DOI: 10.11817/j.issn.1672-7207.2020.12.007

铝电解阴极燕尾槽内炭块-糊料-钢棒界面接触状态仿真优化

吕晓军,孙启东,陈昌,李劼

(中南大学 冶金与环境学院,湖南 长沙,410083)

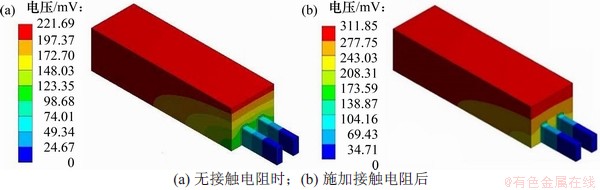

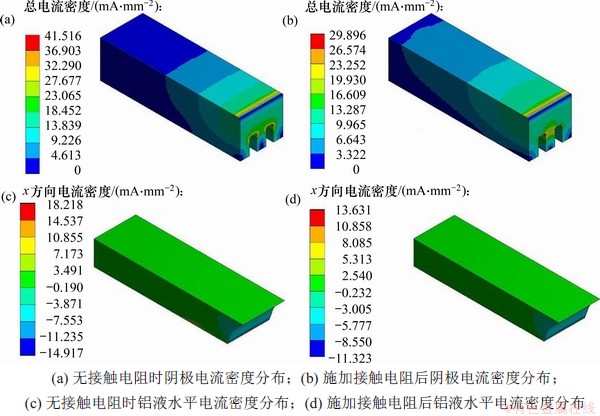

摘要:为探明铝电解槽阴极燕尾槽内各界面的接触行为及其界面接触电阻对阴极电热应力场的影响,建立基于接触电阻的物理场计算方法,对比分析接触电阻对阴极燕尾槽电场-热场-应力场的影响,提出并构建了接触压力与接触电阻之间的双向耦合方法,考察接触应力和接触电阻两者动态平衡下的电热场分布特性。在此基础上,分析钢棒糊膨胀系数对阴极电热场的影响。研究结果表明:施加接触电阻后阴极电压降由221.69 mV增加到311.85 mV,由接触电阻引起的接触电压降为90 mV,约占整个阴极电压降的29%;而阴极电流密度由41.52  减小到29.90

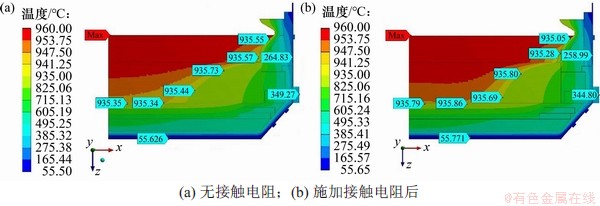

减小到29.90  ,阴极电流密度下降了约28%;燕尾槽侧部接触压力高于顶部接触压力,接触压力主要集中于燕尾槽的“燕尾”处;相比未考虑接触电阻的计算结果,考虑接触电阻的铝电解槽电热场分布及计算结果更加接近生产实际,其接触压力整体上提高了约0.25 MPa;接触电阻会引起阴极高温区域向炭块底部和X轴方向扩张,导致炭块的温度梯度减小;在阴极炭块可承载范围内,通过钢棒糊膨胀系数优化计算,发现适当增大接触压力能够有效降低阴极电压降,当阴极钢棒糊的热膨胀系数增加4倍时,阴极电压降降低了12.68 mV,且温度场未出现明显变化;在铝电解槽物理场的计算过程中,需要考虑与重视燕尾槽内界面接触电阻,这有利于更加准确地认识和了解阴极物理场的分布特性。

,阴极电流密度下降了约28%;燕尾槽侧部接触压力高于顶部接触压力,接触压力主要集中于燕尾槽的“燕尾”处;相比未考虑接触电阻的计算结果,考虑接触电阻的铝电解槽电热场分布及计算结果更加接近生产实际,其接触压力整体上提高了约0.25 MPa;接触电阻会引起阴极高温区域向炭块底部和X轴方向扩张,导致炭块的温度梯度减小;在阴极炭块可承载范围内,通过钢棒糊膨胀系数优化计算,发现适当增大接触压力能够有效降低阴极电压降,当阴极钢棒糊的热膨胀系数增加4倍时,阴极电压降降低了12.68 mV,且温度场未出现明显变化;在铝电解槽物理场的计算过程中,需要考虑与重视燕尾槽内界面接触电阻,这有利于更加准确地认识和了解阴极物理场的分布特性。

关键词:铝电解;接触压力;有限元;电场-热场-应力场耦合

中图分类号:TF845.6 文献标志码:A 开放科学(资源服务)标识码(OSID)

文章编号:1672-7207(2020)12-3331-10

Numerical simulation and optimization of contact state for cathode slot of aluminum electrolytic cell

