文章编号:1004-0609(2013)S1-s0125-05

碳、硼对铸态ZTC4组织与性能的影响

戚运莲1,曾立英1,侯智敏1,洪 权1,刘时兵2,赵 军2,谢华生2

(1. 西北有色金属研究院,西安 710016;

2. 沈阳铸造研究所,沈阳 110022)

摘 要:采用熔铸工艺制备了含硼量为0.2%~0.5%(质量分数)、含碳量为0.5%~2.0%(质量分数)的ZTC4/B/C钛基复合材料,分析并测试了合金的铸态组织和力学性能。研究结果表明:钛硼相提高TC4合金铸棒的弹性模量,硼元素添加量为0.5%时,合金弹性模量提高30%,同时具有较好的强塑性匹配。C元素大大提高ZTC4合金铸棒的强度,添加0.5%C,其抗拉强度达到1 300 MPa,提高了25%。ZTC4合金铸棒的显微组织由片层α或球状α、晶界b及短棒状第二相TiB、球状颗粒且具有浮凸感的第二相TiC组成,B元素具有细化晶粒的作用。

关键词:铸造钛合金;微量元素;弹性模量;显微组织;力学性能

中图分类号:TG146.23 文献标志码:A

Effects of C and B on microstructure and properties of as-cast ZTC4

QI Yun-lian1, ZENG Li-ying1, HOU Zhi-min1, HONG Quan1, LIU Shi-bing2, ZHAO Jun2, XIE Hua-sheng2

(1. Northwest Institute for Nonferrous Metal Research, Xi’an 710016, China;

2. Shenyang Research Institute of Foundry, Shenyang 110022, China)

Abstract: ZTC4/B/C titanium matrix composites containing B and C with B content ranging from 0.2% to 0.5% (mass fraction) and C content ranging from 0.5% to 2% (mass fraction) were fabricated using melting-casting process. The microstructure and mechanical properties of as-cast ZTC4/B/C titanium matrix composite were studied.The results indicate that elastic modulus of ZTC4/B is increased by 30% with 0.5%B. The ultimate tensile strength (UST) of ZTC4/B/C reaches 1 300 MPa with 0.5%B and 0.5%C, which is increased by 25%. The microstructures of as-cast ZTC4/B/C consist of lamellar α, grain boundaries β and the second phase TiB with bar-like shape and the second phase TiC with spherical-like shape. The microstructures of ZTC4/B/C can be refined with the increase of B content.

Key words: cast titanium alloy; trace element; elastic modulus; microstructure; mechanical properties

随着航空、航天和尖端武器的发展,钛合金铸件得到越来越多的应用。尤其是近年来钛精密铸造技术的发展,使得批量铸造生产一些结构复杂的装备零件成为可能。钛铸件不仅能用来制造结构复杂、近净形的铸件,而且金属利用率高,成本低,生产周期短。另一方面,各种技术的进步,尤其是钛合金精铸技术的发展和进步以及热等静压技术(HIP)技术的出现,大大提高了钛铸件的质量,推动了钛铸件在发动机和飞机上的应用[1-4]。相对于细长和薄壁零件,钛合金刚性差,在使用过程中容易变形,因此,如何提高钛合金的综合性能是研究者一直关心的问题。人们发现向传统钛合金中加入少量的硼和碳,其显微组织及相关性能都会产生重大变化,将传统钛合金铸件晶粒尺寸细化一个数量级。晶粒得以细化,强度和刚度都随着提高,这就有可能研发出新型且经济适用的加工工艺,提升传统钛合金的性能。本文作者主要研究微量元素硼(B)、碳(C)对Ti-6Al-4V的铸造组织与性能影响,期望该材料能够获得较为广泛的应用[5-8]。

1 实验

实验所用原材料为海绵钛、铝豆、纯钒、纯硼粉、纯碳粉、钛箔,将其按一定比例混合压制成电极块,配制出含硼为0.2%~0.5%,碳为0.5%~2.0%的钛基复合材料。设计4种成分ZTC4/B、ZTC4/B/C钛基复合材料。为保证材料成分均匀,在感应熔炼炉中熔炼2次,在非自耗真空电弧熔炼炉中,采用电磁搅拌熔炼,冷却后翻转合金铸锭,重熔,反复熔炼4次。之后采用紫铜模具进行铸棒浇铸。从铸棒上线切割d 8 mm×10 mm试样,用于相组成和显微组织分析,线切割d 8 mm×40 mm试样,用于力学性能测试。热等静压处理制度为:加热温度920 ℃,氩气压力110 MPa,氩气纯度为99.995%,保温时间2 h。

