Experimental and theoretical study on thermal and moisture characteristics of new-type bamboo structure wall

来源期刊:中南大学学报(英文版)2012年第3期

论文作者:李念平 龙激波 苏林 王厉 钟珊

文章页码:600 - 608

Key words:porous media; bamboo structure; thermal expansion; moisture expansion; thermal and moisture stress

Abstract:

Thermal and moisture characteristics of the bamboo structure wall were tested in natural climate and three representative variation processes of heat and moisture: heating from solar radiation in summer at normal temperature and humidity, heating from solar radiation in summer at normal temperature and high humidity after rain, humidifying from brash in summer at high temperature and normal humidity. The results show that, in summer, the largest temperature difference between external and internal surface of the 28 mm-thick bamboo plywood wall is 11.73 °C (at 15:40) and the largest strain difference is 136 μm/m (at 18:50), both in ambient and indoor conditioned environment. In heating process, lengthways of the wall surface are in contracting strain while transverse ways are in expanding strain at initial stage and in contracting strain during later period. When the high temperature wall is humidified by rain, the surface temperature drops, moisture content increases and the expanding strain is presented on the surface during the whole process. Temperature and moisture content are two important factors which affect thermal and moisture stress (TMS) of the bamboo structure wall. The TMS is not only related to temperature and moisture content, but also greatly affected by temperature gradient, moisture content gradient and rates of changing.

J. Cent. South Univ. (2012) 19: 600-608

DOI: 10.1007/s11771-012-1045-y![]()

LI Nian-ping(李念平)1, LONG Ji-bo(龙激波)1, 2, SU Lin(苏林)1, WANG Li(王厉)1, ZHONG Shan(钟珊)2

1. College of Civil Engineering, Hunan University, Changsha 410082, China;

2. College of Civil Engineering and Mechanics, Xiangtan University, Xiangtan 411105, China

? Central South University Press and Springer-Verlag Berlin Heidelberg 2012

Abstract: Thermal and moisture characteristics of the bamboo structure wall were tested in natural climate and three representative variation processes of heat and moisture: heating from solar radiation in summer at normal temperature and humidity, heating from solar radiation in summer at normal temperature and high humidity after rain, humidifying from brash in summer at high temperature and normal humidity. The results show that, in summer, the largest temperature difference between external and internal surface of the 28 mm-thick bamboo plywood wall is 11.73 °C (at 15:40) and the largest strain difference is 136 μm/m (at 18:50), both in ambient and indoor conditioned environment. In heating process, lengthways of the wall surface are in contracting strain while transverse ways are in expanding strain at initial stage and in contracting strain during later period. When the high temperature wall is humidified by rain, the surface temperature drops, moisture content increases and the expanding strain is presented on the surface during the whole process. Temperature and moisture content are two important factors which affect thermal and moisture stress (TMS) of the bamboo structure wall. The TMS is not only related to temperature and moisture content, but also greatly affected by temperature gradient, moisture content gradient and rates of changing.

Key words: porous media; bamboo structure; thermal expansion; moisture expansion; thermal and moisture stress