LU Xiaojun, SUN Qidong, CHEN Chang, LI Jie

(College of Metallurgy and Environment, Central South University, Changsha 410083, China)

Abstract: To explore the influences of interfacial contact behaviors and contact pressure in aluminum reduction cell cathode slot on electrothermal and mechanical field, the physical field calculation based on contact resistant was performed to analyze the effects of contact resistance on electrothermal and mechanical field of the cathode slot. The method of coupling between contact pressure and contact resistance was reported and the electrothermal field distribution characteristics during the dynamic balance of contact stress and contact resistance were studied. In addition, the effect of expansion coefficient of the ramming paste on the cathode electrothermal field was considered based on the calculation model. The results show that the cathode voltage drop increases from 221.69 mV to 311.85 mV with the contact resistance applied, and the contact voltage drop caused by the contact resistance is 90 mV, which accounts for about 29% of the entire cathode voltage drop. Furthermore, the cathode current density decreases from 41.52  to 29.90

to 29.90  , which drops by about 28%. The side contact pressure of the slot is larger than the top contact pressure and the pressure is mainly concentrated at the end termination of the slot. Compared with the result without considering contact resistance, the existence of contact resistance leads to the calculation result of the electrothermal field distribution closer to the actual production, and the overall contact pressure increases by about 0.25 MPa. Meanwhile, contact resistance promotes the high-temperature region to expand to the block bottom and X-axis, and then the temperature gradient of the carbon block decreases. Additionally, the cathode voltage drop can effectively decrease by optimizing the expansion coefficient of the steel rod paste. The cathode voltage drop decreases by 12.68 mV when the thermal expansion coefficient of the cathode steel rod paste increases by 4 times, and the temperature field does not change significantly. Therefore, the interfacial contact resistance in the slot should be considered and paid attention to the calculation process of physical field of the aluminum reduction cell, which facilitates the understanding of the distribution of the cathode physical field.

, which drops by about 28%. The side contact pressure of the slot is larger than the top contact pressure and the pressure is mainly concentrated at the end termination of the slot. Compared with the result without considering contact resistance, the existence of contact resistance leads to the calculation result of the electrothermal field distribution closer to the actual production, and the overall contact pressure increases by about 0.25 MPa. Meanwhile, contact resistance promotes the high-temperature region to expand to the block bottom and X-axis, and then the temperature gradient of the carbon block decreases. Additionally, the cathode voltage drop can effectively decrease by optimizing the expansion coefficient of the steel rod paste. The cathode voltage drop decreases by 12.68 mV when the thermal expansion coefficient of the cathode steel rod paste increases by 4 times, and the temperature field does not change significantly. Therefore, the interfacial contact resistance in the slot should be considered and paid attention to the calculation process of physical field of the aluminum reduction cell, which facilitates the understanding of the distribution of the cathode physical field.

Key words: aluminum electrolysis; contact pressure; finite element; electric-thermal-mechanical coupling

铝电解槽是一种多相多场交互作用下的大型复杂高温电化学反应器,且槽内涉及多种材料间的相互接触以及接触界面之间的电场-热场-应力场等传递,直接影响着铝电解槽运行的稳定性与技术经济指标。如在阴极炭块燕尾槽内,存在着炭块-钢棒糊-钢棒3种材料的接触,主要起传导电流的作用,过高的接触电阻不仅会引起不必要的能耗,而且会影响接触面上的电流分布,进而影响温度场;而温度变化会反过来通过材料的热膨胀性能影响界面应力及接触压力分布,不仅影响阴极使用寿命,而且还会改变接触面上“导电斑”以及接触电阻分布。因而,深入了解炭块-钢棒糊-钢棒界面接触状态,不仅有利于延长阴极使用寿命,而且可以为降低阴极电压降实现节能提供理论指导。

