模压法制备C/C-SiC复合材料的力学性能

熊 翔,旷文敏,肖 鹏,杨 阳,姜四洲

(中南大学 粉末冶金国家重点实验室,湖南 长沙,410083)

摘 要:以炭纤维、硅粉、石墨粉等为原材料,采用模压法制备炭纤维增强C/C-SiC复合材料;采用电子万能试验机测定材料抗弯、抗压强度与冲击韧性,利用扫描电子显微镜观察其断口形貌;研究纤维分布状态、纤维长度以及后续炭化处理对C/C-SiC复合材料力学性能的影响。研究结果表明:当分散纤维以单丝状态分布在基体中时,纤维与基体结合紧密,材料力学性能较佳;纤维长度为5 mm时,材料具有较好的综合力学性能,抗弯强度、垂直和平行抗压强度、冲击韧性分别为59.06 MPa,147.03 MPa,134.25 MPa和2.45 kJ/m2;后续炭化处理使材料压缩性能提高22%以上,冲击韧性则有所下降,断裂方式为脆性断裂。

关键词:模压法;炭纤维;C/C-SiC复合材料;力学性能

中图分类号:TP332 文献标识码:A 文章编号:1672-7207(2008)03-0486-07

Mechanical properties of C/C-SiC composites by compression molding

XIONG Xiang, KUANG Wen-min, XIAO Peng, YANG Yang, JIANG Si-zhou

(State Key Laboratory of Powder Metallurgy, Central South University, Changsha 410083, China)

Abstract: C/C-SiC composites were prepared by compression molding with carbon fiber,silicon powder,graphite powder and so on. The effects of fiber dispersion, fiber length and succession carbonization process on mechanical properties were studied with electron omnipotence test equipment, and the fracture morphologies were observed by scanning electron microscopy. The results show that when the distribution of fiber in composites is in single fiber state, the combination of fiber and matrix is compact, and the mechanical properties of composites improve. When the fiber is 5 mm in length, the integrated mechanical properties of composites are better with bending strength 59.06 MPa, compressive strength 147.03 MPa in parallel direction, 134.25 MPa in vertical direction and impact toughness 2.45 kJ/m2. The compressive strength of composites increases by 22% after successive carbonization process, but the impact toughness decreases slightly, and the fracture model of composites is of brittle fracture.

Key words: compression molding; carbon fiber; C/C-SiC composites; mechanical properties

C/C复合材料具有密度低、比热容大、耐热性良好等优点,已经作为一种先进的摩擦材料在一些领域取代了传统的摩擦材料[1]。但是,C/C复合材料的制备周期长,成本高,湿态下摩擦因数不稳定,很难在交通工具上大规模使用[2]。添加了SiC基体的C/C-SiC复合材料具有密度低、耐磨性好、制动平稳、抗腐蚀、湿态下摩擦因数不减退等优点,且其生产成本远比C/C复合材料的低,极有希望取代C/C复合材料成为新一代的先进摩擦材料[3]。近年来,C/C-SiC摩擦材料的制备和摩擦磨损机理的研究取得了一定的成果,并已将其成功应用于坦克、高速列车以及高级轿车等刹车用制动器[4]。

目前,C/C-SiC复合材料的制备主要采用整体编织体化学气相沉积或熔融渗硅的方法,但该工艺具有制备周期长、成本高等缺点,而采用模压-原位反应法制备炭纤维增强SiC基复合材料则具有工艺周期短、节约能源、操作简单、近净成形等优点,是一种具有成本优势的工业生产方法[5-8]。

在炭纤维增强SiC基复合材料的体系中,材料的力学性能与工艺条件、纤维的分布状态、纤维长度、纤维与基体的粘接以及界面的应力传递等有关[9]。在此,本文作者研究了纤维分布状态、纤维长度、后续炭化处理对所制备的C/C-SiC复合材料力学性能的影响。

1 实 验

1.1 原 料

以PAN基短切炭纤维、硅粉(粒度为100 ?m)、石墨粉(粒度为100 ?m)、添加剂等为原料。炭纤维长度分别取2,5,8和12 mm。短切炭纤维在自制分散设备中进行分散。