1 Introduction

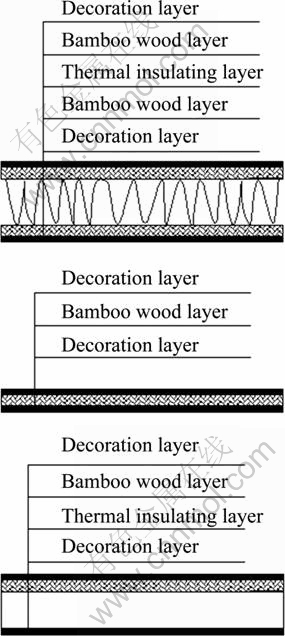

Bamboo is a type of sustainable resource that is of fast growth rate, high mechanical strength and easy processing performance. It is distributed in tropics and subtropics of Asia, Africa and Latin America [1-2]. For a long period, bamboo has been mainly used to build scaffold, guardrail, makeshift houses etc in a raw state in building industry [3-4]. In 1940s, bamboo plywood was developed, and the application of bamboo wood developed rapidly to build girder, wall, pillar, rafter, bamboo mixed structure and interior ornament [5-10]. According to different requirements, modern bamboo structure can be used in three occasions [11]: low-price practical buildings, temporary structures like building used in exhibition or rest, and high-class villa, tearoom etc. The first type is mainly used to solve housing problem in distressed areas, and technical requirement of them is relatively low. The second asks for fast building, easy accessibility and exquisite modeling. The third is delicate and high priced, and this kind of high-class bamboo building has a broad developing space with the development of processing technology. Compared with the traditional building materials, sustainable resource of good mechanical performance and thermal insulation is used in bamboo structure [12-15], and bamboo wood has become a replacement for rebar, concrete and timber gradually [16-17]. Modern bamboo structure walls usually take the forms like bamboo plywood wall, bamboo plywood-thermal insulation material composite wall and so on, as shown in Fig. 1.

In outdoor periodic changing climate, the external surface temperature of the wall is also periodic. With the influence of thermal properties like thermal conductivity and specific heat capacity, temperature wave is delayed and attenuated when it transmits from external surface to internal surface of the wall. The variations of temperature wave and the moment of peak value somewhere are different from elsewhere [18]. Instantaneous temperature and moisture content differences are generated in turn through the thickness direction of the wall. As bamboo is an anisotropic material, alternative changes of temperature and moisture content generate thermal and moisture stress (TMS) within the bamboo structure and the periodic stress is an important factor which affects the safety of the bamboo structure.

Fig. 1 Schematic diagrams of bamboo structure walls

Many studies on mechanical properties of bamboo have been done since the last century. GLENN, SMITH and SAUCIER, MEHRA and GHOSH et al studied application of bamboo used as reinforcing material of the concrete [19]. LI et al analyzed the mechanical properties of steel-bamboo composite structure such as profile steel-bamboo plywood composite slab, girder and wall [20-22]. JIANG et al did experimental study on mechanical properties of bamboo plywood and wood keel-bamboo plywood light-type composite wall [9]. The thickness expansion ratio of the bamboo plywood after 24 h cold-water immersion and 2 h boiling-water soaking are 2.4% and 17.8%, respectively, and horizontal shear strengths are 10.64 MPa while loading vertically and 17.21 MPa while loading parallel. L? et al researched the mechanical properties of bamboo plywood column and girder [23]. Two forms of damage in bamboo plywood column are lateral bending deformation and lateral exploding on top fibre. CHEN and WANG found that bamboo structure had good strength and ductility after joint experiments of bamboo plywood, and instantaneous failure did not happen in the bamboo structure easily when it lied on ultimate load [8].

Nevertheless, designers are not concerned so much with the variation of TMS caused by the change of moisture content in the design of building bamboo structure. In this work, the characteristics of TMS are studied with the variation of heat and moisture in the building bamboo structure based on the thermal and moisture transfer theory of porous media.

2 Experimental

The TMS of the material is generated by restricted strain and the stress is difficult to measure directly. So, in the experiment, characteristics of thermal and moisture expansion of the new-type bamboo plywood in free expanding and contracting condition are tested as well as characteristics at typical temperature and moisture content from simulated outdoor climate. Then, changing trends of TMS can be obtained.

Thermal and moisture strain of the bamboo is measured with the resistance strain patch (BX120- 100AA) and static resistance strain gauge (DH3816) in free expanding and contracting condition. The temperature is measured with the platinum resistance thermometer (PT100) and the non-paper recorder (JLFX135).

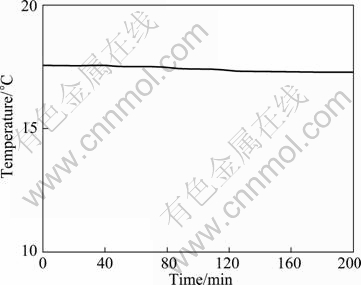

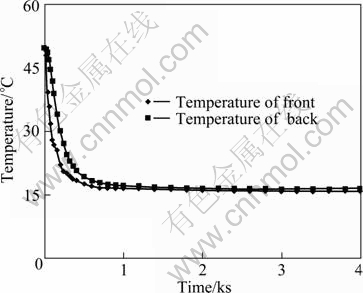

When the test system is applied to measuring thermal and moisture strain of the bamboo structure, the accuracy of results will be affected directly by installation sites and environment of dummy gauges. Dummy gauges are installed on the internal surface of the outer wall in the experiment. Because the thermal inertia of the wall is comparatively large, with invariant indoor air temperature and relative humidity, the wall can be taken as a rigid body that no thermal and moisture strain could be generated in it in a short time. The temperature of the wall is shown in Fig. 2. When the building bamboo structure is tested in the natural climate, strains are generated in both the wall and the bamboo structure in the meantime. The result of the strain test system is strain of the bamboo structure against wall itself.