关于阴极接触电阻,国内外学者开展了相关研究:RICHARD[1-3]研究认为,铝电解槽阴极平均接触电阻要比阳极接触电阻高得多,阴极接触电阻所造成的额外成本更加巨大,同时也存在巨大的节能潜力;李鸿道等[4]认为,随着电解槽运行时间增长,阴极炭块与钢棒间的接触会由于电解质及钠元素的渗入而发生劣化,引起接触电阻的升高;BRASSARD等[5]结合实验与仿真,研究了阴极钢棒槽内磷生铁裂化过程,并分析了由此引起的阴极电压降(CVD)变化;ULISES等[6]采用数值模拟方法,研究了电解槽大修母线转接时旁路接头的接触应力分布,并考虑了材料的热膨胀及接触表面的粗糙度及硬度;刘伟等[7]采用电接触理论建立铝电解槽阴极模型,研究了阴极炭块与阴极钢棒的接触问题,并探索炭块种类、钢棒安装方式及伸腿和沉淀对阴极电压降的影响。但这些研究都未考虑接触电阻与接触压力之间的关系,仅针对接触电阻或接触压力等单因素进行探索。为了降低因接触电阻而引起的接触电压降,FRIEDRICH等[8]研究了燕尾槽形状对阴极电压降的影响,其将燕尾槽设计成“Ω”形,使磷生铁在浇注时能够进入“Ω”槽中,减小燕尾槽内钢棒顶部与炭块间的缝隙,降低接触电阻;BERENDS等[9]在燕尾槽内预先插入钢钉,减少因磷生铁收缩而产生的间隙,降低接触电阻;靳文军等[10]改进磷生铁配方,提高界面接触压力,降低接触电阻,从而使铁-碳接触电压降降低30 mV左右。然而,当前文献仅研究阴极接触电阻的宏观层面,并未研究接触电阻和接触压力在燕尾槽内各接触界面上的分布,无法全面准确了解燕尾槽内各界面的接触状态。在计算方法上,未能考虑接触压力与接触电阻的双向耦合,因而,研究结果的可靠性降低。

为此,本文建立基于接触电阻的仿真方法,对比分析接触电阻施加对阴极燕尾槽电热压力的影响,提出并构建接触压力与接触电阻的双向耦合,考察钢棒糊膨胀系数对阴极电热场的影响。

1 数学模型

1.1 基本方程

电解槽的正常运行需要持续的强大电流供给。依据电工学原理可知,在稳态电场的条件下,电流在电解槽中的传递服从拉普拉斯导电方程,当涉及三维立体电解槽模型时,其微分方程如下所示[11]。

当电场为稳态时, =0,

=0,

(1)

(1)

式中: (i=x,y,z)为材料在三维方向上的电阻率,Ω·m,受温度影响;V为电位;τ为时间,s。

(i=x,y,z)为材料在三维方向上的电阻率,Ω·m,受温度影响;V为电位;τ为时间,s。

铝电解正常运行期间,电解质及铝液为熔融状态,而电解质的熔点一般为935  左右,即电解槽是一个高温反应器,这就涉及热的传递问题。结合传热学原理可知,电解槽中各部分的热量传递符合带内热源的导热泊松方程。对三维模型来说,其控制方程[12]如下。

左右,即电解槽是一个高温反应器,这就涉及热的传递问题。结合传热学原理可知,电解槽中各部分的热量传递符合带内热源的导热泊松方程。对三维模型来说,其控制方程[12]如下。

当涉及稳态热场时, ,

,

(2)

(2)

式中: ,

, 和

和 分别为材料在x,y和z这3个方向上的导热系数,

分别为材料在x,y和z这3个方向上的导热系数, ;

; 为每个节点处的温度,

为每个节点处的温度, ;

; 为热源强度,即单位体积产热率,其中

为热源强度,即单位体积产热率,其中 ·

· ;

; 为材料密度,kg/

为材料密度,kg/ ;c为比热容,

;c为比热容, ·

· 。

。

铝电解槽阴极炭块中的应力主要是在温度的影响下产生的等效应力,在计算过程中需对模型施加体积力及位移边界条件。其所基于的控制方程[13]包括以下几种。

1) 维纳方程:

(3)

(3)

式中: ,

, 和

和 分别为材料在x,y和z这3个方向上的正应力分量;

分别为材料在x,y和z这3个方向上的正应力分量; ,

, 和

和 分别为材料在x,y和z这3个方向上的剪应力分量;

分别为材料在x,y和z这3个方向上的剪应力分量; ,

, 和

和 分别为材料在x,y和z这3个方向上的体积力分量。

分别为材料在x,y和z这3个方向上的体积力分量。

2) 柯西方程:

(4)

(4)

式中: ,

, 和

和 分别为材料在x,y和z这3个方向上的正应变;

分别为材料在x,y和z这3个方向上的正应变; ,

, 和

和 分别为材料在x,y和z这3个方向上的剪应变。

分别为材料在x,y和z这3个方向上的剪应变。

3) 本构方程:

;

; (5)

(5)

式中:i,j=x,y和z; ;

;

系数,

系数, ,

, ;

; 为材料的泊松比;E为弹性模量。

为材料的泊松比;E为弹性模量。

1.2 假设

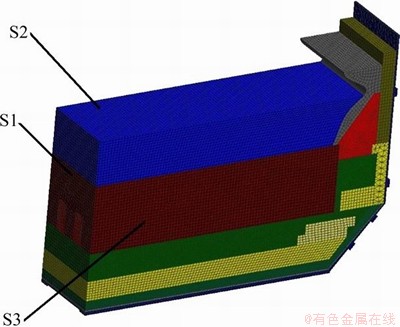

由于铝电解槽阴极是重复且对称的结构,为节省计算资源及计算时间,对电解槽模型进行了简化,建立铝电解阴极1/2切片模型,如图1所示。S1,S2和S3分别设置为对称边界,在此边界上没有电流及热量的传递与散失。同时,为简化模型对阴极切片模型作以下假设:

