单晶连铸技术原理及试验研究①

来源期刊:中国有色金属学报1996年第4期

论文作者:范新会 魏朋义 李建国 傅恒志

文章页码:109 - 112

关键词:金属单晶; 连续铸造; 导电线材; 工艺试验; 技术原理

Key words:single crystal metal; continuous casting; electric wire; technology test; principle

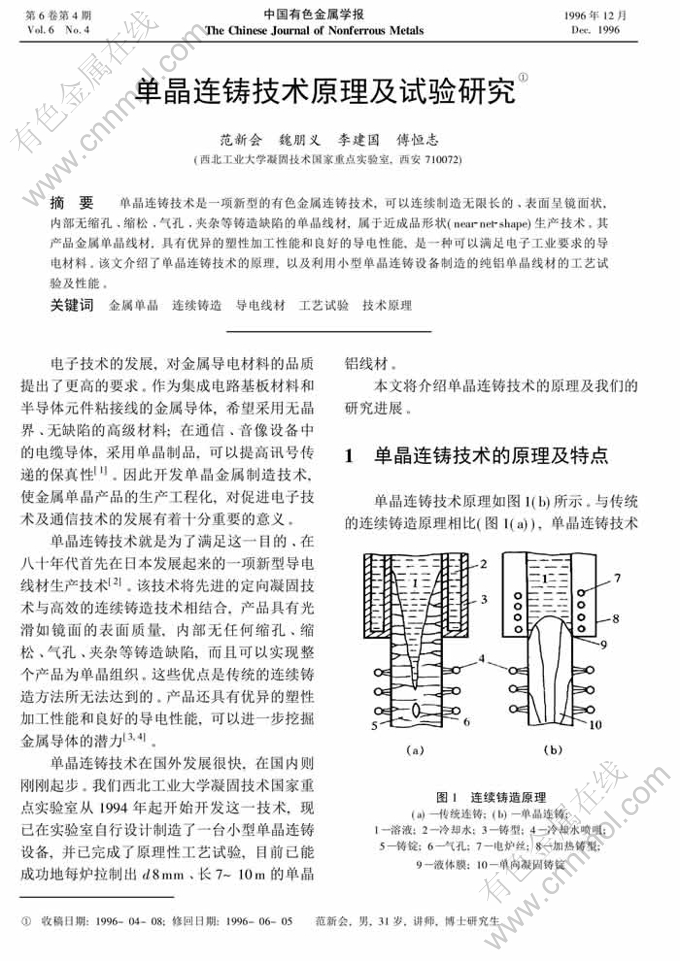

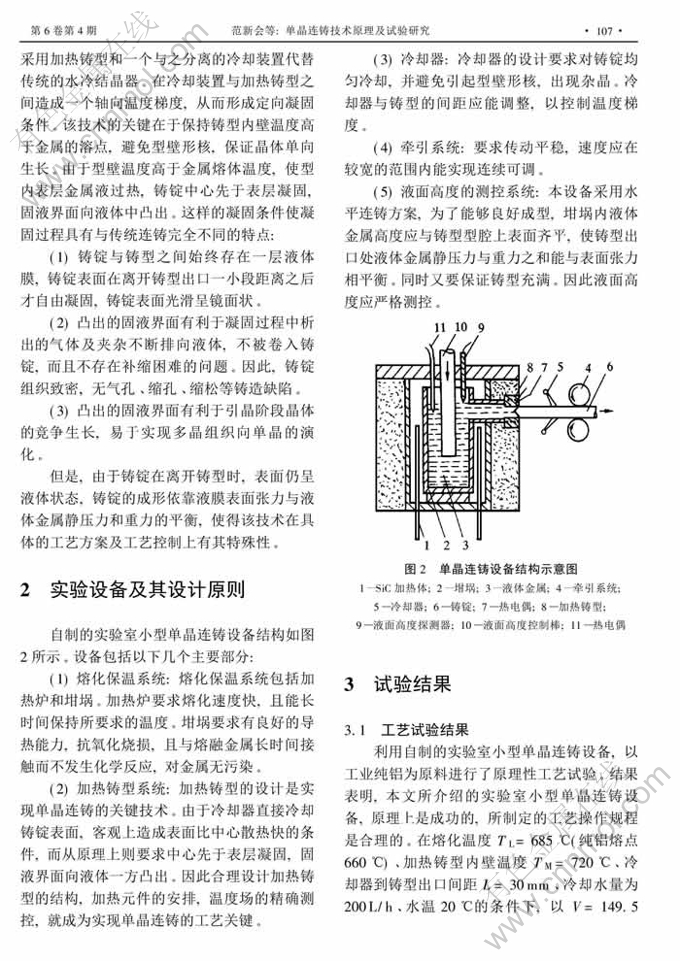

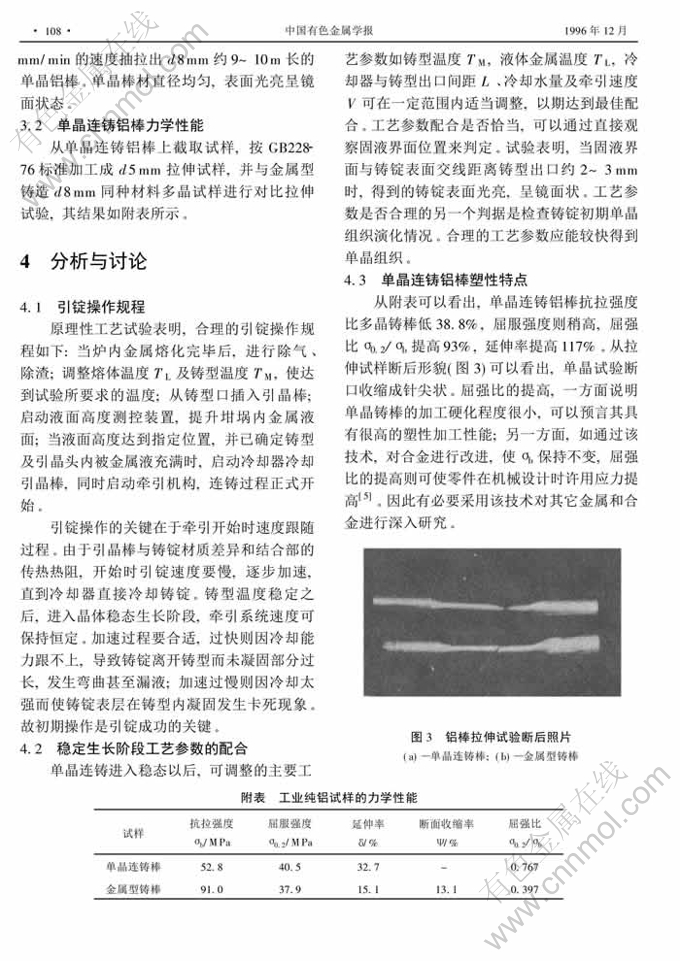

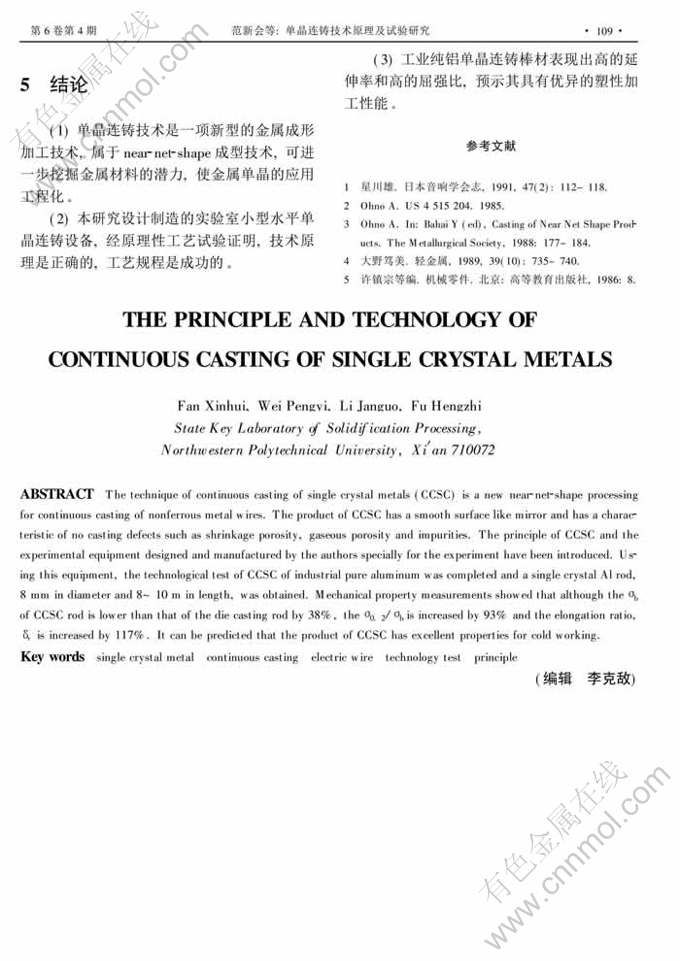

摘 要:单晶连铸技术是一项新型的有色金属连铸技术,可以连续制造无限长的、表面呈镜面状,内部无缩孔、缩松、气孔、夹杂等铸造缺陷的单晶线材,属于近成品形状(near-net-shape)生产技术。其产品金属单晶线材,具有优异的塑性加工性能和良好的导电性能,是一种可以满足电子工业要求的导电材料。该文介绍了单晶连铸技术的原理,以及利用小型单晶连铸设备制造的纯铝单晶线材的工艺试验及性能。

Abstract: The technique of continuous casting of single crystal metals (CCSC) is a new near-net-shape processing for continuous casting of nonferrous metal wires. The product of CCSC has a smooth surface like mirror and has a characteristic of no casting defects such as shrinkage porosity, gaseous porosity and impurities. The principle of CCSC and the experimental equipment designed and manufactured by the authors specially for the experiment have been introduced. Us- ing this equipment, the technological test of CCSC of industrial pure aluminum was completed and a single crystal Al rod,8 mm in diameter and 8~10 m in length, was obtained. Mechanical property measurements showed that although theσb of CCSC rod is lower than that of the die casting rod by 38%, theσ0.2/σbis increased by 93% and the elongation ratio,δ,is increased by 117%. It can be predicted that the product of CCSC has excellent properties for cold working.