文章编号:1004-0609(2010)03-0390-07

Mg-Gd-Y-Zr合金热轧板材的粗晶超塑性行为与微结构

李 理1, 2,张新明1,周 楠1,唐昌平1,邓运来1

(1. 中南大学 材料科学与工程学院,长沙 410083;

2. 湖南工学院 机械工程系,衡阳 421008)

摘 要:对初始晶粒度为66 μm的轧制板材在不同温度和不同变形速率下进行超塑性拉伸实验,研究Mg-Gd-Y-Zr合金粗晶热轧板材的超塑性行为与微结构特征。在温度为435 ℃、应变速率为5×10?4 s?1的变形条件下获得的最大伸长率为380%,应变速率敏感系数为0.56。合金的表观变形激活能高于镁的晶界扩散激活能或晶格扩散激活能;合金的超塑性变形机制为晶格扩散控制的位错协调晶界滑动机制。微结构分析结果表明:第二相钉轧晶界,较软的不规则块状的β相承受了部分塑性变形。

关键词:Mg-Gd-Y-Zr合金;热轧;第二相;超塑性变形行为;微结构

中图分类号:TG 146.2 文献标识码:A

Coarse-grained superplastic behavior and microstructural characterization of Mg-Gd-Y-Zr hot-rolled sheet

LI Li1, 2, ZHANG Xin-ming1, ZHOU Nan1, TANG Chang-ping1, DENG Yun-lai1

(1. School of Materials Science and Engineering, Central South University, Changsha 410083, China;

2. Department of Mechanical Engineering, Hunan Institute of Technology, Hengyang 421008, China)

Abstract: The superplastic behavior and microstructural characteristics of coarse-grained Mg-Gd-Y-Zr rolled sheet with initial grain size of 66 ?m were investigated systematically, the tensile tests at various temperatures and strain rates were conducted. The results show that the sheet exhibits a maximum elongation of 380% and a sensitivity coefficient of strain rate of 0.56 at 435 ℃ and 5×10?4 s?1. The apparent activation energy of this alloy is larger than the diffusion activation energy of grain bound or lattice diffusion energy of Mg. The superplastic behavior is attributed to grain boundary sliding accommodated by dislocation motion assisted by lattice diffusion. It is suggested from microstructural analysis results that the second phases exhibit significant effect of pinning grain boundaries, and that β phase deforms and the strain partly transfers from the matrix to the β phase.

Key words: Mg-Gd-Y-Zr alloy; hot rolling; second phase; superplastic behavior; microstructure

金属板材成形是制造薄壁轻质产品的加工方法。镁合金结构材料由于具有较高的比强度,在交通运输工具轻量化等方面具有很大的应用潜力[1]。已有研究表明,在镁中添加Gd以及其他稀土元素(RE),通过固溶强化与析出强化可使镁合金的耐热性能(200~300 ℃)显著提高[2?5]。这种良好的力学性能满足相关领域耐 热零部件的性能要求。

近年来,超塑性成形(SPF)技术已应用于成形复杂形状的镁合金零件,其力学性能及可靠性明显优于一般铸造件[6?8]。稀土镁合金中的稀土元素大部分存在 于第二相中,稀土对超塑性的影响是双方面的。分布于晶界的第二相具有稳定细晶组织的作用,对超塑性变形有利;同时,稀土第二相也阻碍超塑性变形时晶界的滑动,对进一步的超塑性变形不利。马洪涛等[9]对加工态的MB26研究表明:超塑性变形机制是位错运动与扩散蠕变协调下的晶界滑动机制,变形初期的动态再结晶(DRX)对获得微细等轴晶粒起重要作用。WATANABE[10]研究了WE43合金的超塑性变形行为,认为强化相界面上几乎无应力集中,超塑性机制是 晶界滑动控制下的强化相界面通道协调机制。大量关于AZ系列SPF研究工作[11?14]表明:镁合金在超塑变形过程中易发生DRX。TAN等[15]发现AZ31合金在 超塑变形时发生连续动态再结晶(CDRX),首先由位错胞转变为亚晶界,再由亚晶界不断吸收位错转变成大角度晶界,而且不需要额外的沉淀相颗粒作为形核 中心。