2 结果与讨论

2.1 碳、硼元素对ZTC4合金弹性模量的影响

表l列出了添加不同微量元素B、C对TC4合金铸棒弹性模量的影响。由表1可以看出,添加0.2%硼元素,铸态TC4合金的弹性模量增大(未添加微量元素铸态TC4合金的弹性模量为95~105 GPa),提高了20~30 GPa;硼元素为0.5%时,铸态ZTC4合金的弹性模量达到125~145 GPa,这是由于生成了TiB增强相,提高弹性模量。在ZTC4/0.5%B基础上,添加了0.5%~2%C元素,ZTC4合金铸棒的弹性模量为123~130 GPa,弹性模量稍有降低。B元素对弹性模量的提高有较大贡献,C元素对ZTC4合金铸棒弹性模量的作用不明显[9]。

表1 ZTC4/B/C钛基复合材料弹性模量

Table 1 Elastic modulus of ZTC4/B/C titanium matrix composite

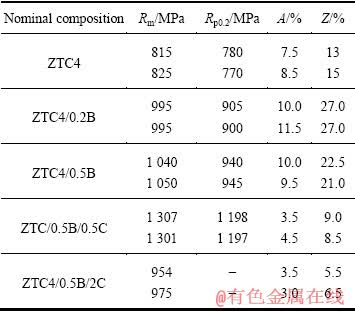

2.2 碳、硼元素对ZTC4合金室温拉伸性能的影响

铸棒经热等静压处理后的室温力学性能如表2所示。由表2 可以看出,硼元素的添加明显提高强度和塑性,TC4铸棒的抗拉强度提高20%~30%,伸长率提高25%~30%。在ZTC4/0.5%B基础上添加0.5%C,ZTC4铸棒的抗拉强度大幅度提高,达到1 300 MPa,提高了59%,塑性降低50%,C含量增加到2%时,ZTC4铸棒的室温力学性能较差,呈脆性断裂。原因是C含量较高,TiC相颗粒的体积分数增大,脆硬的TiB 相聚集在晶界处,抵消了晶粒细化的效果,限制合金的塑性[6]。综上所述,B元素对ZTC4合金铸棒的强度和塑性均有明显提高;微量C元素(小于0.5%)可以提高ZTC4合金铸棒的强度,但同时塑性会降低。

表2 ZTC4/B/C钛基复合材料的室温力学性能

Table 2 Room temperature tensile properties of TC4/B/C titanium matrix composite

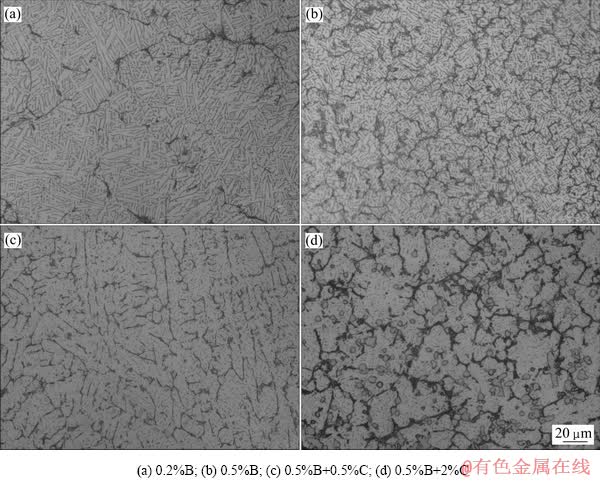

2.3 碳、硼元素对ZTC4合金显微组织的影响

添加不同微量元素B、C对ZTC4钛合金铸棒显微组织的影响如图1所示。由图1(a)和(b)可以看出,添加0.2%~0.5%B,ZTC4铸棒的显微组织由片层α、晶界β以及第二相(TiB)组成,随B含量增加,第二相的体积分数明显增加,显微组织细化效果明显,当B含量为0.2%时(图1(a)),晶粒内部α形态为长而粗大的板条状,当B含量为0.5%时(图1(b)),晶粒内部α形态细化为短粗板条。在ZTC4/0.5%B基础上添加0.5%~2%C的显微组织如图1(c)和(d)所示,C含量为0.5%时(图1(c)),晶粒内部α呈细针状,与其强度提高、塑性降低相对应。C含量为2%时(图1(d)),第二相(TiC)颗粒呈球状,均匀分布在晶粒内,TiC颗粒使其塑性较差。