Fig. 2 Temperature variation of dummy gauge

Characteristics of thermal and moisture expansion of the test-piece have been tested in previous studies. The results show that the lengthways thermal expansion coefficient is 9.45 μm·m-1·°C-1 and the transverse one is 22.08 μm·m-1·°C-1 when the temperature of the test-piece rises from 10 °C to 95 °C at low moisture content. The transverse coefficient is two times larger than that of the lengthways. Expansion rate with wet state is comparatively large when the test-piece is immersed in water. The lengthways expansion of the test-piece is 990 μm·m-1 in the water of 30 °C constantly after 48 h and the transverse expansion is 5 580 μm·m-1. The transverse expansion is 5 times larger than that of the lengthways, and the transverse expansion still tends to increase [24]. The variation of moisture strain is greater than that of thermal strain in natural climate after the synthetic comparison between thermal expansion and moisture expansion.

The test-piece in this experiment is a new-type composite bamboo wood. Considering the influence of gradients of temperature and moisture content, expanding uniformity and maneuverability, 300 mm× 300 mm×4 mm is identified as the size of the test-piece. Four resistance strain patches and one platinum resistance thermometer are installed in each side of the test-piece.

Several typical thermal and moisture processes are tested, e.g. heating from solar radiation in summer under dry condition, humidifying from brash in summer at high temperature, and heating from solar radiation at high humidity after rain.

Variations of temperature and humidity of the air are simulated using radiation furnace (2×450 W) (0.5 m away from the test-piece) to heat the test-piece unilaterally and using water atomizer to humidify it unilaterally. The test contents include: heating experiment while the test-piece is at normal temperature and moisture content (the normal moisture content is about 10%), rapid humidifying experiment while it is at high temperature, and rapid heating experiment while it is at high moisture content. It is supposed that the heating surface is the front and the other side is the back in the experiment.

3 Results and discussion

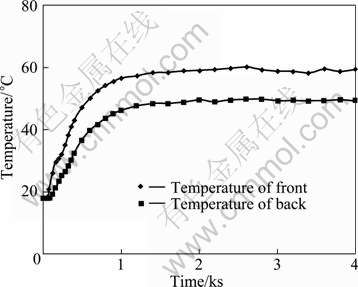

3.1 Heating test-piece of normal temperature and moisture content unilaterally

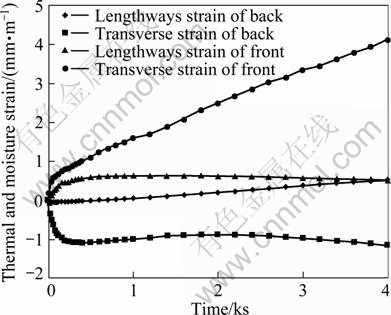

As shown in Fig. 3 and Fig. 4, during the process of unilaterally heating test-piece of normal temperature and moisture content, the temperature rising is very fast at the beginning, then temperature of the front and back both tend to be stable gradually after 800 s. In fact, moisture content dropping occurs while the temperature is rising. With the combined action of temperature and moisture, contraction happens at lengthways of both the front and the back. Lengthways contracting strain of the front is larger than that of the back because temperature of the front is higher. However, variation of transverse strain is a process of expanding before contracting. The phenomenon shows that the variation of temperature is the main factor affecting the transverse strain at the beginning of temperature rising. In the later stage with water evaporation, the variation of moisture content turns into the main factor. The variations of temperature and moisture content in the front are larger, so the front transverse strain is larger than that of the back.

Fig. 3 Temperature variation of unilaterally heated test-piece of normal temperature and moisture content

Fig. 4 Expansion of unilaterally heated test-piece of normal temperature and moisture content

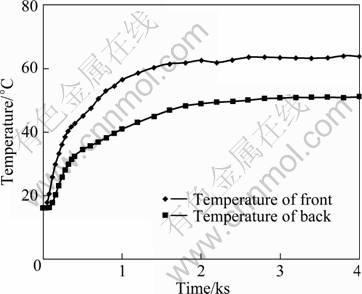

3.2 Heating test-piece of normal temperature and saturation of moisture unilaterally

As shown in Fig. 5 and Fig. 6, changing trends of temperature and expansion with heating under condition of moisture saturation are similar to those at normal moisture content. Variations of initial temperature before heating and after heating are both similar to those at normal moisture content. But the strain of test-piece is larger than that at normal moisture content. Especially, transverse strains of the test-piece, the expanding strain at the beginning and the contracting strain at 4 ks, are both more than twice of those at normal moisture content.