1) 不考虑铝液与阴极炭块上表面间的氧化铝沉淀;

2) 不考虑电解槽中的铝液波动;

3) 忽略由钠渗透引起的阴极炭块膨胀;

4) 不考虑电解质渗透引起的阴极钢棒的侵蚀。

图1 铝电解槽阴极切片模型

Fig. 1 Cathode slice model of aluminum electrolytic cell

1.3 边界条件设定

模型网格划分完成后,设置边界条件并施加载荷。当计算电场合热场时,在铝液表面设置温度载荷,t=960 ℃;电流均分并由铝液上表面进入阴极,I=6 000 A;零电势面设置在阴极钢棒端部,V=0 V,电流由此处流出。炉帮与铝液间对流传热系数很难确定,根据TAYLOR等[14-16]的研究,本文槽内的换热系数取550 W/(m2· )。

)。

电解槽外表面的对流与辐射换热系数由下式计算可得。

上表面:

1/3

1/3

下表面:

1/4

1/4

垂直面:

1/3 (6)

1/3 (6)

垂直面:

1/3(7)

1/3(7)

式中: 为对流散热系数;

为对流散热系数; 为辐射散热系数[17];

为辐射散热系数[17]; 和

和 分别为物体表面的热力学温度和环境热力学温度。

分别为物体表面的热力学温度和环境热力学温度。

当进行应力场计算时,将阴极电场和热场计算结果作为体载荷输入应力计算模型,对整个阴极模型施加向下的重力加速度, ;在铝液上表面施加电解质等效载荷,P=2 115 Pa;在S1,S2和S3施加对称边界约束并在铝电解槽底部及侧部垫块处施加位移约束。

;在铝液上表面施加电解质等效载荷,P=2 115 Pa;在S1,S2和S3施加对称边界约束并在铝电解槽底部及侧部垫块处施加位移约束。

1.4 接触压力与接触电阻的转化关系

电接触分为强电接触和弱电接触,电解槽就是典型的强电接触。此处将阴极接触看做强电接触,现代电接触领域通常采用式(8)[18]计算接触电阻:

(8)

(8)

式中:Rc为接触电阻;K为综合接触材料的物理性能及接触表面膜性能的系数,由接触材料决定,通常为常数;m为与表面膜有关的指数,取值范围为0.3~1.5,强电接触中常取为1.3;F为接触压力。由于材料硬度变化很难得到,本文假设其硬度不随温度变化。

2 结果与讨论

不同部位间的相互接触会产生接触电阻,如阴极炭块与钢棒糊、钢棒糊与阴极钢棒间都会存在接触电阻。当有电流通过时会产生接触电压降,在同一个接触界面,各点的接触电阻并非相同,进而影响接触面上的电流分布和热场分布。接触电阻在不同材料界面是不同的,其中,在炭块与钢棒糊间的接触电阻一般取1.0 ,而在钢棒糊与阴极钢棒间的接触电阻为0.3×

,而在钢棒糊与阴极钢棒间的接触电阻为0.3× [19]。

[19]。

2.1 电-热场计算结果

图2所示为施加接触电阻前后阴极电压降分布变化。从图2可见:电压分布形态由炭块中央向阴极钢棒出电端逐渐减小,电压最大值位于阴极炭块中部,最小值位于阴极钢棒末端。未施加接触电阻的阴极电压降为221.69 mV,施加接触电阻的阴极电压降为311.85 mV。由接触电阻引起的接触电压降高达90 mV,占整个阴极电压降的29 %。

图2 阴极电压变化分布

Fig. 2 Cathode voltage drop distribution

采集电解厂实测阴极电压降取平均值为325 mV,对比阴极电压降计算值与测量值可知,施加接触电阻后的计算结果更接近实际电解槽阴极电压降,更贴近电解槽实际生产参数。

图3所示为施加接触电阻前后阴极电流分布,由于电流会在阴极炭块的出电端汇集,因此,在靠近出电端电流密度较大。但电流密度集中区域未出现在炭块的最边部,这是由于侧部伸腿对电流产生了阻挡。由图3(a)和3(b)可见:施加接触电阻后阴极炭块中的最大电流密度由41.52  减小到29.90

