文章编号:1004-0609(2008)09-1577-07

镁合金轧制板材低温变形行为与微观机制

刘俊伟,陈振华,陈 鼎

(湖南大学 材料科学与工程学院,长沙 410082)

摘 要:研究AZ31镁合金轧制板材在低温(室温至423 K)拉伸条件下的力学性能,并通过高温金相显微镜的拉伸附件观察动态微观组织的变化过程。结果发现:镁合金的塑性随温度的升高和应变速率及负载的降低而增 加,表现出一定的应变速率敏感性。常温下的主要变形机制为{ }压缩孪生,其形核和长大速度很快,但同时也存在少量的基面滑移,不同类型的孪晶在晶粒中彼此相交;而随着温度的升高,a+c非基面滑移的临界剪切应力迅速下降,大量非基面滑移系被激发,板材塑性性能明显改善;当应变速率较高时(423 K,应变速率10?2 /s),断裂方式为有一定塑性特征的解理形貌;随着应变速率的降低(423 K,应变速率10?3 /s),断裂方式逐渐变为塑性断裂。

}压缩孪生,其形核和长大速度很快,但同时也存在少量的基面滑移,不同类型的孪晶在晶粒中彼此相交;而随着温度的升高,a+c非基面滑移的临界剪切应力迅速下降,大量非基面滑移系被激发,板材塑性性能明显改善;当应变速率较高时(423 K,应变速率10?2 /s),断裂方式为有一定塑性特征的解理形貌;随着应变速率的降低(423 K,应变速率10?3 /s),断裂方式逐渐变为塑性断裂。

关键词:镁合金;压缩孪晶;基面滑移;变形行为;断裂机制

中图分类号:TG 146.2 文献标识码:A

Microstructure evolution and deformation behavior of

hot-rolled Mg alloy at low temperatures

LIU Jun-wei, CHEN Zhen-hua, CHEN Ding

(School of Materials Science and Engineering, Hunan University, Changsha 410082, China)

Abstract: The mechanical behavior and dynamic microstructural evolution of hot-rolled AZ31 Mg alloy were studied by tensile attachment of high-temperature microscopy (HTM) at different temperatures from room temperature (RT) to 423 K. The results show that the ductility of Mg alloy material increases with the increase of deformation temperature and the decreases of load and strain rate and has certain strain rate sensitivity. The main deformation evolution is { } contraction twinning at RT which has high nucleation rate and growth velocity and little basal slips. Different types of twins can intersect with each other and results in severe shear in the existing twin. With the increase of temperature, the critical resolved shear stress (CRSS) of a+c non-basal slip is surpassed easily, a great many non-basal slip systems are activated and the plastic property of Mg alloy is improved obviously. At 423 K, when the strain rate is 10?2 /s, the alloy exhibits ductile fracture with dimples. With the decrease of strain rate (10?3 /s), the fracture transfer plastic deformation step by step.

} contraction twinning at RT which has high nucleation rate and growth velocity and little basal slips. Different types of twins can intersect with each other and results in severe shear in the existing twin. With the increase of temperature, the critical resolved shear stress (CRSS) of a+c non-basal slip is surpassed easily, a great many non-basal slip systems are activated and the plastic property of Mg alloy is improved obviously. At 423 K, when the strain rate is 10?2 /s, the alloy exhibits ductile fracture with dimples. With the decrease of strain rate (10?3 /s), the fracture transfer plastic deformation step by step.

Key words: magnesium alloys; contraction twin; basal slip; deformation behavior; fracture mechanism

由于镁合金具有密度小,比强度和疲劳强度高,比弹性模量好以及优良的切削加工性能和抛光性能,使镁合金在一系列国防尖端领域及汽车、产品和化工等日常制造业中被广泛应用[1?2]。尽管如此,由于大部分镁合金具有密排六方结构,导致其塑性变形能力差,低温下a+c非基面滑移(包括柱面滑移和锥面滑移)很难发生,易出现较为明显的各向异性[3?4]。