关于Mg-Gd-X合金超塑性变形的研究尚不系统;向镁中添加稀土元素(如Gd)后,过饱和的Mg-Gd-X合金的析出序列为β″相→β″相→β1相→β相[2?5],析出相对Mg-Gd-X合金的超塑变形及DRX的影响尚不清楚。为此,本文作者在对Mg-Gd-Y-Zr合金轧制板材的超塑性变形机制进行研究,分析Mg-Gd-Y-Zr合金中的第二相对超塑性变形的影响。

1 实验

实验合金为Mg-9.0Gd-4.0Y-0.4Zr合金(质量分数,%)。合金铸锭经(520 ℃, 8 h)均匀化处理(图1)后,平均晶粒尺寸为200 μm,在350 ℃下轧制成板材。每道次的下压量小于10%,道次间的退火工艺为(500 ℃, 15 min)。从初始厚度为4 mm的铸锭轧至1.3 mm的板材,轧辊以汽油喷灯加热。高温拉伸试样直接从轧制板材上以电火花线切割切取,标距长为10 mm、跨度为3.5 mm,拉伸方向平行于轧向。高温拉伸实验在配备有电阻炉的MTS万能试验机上进行,夹头两端及试样标距内安置灵敏的铂铑合金热电偶,数字温控仪保证3处的温度差不超过2 ℃。

图1 均匀化处理的Mg-9.0Gd-4.0Y-0.4Zr合金铸锭的金相组织

Fig.1 Optical photograph of homogenized Mg-9.0Gd-4.0Y- 0.4Zr billet

为了研究实验合金的超塑性变形机制,在恒应变速率下进行拉伸实验,测定应变速率敏感系数(m)。应变速率为1×10?4~1×10?2 s?1,温度为400~500 ℃。样品在实验温度下保温1 800 s后开始拉伸。样品拉断后,空冷进行微观组织观察。

XJP-6A金相显微镜(OM)用来对晶粒结构进行分析;用KYKY2800扫描电子显微镜(SEM)对第二相形貌进行观察;D/Max2500型X射线衍射仪(XRD)与Genesis 60S能谱仪(EDS)用来确定第二相组成与成分;JEM2100透射电子显微镜(TEM)进行微观组织分析,TEM样品的膜面平行于拉伸方向,用离子减薄法获得薄区。

2 结果与分析

2.1 超塑性行为

经拉伸变形后试样的流变应力与伸长率随应变速率的变化如图2所示。由图2可看出,板材在温度为435 ℃,应变速率为5×10?4 s?1的条件下,获得380%的最大伸长率。

由图2(a)可以看出,流变应力随应变速率的增加而上升。σ— 的关系曲线在对数坐标上呈现出常见 的“S”形,S曲线的斜率即为m(应变速率敏感系数),定义为

的关系曲线在对数坐标上呈现出常见 的“S”形,S曲线的斜率即为m(应变速率敏感系数),定义为

在各种实验条件下,m的范围为0.14~0.56。m越大,抗缩颈发展的能力越好,伸长率越大。

在图2(b)中,伸长率随应变速先增加后减少,最大伸长率对应于较高的m (0.56)。

图2 拉伸变形后Mg-9.0Gd-4.0Y-0.4Zr合金试样的流变应力与伸长率随应变速率的变化

Fig.2 Changes of flow stress (a) and elongation-to-failure (b) with strain rate for deformed specimens

2.2 轧制板材的微观组织

图3所示为轧制板材的金相组织。由图3可看 出,与均匀化处理后的铸锭组织相比,轧制板材的平均晶粒尺寸为66 μm。测量方法按照d=1.74L(其中,L为轧面上的晶粒平均截线长度),统计晶粒的数量为 1 000个。经过多道次轧制及中间退火后,轧制板材中出现大量形变孪晶及部分再结晶晶粒。

图3 Mg-9.0Gd-4.0Y-0.4Zr合金热轧板的金相组织

Fig.3 Optical photograph of rolled Mg-9.0Gd-4.0Y-0.4Zr sheet

图4所示为轧制板材在435 ℃静态退火的晶粒尺寸演变。由图4可看出,在435 ℃保温约2.5 h后,晶粒尺寸仅仅长大至74 μm,长大速度远远低于AZ或ZK系列镁合金的。

图4 Mg-9.0Gd-4.0Y-0.4Zr合金轧制板材在435 ℃静态退火的晶粒尺寸演变

Fig.4 Grain size evolution of rolled Mg-9.0Gd-4.0Y-0.4Zr sheet after static annealing at 435 ℃