图1 ZTC4/B/C钛基复合材料的显微组织

Fig. 1 Microstructures of ZTC4/B/C titanium matrix composite

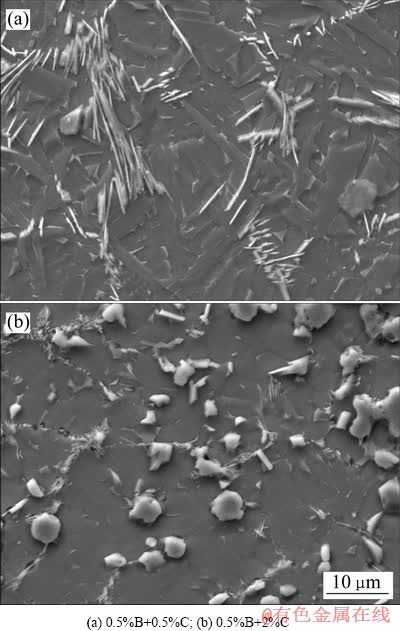

添加不同微量元素B、C的ZTC4钛合金铸棒的SEM照片如图2所示。由图2(a)可以看出,添加0.5%B和0.5%C,第二相TiB以短棒状析出,第二相TiC呈球状颗粒,C含量添加增大到2%时(图2(b)),TiC颗粒球化更明显,且浮在基体上,具有较强的浮凸感[10]。

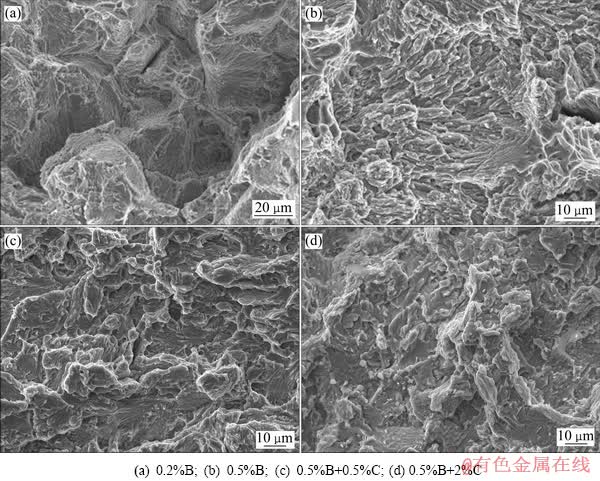

2.4 ZTC4合金室温拉伸断口特征

B/C钛基复合材料铸棒室温拉伸断口形貌如图3所示。可以看出,图3(a)和3(b)断口具有较深、较大的韧窝,这些较深、较大的韧窝与铸棒具有较好的塑性相对应;图3(c)和3(d)的断面相对要平坦一些,有大小不等的韧窝,但韧窝较浅,致使铸棒塑性较低。所有断口上有明显的撕裂棱,断面上呈沿晶断裂,并伴有沿晶二次裂纹,断裂起源位置不明显[11]。

图2 ZTC4/B/C钛基复合材料的SEM照片

Fig. 2 SEM images of ZTC4/B/C titanium matrix composite

图3 ZTC4/B/C钛基复合材料的室温拉伸断口形貌

Fig. 3 SEM images of fracture surface of ZTC4/B/C titanium matrix composite

3 结论

1) B元素可以大大提高ZTC4铸棒的弹性模量,C元素对提高ZTC4合金铸棒的弹性模量作用不明显。B含量为0.5%时,TC4弹性模量达到145 GPa。

2) B元素对ZTC4合金铸棒的强度和塑性均有明显提高,具有较好的强塑性匹配;C元素可以提高ZTC4合金铸棒的强度,C元素含量达到2%时,塑性低于5%,或呈脆性断裂。

3) ZTC4合金铸棒的显微组织由片层α或球状α、晶界β及短棒状第二相TiB、球状颗粒且具有浮凸感的第二相TiC组成,B元素具有细化晶粒的作用。

REFERENCES

[1] 张 满, 南 海, 黄 东, 曹国平. 钛合金铸件的热等静压和氢处理工艺研究[J]. 中国铸造装备与技术, 2002(5): 1-3.