Fig. 5 Temperature variation of unilaterally heated test-piece of normal temperature and saturation of moisture

Fig. 6 Expansion of unilaterally heated test-piece of normal temperature and saturation of moisture

3.3 Spraying on test-piece of high temperature and low moisture content unilaterally

While the test-piece is at high temperature and low moisture content, spraying on it is a process of humidifying and cooling. As shown in Fig. 7 and Fig. 8, temperature of the front drops fast at the beginning, and moisture content of the front also rises very fast. Moisture strain is larger than thermal strain, so both lengthways and transverse strains become larger at the beginning and the variation of transverse strain is far larger than that of lengthways strain. The test-piece is of small thickness and small heat resistance, and the temperature of the back drops fast compared with that of the front. But the moisture content of the back changes slowly, and the thermal and moisture strain of the back is contracting strain.

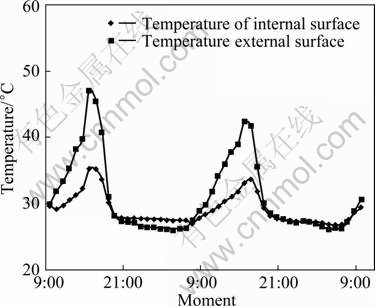

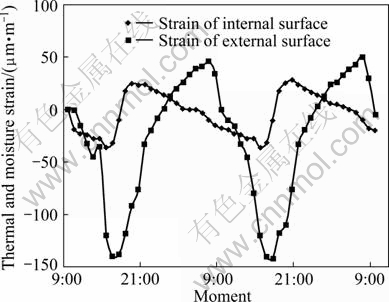

3.4 Thermal and moisture expansion of bamboo structure wall in cycle-action of natural climate

Bamboo plywood of 1 500 mm×800 mm×28 mm is installed in the window facing the west. Gaps between the bamboo plywood and the window are filled with polyurethane foam. The outdoor meteorological condition is the climate of September in Hunan Province, China. The initial temperatures of outdoor and indoor are both 29.6 °C (9:45). The temperature of the indoor air conditioner is set at 26 °C during the test. Temperature variations of external and internal surfaces and strain variation of the bamboo plywood against the wall are recorded by field measurement.

Fig. 7 Temperature variation of unilaterally sprayed test-piece of high temperature and low moisture content

Fig. 8 Expansion of unilaterally sprayed test-piece of high temperature and low moisture content

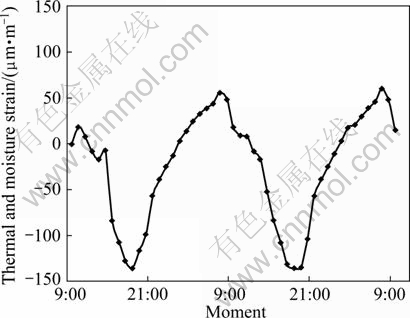

As shown in Fig. 9 and Fig. 10, the changing trends of temperature between internal and external surfaces are similar and the temperature reaches the highest point at 16:00. With the combined action of temperature and moisture, the variation of TMS is a polytropic process. During 9:00-18:00, though the temperature rises up and reaches the highest point at 16:00, contracting strain still occurs on external surface of the bamboo plywood because temperature rising is a process of water evaporation and the contracting strain from water evaporation is larger than the expanding strain from temperature rising. After 16:00, the temperature of the bamboo plywood drops, but it is still higher than the environmental temperature, and it is still a process of water evaporation. Variations of temperature and moisture content both lead to contracting strain. At this point, the changing rate of thermal and moisture strain is the fastest. At night, when the air temperature is low and the relative humidity of air rises, the process of moisture absorption of the bamboo plywood replaces the process of water evaporation. At about 18:00, contracting from temperature dropping balances with the expanding from moisture absorption. During 18:00-9:00 of the next day, expansion from moisture absorption occurs in the bamboo plywood, though the dropping process of temperature still exists. The indoor temperature and relative humidity remain almost unchanged, and a slow process of water evaporation occurs on the internal surface of the bamboo plywood. So, variations of thermal and moisture strains on the internal surface are very small and the changing trends are different from those on the external surface.