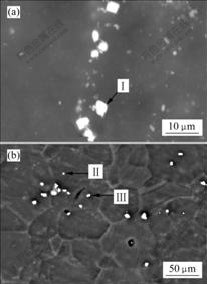

图5所示为均匀化处理后铸锭及轧制板材的SEM像。图5(a)显示,均匀化处理后在晶界与晶内依然存在少量1~2 μm的第二相粒子(标记为Ⅰ)。图5(b)中存在2种形貌的粒子:一种为圆形粒子(标记为Ⅱ),另一种为方形粒子(标记为Ⅲ)。表1中的相应能谱分析(EDS)显示,圆形粒子富含Zr元素。由于Zr与Gd和Mg均不反应,因此,圆形粒子为Zr核;方形相与铸锭中第二相(标记为I)都富含Gd、Mg与Gd,其平均原子含量比为76.13?24.32,由此可以确定该富Gd相为Mg3Gd[16],它的存在将提高合金的耐热性能。这些第二相均是在熔铸时产生的结晶相[5]。

图5 Mg-9.0Gd-4.0Y-0.4Zr合金均匀化处理后的铸锭(a)与轧制板材(b)的SEM像

Fig.5 SEM images of homogenized Mg-9.0Gd-4.0Y-0.4Zr billet (a) and sheet after repeating rolling (b)

表1 EDS鉴定的图5与图6中的第二相化学成分

Table 1 Corresponding compositions of second phases identified by EDS in Figs.5 and 6 (mass fraction, %)

2.3 试样拉伸后的微观组织

图6所示为试样在435 ℃、5×10?4 s?1拉断后的SEM像。由图6可看出,相对于初始板材及试样夹头,标据内的基体晶粒明显细化(12 μm)且为等轴状,晶界明显宽化,在晶界及晶内出现了大量的第二相。由于试样夹头的晶粒结构仅受到热影响未受到应变的影响,而标距内的晶粒结构既受到热影响又受到应变的影响,因此,标据内晶粒细化是DRX的结果。

图6 Mg-9.0Gd-4.0Y-0.4Zr合金试样在温度为435 ℃、应变速率为5×10?4 s?1的条件下拉伸后的SEM像

Fig.6 SEM images of Mg-Gd-Y-Zr rolling sheet stretched under conditions of 435 ℃ and 5×10?4 s?1: (a) Gauge of specimen; (b) Grip of specimen

图5与图6中的第二相的EDS成分鉴定结果列于表1中。其中,多数第二相是与Ⅳ处成分接近的白色不规则块状相,运用化学计量方法,分析5处白色不规则块状相的成分,Mg与(Gd+Y)的平均物质量比为5.03?1,可以确定不规则块状相为Mg5(Gd, Y),即β相[16];拉伸后,存在从β相析出的Mg2Y3Gd2(Ⅴ处)[17];此外,依然存在结晶相Mg3Gd(Ⅵ处)。

图7所示的XRD扫描结果显示:拉伸后的谱线中β的小峰(标记为“●”)数量明显增加,可知析出了大量的β相,这与SEM分析结果一致。

图7 拉伸Mg-Gd-Y-0.4Zr合金试样的XRD谱

Fig.7 XRD patterns of rolled sheet (a) and specimen tested at 435 ℃ and 5×10?4 s?1 (b)

图8所示为试样在435 ℃、5×10?4 s?1的条件下拉断后的TEM像。在图8(a)中,观察到晶界(GB)及亚晶界(SGB)被第二相粒子钉扎在图8(b)中,观察到晶内残存位错的条状再结晶晶粒形成于第二相粒子之间。再结晶晶粒中存在位错说明再结晶的过程是连续动态再结晶[18]。

从图8(c)中清楚地看到β相中存在大量位错网,这说明β相也参与了变形。图8(c)中的小图为β相选区电子衍射照片,入射束平行于β相的 晶带轴。可以看到,β相中又有新相析出,新析出相可能为Mg2Y3Gd2相[17]。

晶带轴。可以看到,β相中又有新相析出,新析出相可能为Mg2Y3Gd2相[17]。

图8 Mg-Gd-Y-0.4Zr合金试样在温度为435 ℃、应变速率为5×10?4 s?1的条件下拉伸后的TEM像

Fig.8 TEM images of fractured specimen tested at 435 ℃ and 5×10?4 s?1: (a) Grain boundary and subgrain boundary pinned by second phases; (b) Strip recrystallized grain developed between second phases; (c) Dislocation network within β phase and electron diffraction pattern of selected area of β phase with zone axis parallel to  β