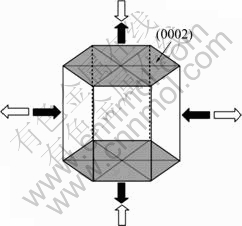

在这种情况下,对镁合金低温塑性变形机理进行深入研究有助于扩大镁合金的应用范围,并受到越来越多国内外研究者的关注。WANG等[5]认为在镁合金低温变形过程中,当应力方向平行于c轴进行拉伸或垂直于c轴压缩时,会产生{ }拉伸孪晶;而当应力方向平行于c轴压缩或垂直于c轴拉伸时,会产生{

}拉伸孪晶;而当应力方向平行于c轴压缩或垂直于c轴拉伸时,会产生{ }压缩孪晶和{

}压缩孪晶和{ }-{

}-{ }二次孪晶,如图1所示。YIN等[6]在研究轧制态AZ31镁合金中低温变形机理时发现,孪生在变形过程中起主要作用,并可诱发动态再结晶(DRX)的产生。JIANG等[7] 认为,{

}二次孪晶,如图1所示。YIN等[6]在研究轧制态AZ31镁合金中低温变形机理时发现,孪生在变形过程中起主要作用,并可诱发动态再结晶(DRX)的产生。JIANG等[7] 认为,{ }孪晶对镁合金塑性性能的影响极其复杂,一方面,变形过程中孪晶界会阻碍位错的运动,根据Basinski机制,孪生也会使滑动位错转变为不滑动位错,使得材料的加工硬化率提高;另一方面,孪生又可以缓解晶界处的应力集中,并引起晶粒转动,使晶粒宜于变形,提高材料的软化效果。因此,理解孪晶在变形过程中的作用,对提高镁合金的低温塑性至关重要。

}孪晶对镁合金塑性性能的影响极其复杂,一方面,变形过程中孪晶界会阻碍位错的运动,根据Basinski机制,孪生也会使滑动位错转变为不滑动位错,使得材料的加工硬化率提高;另一方面,孪生又可以缓解晶界处的应力集中,并引起晶粒转动,使晶粒宜于变形,提高材料的软化效果。因此,理解孪晶在变形过程中的作用,对提高镁合金的低温塑性至关重要。

图1 { }压缩孪晶和{

}压缩孪晶和{ }拉伸孪晶产生的示意图

}拉伸孪晶产生的示意图

Fig.1 Schematic diagram of applied loading directions and types of twinning (Black arrows applied loading directions of favorable { } tensile twinning; white arrows applied loading directions of favorable {

} tensile twinning; white arrows applied loading directions of favorable { } contraction twinning)

} contraction twinning)

传统金相学领域中,静态金相技术仅能反映出材料的最终组织形态,无法了解真实的金属变形过程。而采用动态原位技术则可以直接观察到微观结构的演变过程,这对于判断材料的变形机理具有重大意义。目前,大多数研究都集中于高温、高真空条件下的原位观察,对室温及低温下的原位观察报道极少[8]。

本研究通过对样品表面的特殊处理(仅电解抛光,不腐蚀),利用高温金相显微镜(HTM)的拉伸附件在常温和373 K下观察到了AZ31镁合金的微观结构动态变化过程,并通过对微观结构的分析进一步探讨了镁合金低温塑性变形机理。

1 实验

本研究所用合金为AZ31镁合金轧制板材,化学成分如表1所列。首先将厚度约为7.5 mm的镁合金挤压板材加热到673 K保温1 800 s,随后以每道次以10%~20%的压下量轧制10道次,并进行退火处理,最终得到厚度约为1.1 mm的板材。沿轧制方向(RD)对轧制板材进行线切割加工,得到长27 mm,宽4 mm的拉伸样品。

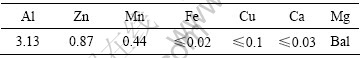

表1 热轧镁合金AZ31板材的化学成分

Table 1 Chemical composition of hot-rolled AZ31 Mg alloy (mass fraction, %)

在放入高温金相显微镜(HTM?4134,日本东京联合光学公司)的拉伸附件前,对拉伸样品表面进行打磨和机械抛光处理,并将样品放入磷酸和高纯酒精的混合液中(体积比为3.75?6.25)电解抛光7~10 min,抛光电压为4 V。抛光结束后,迅速将样品放入拉伸附件中密封,抽取真空(真空度小于13.3 MPa),并在试样两端加入载荷进行表面观察。