Fig. 9 Temperature of bamboo plywood on internal surface and external surface

Fig. 10 Thermal and moisture strain of gauging points on internal surface and external surface

4 Analysis and discussion

Based on the above experimental results, it can be obtained that the factors affecting TMS of the bamboo structure wall include thermal and moisture expansion characteristics of the material, the distribution of the temperature and moisture content inside the composite wall, their changing rates and so on. The expansion coefficients of materials in the bamboo structure wall are different from other inorganic non-metallic building materials. Besides, the bamboo structure wall is mainly made up of bamboo plywood, and bamboo wood is criss-cross inside the board. Therefore, the variations of TMS of the wall are complex. TMS is generated between bamboo plywood and other material layers, and is also generated by different lengthways and transverse expansion coefficients of bamboo wood inside the bamboo plywood.

4.1 Theoretical analysis

4.1.1 TMS under change of temperature or moisture content

The components of the new-type bamboo structure wall, like bamboo plywood, brick, concrete, thermal insulation material and decorative material, are all porous media. Though acting mechanisms of thermal and moisture transfer are different in porous media, effects of expanding and contracting properties due to change of heat and moisture (known as expanding with heat and contracting with cold, expanding with wet and contracting with dry) are the same. To simplify the analysis, effect from the anisotropism of the material is ignored on analyzing TMS of the wall. Supposing that sizes along y and z directions in the wall are much larger than the thickness along x direction, and there is no interior heat source or moisture source in the wall, the thermal and moisture transfer of the wall can be seen as one-dimensional transfer when environmental temperature and humidity are changed. The distribution functions of temperature and moisture content are supposed as

T=fT (x, t), w=fw (x, t) (1)

Thermal and moisture expansions of the bamboo plywood in free expanding condition respectively are

εy,T =εz,T =αT (fT (x, t)-fT (x, t0))=αT?fT (2)

εy,w =εz,w =αw (fw (x, t)-fw (x, t0))=αw?fw (3)

Under gradients of temperature and moisture content, thermal and moisture expansions of y and z directions are generated in the bamboo plywood and a bending deflection is also generated with radius of curvature R. Supposing that variations of temperature and moisture content are linear along the δ direction of thickness, thermal and moisture expansions and bending deflections of the bamboo plywood in free expanding condition are

εy =εz =x/R-k1(αT?fT +αw?fw) (4)

![]() (5)

(5)

If there is no bending deflection in the wall and all directions of the wall are fixed. Eq. (4) is transformed into

εy =εz =-k1(αT ?fT +αw?fw) (6)

According to the Hooke’s law, the TMS caused by the strain is

![]()

![]() (7)

(7)

In Eq. (7), variations of temperature and moisture content in the bamboo plywood are two important factors affecting variation of the TMS. Thermal stress and moisture stress are both expansion stresses when temperature and moisture content both rise, and they are both contracting stresses when temperature and moisture content drop. Due to the superposition of thermal stress and moisture stress, TMS is larger than either of two. When changing trends of temperature and moisture content are opposite, the TMS expands with heat and contracts with drying when temperature rises and moisture content drops, or the TMS contracts with cold and expands with wet when temperature drops and moisture content rises. Because of the interaction between the two stresses, the TMS is weakened and smaller than the larger one of the two.

If all directions of the wall are fixed, the new-type bamboo plywood can expand freely along x direction, and no stress is generated along this direction. The bamboo plywood cannot expand freely along y and z directions and strains are generated, but the bamboo plywood cannot bend because of the restraint around, and bending moment is generated around the bamboo plywood. The bending moment offsets the curvature of bending deflection:

![]() (8)

(8)

So, the largest bending TMS with the thickness δ and the width per unit length is

![]()

![]() (9)

(9)

4.1.2 TMS of new-type bamboo plywood under gradients of temperature and moisture content

The new-type bamboo plywood in the building wall is in the changing environment of heat and moisture. Variation of thermal and moisture environment results from seasonal change as well as instantaneous changes of thermal and moisture distributions in the bamboo plywood. Under natural climate, the variation of TMS is caused by real-time temperature difference and moisture content difference; moreover, changing gradients along the thickness direction can also lead to the variation of TMS.

