织构类型, 因取向差异而有所不同。

异步轧制可看成是由拉伸压缩以及剪切变形迭加而成(见图3), 因此, 异步轧制所产生的织构应是同步轧制产生的织构和纯剪切产生的织构的迭加。 根据文献[2-4], 在剪切变形中除常见铜织构{112}〈111〉外, 还出现旋转立方织构{001}〈110〉, 这与实验结果基本一致, 但文献中并未提到{102}丝织构的出现, 同时, 快、 慢辊侧的旋转立方织构差异较大。 由此说明: 异步轧制中的搓轧区激发更多的滑移系参与滑移和交滑移引起了旋转立方织构的增强和{102}丝织构的出现。 同时, 在不同层面, 剪切力不同, 激发不同的滑移系参与滑移和交滑移, 这是由于在异步轧制下, 高纯铝箔冷轧织构在慢、 快辊侧的类型不同, 且随速比的增加, 织构强度发生变化所致。

图3 异步轧制时搓轧区应力状态的简化模型

Fig.3 Simplified model of stress in rub-rolling region during cross shear rolling

2.2 再结晶织构

图4所示为速比(r)为1.28, 形变量为98.7%, 退火温度为400℃, 退火时间为2h时, 样品的恒ψ-ODF截面图。 由图4可知, 经过退火处理的样品产生了较强的立方织构, 且在此工艺下, 慢、 快辊侧织构类型趋于一致。 速比为1.06和1.17的实验也表明: 当形变量较小时, 慢、 快辊两侧差异较大, 快辊侧的立方织构远远小于慢辊一侧; 当形变量较大时, 慢、 快辊两侧的差异不大, 这种差异也将随着退火时间的进一步延长而趋于消失。

研究表明, 冷轧形变织构直接影响再结晶立方织构的形成和发展, 其中S织构和C织构在退火再结晶时易于转变为立方织构[4, 10]。 由图2可知, 慢辊侧(d=0μm)和快辊侧(d=100μm)S织构的体积分数基本相同, 而慢辊侧的C织构体积分数却高于快辊侧, 故在退火过程中, 慢辊侧的立方织构体积分数普遍高于快辊侧的。 但由于立方晶粒具有形核和生长优势, 随着退火时间的进一步延长, 当立方晶粒尺寸接近铝箔厚度时, 慢、 快辊侧的立方织构数量也趋于一致。 由图2还可见, 慢辊侧的旋转立方织构高于快辊侧, 表明旋转立方织构也有利于再结晶立方织构的加强[11,12]。

由轧面反极图定量计算, 在形变量为98.7%, 退火温度分别为400和500℃, 并保温2h时, 立方织构体积分数随速比的变化如图5所示。 由图5可见, 随着温度的升高, 立方织构体积分数随之升高; 且在相同温度下, 立方织构体积分数随速比

图4 速比为1.28、 退火时间2h和退火温度400℃时慢、快辊侧的恒ψ-ODF截面图

Fig.4 ODFs constant ψ sections of slow(a) and fast(b) roller side under conditions of speed ratio 1.28, annealing time 2h and annealing temperature 400℃

图5 体积分数随速比的变化曲线

Fig.5 Change curves of volume fraction with speed ratio

呈线性增加。 由于在相同的压下量, 在大速比轧制的搓轧区中, 激发更多的滑移系参与滑移和交滑移, 实际变形引起的程度较高, 提供给样品的形变储能较多, 这将有利于再结晶的进行。 图6所示为3种速比样品在退火过程中的显微硬度随温度的变化曲线。 由图6可见, 随着温度的升高, 3种速比样品的显微硬度均降低, 但速比越大, 显微硬度降低得越快, 可见速比对再结晶进程也具有一定的影响。 大速比轧制的样品较易发生再结晶, 且这种差异在低温时表现明显, 当温度较高时, 差异趋于减小, 这表明在再结晶过程中, 速比对再结晶起始阶段的影响最大。