β

3 讨论

在435 ℃与5×10?4 s?1的条件下拉伸,m值约为

0.5(图1(b))以及拉断后的等轴晶粒(图6(a))都证明晶界滑动(GBS)在变形中起到决定作用[19]。晶界滑动出现在许多镁合金的超塑性变形中[20]。晶界滑动依靠扩散控制的位错运动来协调[21]。当表观变形激活能(Q)等于晶格扩散激活能(QL)时,GBS是由晶格扩散控制的;当表观变形激活能等于晶界扩散激活能(QGb)时,GBS是由晶界扩散控制的[21]。图9所示为根据式(2)计算的表观变形激活能[22]:

式中:σ为稳定流动应力;N为应力因子(N=1/m);R与T分别为气体常数与热力学温度。激活能的计算结果为222 kJ/mol,远高于镁的QGb(75 kJ/mol)与QL(134 kJ/mol)[23],这与晶界及晶内大量分布的稀土化合物有关。Ball-Hutchison提出的位错协调晶界滑动模型认为:GBS会在三叉晶界处或晶界弓出处受阻,而位错的滑移(攀移)及后续位错的塞积可以使GBS克服阻碍继续进行。当晶界及晶内存在第二相时,晶界滑动受阻,位错易在相界处塞积,此时会出现2种情况:其一,当温度足够高时,第二相软化并发生变形(图8(c));其二,当第二相强度较高时,位错依靠扩散在相界处攀移产生相界滑动[10]或湮灭于相界的空洞处。这些情况都将消耗更多的能量,致使变形激活能大幅提高。

Mg-Gd-Y-Zr合金板材的组织中有的第二相都是热稳定相(Zr核与富稀土相)。第二相对晶界或亚晶界有强烈的钉扎作用(图8(a))。因此,第二相抑止晶粒的长大,以至于在历经约2.5 h的高温加热后晶粒长大并不显著(图4)。

β相的熔点约为658 ℃,在435 ℃下的高温拉伸过程中,β相已经开始软化,而且明显变形(图8(c)),说明相界上的应力集中容易得到松弛,而且变形从基体转移至β相中。

图9 轧制态Mg-Gd-Y-Zr合金的超塑性变形的表观变形激活能曲线(ln(σ) vs 1/T))

Fig.9 Apparent activation energy curve of ln(σ) vs 1/T in superplastic deformation of rolled Mg-Gd-Y-Zr sheet

4 结论

1) 在温度为435 ℃、应变速率为5×10?4 s?1的条件下,获得材料的最大伸长率为380%,相应的m值为0.56。

2) Mg-Gd-Y-Zr合金轧制板材的超塑性表观变形激活能为222 kJ/mol,变形主导机制为晶格扩散控制的位错协调晶界滑动。

3) 拉伸过程中析出大量的块状β相,硬度较 低的β相松弛了应力集中并且变形从基体转移至β相中。

REFERENCES

[1] LUO A A. Recent magnesium alloy development for elevated temperature applications[J]. Int Mater Rev, 2004, 49(1): 13?30.

[2] NEUBERT V, STUL?KOV? I, SMOLA B, MORDIKE B L, VLACH M, BAKKAR A, PELCOV? J. Thermal stability and corrosion behaviour of Mg-Y-Nd and Mg-Tb-Nd alloys[J]. Mater Sci Eng A, 2007, 462(1/2): 329?333.

[3] MORDIKE B L. Creep-resistant magnesium alloys[J]. Mater Sci Eng A, 2002, 324(1/2): 103?112.

[4] SMOLA B, STUL?OV? I, PELCOV? J, MORDIKE B L. Significance of stable and metastable phases in high temperature creep resistant magnesium-rare earth base alloys[J]. J Alloy Compd, 2004, 378(1/2): 196?201.

[5] 肖 阳, 张新明, 陈健美, 蒋 浩. Mg-9Gd-4Y-0.6Zr合金挤压T5态的高温组织与力学性能[J]. 中国有色金属学报, 2006, 16(4): 709?714.

XIAO Yang, ZHANG Xin-ming, CHEN Jian-mei, JIANG Hao. Microstructures and mechanical properties of extruded Mg-9Gd-4Y-0.6Zr-T5 at elevated temperatures[J]. The Chinese Journal of Nonferrous Metals, 2006, 16(4): 709?714.