When Eqs. (7) and (9) are derived by differentiating with time t, we can get

![]() (10)

(10)

![]() (11)

(11)

From above two equations, the larger the changing rates of temperature and moisture content are, the larger the changing range of expanding and contracting stresses and the greatest bending stress are.

When Eqs. (7) and (9) are derived by differentiating with x, we can get

![]() (12)

(12)

![]() (13)

(13)

From above two equations, the larger the gradients of temperature and moisture content are at a time, the larger the gradient of TMS is. The greatest bending stress in the new-type bamboo wood rises with the increase of gradients of temperature and moisture content.

4.2 Thermal and moisture expansion of pure bamboo plywood wall

Pure bamboo plywood wall is one of the most popular types in bamboo structure walls.

As shown in Fig. 11, for the 28 mm-thick wall made up of pure bamboo plywood, when indoor temperature is constant, the smallest instantaneous temperature difference between indoor and outdoor is -2 °C and the largest is 11.7 °C due to the variation of outdoor temperature and the effect of solar radiation. With the combined action of temperature and humidity, the smallest instantaneous thermal and moisture strain difference is -136 μm/m and the largest is 247 μm/m. If the wall is fixed around, instantaneous TMS is generated inside the wall. When expansion characteristics of ornamental materials in the wall are different from those of the bamboo plywood, instantaneous TMS will be generated between the bamboo plywood and the ornamental layer. In addition, bamboo wood is criss-cross inside the board, lengthways and transverse expansion coefficients of bamboo wood are different, and expansion coefficients of bamboo and bonding materials are different, so they will also generate instantaneous TMS inside the board. Although the instantaneous stress will not damage the bamboo structure wall, the alternating stress will cause stress fatigue damage to the wall, and the greater the TMS changes, the higher the level of stress fatigue is.

Fig. 11 Instantaneous thermal and moisture strain difference of gauging points on external and internal surface of bamboo plywood

4.3 Thermal and moisture expansion of bamboo plywood wall with thermal insulation material interior

Due to heat insulation of the insulating layer, temperature gradient of the bamboo plywood wall with thermal insulation material interior is mainly generated in the insulating layer. Bamboo plywood inside the wall is mainly affected by the indoor air, and its temperature is close to the indoor air temperature. When the indoor air temperature and relative humidity keep constant, bamboo plywood is in the process of moisture diffusion with constant temperature. Bamboo plywood outside the wall is mainly affected by the outdoor climate, and TMS changes greatly. Therefore, for bamboo plywood wall with thermal insulation material interior, besides TMS generated inside bamboo plywood, strain and stress of bamboo plywood on both sides of the insulating layer caused by different thermal and humidity environment are two important factors affecting the mechanical properties of the wall.

4.4 Thermal and moisture expansion of bamboo plywood-concrete composite wall

The temperature variation of the bamboo plywood-aerated concrete composite wall was tested on July 1st to 3rd in 2010. The size of the experiment room is 1 500 mm×1 500 mm×1 800 mm.

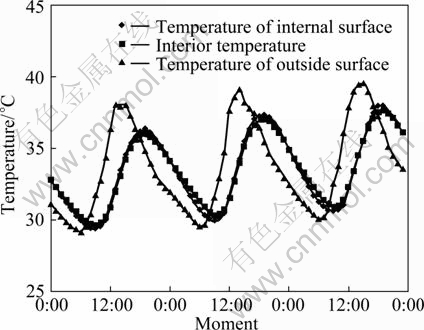

The external wall is paved with aerated concrete blocks of 120 mm thick and internal wall is paved with bamboo plywood of 20 mm thick. Experimental room of bamboo plywood-concrete composite wall is shown in Fig. 12 and the test results of instantaneous temperature of the south wall are shown in Fig. 13. Variation of the inside temperature is very large due to the small size of the room, small heat capacity and no air conditioner in the room. In Fig. 13, temperatures on both sides of the bamboo plywood are the same during changing of instantaneous temperature. However, the highest temperature on external surface of aerated-concrete layer is 40 °C and the greatest temperature difference compared with the internal surface temperature is 6.2 °C. The temperature gradient in the composite wall is mainly distributed in the aerated-concrete layer and temperature gradient in bamboo plywood is small. If we use air conditioner to control air temperature and humidity in the room, TMS in the bamboo plywood will be very small. If the bamboo plywood lies outside of the aerated-concrete layer, the gradient of the bamboo plywood is not large, but the daily bamboo plywood temperature variation will rise and then variation of moisture content will rise. Larger TMS will be generated between the bamboo plywood and the aerated-concrete layer or inside the bamboo plywood.