图6 显微硬度随温度的变化曲线

Fig.6 Change curves of microhardness with temperature

2.3 阈值温度

图7所示为速比为1.06、 1.17、 1.28的样品在退火过程中, 立方{001}〈100〉织构组分的体积分数随退火温度的变化曲线。 由图7可见, 当速比r=1.06时, 只有当退火温度升至300℃时, 才开始出现立方织构组分; 而当速比r=1.17时, 温度升至200℃即可出现立方织构组分; 当速比为r=1.28时, 在更低温度下就出现立方织构组分, 且随着退火温度的升高, 立方织构组分迅速增加, 当温度为100℃时, 立方织构的体积分数就已经增加到约60%。 实验结果表明[13], 在退火过程中, 立方织构组分的出现有一个阈值温度, 阈值温度的大小与速比近似成反比, 且速比越大, 立方织构组分出现的温度阈值就越小。

根据Gibbs-Thomson理论, 晶核长大的临界半径为

式中 为各种取向亚晶的平均晶界能; Fd为再结晶驱动力。

为各种取向亚晶的平均晶界能; Fd为再结晶驱动力。

当一亚晶尺寸大于临界半径时, 它将成为再结晶晶核。 当速比较小时, 异步轧制就接近于同步轧制, 且在搓轧区中, 剪应力也较小。 虽然形变储能存在, 在形变带处原子的移动、 无畸变的立方{001}〈100〉织构组分再结晶晶核的形成和长大, 仍需具有一定的能量。 因此, 立方织构组分的形成与发展需要在较高的温度下进行, 该结论在同步轧制方面, 早已被国内、 外从事铝合金织构研究的学者所证实[14]。 但在异步轧制下, 当速比增加时, 搓轧区中的剪应力相应增大, 形变储能也相应增加, 在形变组织中的各种缺陷也相应增多, 给原子的移动提供了有利条件, 进而提高了再结晶驱动力, 导致式(2)确定的晶核长大的临界半径减小, 即异步轧制下的样品发生再结晶所需临界半径比同步轧制时小, 因此, 无畸变的立方{001}〈100〉织构组分的形成与发展, 可在较低的温度下就开始, 且随着速比的增加, 立方织构出现的阈值温度降低。

图7 体积分数随退火温度的变化曲线

Fig.7 Change curves of volume fraction with annealing temperature

由于异步轧制条件下的高纯铝箔微取向流变行为与同步轧制不同, 这种变形模式、 应力状态和能量的传递方式使织构的类型和数量与常规的轧制过程不同[15] 。 研究表明, 异步轧制高纯铝箔在相同的退火工艺制度下, 其立方织构占有率不低于常规轧制; 异步轧制有利于降低高纯铝箔的再结晶温度, 这就为降低能耗、 提高生产效率奠定了基础, 从而也确定了在工业生产中采用异步轧制的可行性。 同时, 在从同步到异步这种变换轧制方式下, 织构差异主要来源于轧制速比的增加。 因此, 分析速比的影响, 不仅可以深化对高纯铝箔织构转变机理的认识, 也有利于确定合理的异步轧制参数, 建立强立方织构高纯铝箔工业生产的技术原型。

3 结论

1) 异步轧制出现旋转立方织构和{102}取向的织构, 且异步轧制下快、 慢辊侧织构类型差异较大。

2) 异步轧制高纯铝箔的退火织构仍为立方织构, 且快、 慢辊侧织构类型趋于一致。 在同样的退火制度下, 速比越大, 立方织构的体积分数越高。

3) 异步轧制高纯铝箔在退火过程中, 立方织构组分的出现存在一个阈值温度, 该温度与异步轧制速比成反比, 且随着速比的增加, 阈值温度降低。

REFERENCES

[1]Dillamore I L, Katou H. The mechanisms of recrystallization in cube metals with particular reference to their orientation-dependence[J]. Metal Science, 1974, 8: 73-75.

[2]Montheillet F, Cohen M, Jonas J J. Axial stresses and texture development during the torsion testing of Al, Cu and α-Fe[J]. Acta Metall, 1984, 32: 2077-2089.