减小到29.90  ,这表明阴极水平电流分量显著降低。由图3(c)和图3(d)可见:施加接触电阻后铝液中的水平电流由18.22

,这表明阴极水平电流分量显著降低。由图3(c)和图3(d)可见:施加接触电阻后铝液中的水平电流由18.22  降低到13.63

降低到13.63  ,对铝电解槽的运行稳定性影响重大。因此,在电场仿真计算中,接触电阻是不可忽略的。

,对铝电解槽的运行稳定性影响重大。因此,在电场仿真计算中,接触电阻是不可忽略的。

图3 阴极及铝液电流密度变化

Fig. 3 Change of current density of cathode and aluminum liquid

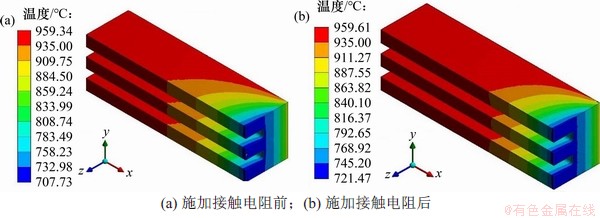

图4所示为施加接触电阻前后的阴极整体温度分布,本研究中,电解质的凝固等温线温度为935  ,施加接触电阻会引起槽内热场变化,最高温度(960

,施加接触电阻会引起槽内热场变化,最高温度(960  )位于电解槽中部,最低温度(55

)位于电解槽中部,最低温度(55  )位于电解槽槽壳底部。但是,施加接触电阻后的凝固等温线形状和位置发生了明显变化,考虑接触电阻后凝固等温线沿炭块X轴方向扩展,这一变化会改变伸腿影响炉膛的规整性,炉膛的规整性对铝电解电流效率、槽稳定性以及换极操作等具有重要影响。

)位于电解槽槽壳底部。但是,施加接触电阻后的凝固等温线形状和位置发生了明显变化,考虑接触电阻后凝固等温线沿炭块X轴方向扩展,这一变化会改变伸腿影响炉膛的规整性,炉膛的规整性对铝电解电流效率、槽稳定性以及换极操作等具有重要影响。

图4 施加接触电阻前后的阴极温度变化

Fig. 4 Cathode temperature changes before and after applying contact resistance

图5所示为施加接触电阻前后的阴极炭块温度分布。施加接触电阻后,阴极炭块高温区域明显增大,且朝阴极炭块出电端方向扩展,致使温度梯度明显降低,其温度梯度主要表现在x方向上。未施加接触电阻的温度梯度为148.44  ,而施加接触电阻的温度梯度为140.50

,而施加接触电阻的温度梯度为140.50  ,这说明施加接触电阻后的阴极炭块温度分布更均匀,有利于延长阴极炭块的使用寿命。因此,在进行铝电解槽热场计算时,接触电阻的影响也是不可忽视的。

,这说明施加接触电阻后的阴极炭块温度分布更均匀,有利于延长阴极炭块的使用寿命。因此,在进行铝电解槽热场计算时,接触电阻的影响也是不可忽视的。

图5 施加接触电阻前后的阴极碳块温度变化

Fig. 5 Cathode carbon block temperature changes before and after applying contact resistance

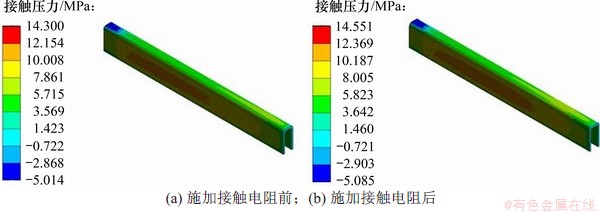

2.2 力场计算结果

图6所示为施加接触电阻前后阴极燕尾槽内接触压力的变化。施加接触电阻后,燕尾槽内接触压力整体提增加了0.25 MPa,且侧部最大接触压力区向出电端延伸。这是施加接触电阻后,接触区域焦耳产热增加,温度升高所导致。接触压力增加反过来会降低接触电阻,有利于降低接触电压降。

图6 施加接触电阻前后的接触压力变化

Fig. 6 Contact pressure change before and after applying contact resistance

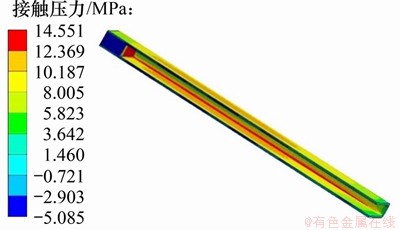

图7所示为施加接触电阻后不同接触面上接触压力的分布状态。钢棒槽侧部接触面上的接触压力集中分布于接触区域的中间部位,接触面两端及边缘区域的接触压力较小;最大接触压力位于顶面与侧面的相交处,即为钢棒槽的燕尾处,达14.55 MPa,这容易导致钢棒糊及钢棒槽开裂,缩短阴极寿命。另外,接触压力较大处位于钢棒槽里面端头,随着电解槽寿命增加以及钢棒蠕变,此处接触压力可能会进一步集中,最终导致钢棒糊的开裂,增加接触电阻。