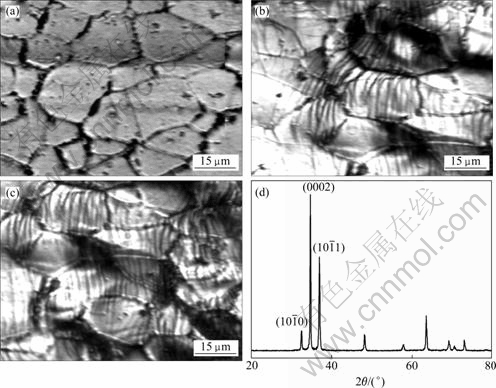

将抛光后的样品未经过化学腐蚀就直接放入拉伸附件中是为了避免腐蚀层对样品表面观察的影响。图2所示为AZ31轧制镁合金的微观组织。由图2可看出,样品在电解抛光后应用清水冲洗且不能在空气

图2 AZ31轧制镁合金的微观组织

Fig.2 Microstructures of hot-rolled AZ31 Mg alloy: (a) Oxide; (b) Initial sheet

中暴露时间过长,否则会产生大块的氧化层,而无法观察(见图2(a));退火后的AZ31镁合金晶粒细小、等轴,平均晶粒度为13.2 μm,不存在任何孪晶组织(见图2(b))。

为了进一步观察镁合金低温塑性性能,在恒定应变速率下采用WDW?E200微机控制电子万能实验机对样品进行拉伸实验,实验温度为293~423 K,应变速率为10?1~10?3 /s。拉伸前和拉伸后的样品表面采用D?5000型X射线衍射仪(XRD)和JEM?3010型高分辨透射电子显微镜(HRTEM)进行观察。采用JSM?6400F冷场发射扫描电镜(SEM)分析断口表面形貌。

2 结果与讨论

2.1 力学性能

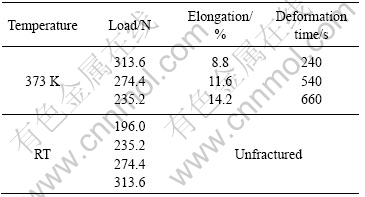

表2所列为室温和373 K下HTM拉伸附件中测得的伸长率和变形时间。由表2可以看出,当室温下载荷逐渐达到最大(313.6 N)时,AZ31镁合金样品仍未被拉断;而随温度的提高,在负载为235.2 N时,材料就产生断裂。这表明样品在室温下的抗拉强度要远高于较高温度下的抗拉强度,以致于由载荷所引起的应力未能达到断裂强度值。

表2 恒定载荷拉伸实验条件和结果

Table 2 Experimental conditions and results in constant loading tension

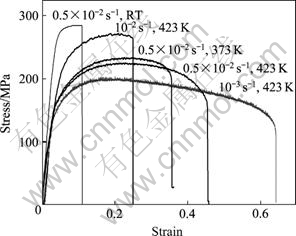

图3所示为不同温度和应变速率下的应力—应变曲线。由图3可看出,较低温度下,AZ31镁合金的拉伸曲线光滑,无锯齿线出现;在室温及应变速率为0.5×10?2 /s时,不存在软化,材料达到峰值应力后立即断裂,且其峰值应力高于其它条件;当温度逐渐升高后,软化效果明显,材料在达到峰值应力后,由于软化作用而继续变形,其伸长率也相应提高。峰值应力被认为是硬化过程和软化过程的平衡点,当负荷产生的应力在达到峰值应力前,硬化现象更为突出,材料的变形较小;且随着温度的升高,峰值应力持续下降,最终引发材料的断裂。

图3 不同温度和应变速率下的工程应力—应变曲线

Fig.3 Engineering stress—strain curves at different temperatures and strain rates

由表2和图3还可以看出,相同温度下镁合金板材的伸长率与负载和应变速率成反比,表现出明显的应变速率敏感性。产生以上现象是由于首先轧制态镁合金在低温塑性变形过程中,变形机制很少,一般只有基面滑移、柱面滑移、锥面滑移和孪生4种[9]。而柱面滑移和锥面滑移的临界剪切应力(CRSS)较高,且这两种滑移系的启动速度远小于孪生而无法被激发。因此,在低温变形过程中如果应变速率较大,则仅有孪生和少量的基面滑移产生,应力被大量集中在晶界处无法缓解,最终发生脆性断裂;而随着温度的升高,a+c非基面滑移的CRSS下降很快,而孪生变形的CRSS则缓慢下降,因此当非基面滑移系的CRSS下降到小于孪生时,孪晶减少,而大量滑移系被激发,集中在晶界处的应力被有效缓解,软化效果明显,塑性性能显著改善。