1.2 C/C-SiC复合材料的制备

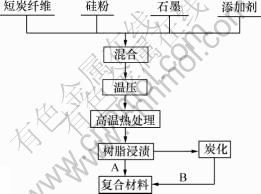

采用A和B 2种工艺路线制备所需C/C-SiC复合材料,工艺路线如图1所示。

图1 试样制备工艺路线

Fig.1 Processing route for manufacturing C/C-SiC composites

1.3 力学性能测试

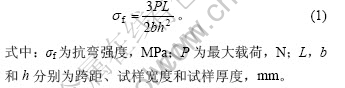

在CSS-44100电子万能试验机(机械工业部长春试验机研究所生产)上进行抗弯、抗压强度测试。抗弯强度采用三点弯曲法,试样尺寸(长×宽×高)为55 mm×10 mm×4 mm,跨距为40 mm,加载速率为0.5 mm/min,计算公式如下:

抗压强度测试分别取垂直纤维层方向(⊥)和平行纤维层方向(∥),试样尺寸为10 mm×10 mm×10 mm。

冲击韧性采用简支梁摆锤式冲击实验机,试样尺寸为55 mm×10 mm×10 mm,计算公式为:

采用JSM-6360LW扫描电镜观察试样断口形貌。

2 结果与讨论

2.1 纤维分布对材料力学性能的影响

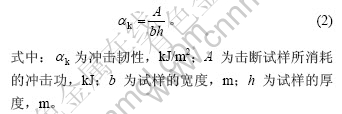

以8 mm长的未分散纤维、分散纤维和经过2 300 ℃热处理后的分散纤维,采用图1所示A工艺路线制备成所需试样,分别测试其力学性能,所得数据如表1所示。

表1 纤维分布对力学性能的影响

Table 1 Effect of fiber distributing on mechanical properties

由表1可知,分散纤维增强的M2试样的力学性能最好,与M1和M3试样相比,各项强度均有所提高,其抗弯、垂直、平行抗压强度和冲击韧性分别为56.65 MPa,89.29 MPa,76.86 MPa和2.63 kJ/m2。

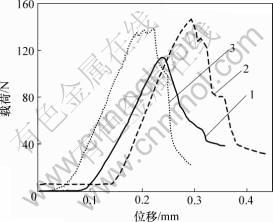

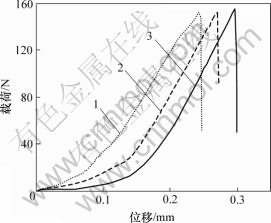

图2所示为不同分布状态纤维增强C/C-SiC复合材料的载荷-位移曲线。可见,M1试样的载荷-位移曲线基本上呈线性变化,载荷达到最大后,曲线以直线下降,表现出脆性断裂特征。M2试样的载荷-位移曲线在开始阶段以线性增加,后以小段抛物线上升到顶点,在下降过程中,该曲线出现了几个平台(转折点),表现为假塑性断裂特征。M3试样的载荷-位移曲线在加载开始阶段上升很快,在载荷顶点处有一波动平台的出现,载荷下降时也有曲线的波折,表现出脆性与假塑性的结合特征。

1—M1试样;2—M2试样;3—M3试样

图2 纤维分布状态与材料抗弯载荷-位移关系曲线

Fig.2 Load-displacement curves of bending with fiber distributing

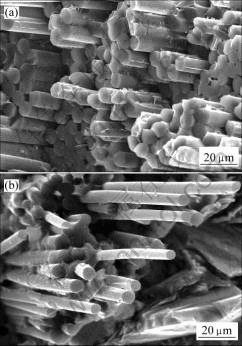

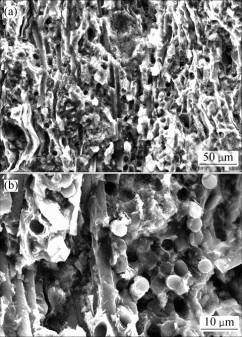

分散纤维增强材料(M2)的力学性能比未分散纤维(M1)的好。主要是由于纤维经过分散后,M2试样中纤维以单丝状态增强材料,而M1中纤维没被分散,纤维以纤维束的状态增强材料。图3(a)所示为M1试样的断口扫描照片,可见,纤维在基体中以纤维束的状态存在,纤维束之间有大量的孔隙存在,单根纤维断口平整,材料失效时纤维束的整体断裂导致材料迅速破坏,纤维没有发挥增强基体的作用,表现出脆性断裂特征。M2中分散纤维在基体中分布较均匀,炭纤维单丝之间的孔隙在压制时能被原料中的树脂粉、石墨粉等填充,纤维与基体结合界面多,材料的孔隙率低。材料加载时,基体能有效的将载荷传递给纤维。材料失效时,可通过纤维拔出、界面脱粘、纤维搭桥等机制吸收更多的外载能量。图3(b)所示为M2材料的断口扫描照片,可以看到有长短不一的纤维被拔出,材料在破坏过程中有界面脱粘等现象出现,可知该材料纤维/基体界面结合适中。另外,拔出纤维上可见有粘附物,断裂时通过拔出纤维与基体的摩擦可吸收大量断裂能,提高了材料的强度[10]。因此,纤维拔出、界面脱粘是M2试样的增强、增韧机制。