图7 施加接触电阻时不同接触面上接触压力的分布状态

Fig. 7 Distribution of contact pressure on different contact surfaces after applying contact resistance

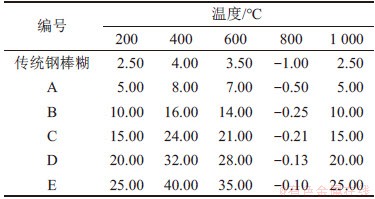

3 钢棒糊热膨胀系数与匹配性优化

为尽可能地降低接触电压降,应在阴极炭块强度承受范围内,调整钢棒糊的热膨胀系数,优化接触界面。而钢棒糊热膨胀系数与炭块、钢棒之间界面的匹配性难以在工作条件中在线测量评价,热膨胀过大,可能会导致炭块开裂,造成电解质渗入,甚至漏炉;热膨胀不足则会增加接触电阻,阻碍电流流通,影响槽内电场分布,并产生较高的额外能耗。

本节采用ANSYS有限元仿真软件,建立阴极切片模型,以传统的钢棒糊热膨胀系数为初始值(如表1所示),调整材料参数,逐渐增大热膨胀系数,设计不同方案即 ,

, ,

, ,

, 和

和 ,使正常工作下的等效应力尽可能地接近阴极炭块许用应力,以考察膨胀系数对界面接触特性的影响。

,使正常工作下的等效应力尽可能地接近阴极炭块许用应力,以考察膨胀系数对界面接触特性的影响。

表1 阴极钢棒糊热膨胀系数

Table 1 Thermal expansion coefficient of cathode ramming paste

阴极炭块的最大强度一般为30 MPa[20],钢棒糊与炭块类似,同属脆性材料且其抗压强度较炭块要小,通常为25 MPa[21]。因此,改变钢棒糊热膨胀系数后,在保证炭块等效应力尽可能接近炭块许用应力的同时,也要低于钢棒糊的最大强度。若应力超出钢棒糊的最大抗压强度,则钢棒糊会被压碎,这将降低界面间的接触性能,增大接触电阻,不利于电流的流通。

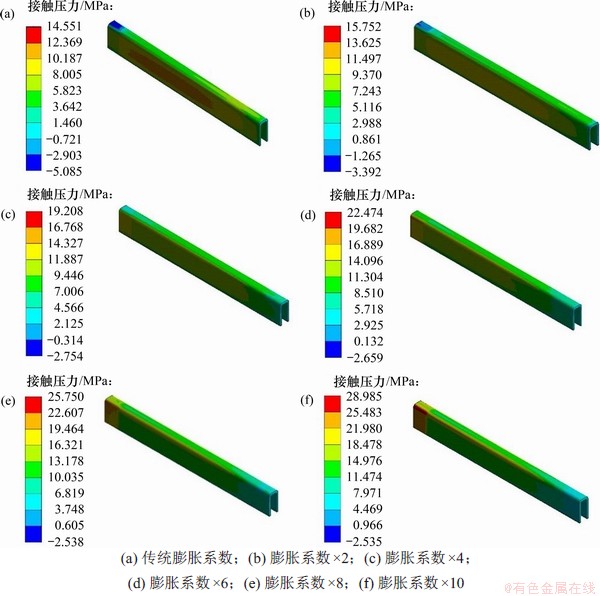

图8所示为在不同钢棒糊膨胀系数下的接触压力分布。由图8可知:随钢棒糊膨胀系数增加,燕尾槽拐角处的接触压力明显增加,侧部接触压力区域扩大。接触压力持续增加会导致钢棒糊存在破裂的风险。

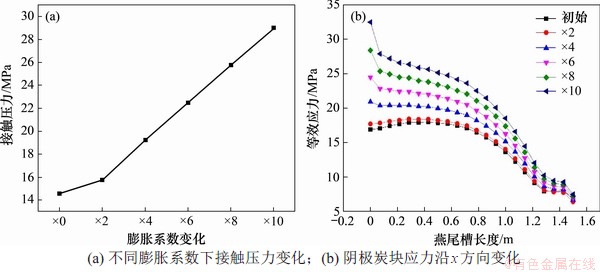

图9(a)所示为采取不同钢棒糊膨胀系数时燕尾槽内最大接触压力的变化。由图9(a)可知:随钢棒糊膨胀系数增加,接触压力逐渐增加;当钢棒糊的膨胀系数扩大到10倍时,接触压力增加到29.98 MPa。图9(b)所示为随钢棒糊膨胀系数增加,阴极炭块在x方向上等效应力的变化。由图9(b)可知:炭块等效应力x方向逐渐减小,且随着钢棒糊膨胀系数增加,等效应力逐渐增大;当钢棒糊热膨胀系数增大到10倍时,等效应力达到32 MPa,超出了阴极炭块的许用应力,会对阴极炭块造成破坏。因此,在保证炭块和钢棒糊完好的前提下,要尽可能提高界面接触压力,由上述内容可知方案B为最佳选择。