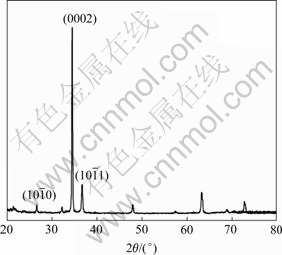

其次,热轧板材通常都有很强的基面织构(见图4),其(0002)面大都平行于板材表面。因此,当拉伸方向垂直于c轴时,会产生{ }压缩孪晶和{

}压缩孪晶和{ }-{

}-{ }二次孪晶。而Barrett根据对本构方程的计算,认为孪生与空洞和材料软化之间关系密切,不同的孪生类型对材料的塑性变形影响也不一样,{

}二次孪晶。而Barrett根据对本构方程的计算,认为孪生与空洞和材料软化之间关系密切,不同的孪生类型对材料的塑性变形影响也不一样,{ }压缩孪晶会使材料延着剪切带断裂,不利于伸长率的提高[10]。综合以上原因,滑移系的缺乏和大量压缩孪晶的产生都会导致材料塑性性能的降低。

}压缩孪晶会使材料延着剪切带断裂,不利于伸长率的提高[10]。综合以上原因,滑移系的缺乏和大量压缩孪晶的产生都会导致材料塑性性能的降低。

2.2 金相分析

图5所示为样品在HTM中室温拉伸的动态显微

图4 原始板材的XRD谱

Fig.4 XRD pattern of initial sheet

图5 试样室温拉伸的动态显微组织和拉伸后的XRD谱

Fig.5 Dynamic microstructures of specimen deformed at room temperature under different loads and XRD pattern of specimen after tension: (a) 235.2 N; (b) 274.4 N; (c) 313.6 N; (d) XRD pattern

组织和拉伸后的XRD谱。由图5可看出,当负载为235.2 N时,相对于成形前的原始组织,微观结构(见图5(a))没有明显变化,晶粒仍保持均一、等轴,晶粒尺寸也基本不变;将负载逐渐增加至274.4 N时,样品微观组织变化还是不明显;继续将负载增加到HTM所能承受的最大负载313.6 N,在相当短的时间内(不到5 s),晶粒中出现了大量孪晶(见图5(b))。低温下hcp结构的金属中孪生对应力的敏感性要远大于滑移,其形核与长大的速度高于声速[11?12]。因此,随着晶界处不断集中的应力达到孪生所需要的CRSS,孪生优先发生,大量孪晶在几秒钟就完成了形核和长大过程,相似现象在373 K下也可以观察到;随着拉伸的持续进行,晶粒中出现少量孔洞(见图5(c)),但由于负载质量的限制,应力无法进一步集中,晶粒内的孔洞没有持续长大,材料最终未能断裂。

众所周知,镁合金中的基面滑移和非基面滑移会致使晶界处的位错线塞积,并引起滑移台阶产生,但却无法使晶粒取向发生变化。只有孪生会使晶粒偏转一定角度,且孪晶类型不同偏转角度也不相同(见表3)。图5(d)所示为在HTM中常温拉伸后样品(伸长率为5.4%,未断裂)的XRD谱。与有较强基面取向的原始板材(见图4)相比,拉伸后的{ }峰明显增大,由原来的0.17变化至0.67。{

}峰明显增大,由原来的0.17变化至0.67。{ }峰的增大表明了孪生对晶粒取向有较大影响,而与滑移机制无关。

}峰的增大表明了孪生对晶粒取向有较大影响,而与滑移机制无关。

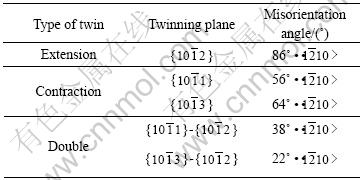

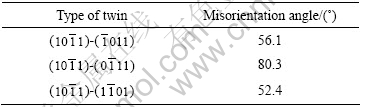

表3 孪晶类型与晶粒偏转角度[7]