(a) M1试样;(b) M2试样

图3 材料抗弯断口SEM形貌

Fig.3 SEM micrographs of damage surface of composites

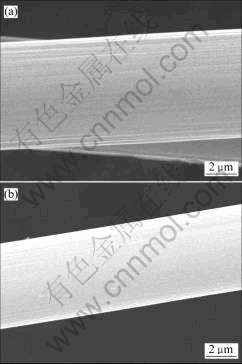

经2 300 ℃高温处理后的纤维(M3试样)增强效果比原始纤维(M2试样)的差,这是因为经2 300 ℃的热处理后,去除了炭纤维表面涂敷的环氧树脂上料剂,改善了纤维与基体的结合状况,提高了炭纤维表面的石墨化度,使微晶尺寸长大,取向一致,形成一层微晶石墨炭层[11],并有效延缓硅碳反应时液硅对炭纤维的侵蚀损伤,这对复合材料强度的提高有利。但同时2 300 ℃的处理温度对炭纤维本身强度损伤更大,所以,制备的材料总体力学性能反而下降[12],对比纤维热处理前后纤维表面形貌变化(图4)可知,经2 300 ℃热处理后纤维表面的原始沟槽减少,表面变得光滑。高温液硅铺展与炭纤维表面反应时,纤维光滑表面可以减少反应接触面积,表面生成的微晶石墨炭层又可以降低硅/炭反应速度,这些都可减轻液硅与纤维反应时对纤维的侵蚀损伤,并可使纤维/基体的界面结合弱化,所以,材料断裂时出现了图2中M3试样的脆性与假塑性结合特征。

2.2 炭纤维长度对材料力学性能的影响

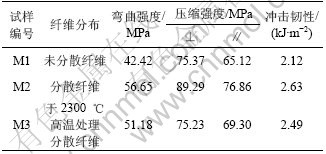

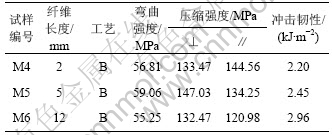

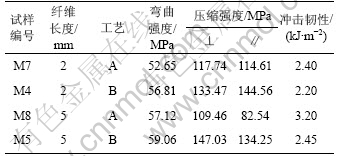

采用长度为2 mm,5 mm和12 mm的分散炭纤维,并采用如图1所示B工艺制备所需复合材料,分别测试其力学性能,所得数据如表2所示。

(a) 炭纤维原始形貌;(b) 经2 300 ℃热处理后形貌

图4 炭纤维表面形貌

Fig.4 SEM images of carbon fiber surface

表2 纤维长度对力学性能的影响

Table 2 Effect of fiber length on mechanical properties

由表2可见,随着纤维长度的增加,复合材料的弯曲强度、垂直压缩强度先增加后减小,平行压缩强度单调下降,冲击韧性则为单调上升。5 mm长炭纤维制备的材料综合力学性能较好,其抗弯、垂直和平行抗压强度、冲击韧性分别为59.06 MPa,147.03 MPa,134.25 MPa和2.45 kJ/m2。而2 mm纤维增强的M4试样平行压缩强度为144.56 MPa,超过了其垂直压缩强度(133.47 MPa),主要原因是2 mm的纤维长度较短,混料时较易混合均匀。宏观上观察混合料,2 mm混合料接近球型,其他长度纤维混合料则为棉絮层片状。由2 mm纤维所制备的材料在平行压制压力方向上有相对较多的纤维分布,当垂直压制压力方向压缩时,纤维的断裂、拔出和劈裂能有效延缓、抵制分层开裂,因此,其平行抗压强度得到提高。