图8 膨胀系数变化时接触压力分布云图

Fig. 8 Contact pressure distribution with the expansion coefficient changes

图9 接触应力随膨胀系数变化曲线及阴极炭块x方向应力变化曲线

Fig. 9 Contact pressure plots as a function of expansion coefficient and the change of pressure along the x-direction of cathode carbon

以方案B为例,首先依据钢棒糊的膨胀系数进行仿真,获取燕尾槽内接触压力分布,再基于接触压力分布计算出相应的接触电阻,进而转化为电阻率施加到电热场分析模型中进行模拟计算,以此考察热膨胀系数对阴极电热场的影响情况。

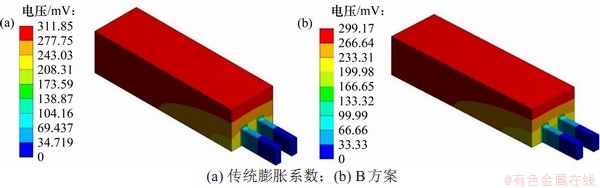

图10所示分别为钢棒糊热膨胀系数变化前后阴极部分的电压降变化。由图10可见:采用B方案优化后(即钢棒糊膨胀系数提高4倍),此时铝电解槽阴极电压降(CVD)为299.19 mV,而未经优化的正常状态下的阴极电压降为311.85 mV,两者相差12.68 mV;当槽电压为4.2 V,电流效率为95%时,每吨铝可减少额外电能消耗39.72 kW·h。由此可见,优化钢棒糊的热膨胀系数有利于降低阴极电压降。

图10 优化前后阴极电压变化

Fig. 10 Changes in cathode voltage before and after optimization

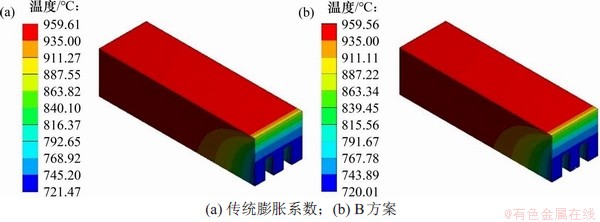

图11所示为热膨胀系数优化前后阴极部分的热场分布。从图11可见:膨胀系数提高4倍后,阴极区域的最高温度及其热场分布基本一致,这表明优化钢棒糊膨胀系数对铝电解槽热场影响不大,基本没改变热场分布。

图11 优化前后阴极温度变化

Fig. 11 Cathode temperature changes before and after optimization

4 结论

1) 当施加接触电阻时,阴极电压降升高达到311 mV,且由接触电阻引起的接触电压降为90 mV,阴极电流密度由41.52 mA/mm2降低到29.90  ;阴极炭块温度升高,高温区扩张,温度梯度降低,温度分布更加均匀。

;阴极炭块温度升高,高温区扩张,温度梯度降低,温度分布更加均匀。

2) 接触电阻存在时的电热场分布更加接近实际电解槽生产状态;施加接触电阻后的最大接触压力比无接触电阻时的高0.25 MPa。

3) 随着钢棒糊膨胀性能增强,接触压力逐步增加,有利于降低接触电压降。当采用B方案膨胀系数放大4倍时,阴极电压降降低了12.68 mV,温度场未出现明显变化。

参考文献:

[1] RICHARD. Conception des tourillons d′anode en usage dansune cuve de Hall-Héroult à l′aide de la méthod des élémentsfinis[D]. M.Sc. Thesis, Université Laval, Québec, Canada, 2000: 1-5.

[2] DUPUIS M. Development and application of an ansys based thermo-electro-mechanical collector bar slot design tool[J]. Light Metals 2011: 519-524.

[3] DUPUIS M. Development and application of an ansys based thermo-electro-mechanical anode stub hole design tool[C]// Light Metals 2010. San Diego. USA: Springer International Publishing, 2010: 433-438.

[4] 李鸿道, 张松江, 李殿周. 中孚320 kA电解槽降低阴极电压降的措施浅析[C]// 豫晋两省有色金属工业发展论坛, 郑州, 2006: 361-364.

LI Hongdao, ZHANG Songjiang, LI Dianzhou. Analysis on the measures to reduce the cathode pressure drop of the Zhongfu 320 kA electrolyzer[C]// Henan and Jinan Nonferrous Metal Industry Development Forum. Zhengzhou, 2006: 361-364.

[5] BRASSARD M, DESILETS M, SOUCY G, et al. Chemical degradation of the cathodic electrical contact between carbon and cast iron in aluminum production cells[J]. Metallurgical and Materials Transactions B, 2017, 48(3): 1675-1689.