Fig. 12 Experimental room of bamboo plywood-concrete composite wall

Fig. 13 Instantaneous temperature of south wall of experimental room

5 Conclusions

1) When changing trends of heat and moisture are the same, TMS is enhanced and its value is larger than the stress generated by each single factor and the damaging effect to the wall is also enhanced. When changing trends are opposite, TMS is weakened and smaller than the larger one of the two stresses and the damaging effect is also weakened.

2) When temperature and moisture content on surface of the wall change rapidly, large gradients of temperature and moisture content will be generated. When the wall surface is heated and dried rapidly, a rapid contracting strain is generated on the surface as well as expanding strain generated inside the wall, and large gradient of TMS will be generated on surface layer of the wall. When the wall surface of high temperature is humidified rapidly, expanding strain is generated on the surface as well as contracting strain inside the wall. Similarly, large gradient of TMS will be generated on surface layer of the wall. And the larger the change rates of temperature and moisture content are, the larger the gradients are.

3) Thermal and moisture expansion characteristic of bamboo wood is another important factor. Under condition of periodic temperature and humidity in natural climate, even if temperature and moisture content inside the wall are distributed evenly, periodic TMS is still generated inside the bamboo structure.

Nomenclature

T

Temperature, °C

w

Moisture content, %

εy,T

Thermal expansion of y direction, μm/m

εz,T

Thermal expansion of z direction, μm/m

εy,w

Moisture expansion of y direction, μm/m

εz,w

Moisture expansion of z direction, μm/m

αT

Thermal expansion coefficient, μm/(m·°C)

αw

Moisture expansion coefficient, μm/(m·%)

fT(x,t)

Instantaneous temperature, °C

fw(x,t)

Instantaneous moisture content, %

fT(x,t0)

Initial temperature when bamboo wood is installed, °C

fw(x,t0)

Initial moisture content when bamboo wood is installed, %

ΔfT

Temperature difference, °C

Δfw

Moisture content difference, %

Δ

Thickness of bamboo wall, m

R

Radius of curvature, m

k1

Coupled coefficient of strain

k2

Coupled coefficient of stress

σy

Thermal and moisture stress of y direction, MPa

σz

Thermal and moisture stress of z direction, MPa

σy,T

Thermal stress of y direction, MPa

σy,w

Moisture stress of y direction, MPa

σmax

Greatest bending thermal and moisture stress with thickness and width per unit length, MPa

M

Bending moment, kN·m

E

Elastic modulus, GPa

I

Rotational inertia per unit length along edge, kg·m2

μ

Poisson ratio

References

[1] TOMMY Y L, CUI H Z, TANG P W C, LEUNG H C. Strength analysis of bamboo by microscopic investigation of bamboo fibre [J]. Construction and Building Materials, 2008, 22: 1532-1535.

[2] LUGT P, DOBBELSTEEN A A J F, JANSSEN J J A. An environmental, economic and practical assessment of bamboo as a building material for supporting structures [J]. Construction and Building Materials, 2006, 20: 648-656.

[3] YU W K, CHUNG K F, CHAN S L. Axial buckling of bamboo columns in bamboo scaffolds [J]. Engineering Structures, 2005, 27: 61-73.

[4] PAUDEL S K, LOBOVIKOV M. Bamboo housing: Market potential for low-income groups [J]. Journal of Bamboo and Rattan, 2003, 2(4): 381-396.

[5] FERNANDO P T, SAID J. Cementitious building materials reinforced with vegetable fibres: A review [J]. Construction and Building Materials, 2011, 25: 575-581.

[6] GHAVAMI K. Bamboo as reinforcement in structural concrete elements [J]. Cement and Concrete Composites, 2005, 27: 637-649.

[7] ZHAI Z Q, PREVITALI J M. Ancient vernacular architecture: Characteristics categorization and energy performance evaluation [J]. Energy and Buildings, 2010, 42: 357-365.