图5所示为不同长度炭纤维增强C/C-SiC复合材料的弯曲载荷-位移曲线图,该组试样是采用B工艺路线制备。由图5可见,3条曲线在加载的开始阶段,随着位移的增加,载荷以线性增大至顶点,然后,以陡线垂直下降,3种试样的断裂方式都为脆性断裂。3条曲线不同点在于最大载荷对应的位移不同,随着纤维长度的增加,材料断裂失效时的位移增大。

1—M4试样;2—M5试样;3—M6试样

图5 纤维长度与材料抗弯载荷-位移关系曲线

Fig.5 Load-displacement curves of bending with fiber length

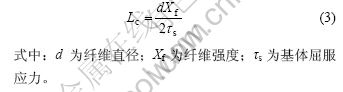

复合材料中增强相纤维的长度是影响其增强效果的重要因素,当应力达到纤维断裂时,最短纤维的长度称为纤维的临界长度Lc,其计算公式如下:

对于不同长度的纤维,作用在纤维上的拉应力也不同,短纤维复合材料的强度,取决于纤维长度L,若L<Lc,则短纤维上的拉应力达不到纤维的断裂强度,复合材料的破坏由基体或界面破坏引起;若L>Lc,则纤维发生断裂,导致材料的失效[13-14]。在短炭纤维增强C/C-SiC复合材料中,一般取d=7 μm,Xf = 4 GPa,τs=20 MPa[15],由式(3)可得Lc=0.7 mm。所以,只要纤维长度L≥0.7 mm,就可以发挥纤维的增强作用。实验中采用的纤维长度均大于0.7 mm,故从理论上都能发挥炭纤维的增强作用,所造成的力学性能差异,应是纤维长度与纤维分布、纤维/基体界面结合强度以及制备工艺等其他因素共同作用的结果。

图6所示为采用B工艺路线制备试样的抗弯断口扫描照片。可见,断面上纤维断口平整,为直接脆性断裂。纤维周围有大量灰白色物质(见图6(a)),经能谱分析是残留的单质Si以及生成的SiC,可见断裂主要发生在硅碳反应剧烈的地方。残留Si、脆性生成物SiC、脆性SiC/纤维界面都是造成脆性断裂的原因,同时,断面上有浸渍树脂炭化收缩所产生的孔隙、裂纹(见图6(b)),这些都易成为材料脆性断裂的有利路径。

(a) 生成SiC处断裂;(b) 树脂收缩孔隙、裂纹处断裂

图6 B工艺制备试样抗弯断口SEM形貌

Fig.6 SEM micrographs of bending fracture surface by process B

2.3 后续炭化处理对材料力学性能的影响

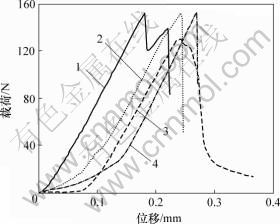

对2 mm和5 mm长分散炭纤维,分别采用如图1所示A和B 2种工艺路线制备所需复合材料,测试其力学性能,所得结果如表3所示。

表3 后续炭化处理对力学性能的影响

Table 3 Effect of succession carbonization disposal on mechanical properties

由表3可知,对于A和B 2种工艺制备的相同长度炭纤维增强的C/C-SiC复合材料,采用B工艺制备的材料其抗弯强度、垂直和平行抗压强度均比A工艺的大,但冲击韧性下降。

图7所示为采用A和B 2种工艺路线制备材料的抗弯载荷-位移曲线。可见,采用A工艺路线的M7和M8试样在载荷到正顶点后,下降过程中出现了2个载荷峰(M7试样),或是下降时载荷下降缓慢(M8试样),为非脆性断裂。采用B工艺路线的M4和M5材料在载荷开始阶段曲线缓慢增加,然后以直线快速上升,到达最大值后直线陡降,曲线表现出明显的脆性断裂特征。

1—M7试样;2—M4试样;3—M8试样;4—M5试样

图7 后续炭化处理与材料抗弯载荷-位移关系曲线

Fig.7 Load-displacement curves of bending with successional carbonization disposal

图8所示为A工艺路线制备材料的弯曲断口扫描电镜照片。可见,断面上有纤维拨出留下的纤维断头和大量孔洞以及纤维劈裂剥离留下的纤维槽(见图8(a)),只是纤维与基体的界面破坏并不如炭纤维那样光滑,纤维断头也较短(见图8(b))。可见,采用A工艺后续浸渍的树脂能有效填充基体,减少材料的缺陷,使材料成为一个统一整体。加载裂纹形成后,浸渍树脂在一定程度上能阻止裂纹的快速扩展,能较好地将载荷传递给纤维,并通过纤维在与树脂结合处的脱粘以及纤维从基体中的拔出延缓材料的迅速失效,材料断裂表现为非脆性断裂。