Table 3 Misorientation angle of various types of twin

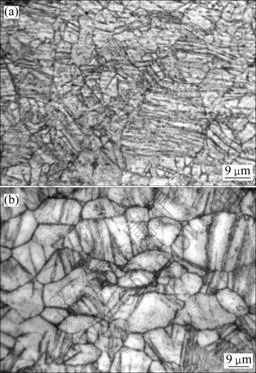

图6所示分别为HTM拉伸附件中观察到的373 K下负载235.2 N和313.6 N的微观组织。从图6中可以看出,晶粒中孪晶分布密集,且其形貌大多数为细长的线状。根据孪晶生长的动力学理论和孪晶中的位错生长机制可知,镁合金中 压缩孪晶与

压缩孪晶与 拉伸孪晶在金相显微镜中的形貌存在很大差异,前者细而长,后者却短而粗。因此,图4的微观组织进一步证明了轧制镁合金拉伸变形中所产生的为

拉伸孪晶在金相显微镜中的形貌存在很大差异,前者细而长,后者却短而粗。因此,图4的微观组织进一步证明了轧制镁合金拉伸变形中所产生的为 压缩孪晶。由图6(b)中还可以看出,样品断裂后晶粒内部有少量的长条状孔洞(A位置)出现。这些孔洞都在晶界处受阻,无法贯穿晶粒,而有些孔洞则受阻于孪晶界,BARRETT则认为这些晶粒内部未能长大的孔洞是由压缩孪晶引起的[10]。这些孔洞的形核长大速度很快,但受晶界和孪晶界的影响而无法继续扩展,且由于孔洞数量较少,无法进一步缓解应力集中,材料的断裂仍以解理断裂为主。

压缩孪晶。由图6(b)中还可以看出,样品断裂后晶粒内部有少量的长条状孔洞(A位置)出现。这些孔洞都在晶界处受阻,无法贯穿晶粒,而有些孔洞则受阻于孪晶界,BARRETT则认为这些晶粒内部未能长大的孔洞是由压缩孪晶引起的[10]。这些孔洞的形核长大速度很快,但受晶界和孪晶界的影响而无法继续扩展,且由于孔洞数量较少,无法进一步缓解应力集中,材料的断裂仍以解理断裂为主。

图6 试样在373 K时不同负载下的HTM像

Fig.6 HTM images of specimens deformed at 373 K under different loads: (a) 235.2 N, 480 s; (b) 313.6 N, 160 s

图7所示分别为试样在373 K、应变速率为10?1 /s和10?3 /s时的微观组织。从图7可看出,随着应变速率的增加,孪晶的数量也随之增大,且其中许多孪晶彼此相交,存在一定的交角。这是由于hcp结构的单晶中存在6个{ }面,而这6个面发生{

}面,而这6个面发生{ }压缩孪生变形的机会是均等的。此外,变形过程中也有可能会产生{

}压缩孪生变形的机会是均等的。此外,变形过程中也有可能会产生{ }压缩孪晶[13]。因此,在单个晶粒中同一种类不同类型的孪晶或不同种类的孪晶都有可能相交,其夹角关系如表4所列。

}压缩孪晶[13]。因此,在单个晶粒中同一种类不同类型的孪晶或不同种类的孪晶都有可能相交,其夹角关系如表4所列。

图7 试样在373 K时不同应变速率下拉伸试样断裂的微观组织

Fig.7 Microstructures of fractured specimens deformed at 373 K and different strain rates: (a) 10?1 /s; (b) 10?3 /s

表4 不同类型{ }孪晶的夹角[14]

}孪晶的夹角[14]