[8] CHEN Xu-he, WANG Zheng. Bamboo based panels for structural application [J]. World Bamboo and Rattan, 2005, 3(3): 18-20. (in Chinese)

[9] JIANG Ze-hui, WANG Zheng, CHANG Liang, GAO Li, CHEN Xu-he. Manufacture technology of the bamboo building wall [J]. Journal of Beijing Forestry University, 2006, 28(6): 155-158. (in Chinese)

[10] XIAO Yan, SHE Li-yong, SHAN Bo, ZHOU Quan, CHEN Guo, YUAN Rui-zhen. Application of modern bamboo structure to reconstruction after Wenchuan earthquake [J]. Journal of Natural Disasters, 2009, 18(3): 14-18. (in Chinese)

[11] LI Hui, ZHANG Yu-kun. Analysis on ecological architectural material of bamboo [J]. Building Science, 2007, 23(8): 20-26, 31. (in Chinese)

[12] ZHANG Ye-tian, HE Li-ping. Comparison of mechanical properties for glued laminated bamboo wood and common structural timbers [J]. Journal of Zhejiang Forestry College, 2007, 24(1): 100-104. (in Chinese)

[13] ALBERMANIA F, GOHA G Y, CHANB S L. Lightweight bamboo double layer grid system [J]. Engineering Structures, 2007, 29: 1499-1506.

[14] ZOU L H, JIN H, LU W Y, LI X D. Nanoscale structural and mechanical characterization of the cell wall of bamboo fibers [J]. Materials Science and Engineering C, 2009, 29: 1375-1379.

[15] UTAMA A, GHEEWALA S H. Influence of material selection on energy demand in residential houses [J]. Materials and Design, 2009, 30: 2173-2180.

[16] ICBO, AC 162: Acceptance criteria for structural bamboo [M]. ICBO Evaluation Service Ltd, California, USA, 2000: 1-5.

[17] FLANDER K D, ROVERS R. One laminated bamboo-frame house per hectare per year [J]. Construction and Building Materials, 2009, 23: 210-218.

[18] BAI Bing. Thermo-hydro-mechanical responses of saturated porous media under cyclic thermal loading [J]. Engineering Mechanics, 2007, 24(5): 87-92. (in Chinese)

[19] BRINK F E, RUSH P J. Bamboo reinforced concrete construction [EB/OL]. http://www.romanconcrete.com/docs/bamboo1966/ Bamboo Reinforced Concrete Feb 1966. htm# Toc 501122839.

[20] LI Yu-shun, SHAN Wei, HUANG Zu-bo, XU Jie, L? Bo. Experimental study on mechanical behavior of profiled steel sheet-bamboo plywood composite slabs [J]. Journal of Building Structures, 2008, 29(1): 96-102, 111. (in Chinese)

[21] SHEN Huang-ying, LI Yu-shun, ZHANG Wang-li, XU Jie, L? Bo. Experimental study on flexural behavior of cold-formed thin-wall steel-bamboo plywood composite beams [J]. Journal of Building Structures, 2010, (Sup 2): 171-175. (in Chinese)

[22] LI Yu-shun, SHEN Huang-ying, ZHANG Wang-li, HAN Tian-shi. Experimental study on aseismic behavior of profiled steel sheet-bamboo plywood composite walls [J]. Engineering Mechanics, 2010, 27 (Sup I): 108-112, 126. (in Chinese)

[23] L? Qing-fang, WEI Yang, ZHANG Qi-sheng, YU Yong-zhe, L? Zhi-tao. Experimental study on mechanical properties of basic components for a new anti-seismic room with bamboo engineering materials [J]. Building Technology and Applications, 2008, (11): 1-5. (in Chinese)

[24] LONG Ji-bo, LI Nian-ping, WANG Qian, ZENG De-jun, SU Lin. Analysis on thermal and moisture stress in bamboo reinforced concrete [J]. Journal of Hunan University: Natural Sciences, 2010, 37(12): 1-6. (in Chinese)

(Edited by YANG Bing)

Foundation item: Project(50878078) supported by the National Natural Science Foundation of China

Received date: 2011-07-26; Accepted date: 2011-11-14

Corresponding author: LI Nian-ping, Professor, PhD; Tel: +86-731-88822610; E-mail: linianping@126.com