[6] ULISES O, SALAZARJ E, GONZALEZJ. Numerical simulation of electrical joints in the by-pass system of 230 kA aluminum reduction cells[C]// TMS Light Metals. PA: Springer International Publishing,2007: 333-337.

[7] 刘伟, 李劼, 赖延清, 等. 采用电接触模型的铝电解槽阴极电压降分析[J]. 材料与冶金学报, 2008, 7(2): 99-102, 134.

LIU Wei, LI Jie, LAI Yanqing, et al. Analysis of cathode voltage drop in aluminum electrolysis cells with an electric contact model[J]. Journal of Materials and Metallurgy, 2008, 7(2): 99-102, 134.

[8] FRIEDRICH R, HILTMANN F, LUTZERATH A, et al. Minimizing cathode voltage drop by optimizing cathode slot design[C]// Light Metals 2017. San Diego. USA: Springer International Publishing, 2017: 705-711.

[9] BERENDS W. Reducing cathode voltage drop and reducing peak current density by use of cathode nails across the carbon to cast iron interface[C]// Light Metals 2017. San Diego. USA: Springer International Publishing, 2017: 1365-1373.

[10] 靳文军, 任必军, 李贺松, 等. 伊川铝厂阳极组装新型磷生铁配方的研究[J]. 轻金属, 2008(10): 30-33.

JIN Wenjun, REN Bijun, LI Hesong, et al. Study of the recipe of cast iron for anode rodding in Yichuan Aluminium Smelter[J]. Light Metals, 2008(10): 30-33.

[11] 尹诚刚, 李劼, 徐宇杰, 等. 新型阴极钢棒对铝电解槽电热场的影响[J]. 中国有色金属学报, 2014, 24(1): 246-253.

YIN Chenggang, LI Jie, XU Yujie, et al. Effects of innovative cathode collector bars on thermal-electric field of aluminum reduction cells[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(1): 246-253.

[12] BLAIS M , DESILETS M, LACROIX M. Optimization of the cathode block shape of an aluminum electrolysis cell[J]. Applied Thermal Engineering[J] Applied Thermal Engineering, 2013, 58(1/2): 439-446.

[13] 刘业翔. 现代铝电解[M]. 北京: 冶金工业出版社, 2008: 329-330.

LIU Yexiang, Modern aluminum electrolysis[M]. Beijing: Metallurgical Industry, 2008: 329-330.

[14] TAYLOR M P, WELCH B J. Bath/freeze heat transfer coefficients: experimental determination and industrial application[M]// Essential Readings in Light Metals. Hoboken, NJ, USA: John Wiley & Sons, Inc., 2013: 217-221.

[15] FENG Naixiang, LIANG Fanghui, SUN Yang, et al. Numerical calculation of thermal field and heat transfer coefficient for 160 kA aluminum reduction cell[J]. Transactions of Nonferrous Metals Society of China, 2003, 13(4): 953-957.

[16] YANG Shuai, LI Jie, XU Yujie, et al. A modelling of heat losses in aluminium reduction cell with slotted anodes[C]// Light Metals 2014. San Diego. USA: Springer International Publishing, 2014: 667-672.

[17] 吉玉辰, 王昭俊, 苏小文. 严寒地区被动房辐射楼板换热性能实验研究[J]. 煤气与热力, 2019, 39(8): 16-22, 42.

JI Yuchen, WANG Zhaojun, SU Xiaowen. Experimental study on heat transfer performance of passive house radiant floor in severe cold area[J]. Gas & Heat, 2019, 39(8): 16-22, 42.

[18] CHENG Jigao, SONG Yu. Electrical contact[M]. Beijing: Mechanical Industry, 1988: 235-236.

[19] LI Jie, LIU Wei, LAI Yanqing, et al. Analysis of cathode voltage drop in aluminum electrolysis cells with an electric contact model[C]// Orlando, USA, Springer International Publishing, 2007: 465-470.

[20] YS/T 287—2005. 铝电解用半石墨质阴极炭块[S].

YS/T 287—2005. Partially graphitiferous cathode carbon block for aluminium electrolysis[S].

[21] YS/T 65—2012. 铝电解用阴极糊[S].

YS/T 65—2012. Cathodic pastes for aluminium electrolysis[S].

(编辑 秦明阳)

收稿日期: 2020 -06 -24; 修回日期: 2020 -08 -30

基金项目(Foundation item):国家自然科学基金资助项目(51674302) (Project(51674302) supported by the National Natural Science Foundation of China)

通信作者:吕晓军,博士,教授,从事高温熔盐电化学、材料冶金及模拟计算研究;E-mail:lvxiaojun@csu.edu.cn