Table 4 Misorientation angle of various types of { } twin

} twin

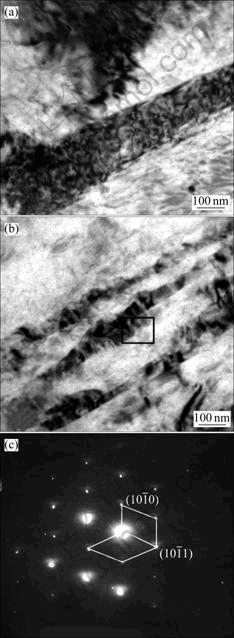

2.3 HRTEM分析

图8所示为镁合金轧制板材在423 K和10?1 /s时拉伸后的TEM像。尽管在低温高下塑性变形方式以孪生为主,但图8(a)中存在少量的滑移线,这些滑移线终止于孪晶。滑移线的出现由以下几方面原因引起:1) 尽管轧制板材中大部分晶粒的(0002)面都平行于拉伸方向,但仍有少量晶粒的基面与拉伸方向存在一定的夹角;2) AZ31镁合金基面滑移的CRSS非常小,仅有2 MPa。如果基面滑移与拉伸方向仅存在很小的夹角,基面滑移可以很容易被激发;3) 在423 K下,a+c非基面滑移的CRSS下降很快,大量滑移系被启动。且在孪晶内部还可以观察到存在少量滑移线,这是由于孪生变形导致晶粒转向,使晶粒取向宜于滑移机制的产生所引起的。图8(b)中分布着许多形貌较细长的孪晶,其宽度仅有40 nm左右。图8(c)所示为图8(b)中孪晶的衍射花样,通过计算分析可以确定图8(b)中的孪晶为{ }压缩孪晶。

}压缩孪晶。

图8 试样在423 K及10?1 /s时镁合金轧制板材的TEM像

Fig.8 TEM images of specimens deformed at 423 K and 10?1 /s: (a), (b) Morphologies of twins; (c) Diffraction pattern

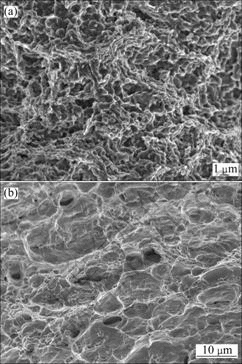

2.4 SEM分析

图9所示为轧制板材不同拉伸条件下的断口形貌。由图9可看出,在423 K及10?2 /s条件下,拉伸断口处韧窝分布相对较少,塑性变形量小,拉伸处颈缩小,断裂方式为具有一定塑性特征的解理形貌(见图9(a));随着应变速率的降低(10?3 /s),塑性性能提 高,材料发生了一定量的颈缩,断口处韧窝变大、变深,数量明显增多,其断裂机制已转变为塑性断裂(见图9(b))[15?16]。

图9 AZ31镁合金不同条件下拉伸断口的SEM像

Fig.9 SEM images of hot-rolled AZ31 Mg alloy under different conditions: (a) 423 K, 10?2 /s; (b) 423 K, 10?3 /s

3 结论

1) { }压缩孪晶在热轧AZ31镁合金板材的低温拉伸过程中起主要作用,同时也存在少量的基面滑移。随着温度的升高和应变速率及负载的降低,a+c非基面滑移的临界剪切应力(CRSS)迅速下降,a+c非基面滑移逐渐发挥作用,软化效果明显,塑性也逐渐提高,表现出一定的应变速率敏感性。

}压缩孪晶在热轧AZ31镁合金板材的低温拉伸过程中起主要作用,同时也存在少量的基面滑移。随着温度的升高和应变速率及负载的降低,a+c非基面滑移的临界剪切应力(CRSS)迅速下降,a+c非基面滑移逐渐发挥作用,软化效果明显,塑性也逐渐提高,表现出一定的应变速率敏感性。

2) { }压缩孪晶的形核和长大速度很快,并引起了晶粒转向,不同类型的孪晶在晶粒中彼此相交。

}压缩孪晶的形核和长大速度很快,并引起了晶粒转向,不同类型的孪晶在晶粒中彼此相交。

3) AZ31轧制镁合金板材在常温下为脆性断裂,随温度的升高和应变速率的降低,断裂方式逐渐变为具有一定塑性特征的解理形貌。

REFERENCES

[1] 刘 正, 张 奎, 曾小勤. 镁基轻质合金理论基础及应用[M]. 机械工业出版社, 2002: 31?35.

LIU Zheng, ZHANG Kui, ZENG Xiao-qin. Academic basis and application of magnesium based alloy[M]. China Machine Press, 2002: 31?35.

[2] 陈振华, 严红革, 陈吉华, 全亚杰, 王慧敏, 陈 鼎. 镁合金[M]. 北京: 化学工业出版社, 2004: 88?90.

CHEN Zhen-hua, YAN Hong-ge, CHEN Ji-hua, QUAN Ya-jie, WANG Hui-min, CHEN Ding. Magnesium alloy[M]. Beijing: Chemical Industrial Press, 2004: 88?90.