[6] BLANDIN J J. Superplastic forming of magnesium alloys: Production of microstructures, superplastic properties, cavitation behaviour[J]. Superplasticity in Advanced Materials, 2007, 551/552: 211?217.

[7] del VALLE J A, PENLBA F, RUANO O A. Optimization of the microstructure for improving superplastic forming in magnesium alloys[J]. Mater Sci Eng A, 2007, 467(1/2): 165?171.

[8] 文九巴, 杨蕴林, 杨永顺, 陈拂晓, 张柯柯, 张耀宗. 超塑性应用技术[M]. 北京: 机械工业出版社, 2005: 306.

WEN Jiu-ba, YANG Yun-lin, YANG Yong-shun, CHEN Fu-xiao, ZHANG Ke-ke, ZHANG Yao-zong. Superplasticity applied technology[M]. Beijing: China Machine Press, 2005: 306.

[9] 马洪涛, 杨蕴林. MB26合金超塑性的研究[J]. 材料工程, 1998(9): 11?13.

MA Hong-tao, YANG Yun-lin. Study of MB26 alloy superplasticity[J]. Mater Eng, 1998(9): 11?13.

[10] WATANABE H. Superplasticity of a particle-strengthened WE43 magnesium alloy[J]. Mater Trans Jim, 2001, 42(1): 157?162.

[11] SOMEKAWA H, HIRAI K, WATANABE H, TAKIGAWA Y, HIGASHI K. Dislocation creep behavior in Mg-Al-Zn alloys[J]. Mater Sci Eng A, 2005, 407(1/2): 53?61.

[12] FUJII H, IWASAKI H, ARAKI J K. Press forming technology using superplastic deformation for Mg alloy sheet[J]. Magnesium-Science, Technology and Applications, 2005, 488/489: 571?574.

[13] WEI Y H. Superplasticity and grain boundary sliding in rolled AZ91 magnesium alloy at high strain rates[J]. Mater Sci Eng A, 2003, 360(1/2): 107?115.

[14] KIM W J, CHUNG S W, CHUNG C S, KUM D. Superplasticity in thin magnesium alloy sheets and deformation mechanism maps for magnesium alloys at elevated temperatures[J]. Acta Mater, 2001, 49(16): 3337?3345.

[15] TAN J C, TAN M J. Dynamic continuous recrystallization characteristics in two stage deformation of Mg-3Al-1Zn alloy sheet[J]. Mater Sci Eng A, 2003, 339(1/2): 124?132.

[16] ZHANG X, LI L, DENG Y, ZHOU N. Superplasticity and microstructure in Mg-Gd-Y-Zr alloy prepared by extrusion[J]. J Alloy Compd, 2009, 481(1/2): 296?300.

[17] GAO Y, WANG Q, GU J, ZHAO Y, TONG Y. Behavior of Mg-15Gd-5Y-0.5Zr alloy during solution heat treatment from 500 to 540 ℃[J]. Mater Sci Eng A, 2007, 459(1/2): 117?123.

[18] MOHRI T, MABUCHI M, NAKAMURA M, ASAHINA T, IWASAKI H, AIZAWA T, HIGASHI K. Microstructural evolution and superplasticity of rolled Mg-9Al-1Zn[J]. Mater Sci Eng A, 2000, 290(1/2): 139?144.

[19] TAN J C, TAN M J. Superplasticity in a rolled Mg-3Al-1Zn alloy by two-stage deformation method[J]. Scrip Mater, 2002, 47(2): 101?106.

[20] WATANABE H, TSUTSUI H, MUKAI T, ISHIKAWA K, OKANDA Y, KOHZU M, HIGASHI K. Superplastic behavior in commercial wrought magnesium alloys[J]. Materials Science Forum, 2000, 350/351: 171?176.

[21] SHERBY O D, WADSWORTH J. Superplastic-recent advances and future direction[J]. Prog Mater Sci, 1989, 33: 169?221.

[22] WU X, LIU Y. Superplasticity of coarse-grained magnesium alloy[J]. Scrip Mater, 2002, 46(4): 269?274.

[23] FROST H J, ASHBY M F. Deformation mechanism maps[M]. Oxford: Pergamon Press, 1982.

基金项目:国家重点基础发展计划资助项目(5311001E)

收稿日期:2009-05-19;修订日期:2009-10-12

通信作者:张新明,博士生导师,教授;电话:0731-88830265;E-mail: zmzhang_cn@yahoo.cn

(编辑 杨 华)