(a) 低倍;(b) 高倍

图8 A工艺制备试样抗弯断口SEM形貌

Fig.8 SEM micrographs of bending fracture surface by process A

采用B工艺所制备的材料由于采用了后期树脂浸渍—炭化工艺,炭化过程中树脂转化成树脂炭,并放出H2O,CH4,CO和CO2等小分子化合物,同时,树脂向纤维收缩靠拢,在纤维上产生了一种收缩压应力,树脂与纤维依靠这种物理压力以机械啮合方式紧密结合在一起,使材料的强度提高。同时,树脂炭化后生成的树脂炭是一种很硬的玻璃炭,比未炭化的树脂能承受更大载荷,这些都使得炭化后复合材料的压缩强度较大地提高。但是,炭化后原来填充树脂的区域留下了树脂炭化收缩时形成的微孔和裂纹(见图6(a)),同时,在硅炭反应中纤维表面与硅接触生成的SiC属于界面化学强结合,这些特点使采用B工艺制备的材料在加载时基体裂纹易在炭化收缩形成的微孔和裂纹处产生,迅速扩展。遇到纤维时,由于SiC与纤维界面结合强,纤维拔出、纤维桥接、界面脱粘等增强增韧机制无法发挥[16-17],纤维与基体同时失效断裂,材料表现为脆性断裂。

3 结 论

a. 分散纤维以纤维单丝状态分布于基体中时,纤维与基体结合紧密,孔隙填充好,所制备材料的力学性能比未分散纤维束增强的材料的力学性能优。经 2 300 ℃热处理后的分散纤维,由于纤维本身强度受损,所制备材料的力学性能下降。

b. 随纤维长度的增加,复合材料的弯曲强度、垂直压缩强度先增加后减少,平行压缩强度单调下降,冲击韧性则单调上升。当纤维长度为5 mm时,所制备材料的综合力学性能好,其抗弯、垂直和平行抗压强度分别为59.06,147.03和134.25 MPa,冲击韧性为2.45 kJ/m2。

c. 后续炭化处理使材料压缩性能提高22%以上,冲击韧性则有所下降。树脂炭化留下的收缩微孔、裂纹成为材料脆性断裂的有利通道,材料脆性大幅度增加,断裂方式为脆性断裂。

参考文献:

[1] Krenkel W, , Heidenreich B, , Renz R. C/C-SiC composites for advanced friction systems[J]. Advanced Engineering cMaterials ,, 2002,, 4(7).): 427-436.

[2] Krenkel W, . Cost effective processing of CMC composites by melt infiltration[J]. Ceramic Engineering and Science Proceeding, 2001, 22: 443-454.

[3] LiuIU Wen-chuan,, Wei WEI Yong-liang, , Deng DENG Jing-yi. Carbon-fiber- reinforced C-SiC binary matrix composites[composites[J]. Carbon,, 1995, ,33(4):]: 441-447.

[4] 肖 鹏, 熊 翔, 张红波,,, 等. C/C-SiC陶瓷制动材料的研究现状与应用[J]. 中国有色金属学 报,,, 2005,,, 15((5)):: 667-674..

XIAO Peng,, XIONG Xiang,, ZHANG Hong-bo,, et al. Progress and application , , 2005,,, 15((5): :667-674.

[5] 万玉慧,, 徐永东,, 潘文革. . 反应熔体浸渗法制备C/SiC复合材料的结构和力学性能[J]. .玻璃钢/复合材料,,, 2005,,, 3(5): :20-24.

,., XU Yong-dong,, PAN Wen-ge. Structure and mechanical properties of C/SiC composites by reactive melt infiltration[J] .. FRP/CM,, 2005,, 3(5):: 20-24.

[6] 宋麦丽,, 王 涛,, 闫联生,, 等. 高性能C/SiC复合材料的快速制备[J]. 新型炭材料,,, 2001,,, 16((2)):: 57-60.

,, WANG Tao,, YAN Lian-sheng, et al. Rapid fabrication of C/SiC composites with high performances[J]. New Carbon Materials,,, 2001,,, 16((2): 2):57-60.