[3]Montheillet F, Gilormini P, Jonas J J. Relation between axial stresses and texture development during torsion testing: a simplified theory[J]. Acta Metall, 1985, 33: 705-717.

[4]Hjelen J, rsund R, Nes E. On the origin of recrystallization textures in aluminum[J]. Acta Metall Mater, 1991, 39(7): 1377-1380.

[5]Lee D N. The evolution of recrystallization textures from deformation textures[J]. Scripta Metall Mater, 1995, 32(10): 1689-1694.

[6]LIU Chu-ming, ZHANG Xin-ming, CHEN Zhi-yong, et al. The effect of hot finishing rolling on cube texture in high purity aluminum foils[J]. Trans Nonferrous Met Soc China, 2001, 11(1): 105-109.

[7]XIAO Ya-qing, ZHANG Xin-ming, TANG Jian-guo, et al. Texture in high purity aluminum foils and AA3004 sheets[J]. Trans Nonferrous Met Soc China, 2003, 13(3): 491-498.

[8]吕爱强, 黄涛, 王福, 等. 异步轧制高纯铝箔冷轧织构沿板厚的分布规律[J].中国有色金属学报, 2003, 13(1): 56-59.

L Ai-qiang, HUANG Tao, WANG Fu, et al. Texture distribution along thickness after cross shear rolling of high purity aluminum foils[J]. The Chinese Journal of Nonferrous Metals, 2003, 13(1): 56-59.

[9]梁志德, 徐家桢, 王福. 织构材料的三维取向分析术——ODF分析[M]. 沈阳: 东北工学院出版社, 1986.

LIANG Zhi-de, XU Jia-zhen, WANG Fu. 3-D Orientation Distribution Analysis of Textured Materials[M]. Shenyang: Northeastern University of Technology Press, 1986.

[10]Nes E, Vante H E. The 40° 〈111〉 orientation relationship in recrystallization[J]. Metallkde Z, 1996, 87(6): 448-450.

[11]Hirsch J, Nes E, Lücke K. Rolling and recrystallization texture in directionally solidified aluminium[J]. Acta Metall, 1987, 35: 427-438.

[12]邓运来, 张新明, 唐建国, 等. 剪切变形方向特征对高纯铝箔轧制织构的影响[J]. 中国有色金属学报, 2005, 15(6): 829-835.

DENG Yun-lai, ZHANG Xin-ming, TANG Jian-guo, et al. Effect of direction change of shear deformation on rolling textures in high purity Al foils[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(6): 829-835.

[13]黄涛, 曲家惠, 胡卓超, 等. 高纯铝箔在异步轧制和再结晶过程中取向的演变[J]. 金属学报, 2005, 41(9): 953-957.

HUANG Tao, QU Jia-hui, HU Zhuo-chao, et al. Evolution of the orientation of cross shear rolling high purity aluminum foils during deformation and recrystallization[J]. Acta Metallurgica Sinica, 2005, 41(9): 953-957.

[14]Hutchinson B. Nucleation of recrystallization[J]. Scripta Metall Mater, 1992, 27: 1471-1475.

[15]刘刚, 王福, 齐克敏, 等. 异步轧制取向硅钢中织构沿板厚的分布与发展[J]. 金属学报, 1997, 33(4): 365-369.

LIU Gang, WANG Fu, QI Ke-min, et al.Texture distribution and development through thickness after cross shear rolling of oriented silicon steel[J]. Acta Metallurgica Sinica, 1997, 33(4): 365-369.

(编辑李艳红)

基金项目: 国家高技术研究发展计划资助项目(2003AA331080); 沈阳市应用开发研究计划资助项目(1032040-1-04)

收稿日期: 2005-04-15; 修订日期: 2005-09-30

作者简介: 黄 涛(1962-), 女, 副教授, 博士研究生

通讯作者: 黄 涛, 副教授; 电话: 024-24193686; E-mail: sysdht@sina.com