ZHANG Man, NAN Hai, HUANG Dong, CAO Guo-ping. Study of heat isostatic pressing and thermohydrogen treatment of titanium alloy castings[J]. China Foundry Machinery & Technology, 2002(5): 1-3.

[2] 闫 平, 王 利, 赵 军, 汪志华, 张春辉, 游 涛. 高强度铸造钛合金的应用及发展[J]. 铸造, 2007, 56(5): 451-454.

YAN Ping, WANG Li, ZHAO Jun, WANG Zhi-hua, ZHANG Chun-hui, YOU Tao. Development and applications of the high-strength cast titanium alloy[J]. Foundry, 2007, 56(5): 451-454.

[3] 南 海, 谢成木. 国外铸造钛合金及其铸件的应用与发展[J]. 中国铸造装备与技术, 2006(3): 1-3.

NAN Hai, XIE Cheng-mu. The application and development of cast thonium alloys and their castings abroad[J]. China Foundry Machinery & Technology, 2006(3): 1-3.

[4] 苏贵桥, 谢华生, 张春辉, 赵 军, 王 利, 于志强, 刘宏宇. ZTi-3B铸造钛合金材料的组织和性能[J]. 钛工业进展, 2005, 22(2): 26.

SU Gui-qiao, XIE Hua-sheng, ZHANG Chun-hui, ZHAO Jun, WANG Li, YU Zhi-qiang, LIU Hong-yu. Microstructures and mechanical properties of ZTi-3B cast titanium alloy material[J]. Titanium Industry Progress, 2005, 22(2): 26.

[5] 谢华生, 刘时兵, 苏贵桥, 汪志华, 赵 军. 我国钛合金精铸件铸造技术的发展及应用[J]. 特种铸造及有色合金, 2008: 462-464.

XIE Hua-sheng, LIU Shi-bing, SU Gui-qiao, WANG Zhi-hua, ZHAO Jun. Development and application of invest casting technology for titanium alloys castings of China[J]. Special Casting & Nonferrous Alloys, 2008: 462-464.

[6] 张志辉, 王希哲, 商顺利, 白克武, 沈剑韵. 加工工艺对高弹高强钛合金弹性模量的影响[J]. 稀有金属, 2001, 25(1): 19-21.

ZHANG Zhi-hui, WANG Xi-zhe, SHANG Shun-li, BAI Ke-wu, SHEN Jian-yun. Influence of processing on elastic modulus for a titanium alloy with high strength and high elastic modulus[J]. Chinese Journal of Rare Metals, 2001, 25(1): 19-21.

[7] 张尚洲, 雷家峰, 关少轩, 刘羽寅, 李 东. 热处理对高弹高强高韧钛合金性能的影响[J]. 金属学报, 2002, 38: 74-77.

ZHANG Shang-zhou, LEI Jia-feng, GUAN Shao-xuan, LIU Yu-yin, LI Dong. Influence of heat treatment on mechanical properties of high elastic modulus, high strength, high toughness and weldable titanium alloys[J]. Acta Metallurgica Sinica, 2002, 38: 74-77.

[8] 罗 皓, 陈志强. 硼改性钛合金研究进展[J]. 材料开发与应用, 2010, 25(4): 77-80.

LUO Hao, CHEN Zhi-qiang. Progress in boron-modified titanium alloys[J]. Development and Application of Materials, 2010, 25(4): 77-80.

[9] SEN I, RAMAMURTY U. Elastic modulus of Ti-6Al-4V-xB alloys with B up to 0.55wt.%[J]. Scripta Materialia, 2010, 62: 37-40.

[10] GIANNOPOULOS G I, KARAGIANNIS D, ANIFANTIS N K. Micromechanical modeling of mechanical behavior of Ti-6Al-4V/TiB composites using FEM analysis[J]. Computational Materials Science, 2007, 39: 437-445.

[11] 崔约贤, 王长利. 金属断口分析[M]. 哈尔滨: 哈尔滨工业大学出版社, 1998: 34-216.

CUI Yue-xian, WANG Chang-li. Analysis of metal fracture surface[M]. Harbin: Harbin Institute of Technology Press, 1998: 34-216.

(编辑 杨 兵)

基金项目:国家重点基础研究发展计划资助项目(2007CB613805,2007CB613807)

收稿日期:2013-07-28;修订日期:2013-10-10

通信作者:戚运莲,教授级高级工程师,硕士;电话:029-86231078;E-mail: qiyunlian@126.com