[7] ,, 陈长乐,, 邹 武,, 等. ,,, 2001, 7,,((2):): 28-32.

YU Hui-qin,, CHEN Chang-le, , ZOU Wu,, et al. Fabrication and properties of C/C-SiC matrix composite[J]. Aerospace Materials and Technology,,, 2001,(, 7(2)):: 28-32.

[8] 吴庆军. 汽车制动用用C/C-Si复合材料的制备及其性能研究[D]. 长沙:: 中南大学粉末冶金研究院, 2004: 8-14.

,2004,: 8-14.

[9] 郭领军, 李贺军, 李克智, 等. 模压工艺制备短纤维增强C/C复合材料的研究[J]. 宇航材料工艺, 2004, 3(6): 11-15.

GUO Ling-jun, LI He-jun, LI Ke-zhi, et al. Study on short carbon fiber reinforced C/C composites fabricated with molding[J]. Technique Aerospace Materials and Technology, 2004, 3(6): 11-15.

[10] 蔡大勇, 李东春. 纤维含量对C/C复合材料力学性能的影响[J]. 炭素技术, 2001, 16(1): 16-18.

CAI Da-yong, LI Dong-chun. Effect of carbon fiber content the mechanical properties of C/C Composites[J]. Carbon Techniques, 2001, 16(1): 16-18.

[11] 陈腾飞. 炭纤维坯体结构及增密方式对炭/炭复合材料界面及性能的影响研究[D]. 长沙: 中南大学粉末冶金研究院, 2003: 59-64.

CHEN Teng-fei. Study on the effect of carbon fiber perform and densifying mean on CF/matrix interface and performance of carbon/carbon composites[D]. Changsha: Powder Metallurgy Research Institute, Central South University, 2003: 59-64.

[12] 闫联生, 李贺军, 崔 红, 等. 内部硅化法制备低成本C/SiC复合材料[J]. 材料工程, 2005, 10(9): 41-45.

YAN Lian-sheng, LI He-jun, CUI Hong, et al. C/SiC composites prepared by inners siliconizing process[J]. Material Engineering, 2005, 10(9): 41-45.

[13] 沈观林. 复合材料力学[M]. 北京: 清华大学出版社, 1996: 103-108.

SHEN Guan-lin. Composites mechanics[M]. Beijing: Tsinghua University Press, 1996: 103-108.

[14] 才 红. 剑麻纤维/酚醛树脂力学性能的研究[J].塑料, 2003, 33(5): 70-73.

CAI Hong. Mechanical property of sisal fiber/phenol formaldehyde composites[J]. Plastic, 2003, 33(5): 70-73.

[15] 周长城, 周新贵, 于海蛟, 等. 短碳纤维增强碳化硅基复合材料的制备[J]. 高科技纤维与应用, 2004, 29(4): 35-37.

ZHOU Chang-cheng, ZHOU Xin-gui, YU Hai-jiao, et al. Processing and mechanical properties of short carbon fiber reinforced SiC matrix composites[J]. Hi-Tech Fiber & Application, 2004, 29(4): 35-37.

[16] 梁锦华, 黄启忠, 苏哲安, 等. 短纤维C/C-SiC复合材料的组织结构与断裂机[J]. 中南大学学报: 自然科学版, 2005, 36(6): 924-928.

LIANG Jin-hua, HUANG Qi-zhong, SU Zhe-an, et al. Structure and fracture mechanism of short fiber reinforced C/C-SiC composites[J]. Journal of Central South University: Science and Technology, 2005, 36(6): 924-928.

[17] 郭领军, 李贺军, 薛 辉, 等. 短切炭纤维增强沥青基C/C复合材料的力学性能[J]. 新型炭材料, 2006, 21(1): 36-40.

GUO Ling-jun, LI He-jun, XUE Hui, et al. Mechanical properties of short carbon fibers reinforced pitch-based carbon/carbon composites[J]. New Carbon Materials, 2006, 21(1): 36-40.

收稿日期:2007-07-22;修回日期:2007-09-18

基金项目:国家“863”计划项目(2006AA03Z560);湖南省杰出青年科学基金资助项目(06JJ10007)

通信作者:熊 翔(1963-),男,湖南湘潭人,博士,教授,博士生导师,从事C/C及C/C-SiC复合材料的制备与性能研究;电话:0731-8836079;E-mail: xiongx@mail.csu.edu.cn