[3] 陈振华, 夏伟军, 严红革, 李落星, 程永奇, 郭 强, 陈 鼎. 变形镁合金[M]. 北京: 化学工业出版社, 2005: 76?78.

CHEN Zhen-hua, XIA Wei-jun, YAN Hong-ge, LI Luo-xing, CHEN Yong-qi, GUO Qiang, CHEN Ding. Deformed magnesium alloy[M]. Beijing: Chemical Industrial Press, 2005: 76?78.

[4] 陈振华, 夏伟军, 陈吉华, 严红革, 陈 鼎, 腾 杰, 张 昊, 贺毅强, 盛绍顶. 耐热镁合金[M]. 北京: 化学工业出版社, 2007: 102?105.

CHEN Zhen-hua, XIA Wei-jun, CHEN Ji-hua, YAN Hong-ge, CHEN Ding, TEN Jie, ZHANG Hao, HE Yi-qiang, SHEN Shao-ding. Heat-proof magnesium alloy[M]. Beijing: Chemical Industrial Press, 2007: 102?105.

[5] WANG Y N, HUANG J C. The role of twinning and untwinning in yielding behavior in hot-extruded Mg-Al-Zn alloy[J]. Acta Materialia, 2007, 55(3): 897?905.

[6] YIN D L, ZHANG K F, WANG G F, HAN W B. Warm deformation behavior of hot-rolled AZ31 Mg alloy[J]. Mater Sci Eng A, 2005, 392(1/2): 320?325.

[7] JIANG L, JONAS J J, LUO A A, SACHDEV A K, GODET S. Twinning-induced softening in polycrystalline AM30 Mg alloy at moderate temperatures[J]. Scripta Materialia, 2006, 54(5): 771?775.

[8] BOCCACCINI A R, HAMANN B. In situ high-temperature optical microscopy[J]. Journal of Material Science, 1999, 34(22): 5419?5436.

[9] JIANG J, GODFREY A, LIU W, LIU Q. Identification and analysis of twinning variants during compression of a Mg-Al-Zn alloy[J]. Scripta Materialia, 2008, 58(2): 122?125.

[10] BARRNETT M R. Twinning and the ductility of magnesium alloys (Part Ⅱ): Contraction twins[J]. Mater Sci Eng A, 2007, 464(1): 8?16.

[11] CHRISTIAN J W, MAHAJAN S. Deformation twinning[J]. Progress in Materials Science, 1995, 39(1/2): 1?157.

[12] GARY S. Mechanisms of twinning: Ⅷ. Maternal height, insulinlike growth factor and twinning rate[J]. The Journal of Reproductive Medicine, 2006, 51(9): 694?698.

[13] SUN H Q, SHI Y N, ZHANG M X, LU K. Plastic strain-induced grain refinement in the nanometer scale in a Mg alloy[J]. Acta Materialia, 2007, 55(3): 975?982.

[14] 陈振华, 杨春花, 黄长清, 夏伟军, 严红革. 镁合金塑性变形中孪生的研究[J]. 材料导报, 2006, 20(8): 107?113.

CHEN Zhen-hua, YANG Chun-hua, HUANG Chang-qing, XIA Wei-jun, YAN Hong-ge. Investigation of the twinning in plastic deformation of magnesium alloy[J]. Materials Review, 2006, 20(8): 107?113.

[15] GUO Q, YAN H G., ZHANG H, CHEN Z H, WANG Z F. Behaviour of AZ31 magnesium alloy during compression at elevated temperatures[J]. Materials Science and Technology, 21(11): 1349?1354.

[16] 房文斌, 王尔德, 于 洋. 95W-5(Ni/Fe/Co)合金的低温显微组织和力学性能[J]. 中国有色金属学报, 2004, 14(6): 907?911.

FANG Wen-bin, WANG Er-de, YU Yang. Low temperature microstructure and mechanical properties of 95W-5(Ni/Fe/Co) alloy[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(6): 907?911.

收稿日期:2008-01-21;修订日期:2008-05-29

通讯作者:陈振华,教授,博士;电话:0731-8821648;E-mail: liujw1981@yahoo.com.cn

(编辑 李艳红)